-

Posts

4053 -

Joined

-

Last visited

-

Days Won

29

Iceverge's Achievements

Advanced Member (5/5)

1.7k

Reputation

-

Getting better at digging with an excavator?

Iceverge replied to Alan Ambrose's topic in General Self Build & DIY Discussion

Nope! Just get it in a position that you won't need to move it for a stroke. -

Closing cavity at the top for blown beads

Iceverge replied to MortarThePoint's topic in Heat Insulation

I wouldn't worry about it. -

Eps is a great material in the right application (usually underground !) but you've hit the nail on the head with fire concerns. It tends to melt into air the small bit of liquid dribbles away then when you burn it. Alarmingly quickly too. Rockwool hardrock is expensive in comparison but over your area the difference won't be mega. I'd stick with that. There's other brands too. Knauf rocksilk etc or maybe woodfiber. Is there any reason you don't want to have fullfill rafters with insulation inside like I suggested above.

-

Yup they're rubbish, specifically sliding sash with brush seals. You can fake ones with the horns that look ok but I'd be looking at compression seals on the windows whatever I did. Have you considered that noise may be coming through the ceiling or from under a suspended floor too?

-

Might you have forgotten that you put kooltherm in there instead of PIR.......🥷. Say 50mm between the rafters and 80mm below....... Also stupid rules. This would be easy to solve if everyone was allowed to simply bulldoze and rebuild their houses properly every 70 years.

-

Top down, Tiles 38mm Tile Battens across the rafters 25*75 Battens up the rafters Glidevale VP400 membrane. 11mm OSB taped at all joints. 200*44mm rafters at 600cc full fill with blown cellulose ( or mineral wool batts) Airtight membrane, 45*50mm battens at 400cc across the rafters with 50mm mineral wool in the service cavity . 12.5mm plasterboard a skim. U value about 0.17.

-

I would argue this is exactly what you need to avoid, primarily through good airtighess. Buildings die when water (in whatever medium ) gets into the structure and cannot get out. Stop all drafts taking vapour through a structure. Also at all costs avoid sandwiching materials of very low permeability. That's why I don't like the polythene VCL, Foil faced PIR and EDPM all together. If water gets in then it's never getting out. Always better to stick to one impermeable layer maximum. Are you suggesting that just having poor airtightness is a solution to ventilation? That's much the same as having a hole in the roof as a solution to getting drinking water into your house. Beware your designer and NHBC aren't gospel either. It's a woefully misunderstood topic this. Stick up a section of your roof and we'll have a look at it. What roof covering is on your current house?

-

Reality unfortunately gets in the way of these assumptions. Mistakes and sloppyness are a part of building and I think any design should be somewhat tolerant of non perfect workmanship.

-

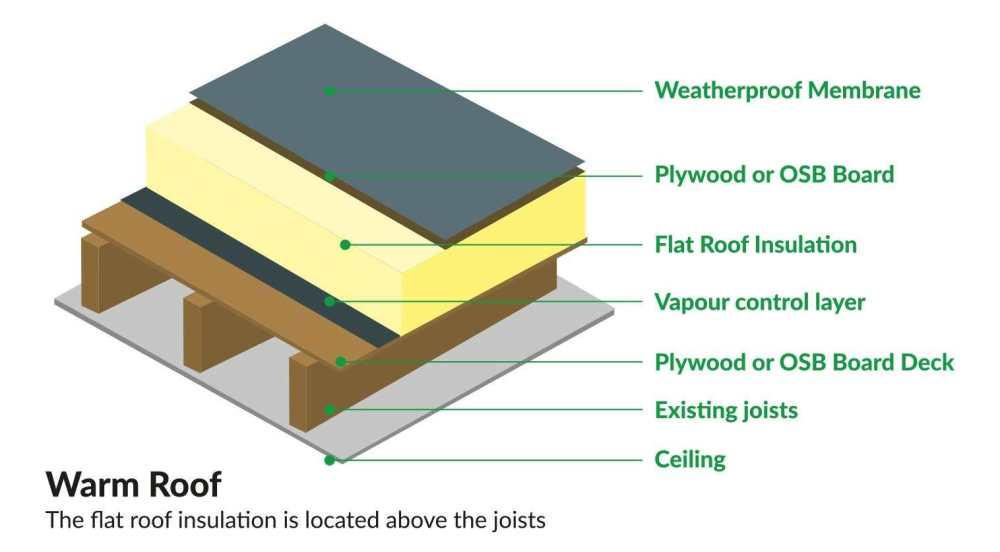

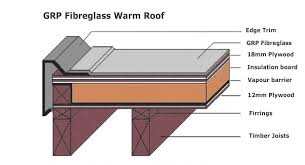

It's there in pretty much every detail. That comes up on Google so I assume that's how the majority are built too. Ply or OSB above the insulation. I think you can get some types of insulation with specific fleeces bonded to one side to take grp/EDPM.

-

Also I would prefer something like metal cladding as instead of EDPM or GRP as it isn't weather dependent for install and as vulnerable to imperfect workmanship.

-

I think we're storing a mountain of problems with unventilated flat roofs in the long term. The grp/edpm is the only barrier to water ingress. Its waterproofness is completely reliant on its total integrity. Being exposed to the temperature variations of the sun and weather it will inevitably fail at some stage. The first thing the occupants will know, is water will emerge from somewhere in their roof, with zero clue to where it started. Maybe months after it has failed, in the meantime causing significant damage. We all know how sloppy builders can be with membranes so I bet most VCLs are full of holes or nobody's taped the joints properly. The layer of OSB under the is GRP is the ultimate stopping point for the internal vapour to condensate. I think these will start to rot out and nobody will know until the roof leaks. I would far prefer something like this. GRP/EDPM 18mm OSB 25*75mm battens across the joists. 25*75mm battens up the joist with the void fully ventilated at both ends. Breather membrane Rigid insulation. Furring strips. 18mm OSB diligently taped as airtightness. Joists . Plasterboard I would also happily install insulation between the joists if I was doing it myself for a hybrid roof. However I understand the issues and am picky about details.

-

It's a confusing issue this. The vapour permeability of materials and house ventilation are two separate issues really. Add airtightness in there is you really want to make some soup from your brain. Vapour permeability has to do with the ability of airborne vapour (from breathing, cooking showering etc) to pass through a material, something like a cotton sheet is high permeability, something like a polythene sheet is low, something's like plasterboard is in the middle somewhere. Ventilation has to do with taking the stale air outside and bringing in fresh air outside, very important for the health of the occupants and the building. Airtightness has a dual mandate. It keeps the wind from blowing cracks and gaps and making the house very uncomfortable and hard to heat/cool. The other important one is that it keeps that internal vapour from travelling into the structure of the house and condescending causing rot etc. The polythene VCL in your roof is an air barrier ensuring there are none of these gaps let wind blow through the structure. It should be taped diligently and returned to the airtighess layer on your wall. It is a vapour blocker too as the microscopic holes in the polythene are too small for gaseous water molecules. Worry about airtighess before vapour as big holes are more of a problem than microscopica ones. You are right to want to get the stale vapour laden air out of the house. The best way is with continuous mechanical ventilation, something like a dMEV fan is cheap and very effective. Trickle vents on windows and extractor fans might work in theory with very diligent occupant's but in practice it doesn't. Don't allow it pass through the roof as it will condensate and cause issues.

-

Getting better at digging with an excavator?

Iceverge replied to Alan Ambrose's topic in General Self Build & DIY Discussion

For grading I would take 4 corner points of my work and drive pegs. Run 2 string lines along the long sides say at 200mm above the final grade. Then run a third string between the two others and slide it slowly towards you so the string forms a “H”. It’ll pull the long strings together but that doesn’t matter so long as it’s taut. With a white marker or some paint draw a line on your bucket about 200mm from the base at approx the angle you’ll be dragging at. Try your best when grading to keep it level with the strings. Move the cross string down the H to maintain accuracy as you go. I’ve had good success with this method. -

Getting better at digging with an excavator?

Iceverge replied to Alan Ambrose's topic in General Self Build & DIY Discussion

Start with your tracks in line to the area to be levelled towards you, blade down for stability. Extend the dipper until it makes about an 45 degree angle away from you. Have the base of the bucket open so it makes about a 45 degree angle with the ground maybe slightly steeper. Lower it to near the surface of the work, not even touching it to begin with. Pull back your left hand a small bit so that the dipper moves towards you at a steady rate (slower is better) freeze your left hand in that position to keep the rate. This is important as you want to have only one variable. The with your eyes glued to the eye of the blade of the bucket (this is very very important, fixate on the bucket blade) pull back your right arm to raise the boom as the dipper comes towards you. Until it makes 90 degrees with the ground. For your first few passes don’t even contact the ground. Just concentrate on getting movement parallel to the ground. Remember, bucket frozen in position, slew frozen, dipper at steady rate, eyes fixated on bucket blade varying only the boom. Take small bites. 30mm maybe, it’s far easier to take than replace. When you’re happy with your initial grade slew slightly left and begin the same again with about half a bucket overlap as a guide. TLDR. 1. Steady machine with tracks and blade. 2. Retract Dipper a slow steady rate from 45deg away to 90deg. 3. Raise the boom to keep bucket blade at desired grade. 4. GLUE YOUR EYES ON THE BUCKET BLADE!! 5. Small bites. 6. Work in an arc from right to left using overlapping each bucket pass. 7. Track back and repeat. -

Is there an option to just use the conservatory as a bedroom and making a new home office in a garden room ? You could add a shower downstairs too then which should broaden the market for potential buyers.