-

Posts

336 -

Joined

-

Last visited

Personal Information

-

Location

Dumfries & Lancashire

Recent Profile Visitors

iSelfBuild's Achievements

Regular Member (4/5)

89

Reputation

-

New Garage Floor - Lower than my driveway 500mm

iSelfBuild replied to iSelfBuild's topic in Garage & Cellar Conversions

Hmmm tricky one, I love it here - depends how much money I make though ultimately - 5 year plan is buying a farm with plenty of space to develop a small holiday park and run my other business's from. Taking myself back to the Scotland project and the 33m long x 3.6m retaining wall I built... which we had a concrete blow out. Not sure I want the hassle of a basement! -

New Garage Floor - Lower than my driveway 500mm

iSelfBuild replied to iSelfBuild's topic in Garage & Cellar Conversions

Wee update - decided going down the planning and regs route is much more hassle than it's worth. Sticking a log cabin alongside the hedge - 2m away from boundaries on a reinforced raft. Single Wooden Garage TWIN (44 mm), 4x6 m (13'x20'), 24 m² Won't block too much view from the downstairs and makes absolutely no difference to upstairs or the new extension. Just need to convince my wife that adding a basement is a good idea for the big extension... even though I know myself it's a horrible idea that will be nothing but a headache and expense! Would love to build the garage myself but too busy with my business, thanks again everyone for your input and suggestions - always good to get others opinions and insight. Rich -

New Garage Floor - Lower than my driveway 500mm

iSelfBuild replied to iSelfBuild's topic in Garage & Cellar Conversions

Definitely no windows planned. The hedge from their side is a mess. Cut back and it's all brown and dead. I shall replace it with a nice fence most likely. -

New Garage Floor - Lower than my driveway 500mm

iSelfBuild replied to iSelfBuild's topic in Garage & Cellar Conversions

Only one way to find out... 🤣 There is also the neighbours garage on the right side which is part of their retaining structure - probably comes 1/3 of the way. -

New Garage Floor - Lower than my driveway 500mm

iSelfBuild replied to iSelfBuild's topic in Garage & Cellar Conversions

Wondering even if i just take out the hedge to open up the sea views...could that cause any issues to the retaining wall which has been there 100 years or so? -

New Garage Floor - Lower than my driveway 500mm

iSelfBuild replied to iSelfBuild's topic in Garage & Cellar Conversions

Money is no problem, It just might make sense to make a partial basement on my extension instead of the garage where I was first thinking. Extension is 100m2 don't quite need that big of a man cave though! I'll let the structural engineer advise on suitability just floating ideas for now 👍 If I do build something on the drive I will likely keep the garage at under 30m2 and 1m away from the boundary to avoid a load of bollox so it's outside of planning and regulations. -

New Garage Floor - Lower than my driveway 500mm

iSelfBuild replied to iSelfBuild's topic in Garage & Cellar Conversions

I would be using a raft foundation so the 45* impact would be less than strip footings I imagine? Taking a closer look it looks like once I remove the banked up soil (there is also a dwarf wall my side) the drop to next door will be more like 1m. If I keep it 1m away from the boundary retaining wall by the time the 500mm wall height and 200mm raft epth it's going to be almost level with their side. Just my house to worry about falling into my man cave 😆 -

New Garage Floor - Lower than my driveway 500mm

iSelfBuild replied to iSelfBuild's topic in Garage & Cellar Conversions

Hadn't really considered that! It's just a stone wall - in good condition no cracks etc - but there is a big root structure of the Leylandii hedge which I imagine "reinforces" it all. I imagine the soil I take out will be more ground pressure than the new structure (as it will be timber frame) however definitely worth considering and looking into! Yes a door on the drive way and steps down. -

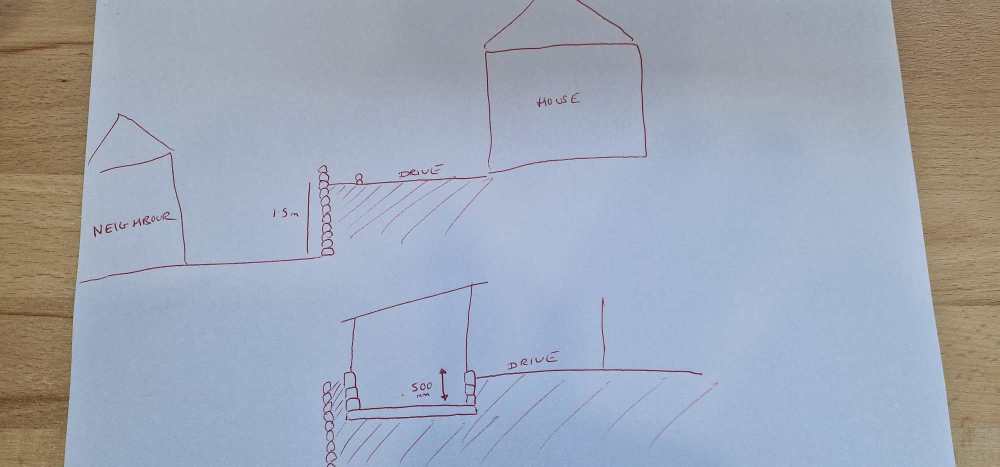

I'm just embarking on a large extension and as part of that I'm building a 30m2 home gym / garage. Please see my marvellous sketch... At the moment there is a large deep boundary hedge which is about 2.7m high - blocking stunning views over the seafront. I am wanting to be able to overhead press in the gym and need 2.8m ideally. So I wondered if I can sink down the base and build up with blocks (laid on their side up to above the driveway height. Fortunately next door it drops away about 1.5m so I'm thinking if I make a French drain all the way around and fill in the sides with EPS then crushed rock it should be ok... Silly idea or should it be ok? Floor level would be 500mm lower than the drive.

-

100mm cavity - Full fill?

iSelfBuild replied to iSelfBuild's topic in House Extensions & Conservatories

Thanks again Mike! 2nd recommendation for Huws Grey. Think I paid £1.06 this morning for two pallets. Used to buy truckloads at £0.60 can't believe price of things creeping up! -

100mm cavity - Full fill?

iSelfBuild replied to iSelfBuild's topic in House Extensions & Conservatories

Thanks! What size cavity did you have with the 125mm PIR? -

100mm cavity - Full fill?

iSelfBuild replied to iSelfBuild's topic in House Extensions & Conservatories

Thanks, I'll be doing it myself so if I do the full fill I'd make sure I get the detailing right, I was going to use the interlocking ones as I know gaps are inevitable otherwise. Just trying to keep the overall thickness as slim as possible - It's only a tiny extension, original house is thick solid stone cottage so seems silly to go over the top. SIPS purely for speed - I've built DIY stick framed before and just CBA with the time it will take etc - getting the whole 100m2 extension up in a week and watertight is a massive appeal so I can plod on with the finishing. -

Just embarking on a wee kitchen extension. Existing kitchen part of the house is 100mm cavity with no insulation. Is it ok to do full fill 97mm celotex/kingspan interlocking insulation - if so what type of wall ties are used for that? Or should I do 75mm and a 25mm gap and top up internally with insualted plasterboard? Internal skin will be thermalite. Externally will be clad in 35mm Cotswold stone veneer and pointed. Only 7m of walling or so - big extension will be SIPS which I'll be posting for advice soon

-

Scandinavian log cabin finally finished!!!

iSelfBuild replied to iSelfBuild's topic in General Self Build & DIY Discussion

Hahah bloody working up till 3am the day before the first guests as well. I left the day of the photos being taken to go to a wedding so my Mum and Dad who manage the property had a bit of a feast in the BBQ hut, well earned rest! It's been a hard slog.

.jpg.943897b017a4666da796e68dd99e4588.jpg)