-

Posts

537 -

Joined

-

Last visited

Personal Information

-

About Me

Living in a cold and draughty 1920's house, badly extended in the 1990s. Do temperatures above 16C exist?

-

Location

Windy coastal Hampshire/Dorset border

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Sparrowhawk's Achievements

Regular Member (4/5)

150

Reputation

-

Good read @marshian, and that matches my experiences very closely. My heating curve ended up as Slope: 1.6 and Level: -7. It's still not perfect, as on days with lots of solar gain it overheats, while on other days, which are warmer outside but with no solar gain, the house is too cold. But I don't think that's fixable until we have better insulation and draft proofing. @Oz07 In my case we left the heating on 24/7 (previous years manually turned on/off) and our usage went from 13,300kWh to 14,500kWh - but the house was always comfortable, whereas in the previous year it had been down to 15C many winter evenings, and we were wearing coats indoors. This is still below the 16,500 kWh it was in 2021 when we tried to have it warmer with the old boiler.

-

Help with kerb appeal of an existing house

Sparrowhawk replied to Sparrowhawk's topic in New House & Self Build Design

Thanks @ETC a sketch or two would be appreciated. That's a good idea about looking back, I will look for earlier photos but I know it was built c1926-8 as the middle of 3 houses and extended (porch, 2 story side extension w. new garage) in the late 90's. I suspect the first floor pebbledash is original and it was red brick for the ground floor. Later rendered over to hold the soft red bricks together! The original roof was slate. Not much help but I have a B&W aerial photo from 1948 where our house (middle) is right at the back. Bournemouth is nearby so I'll look for similar period photos from there. @DevilDamo ChatGPT certainly has ideas 😂 -

Yes. Round here people slap thick render over the downstairs bit to hold the soft red bricks on the lower half together, and if they want contrast add cedral cladding or similar to the top half. Or render it all the way up. If it were affordable to "swap out" the lower half of the brick walls for new brick people would be doing it, because the houses which are still like that look cracking.

-

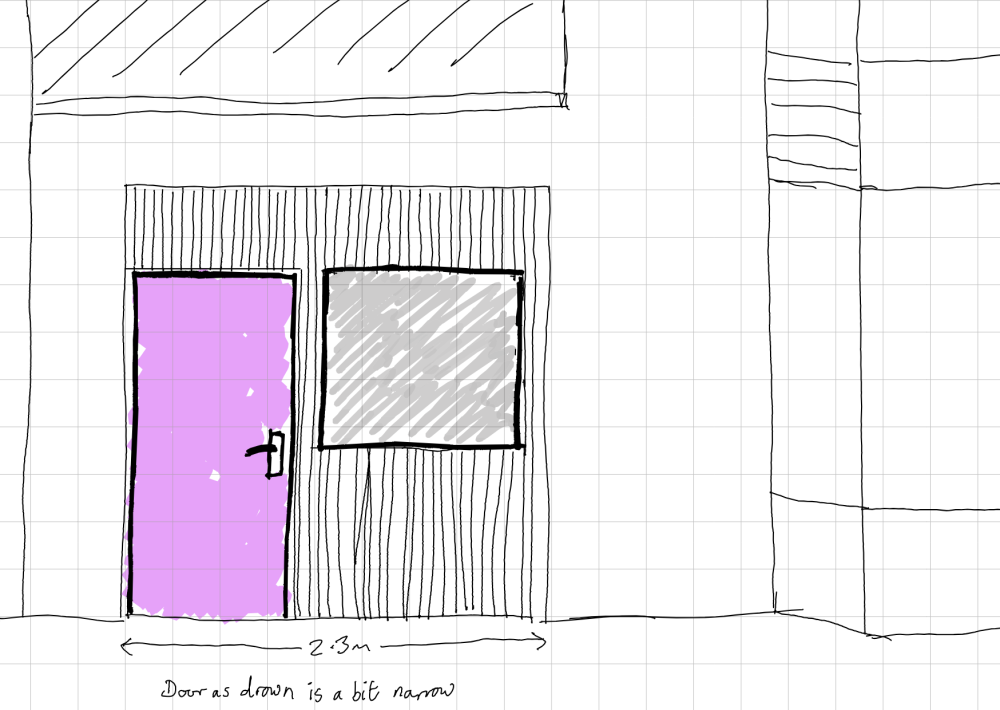

We're going round in circles here with the number of possible options, so I'd appreciate the forum's input. Having overhauled the front garden this spring, we need to bring the rest of the front up to scratch. Over the next few years we need to: Rerender the ground floor Repaint the house Replace the blue painted timber cladding and white PVC cladding (no ventilation behind!) Decide if keeping the barge boards and facias/soffits black or change to white Replace the windows Convert the garage to workshop/gym and pop an airtight front door on it (I see many ugly conversions, I don't want to be them) French windows on front? Or 1.2m+ wide door and window? Need to get wide handlebar push bikes and larges sheets of wood in and out Eventually rebuild the porch, so there's free rein here So there's lots of freedom, except for the roof colour which we're stuck with. We are struggling to choose the garage/porch style and pick colours that work together and visualise what areas should be what colour. We don't like the current magnolia/blue/white/black combo. The blue wood and the white PVC cladding sit awkwardly together. It's a seaside location. Next door has gone sage green for their doors and woodwork. We'd like to add a climbing rose between the current garage door and the bay window. I sketched something modern with cedar cladding for the garage door infill but my wife wasn't keen, and pointed out that french doors are more practical as they give a wider opening and more light, and will need less maintenance than wood, as neither of us like the natural grey it goes.

-

@TerryE Yes let me know the credentials for our GSE account and I'll see how our account looks.

-

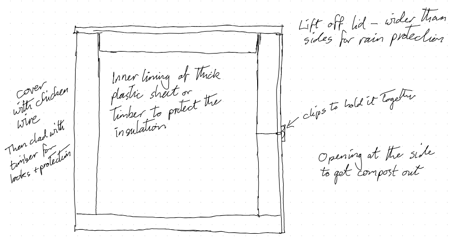

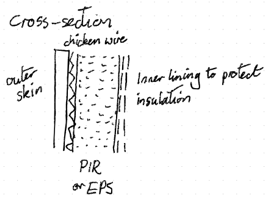

They make no claims beyond it's robust and allows for hot composting. What does sticky stuff mean here? Stuff in the compost bin that's gone into anerobic decomposition? Assuming that home compost is similar to the council-sold "soil improvers" made from green bin composting, which is £125 per cubic metre delivered (and I see plenty to say that it isn't - but those people also want you to buy their "bio" compost at £35 for 15 litres), the economics aren't there but as you say it is very satisfying to make. I find the height and shape of the dalek composers makes it hard to turn their contents every couple of weeks so I've got the idea of replacing them with an insulated cube, ideally held off the ground on blocks to make it harder for rats to attack (OSB or paving slab base?) Unless I can get offcuts of insulation to use it won't be cheap compared to my £25 insulation of the dalek, as this needs £75 of EPS, and that's before making a hard inner lining out of something, probably timber at the same cost again. Which is half-way to the cost of a ready-made hot composting bin. Wrapping a hard shell in insulation would be easier and potentially cheaper, but I haven't found many cube shaped plastic containers, and plastic barrels need flexible insulation like this polyethylene stuff plus I'm back to a shape that's poor for turning the contents to re-aereate it.

-

Insulation allows hot composting, which makes compost in 90 days or so. A mow of our lawn mixed with brown stuff fills half a dalek, and I only have space for 1, so it was very handy when I had it working. 3 years ago I wrapped a Dalek composter in 50mm glass wool inside thick polythene sheet, and it worked brilliantly for the first year, keeping the contents at 45C+ for 2 weeks after every new addition. That winter the rats moved in and tunnelled within the glass fibre and made nests (should've wrapped it in chicken wire), the insulation slumped and got wet, and it stopped keeping things warm. Now in 2025 the bin is still slowly decomposing last year's clippings. Yes this would seem the sensible way, I assume they chose insulation on the inside to keep their product looking smart.

-

Bloody hell that's more expensive than PIR!

-

I can't justify paying the silly money for one of these composters, but I'd like to work out which insulation material they're using and how much insulation it's providing. I don't think it's PIR or EPS. Thes are the best photos I found online: From a close-up it looks layered, like packing material. Maybe polyethylene insulation?

-

Huge MVHR quote

Sparrowhawk replied to Garald's topic in Mechanical Ventilation with Heat Recovery (MVHR)

The "Welcome forum" as a "Retrospective on my journey" thread? -

50°C on sunny days in summer before we added tile vents (it's a 100yr old roof, re-roofed in 1989 with dark tiles, and no economic way to put a vented ridge on it). Thankfully it's nearly always windy here, and from memory the vents knocked at least 10-15C off that figure last summer. You will have loads of insulation in your roof, but it's the decrement delay that also matters. How long does it take the heat to enter - and leave - the insulation? You mount a chunk of crumbling sole plate on a plinth and give it to them as a Christmas present. Many broken nights recently @Iceverge?

-

The ridge vent will also allow a way for the hottest air to get out - which is my current thinking on why to keep a few eaves vents plus ridge vents. Upstairs the biggest overheating problem we have is the roof space warming up and penetrating down through the loft insulation. The cooler I can keep the air in the attic the better...

-

Expectations around MVHR

Sparrowhawk replied to IanofEpping's topic in Mechanical Ventilation with Heat Recovery (MVHR)

@jack Do it!- 13 replies

-

- 1

-

-

Retrospectively sealing cracks at 10+ year old plasterboard joins

Sparrowhawk replied to GP41's topic in Ventilation

Was the dot and dab plasterboard then skimmed with jointing compound or with the hard brown (gypsum?) plaster? For the junctions, having tried to doit myself with CT1, I think your best long-term fix is to sand back a bit, and get a plasterer to insert folded paper tape over the join and feather it in. For cracks on the flat surfaces, scrim tape and a reskim or decent feathering in. None of this helps if you've got cold air circulating behind the dot and dab. Do your thermal camera images show it happening, and help you locate the source? You could drill holes and squirt expanding foam in top and bottom and see how much that improves it.