-

Posts

254 -

Joined

-

Last visited

-

Days Won

6

Simon R last won the day on May 6 2021

Simon R had the most liked content!

Personal Information

-

About Me

Retired form the computer industry. Like getting involved in projects, between my wife and I we have restored cars, built a boat, a done limited house renovation, new electrics, central heating and plumbing.

-

Location

Lee on Solent - Hampshire

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Simon R's Achievements

Regular Member (4/5)

272

Reputation

-

Agree complete, using Bose cube or Cambridge Minx for the satellite speakers also means you can get them out of the way by wall mounting them. They're readily available second hand and give excellent sound.

-

So...I'm about to do Rainwater Harvesting

Simon R replied to mike2016's topic in Rainwater, Guttering & SuDS

Our tank was is 4600ltrs. Just the two of us and a small garden. Lots of washing though as we’re both sporty. -

So...I'm about to do Rainwater Harvesting

Simon R replied to mike2016's topic in Rainwater, Guttering & SuDS

The Kingspan system has a display showing tank level and options to customise auto fill from mains water. As I mentioned the pump had failed before first use and Kingspan wanted silly money just to send someone out. Our system now is very simple. A Divertron pump which switches on when it senses a pressure change in the system ie switching on a tap. No header tank. I also bought a cheap radio tank sensor which displays tank depth. In practice it’s pretty irrelevant and the tank has never run dry. -

So...I'm about to do Rainwater Harvesting

Simon R replied to mike2016's topic in Rainwater, Guttering & SuDS

Our rain water is still clear after 3 years use and is used for washing machine , toilets, window cleaning and garden watering. RWH was not on our original build plan, but a 19K quote to connect to surface water drainage made it a sensible option. After minimal research a Kingspan Klagster 4,600ltr system was purchased. The system included pump and controls for monitoring and maintaining the system. It got delivered and installed early in the build cycle, when we came to use it for the first time two years later the pump had failed. The Kingspan guarantee was 1 year from delivery and they wanted £300 just to look at the pump. Not impressed. To cut a long story short a call to Anglian pumps and some very good customer service the pump was replace with a Divertron pump. The pump is stainless steel and has a float intake, so it's always taking from the top surface of the the water. The pump also auto senses when an outlet is opened. Having ditched the complex Kingspan control system it's been running for three years without problem. I think having a good leaf filter and float intake are key factors in keeping the water clear. We're also fortunate that we don't get much debris in our gutters so silt build up is not a problem. Being able to clean our windows with a pole has been and unexpected bonus, not something you can do with tap water. With the benefit of hindsight I'd have bought a good tank with leaf filter and a decent pump, keep it simple, forget the fancy control system. -

First timers attempting an ICF and Oak Frame house in Devon

Simon R replied to MCoops's topic in Introduce Yourself

It looks as though you've found a lovely plot, good luck with your build Along with a couple of the other comments, building an oak frame within and ICF structure will add considerable cost and complexity. Like you my wife and I had some renovation experience, doing a build was a steep learning curve. With a lot of help from the folks on build hub we ended up building with ICF. It's worked out well for us, we used JUB ICF which is a little different from most ICF solutions as they cut all the blocks in the factory. A little more expensive but it reduces risk, for example all window opening are millimetre perfect. ICF isn't lego, construction is pretty straight forward, filling the walls with concrete is not and definitely requires an experienced contractor. We blogged our build on build hub and also added a thead on the ICF system we used. -

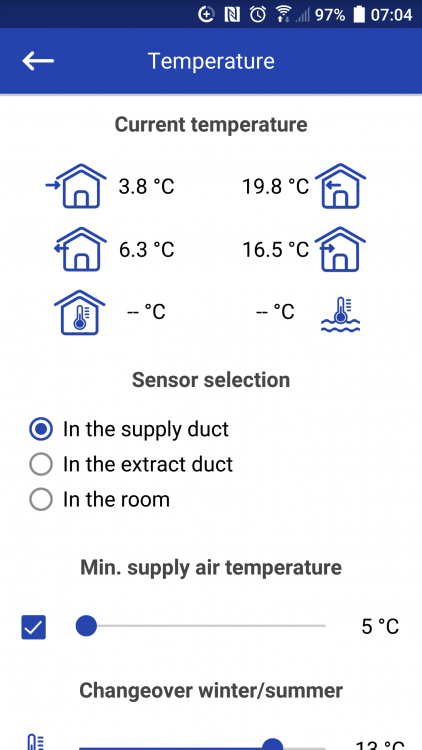

It looks as though the efficiency of my MVHR is diminishing and I've not a clue why so I thought where better to get some input than BuildHub. I'm running a Blauberg SB 550 unit which is possibly a little oversized for our build. When commissioned the air flow temperatures suggested I was getting pretty much 94%, today, three years later it looks as though its running at about 80%. The filters are clear(newly fitted), the heat exchanger core and internals of the unit and clean and indeed look like new. When commissioned the air entering the house was less than 3.3C colder than the air leaving the house. Now it's pretty much 5.3C cooler. That's a big enough difference to notice as a draft. The figures looks like it has to be the heat exchange unit unless I'm getting a lot more air into the house than is leaving it through the MVHR. Our build ACH of 0.6 was, testing the flows should let me know if this has changed. I've contacted Blauberg who made some suggestions about possible causes. Imbalanced flows, dirty filters, dirty heat exchanger etc. I also asked them if they monitored and kept efficiency data for the long term operation of their units, they don't (or won't share it?). I've added myself to the anemometer wait list so I can check flows and compare them to those at the time of commissioning, however as no settings have been changed I'd be surprised if it's a factor. There must be a good number of BuildHub members who have long term data of the efficiency of their MVHR systems heat exchangers. I'd like to know if others have seen a drop off and indeed if they haven't. Here is a copy of the heat exchanger washing instructions:Cleaning Poly brochure_EN.pdf

-

It depends on your budget and how much use they'll get. The main advantage for me was the lack of joints. Reco surfaces have an option to print your photo which gives pretty limitless options and it's not expensive. Here is a thread you may find useful:

-

I think we're both suffering a bit of confirmation bias, I could easily be wrong. The carbon intensity if the grid is not linear. The very times I'm using electricity are the times when the grid carbon intensity is at it's greatest. If having a battery helps smooth this great. I would love to think that if enough people had batteries it would prevent the firing of a gas turbine. Think local , act global. I'm not an expert, but I do care.

-

Yup, that's precisely what I find is the case. Energy generated and stored during the day is used to run the house to cook supper, watch TV, do the washing and make breakfast all done when the sun is not shining. Of 7MWh generated 4MWh went into the house and 3 got exported. Without a battery far more would have been exported as it is generated at times when we couldn't use it. Any residual left in my battery gets used to charge my EV leaving just 20% in the battery to get me through breakfast and into PV time. It's not perfect by any means but it helps.

-

I must confess I’m slightly intimidated when replying to your post….. I don’t think that any sane person would argue that the figures on atmospheric CO2 are just horrible. There are quite a few carbon sequestration options around but few are showing anything like the promise to be able to do the job, which is depressing in itself. Getting control of atmospheric CO2 is the biggest challenge facing humanity. Moving on….I’m trying to get my head around the figures. Google informs me our generating capacity is in the order of 101GW (2022 figure). Energy consumption total in the region of 1,729GW, so a factor of 17ish short when it comes to consumption. That’s a lot of additional generation capacity required and the goal of being oil free is a long way off. Housing accounts for something like 14% of the UK power consumption. Some 5% houses in the UK have PV installed, depending on what figures you take 50-65% are suitable for PV installation. If I could use my EV battery to buffer my use, it would be better than having a separate house battery. However the standards aren’t there and even if they were it would not be a universal solution. For me it’s the ‘ant pissing in the ocean’ approach, every little helps, even if it’s apparently inconsequential.

-

Well, it's true I'm considering PV input to the battery as carbon neutral. If I didn't store any electricity, any residual from local consumption would get exported, which all helps decarbonise the grid. If the grid was carbon neutral then there would indeed be no case for batteries. With a battery in place I use very little electricity from the grid and the times at which it gets used are typically outside the times when solar is being generated. If a battery was not available this would have to come from the grid with the associated carbon cost. In an ideal world it would be great if EV's were grid linked when plugged in and their batteries available as a supply/demand grid buffer. There are moves to make this a future possibility, but like all things it's more complex than it would at first seem.

-

While it's true that consuming is environmentally negative, investing to use less in the future is not environmentally negative. Without it we would not have solar or wind farms. Building to passive house standards consumes more resource, but pays back in reduced energy cost over the building life. Similarly running an EV is less damaging that running an IC over the life of the vehicle. Backup for the grid was not a consideration in my choice to install a battery.

-

It's a case of don't post when jet lagged.... My 7MWh figure is total from 28/10/2022 not this years PV generation which rather changes the figures. However it still does not take long for a battery to become carbon neutral which is the important issue.

-

I've just checked my battery discharge figures and I was including electricity directly from solar. The battery data shows a a discharge of 2.8mWh for the year so it's taken me around 14 months to become carbon neutral, still a very positive reason to have a battery.