Leaderboard

Popular Content

Showing content with the highest reputation on 07/16/19 in all areas

-

Thought I would post a few photographs of the finished room. We love it and the OH made a brilliant light/mirror after seeing what we could get for £140. luckily it was broken so we sent it back and he made his own. it has a sensor at the top, LED lights around the sides and the toothbrush holder is on the right. The shower itself is great. Aqualisa with a control as you enter so no more cold wet arms. Its is brilliant. And it didnt even take that long to do - a few months........4 points

-

Scaffold down and windows in...big dose of euphoria....feels like a real milestone. We can now get a sense of the completed project. With the scaffold removed the house now looks far more suited to the plot and we hope our neighbours will be as relieved as we are. The window install went well. Our windows are Velfac and we opted to use an approved installer as it extended the warrantee to six years. It cost a bit more but the standard of install was good with great care being taken. A few grubby hand prints on the render but nothing we could not clean of with soapy water. One aspect of doing your own build that we had not considered, is the fact you start out with something perfect and new. It will slowly age and degrade. It’s akin to the feeling of the first mark on a new car. Pat and I have restored a couple of cars in the past and avoided going the whole hog of a concourse restore as it can spoil your willingness to use and enjoy the car. We just need to keep the same mind set with the build. With a house we can lock, our intention is to let the dust settle. We’ll come back to the project with fresh enthusiasm in October.2 points

-

By way of update : The roofing co, were jolly decent and once their accountant agreed, they repaid the incorrectly charged VAT.2 points

-

@nod we submitted our VAT claim on the 1st March. They wrote querying the delay from our moving in, on the 19th December 2017 and issuing of the completion certificate at the end of February this year. We wrote back gave them a long spiel about how Terry had been ill for much of 2018 (all true and verifiable) and let them have invoices for work subsequent to our moving in which were zero rated but a requirement of our planning conditions. They passed our claim and returned all invoices on the 28th June, bar the Wickes one of course.2 points

-

As @Russell griffiths says, I think we need a bit more info. Can you try and see where the inspection chambers are, relative to that pipe you've uncovered? There should be inspection chambers wherever a drain connects to that one, so in line with that run. Tracing back where these are will give you a better idea of what you're dealing with. It's debatable as to whether this has anything to do with the water company, it could be just one of your own drains, or it may even not be a foul drain at all, but a rainwater drain leading to a soakaway.2 points

-

PS In the UK the ASA typically prevent companies selling magnetic water treatment devices from claiming they make the water softer. See... https://www.asa.org.uk/advice-online/water-treatment-devices.html Selected quotes: The ASA and CAP understand that magnetic or electromagnetic conditioning devices are not capable of “softening” water and as such should not be claimed to be equivalent to water softeners (International Bathrooms WTS b.v., November 2010). Snip The ASA understands that no universally accepted theory about how these devices operate and no evidence to support the contention that the devices can inhibit scale formation generally exists.2 points

-

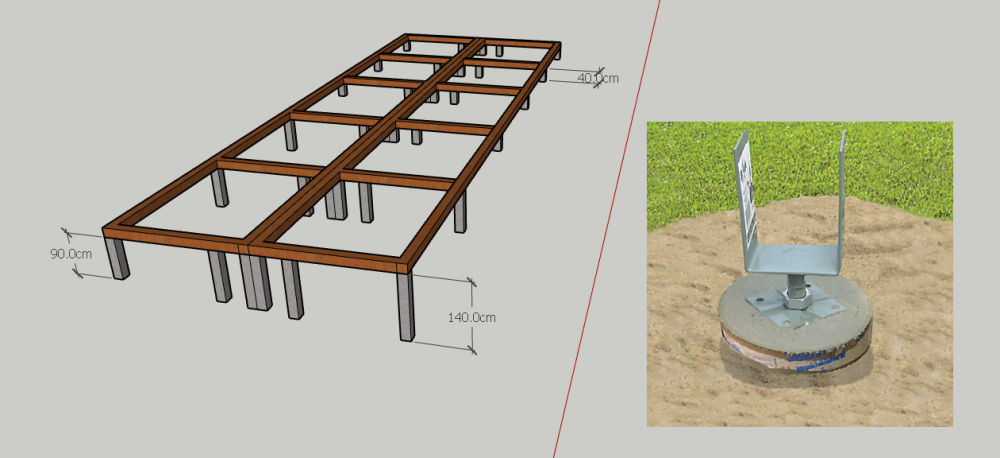

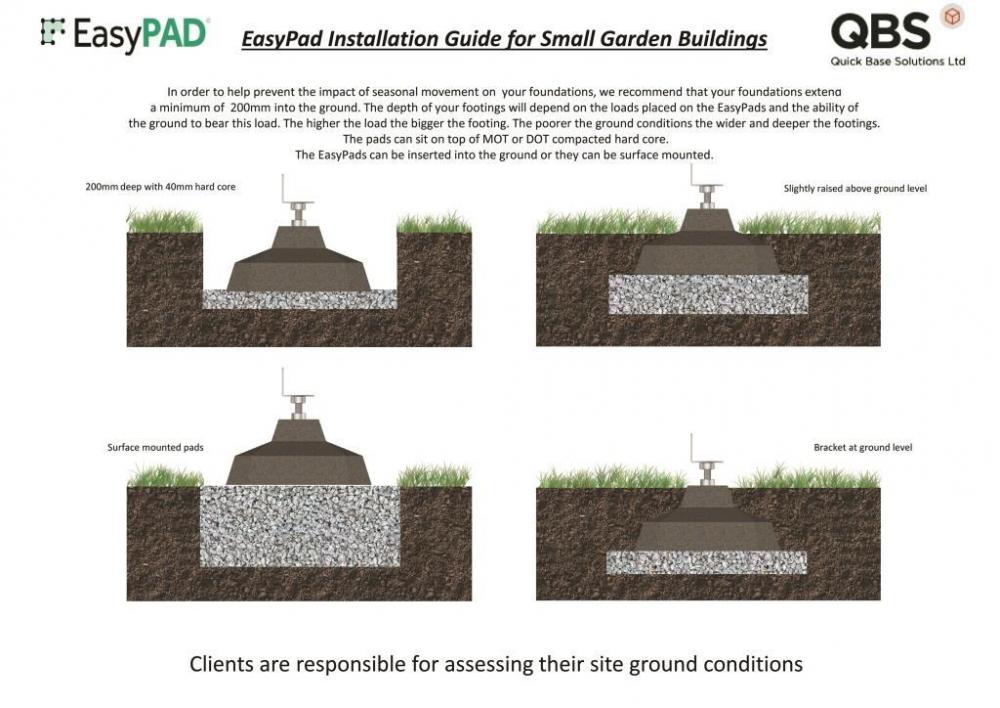

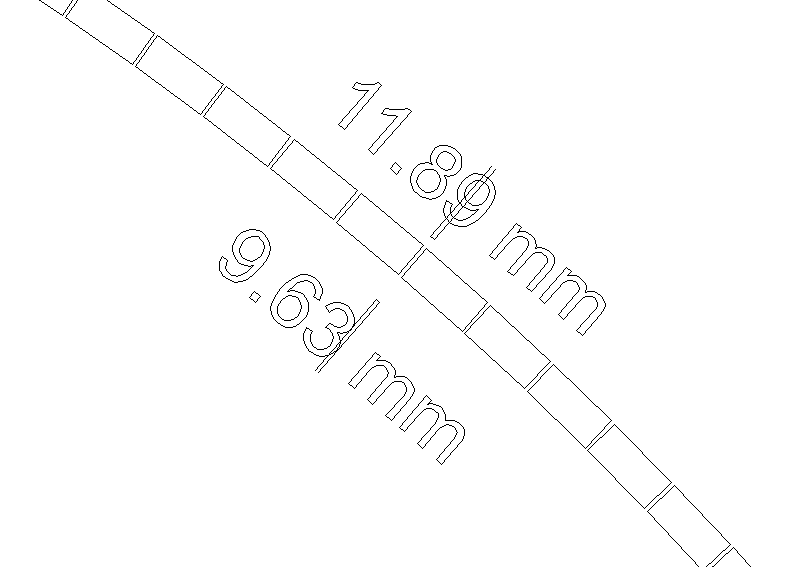

Hello Build-Hubbers As some of you know I'm getting pretty close to starting my 200mm round log cabin now, which is built to mobile regulations and in two sections for transportation. Each section will be about 15T. The overall foot print is 17.6m x 6.1m If I get the green light from planning I could be starting the foundations in August and I want to finalise how I'm doing the foundations. It's out of scope for building control so I pretty much have free reign to do as I please. The ground on my site is solid granite and I don't want to go overkill with the foundation design. At first I was going to have the timber ring beam delivered at the same time as the round logs, so the below system appealed to me as I wouldn't have had to get the location bang on as it all has adjustment. However I'm now constructing the timber ring beam in advance, which will be 4 number 45mm x 195mm, glued, screwed and bolted, potentially ply lined box beams - I'm still awaiting designs from my SE. So I can take my time and get it all correct. What would be a typical design for a building of this size? I was thinking concrete piers made out of 300mm diameter pipe, tied into a base of say 200 x 500 x 500 cast straight on top of the rock. The majority of piers are only 400m high. Some are as high as 1.4m and there will also be a 40m2 stilted decking area. I'm also considering having some T brackets, in-Line brackets, corner and stilt brackets fabricated that cab be cast into the tubing using a fixing socket and offer height adjustment - I'm good friends with the owner of a fixing anchor factory over in China and he has offered to make a system which I can roll out on future projects so it will cost me very little for these brackets and it's very reassuring to think I have say 50mm - 100mm of adjustment. Also the timber will not be directly sat on concrete so no wicking. I have to say the above foundation which uses a precast concrete pad and allows full axis realignment is great - They can take a load of 5T each, not sure I trust them for the stilted areas though, I'm sure they are OK for decking but I have doubts for the log cabin main structure. They are only 400 x 400 and 180 high so extremely efficient. Should I attempt something similar? Precast Pads In Use: My pier plan:1 point

-

140mm is the minimum width for a two storey single skin IIRC. But 140 is non standard and costs more so it can be simpler to use a standard 215 block instead.1 point

-

1 point

-

Whatever was on the floor when I picked them up and gave them to someone who knew what he was doing ?1 point

-

And while your at it go and buy some shorter nails for you nail gun. ??1 point

-

We have Rehau Geneo insulated frames with 3G. They're still doing their job seven years later.1 point

-

Minimum of 50mm from the bottom (to prevent someone putting a screw into it from the celing below)1 point

-

I'd be fitting an REC (isolation switch) myself for them to connect to: https://www.tlc-direct.co.uk/Products/WYREC2S.html Probably easier for you to get: https://www.screwfix.com/p/wylex-100a-dp-isolator-with-enclosure/321fr They don't all sing from the same hymn sheet is the issue. Around here if you talk on the phone they ask for an "INCERT" to be available aka an Electrical Installation Certificate. The lads who turn up never ask. Offer of teas, coffee and a plate of nice biscuits should help.1 point

-

You must have a signed off temporary installation for the electricity supplier (not the DNO) to be able to install a meter. The sequence is usually this: Install empty meter cabinet (anyone can do this). Install a temporary site supply, which at it's simplest can be an isolator switch (optional but a good idea), small consumer unit with RCD/RCBO/MCB protection as required for any connected circuits, plus the site supply outlets, as required. Any electrician (Part P required for England and Wales) can do this, but it needs two visits, one to do the install and dead checks, another to do the live checks after connection. Get DNO to install a supply (has to be done by the DNO). Get a supplier of your choice to install the meter and connect it to both the incoming fuse and to the isolator switch or site supply consumer unit. Get your electrician to complete the live testing and issue an installation certificate.1 point

-

Don't just vent it into the loft space, as you will get a lot of condensation inside the loft, which will drip down everywhere (ask how I know this...). Run the duct out to either the eaves or the gable and then to a terminal outside. Often there is room under the soffit to fit a terminal, saves going through the gable wall. You can get roof fitted vents, but they are a bit more hassle to install, depending on the sort of roofing.1 point

-

I think you were probably unlucky with your TF build. We have a portal timber I-beam frame and have vaulted ceilings upstairs in some rooms. We don't have any movement or creaking but as you say it's not a good idea to change plans half way through with a TF.1 point

-

We're doing similar with Baskil - seems to be about 40% cheaper than Alu or alu clad. The smaller north facing and gable widows will be fixed pane, so plan on these being pvc with minimal frame visible. The rear is a 6m slider with full height windows directly above.... These will be aluminium. Means total cost should be in the low £20k rather than low £30k1 point

-

I use a Dymo Rhino printer, with Flexible Nylon 19mm tape. When the machine is set to wrap, it prints the text longways multiple times, so it can always be seen. Once the tape is stuck, a few hours later its a fight to remove it. It also has modes for printing entire patch panels / consumer units with proper spacing. Costs a lot, but I borrow the work one1 point

-

bought mine from vida xl https://www.manomano.co.uk/filter/stone-fence-2508?brand_names=VIDAXL free delivery, which for me up north, is amazing1 point

-

1 point

-

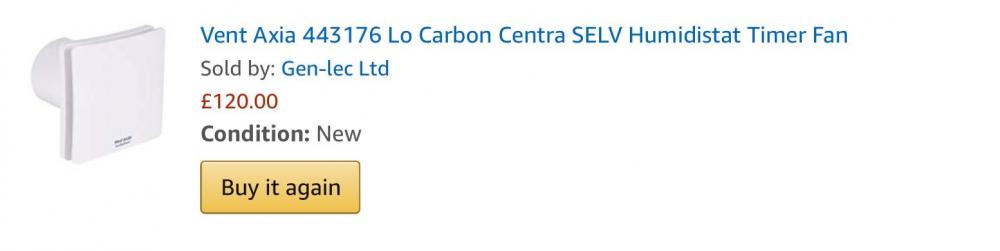

I now use ones with a constant low flow plus boost and timer rather than a backdraft shutter. I do this to provide a better background ventilated space in restored houses where a full MVHR cannot be justified, and trickle vents have been avoided because on principle they are a horrible thing to inflict on energy bills. Vent AxIa do these, and I would recommend. They are silent. I have swapped out a couple of HR units where Ts found the slight noise to be too much. My one comment would be to are sure that the boost extraction is enough, as wet rooms can be steamy places beyond expectations. VA also have some interesting auto response type fans. I have also used the Icon Airflow. One rented property has had one since perhaps 2012. They whirr slightly, but are Fine. They do however do bigger ones, and if you fit the wrong one you will know about it because you will be blown away. F1 point

-

Mines quite noisy I think at 31dB, but it's in and has pretty blue lights...must take the label off and paint over / wipe off the paw prints... Only a stop gap until MVHR...so likely permanent then! ?1 point

-

1 point

-

1 point

-

Forget the cheap ones like that. Look at something like the vent axia ones that have a motorised (hot wax actually) shutter that closes off the outlet when the fan is not on.1 point

-

2g UPVC £167/ m2 fitted inc. composite front door (3g glazed), pair of french doors, and partglazed back door.1 point

-

Hard core game of swing ball you’re proposing there, @JSHarris :)) Not that wacky Id say-I’ve never built a twisted pier but I believe a micro version of what you suggest is one method of building them. Another method might be to keep your centre point as a reference check,set up vertical profiles at say,4 metre intervals & make a curved profile to the shape of the circumference. It’s probably too impractical & time consuming to check every course but you could check maybe every 4th & correct any minor deviations so they don’t increase. Btw,my experience of building curved brickwork (albeit garden walls,so more forgiving of minor inaccuracies) was that production can be surprisingly high. Yes,it’s all level work but that’s offset to an extent that you’re just working the length of your level for the height of the lift before moving along and repeating the process.1 point

-

1 point

-

1 point

-

Here's a list of prices compiled from BH public posting https://docs.google.com/spreadsheets/d/10mPQ-4HnTuUbiKmQVn3fPPoVkxDMPgRFNvaji4R8USg/edit?usp=sharing Apologies anyone if I've made a mistake on your prices or missed you out. I wasn't hugely systematic. I'm surprised not to see any Green Building Store ones. As @craig says, a simple m2 hides a lot of detail that affects price e.g. ratio of fixed vs opening windows, doors, cills, coated glass, non-rectangular, airtightness level of the model, etc. I suspect the mysterious discount factor also distorts things. @lizzie I'd previously had you at £390/m2 - was that just for alu UPVC and you went for alu timber at £566/m2 in the end? From https://forum.buildhub.org.uk/topic/1820-alu-clad-timber-or-pvc/?do=findComment&comment=262861 point

-

1 point

-

1 point

-

Very pricey Russ Even with fitting ourselves it was one of the largest spends Around 20k Go knows what the supply and fit price would have been1 point

-

Shoes off at the front door. While common in many other countries, still seen as unusual in UK. We insisted on this once we moved in as outside was still mostly well worn type 1 so it would wreck the resin & wood floors & stairs. Even though we now have resin bound gravel and paving outside, it's now the norm, so much less dirt is tracked into the house. No-one has ever had an issue being asked to do it.1 point

-

I went with 3g uPVC from Munster joinery (baskil windows in Ni) and there isn't much I can say about them. They keep the wind and rain out the very best and so far over 5 years in they have give me no grief. Cost wise I didn't get any prices for aluclad as at the time the options here where really only upvc or timber. Aluclad where only seen in the self build shows so i hadn't any real world experience of them so didn't give them much of a thought. Not sure how a mixture of different windows would look though, have you seen this done on any other house???1 point

-

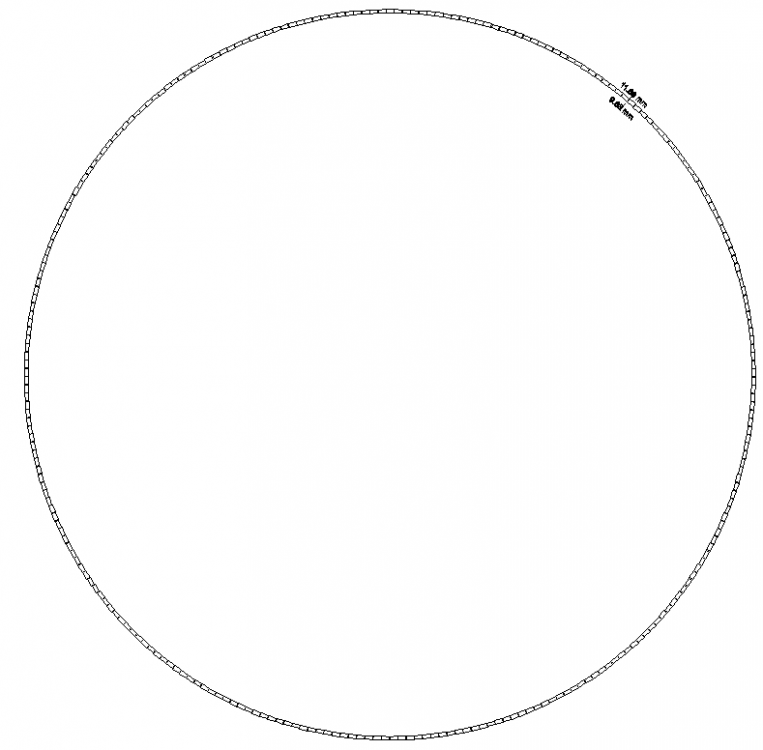

No so, you will easily get standard concrete blocks to go round with no problem and no need to cut the blocks. Given your diameter of 20m, the building circumference is 62.83m, so 279 blocks per course. The difference between the inside and outside of each perp join will be about 2mm and the maximum deviation in render thickness will be about 1mm.1 point

-

With our delay over the windows we have lost 12 months but are really seeing some improvement now. Kitchen is going in end of August and then finish the wood cladding and render garage and we are finished outside apart from the garden. I just keep spraying the Rosate and hope one day I can start on the garden!!1 point

-

I'm finding that inside the need for accuracy and neatness of finish is amplified (...and i'm aiming at a rough industrial finish) but it's having to be reached while accommodating all the inaccuracies that crept in during the earlier core construction. Things therefore get 'fiddly' and time consuming way beyond the armchair theory of how long they're going to take. I've been working alone which is painfully slow and I think counterproductive to achieving that neatness and accuracy.....a second pair of hands would not make things happen twice as fast but more like 4 or 5 times as fast. Continuing this way I reckon easily 5 months more for me (rather more if/when I run out of money for materials/fittings), but if I could open a magic wallet there wouldn't be more than 2 weeks for any individual trade...I could buy it done in a month. So in answer to your question....you pay your money and take your choice. My word of caution is that if you're looking to finish cheap on your own, set a cautious deadline and allow for regular time off as many have said. However unpalatably distant that deadline then becomes, suck it up....it's better than working 6.5 days a week, 11+ hours a day.1 point

-

Yup, we've still got 2×SunAmp PVs and we've had no problems so far except that the total actual thermal capacity seems to be a bit less than stated. Perhaps as a bit of kit, this is over engineered. Given that I love my little Willis (which heats our UFH) and the probs that many of the UniQ users have had, I think that if I did have to replace the PVs then I'd go for something like a UniQ HW 9 with an external Willis and pump to top it up -- that way I can do the heating control integrated into my overall heating strategy. One Q for Martin: do you use a water softener on the HW supply-side? IIRC, when I talked to the SunAmps guys, they though one pretty essential, so we use a Harvey and no complaints here.1 point