Leaderboard

Popular Content

Showing content with the highest reputation on 01/29/23 in all areas

-

My first question is why? Give that render a good clean with a pressure washer and re paint it, job done, low maintenance external finish. Cladding would make sense if it was part of an external wall insulation system to improve the performance of the building.3 points

-

Just found this as an approved retrofit application: https://source.thenbs.com/product/energystore-under-beam-block-insulation-system/bhJN6zXr5iSRNwvFAYrW9G/bSUUubuFs5fkWDGuLZbRzW2 points

-

The deed is done I had to wait until the weather warmed up to be above the "min 5C" temperature for the foam, and used a disposable Soudal can as the straw it came with was small enough to fit through the air brick holes without drilling them out. It took the whole can to get it to seal this plus back to the airbrick so I imagine the cavity has a bit of fill too.2 points

-

Staffordshire blue/black engineering brick… Should be just fine. I don’t like non-engineering bricks below DPC although it has been done like that for decades.2 points

-

Hi, Has anyone had experience with an A2A with DWH? Would love to have feedback please. I'm weighing up my options for a modest retrofit on my 2 bed bungalow in Norfolk. Indeed I have a airtightness test with energy audit on its way that should help me know the order to do things etc including greening space temperature. This winter I reduced my space heating from 8000kwh to 3000kwh with far Infrared heaters plugged into smart sockets so I can live with that for a while. But as I use an 15 year old mitsubishi air-conditioner all summer (using cold to manage pain), finding an a2a heat pump with a water tank seems a good way to get the water heating off gas. And there are 3 that I've found! Argo iseries with their Emix tank - that heats even when AC is on, and uses waste heat from cooling for the water tank Daikin Multi plus - with a 120l tank that could go above the washing machine Panasonic Aquarea Ecoflex - may only just be available. - again reuses the waste heat How effective the filters are is another issue for me to consider - panasonic seem to have gone all out in that respect. So has anyone installed these please? What is the COP for the heating, cooling and hotwater like in real life? Do you know of any more models? Regards, Jt1 point

-

If I was you I would bin the lean mix (With SE's approval) and the PIR boards in the cavity. Just use EPS bonded beads and fill the 150mm cavity right down to the foundation or as low as the engineer will let you. The masons will thank you for not having to fiddle with the boards too. EPS beads are about the same price as concrete (£100/m3) and far far cheaper than PIR boards. You'll be at about £15/m2 for beads installed vs £23.50+fitting for the boards with PIR. You'll have a vastly better performing wall too. The boards CANNOT be installed properly. I've never seen it happen.1 point

-

I also vote for engineering bricks but.. https://nhbc-standards.co.uk/5-substructure-ground-floors-drainage-and-basements/5-1-substructure-and-ground-bearing-floors/5-1-13-durability/1 point

-

Level ground and build up external wall. With Superbead there’s no need for vents. That's very interesting. The gut feeling I had might be right after all. Desperate times... 😅1 point

-

Yes, in the case of the Tesla product it is the "gateway" that does this using a meter on the supply. Other products have different equipment to do this, but they all need to use a 3-phase import/export meter. With the Victron system, you use three seperate charger/inverters (one of each phase), and then it has a seperate contro lsystem called the "Cerbo GX" which connect to all inverters and the 3-phase meter and does this.1 point

-

Only for new build. Not sure how you’d retrofit a dpm under an existing b&b floor?? Under existing Appr Docs and British Standards adding the insulation layer under b&b floor makes it a ‘solid’ floor which requires a dpm.1 point

-

Can you range rate it whilst in there? (limit the max output to only what the house can possibly use; rather than having it whang the flow temperature up to setpoint at the maximum possible firing rate) That helps extend cycle times and reduce operating temps for longer even with dumb hysteresis stat controls.1 point

-

AFAIK when they do DHW on the continent the boiler has a probe in the dhw tank and the boiler controls both the pump and the valves. This boiler will be "coded" as space heating only so doesn't expect sudden changes in heat demand. So squeeze the flow down slowly / open the dhw valve before you close the space heat valve? Or swap it for a diverting valve rather than a pair of two ports and move it quickly; such that the return doesn't have time to cook between the switchover?1 point

-

Yes another vote for engineering brick.. Only solution in my opinion1 point

-

Another vote for the Staffies. Also good for padstones, lintel bearings, manholes etc. About £1 each.1 point

-

Wood-wool and lime? Using it on my extension as I want to avoid plasterboard and gypsum. Heavy, and not cheap.1 point

-

Sounds about right. I’ve recently been working on £2750 ish per tonne with certs for small quantities.1 point

-

1 point

-

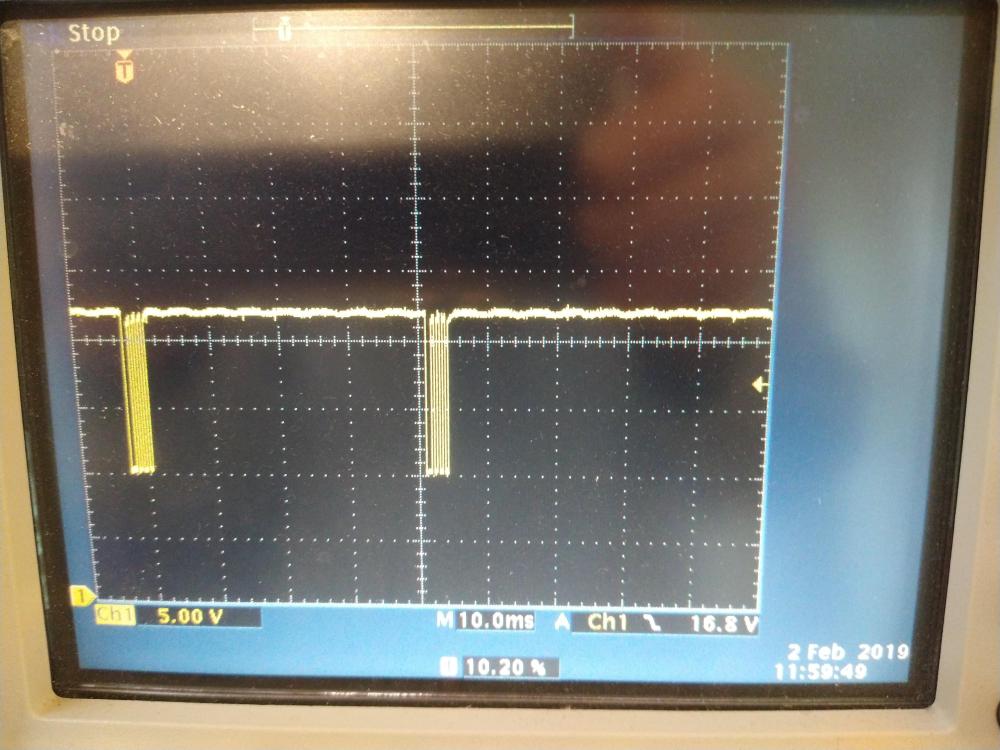

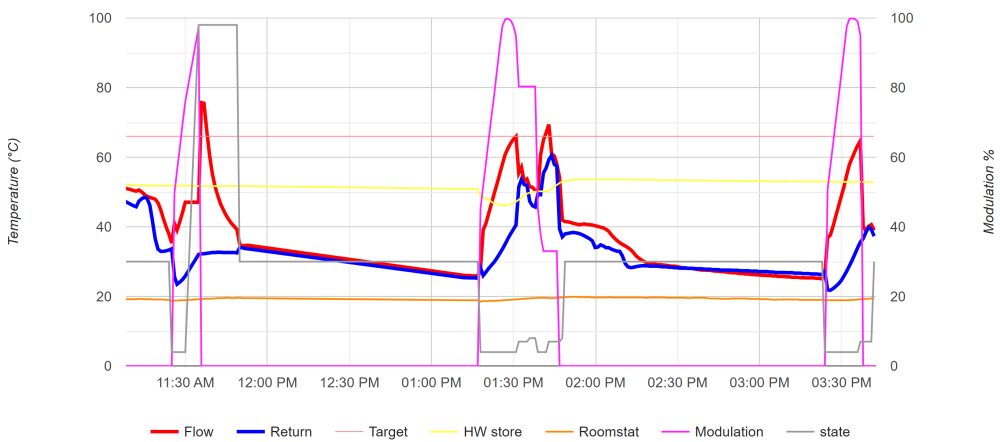

Done! Curiously enough, the 400V input cap on our boiler was a Vishay part whereas the zombie was TDK (Epcos). The LV caps were all TDK on both boards. I've replaced them all with TDK anyway. One of the 470uF I swapped out read 0uF! That's cleaned up the rail quite a bit. There's a bit of 50Hz ripple though nothing serious. Now I can try and have a proper play with flow temperature and see what improvements I can make. Funny you posted about the re-capping today as today I finally got fed up with Fault 13 cropping up as it did just after 11:30 this morning when the boiler went into S.98 (the grey trace below). It has been throwing Fault 13 when modulation is near 100%. This is when the fan is at max RPM and loading the 24V rail the most. This was also when the ebus data got flakey because of the voltage spikes. That's why the graphing has been a bit intermittent. So after changing the capacitors, by 1PM it was back in use and logging again. This time with smooth data. Almost straight away one of the issues I'm trying to solve shows up when, simultaneously, demand for both radiators and hot water cylinder come on. Everything's fine until the Roomstat goes off at 1:30 and the zone valve for the radiators closes. Suddenly, the temperature of the water in the return form the primary loop shoots up and the boiler switches off when it can't modulate down quickly enough. First it goes to S.7 (pump overrun) then S.8 (Anti cycling period) before coming back on (S.4) and finishing off the job with the hot water. I'm currently puzzling over how to prevent this from happening as I'm sure it's unnecessary wear-and-tear.1 point

-

Hi @ruggersI've spoken with a tech guy at Zehnder and he strongly advised not installing the MVHR in a cold loft (mine is a cold loft), as it will vastly reduce performance of the unit. Both in winter (cold) and summer (hot). I explained I was trying to do what you're doing (insulated room around it), and he still said the same. He said to try and locate it within the building envelope. So I'm now burning time trying to find a way to do that.1 point

-

Yes. Add affordability to design errors, project management errors, plain simple disasters, naivete, hip replacement(s) and Beep "Hooston, we gat a prablum" Beep. There's nowt else for it. Just Bloody Do It. Myself. Both of us have faced (and faced down) and beaten huge problems before. This is just another one . We wince, grizzle and niggle regularly, but then Friday night comes along - (International Party Night) , Saturday recovering, Sunday planning. And then along comes a few successes: (piling £6.5K when £22K was the average, successful insurance claim from a wall collapse, cracking architect, kind passers-by, good mates making stuff for me to dig me out of the soft and smelly, good local chippy, excellent orthopaedic surgeon) Not having enough money makes me think - much harder than I normally would. And thats an asset.1 point

-

Lots of wise words in that article. Particularly trying to encourage more generation down south and more usage up north. It shows the lack of joined up planning lets build renewable generation as fast as we can in Scotland, even if that is faster than we can build the infrastructure to actually enable us to use that new capacity Will we finally see proper variable pricing, where electricity for Scottish customers is actually cheaper than for south England customers? (at the moment we perversely have the opposite)1 point

-

I'm thinking about this as well both to create something more distinct than normal PB finish AND to allow diy (and hopefully to a reasonable finish. I have two ideas - a decent ply but as @jackmentions there is a bit of sting in the materials' cost> Birch seems over £100 a sheet but I am hoping to just some samples of Poplar and Maple which are (from memory ) around £60 at least for the poplar. I have also seen D Fir used which looks pretty rustic and could have its place. Anyway I was thinking to mount with maybe 10mm (shadow) gaps around the panels. Originally with hidden fixings but not thinking making a feature of a star head screw and using those rebated. Other idea is to use Fermacell board again with the gaps as a feature. Either hidden fixtures and leave the exposed face as finish or screw just below surface, fill, sand and paint. My thinking is that I can do all the steps and with a bit of care there is the potential to achieve a quality result that is maybe cost neutral over PB ignoring my labour of course. With plywood I have yet to get me head round (Scottish) building regs re fire hazard so that needs more research1 point

-

Even in a small property, I'd price it up before falling too deeply in love with this option. High quality plywood is insanely expensive. Personally, I can't stand the look of OSB. Someone was recently talking about cement board as a lining material. I think that could be an interesting option.1 point

-

There’s nothing to stop you Battening out and using Osb If you are ok with the rustic look A bit more expensive on materials But you will save on labor if you do it yourself The reason why plaster and now plasterboard has stood the test of time Apart from being relatively cheap Is its fireproofing properties1 point

-

The one from Bosch - measuring master. 0.1mm is daft on a building site as a 1degC change in temp makes more than 1mm change in the length of the longest aluminium gutter section (10m) but +/- 2 is fun to work with.1 point

-

Well founded founded persistence always brings increasing resilience in it's wake. You just get better at it. There will be many similar tests. Remember your previous success. It's the foundation of tomorrow's.1 point

-

We are building this way - it some ways it's really good, but be careful it's very different from a single contractor build. There's nobody on-site with visibility of the full build so much more responsibility falls to you to get things right, and it's dragged us to be much more technically involved with the build. You'll find a way, and be relieved your contractor has been honest with you!1 point

-

Just paid £3.80 per metre plus vat for a pack of 10x2 c24 also had a quote for 9x2 c24 at £3.00 per metre. both from jewsons had to buy a pack of 50 odd 4.8m lengths 11mm osb was 15.99 plus vat for ten sheets, would be 13.99 plus vat if I bought a pack. They seemed desperate for the order.1 point

-

I bought a FLIR camera. It’s brilliant and so glad I did. I’m sure it’ll be worth its weight in gold as I move forward with the build.1 point

-

It’s a cliche but everything happens for a reason. best of luck moving forward.1 point

-

1 point

-

1 point

-

Here's a couple that I am using: https://www.earth.org.uk/MHRV-mechanical-heat-recovery-ventilation.html https://www.earth.org.uk/MHRV-Vent-Axia-Lo-Carbon-Tempra-P-REVIEW.html Yes, I think they do their job. Yes, I also see condensation dripping outside from the bathroom MHRV. Rgds Damon1 point

-

Very likely just to be condensation. It's only to be expected on such a cold surface indoors. If you wanted to be sure you could tape a polythene sheet over the whole area (tape it very well so inside air can't get between the sheet and the wall). If water is coming in from outside it will be apparent on the wall side of the plastic, conversley if the wall stays dry but condensation appears on the room side of the sheet then it's coming from the atmosphere indoors.1 point

-

1 point

-

The Vent Axia Tempra is a single room heat recovery unit. It replaces stale air with fresh air that has been heated by the process of heat exchange. So efficient is this process that up to 74% of the heat from the extracted air is reclaimed. That's the claim under ideal conditions. I've never measured the temps . It's a lot better than a plain old extractor, and you can see some condenation dripping externally so it must be recovering some of the latent heat. https://www.extractorfanworld.co.uk/vent-axia-403835-12v-selv-lo-carbon-tempra-lt-heat-recovery-extractor-fan--timer-long-heat-exchange-3904-p.asp1 point

-

In respect to use of PV across phases yes, with a 3-phase supply and vector-sum meter it doesn't matter which phases are producing and consuming. If you have constant production of 5kW on phase-1 and constant consumption of 5kW on phase-2 for an hour then the meter will record zero import and zero export. If the meter wasn't vector sum, then it would record 5kWh import and 5kWh export and (given import tarrif is more export tarrif you'd be paying something instead of nothing) Once you introduce a battery though, there is a bit more thought to it to ensure higher levels of self-consumption, as you really want 5kW load on phase-1 to all come from the battery (even if inverter is limited to 3kW/phase. The video also explains how this works (with batteries that do this) Import is not offset against export over time. Vector-sum metering is the way the instantaous power usage is recorded only. If you export when the sun is shining and import in the metering the evening then this counts as seperate import and export with different pricing. The alternative to this is a specific "net metering tarriff" where import cost and export cost price/kWh is the same. With this type of tarriff a battery makes no sense, you are right, but the only such tarrif in the U.K is the Octopus Tesla Tarrif which required batteries to join.1 point

-

1 point

-

1 point

-

Previous thread on windows in corrugated roof might be worth a read.. https://forum.buildhub.org.uk/topic/8984-corrugated-metal-roofing/1 point

-

yep, engineering brick the colour you want. You could also use a block and have a vertical DPC on sloping ground.1 point

-

As above, Staffordshire blues, order them and move on to the next problem, anymore than two minutes thought on this is overthinking. Only one product suitable for down there. Obviously different manufactures might have colour variation.1 point

-

My planning permission includes one for the insulated metal garage largely because I might eventually build an office inside the garage so wanted the option.1 point

-

Porcelain will be very slippy when wet. Also make sure any tiles are suitable for cold weather as well as nonslip. I have observed paving laying differences uk and Spain. You don't see a lot of cracks and potholes in a spanish street or square because of 1. The weather. But 2. Because under the tiles is a reinforced concrete slab, suitable for forklifts. But good builders do the same in domestic situations too. Therefore as above...dig out some more ground, lay compacted stone. Then I would lay a concrete slab with mesh, 70 thick. Then the tiles or slab are a finish. All on a slope. If you want, you can break up the existing material small, to use as hard-core on the bottom.1 point

-

^^^ Important advice that. Don't copy the way the old slabs were laid by plonking them down on dollops of mortar. It's a terrible shortcut that has all kinds of bad repercussions.1 point

-

As above, dig out, buy MOT, lay min 150mm, hand tamp it down well, then full mortar base on top.1 point

-

1 point

-

I have the Bosch GLM 50 C (around the £150 mark) although its has an accuracy of of +/-1.5mm it will measure to 0.1mm if you fire it with Bluetooth and don't hold it so you can detect tiny wobbles / vibrations. I don't like the battery life, which feels like a couple of hours when you are working it hard but otherwise it is a great workhorse.1 point

-

I think the only way you will identify it for sure is to dig to look for it. I would start by digging at the front corner of the garage in the direction the extension would go, dig about a metre down and dig as far as you would want to extend. If you don't find it, then don't mention it? As to who is responsible? Probably you. I believe this would make you a riparian owner, just like I am with a burn running through my garden. Covering the entire burn would not make it go away. To make alterations if for instance you did find it and would have to move it over or build over it, I suspect it would be the Environment Agency assuming you are in England. One final thought do you know anyone good at dowsing? A set of divining rods might enable you to locate it.1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)