Leaderboard

Popular Content

Showing content with the highest reputation on 06/07/22 in all areas

-

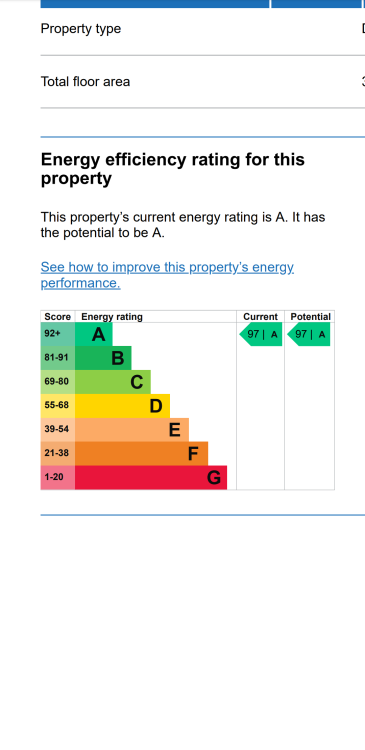

Even though I'm disappointed in the airtest result of 1.8 (the thermohouse roof panel system is NOT airtight, despite what they say!), I'm happy enough. First time seeing an EPC with no potential improvements! We hit the passive House heat requirement target but not the airtightness so certification not an option.3 points

-

We’ve gone with a big rectangle as it's cost effective and will fit well with the surrounding houses. Ignore the roof shape as that's not what it will be, that was just a drawing to show the site layout and prior orientation. Roof will be hipped. Question anyway was on the floor plans. We've not been lied to, was a turn of phrase, will correct. Question anyway was on the floor plan not who drew it or what their qualifications. Appreciate all the concern on that but not what we're after. Helpful feedback is welcome, we're not changing who is doing this and seeking some constructive input not what we could or should have done.2 points

-

The problem is not much better with a conventional unvented hot water cylinder. The ASHP uses the lower of the 2 thermostat pockets to measure the tank temperature. Near the end of a sunny day like today it is reading69 degrees. All that lovely heat courtesy of a bit of sun, some chemistry and some electronics. BUT from watching what happens next, there is "room for improvement" Someone takes a long shower (far longer than necessary, but they blame the duration on the amount of products needed to be applied to their long hair, a problem I do NOT have). The water at the top of the tank is still coming out piping hot, but what has happened is the hot water in the tank has all just "moved up a bit" and at the bottom replaced by cold. As soon as the hot / cold transition gets above that lower thermostat pocket, the ASHP thinks the tank is cold and fires up, and I am there shouting at it saying why the b****y hell do you want to come on? If I were designing this system again, I would specify a whole row of thermostat pockets up the tank, and I would specify an extra tank tapping near the bottom of the tank, not far above the cold inlet tapping, and I would have a circulating pump that could come on to stir up the hot water in the tank to even it;s temperature out a bit, and hopefully avoid the ASHP coming on when not really needed. but I can't see a way to retro fit that with no tank tapping low down to circulate the water to.2 points

-

Just circling back to share that we painted our battens in Bedec matt black Barn Paint - https://www.brewers.co.uk/product/BN041305C We laid them all out on pallets and went hell for leather with paint pads - it took a while but not as bad as expected! We were strategic about which sides we painted for which section/height. Some we did 3 sides, some just one/2. They have just finished installing the horizontal cladding and it looks great (IMO)! Just moving onto the vertical now so we'll see how that turns out.2 points

-

Peach Joe90! (Im sure it was yellow in garage.. undercoat? ) Anyway that.. is the nicest looking mg Ive seen. Positively E type ish.1 point

-

1 point

-

I will be interested how they implement this at flats and inner city builds with no off road parking.1 point

-

I think they are probably more to do with making sure all the phase change material becomes liquid while heating. Convection currents will tend to even the temperature out, but an off set to cater for distance from element could be easily established with experimentation. I do not know the product well enough, but as it knows it is full (element turns off), it would not be too hard to program something to make it take a charge after use. I think it has to treated like a car with a very small fuel tank on a long, unknown, journey. You take every opportunity along the way to fill it up as you go along.1 point

-

1 point

-

No I meant for my veg frame I'll pop a few gussets on at the corners. Doesn't need much. Tbh reckon it'll rot from the inside out down here. Did think about spraying inside the box sections with veg oil... ?1 point

-

It is hard to buy land that is not for sale. But I managed it. the plot we nowhave a house on was empty for years. I by chance met the owner, and asked if he wanted to sell it and the answer was no. Over the years I asked several times and the answer was still no. Then I had resigned myself to buying a plot that was for sale but not in as nice position and further away, so out of courtesy I phoned him one more time and told him of my intention to buy this other plot. His reply was "give me 24 hours" and he phone back next day to say I could buy it.1 point

-

Yes, my idea is aimed at how to mix the very hot water from surplus PV heating around a bit. What I find, is when I get this temperature step thing and the ASHP comes on because the bottom of the tank is cold but the top is still piping hot, is the ASHP does not run for very long, less time than you might expect. I am convinced that once it starts heating, this sets up convection currents within the tank that draws the top hot layer down and helps with the mixing process. Just speculation.1 point

-

What I am talking about is something to stir up the water in the tank so instead of having 70 degrees in the top half and say 30 degrees in the bottom half, it mixes it around a bit when it senses a large stratification like that and ends up all at say a nice even 50 degrees. Thermostatic mixers ensure nobody notices a change in water temperature. To make an accurate "fuel gauge" for an UVC you would need several thermometers all the way up the tank, hence if I were ordering again, I would have got at least say 5 thermostat pockets evenly spaced up the tank.1 point

-

No that is fine. Roots and all doesn't matter tho I read that juicy leaves are best. I opened up a gallon container from last year and it looks just like commercial stuff. Brown just like the seaweed stuff, or tomato feed. Doesn't smell horrible though, so has possibly lost a bit of potency. When ready it makes your hands stink despite a couple of washes. Remember to allow extra time before meeting anyone.1 point

-

Not worried but hate to see a gap that could be filled with insulation wasted.1 point

-

that basically means your PV generates more power than the house uses each year.1 point

-

That is because they don't know it accurately enough. The trouble is that the phase change temperature is a constant. The only way to get it fairly accurate would be to measure the electrical input, measure the thermal output, factor in standing losses, then do the sums. Only needs a cheap thermal energy logger, a simple processor unit and some time. If the flow rate is constant i.e. just showers, no need for a flow meter.1 point

-

I'd think if the gap in the area indicated is unventilated then I could not see why there'd be a problem, if ventilated or outside air can bypass the wool then that would affect your U values. I've just had a butchers at your blog - Well done, good going!1 point

-

really? if so that would be amazing. I thought there midge be some regulation regarding how much roof area feeds into one pipe, but I suppose with it just being an overflow it could avoid this. ideally I'd like to get rid of the barrels as they're unsightly and I'm fed up of emptying them periodically, so if this is a goer I will replace them with an icb (potentially underground), have a pump feed the downstairs loo and then any excess/overflow can be directed into the house down pipe.1 point

-

Go on the Aps store, Google or apple and download CDM wizard. Fill in all the steps and you then have a fully compliant risk evaluation. As principal contractor, anyone on site reports to you, you manage who is on site and when, a single build they should not be tripping over themselves. My build was a single trade and me on site, other than the loads I did myself and then it was me with various helpers as needed. Can I be the domestic client and principal contractor ? Yes or client your wife. Will I still need to notify HSE of a project (F10?) ? Don't believe you do, I didn't. Will I still require a construction phase plan? CDM wizard Will I have to produce RA & MS for every activity? CDM wizard Will I have to submit RAMS to someone ? No but needs to be available, CDM wizard.1 point

-

Have a look at ID Systems. They do a narrower profile triple track pocket door. They are well thought of and specialise in this type of thing.1 point

-

If the frametherm goes right to the apex I don't see an issue. Put any cables in e.g. for lights before you close it all up.1 point

-

Cut the PIR edges at an angle to match the roof pitch and there will be no gap?1 point

-

Here's what you need. Follow the links in the page(s). In brief CDM 2015 does not apply to self builders. Take all reasonable care. Follow Best Practice. Do not do anything that suggests you might be a Client, and therefore NOT a Domestic Client. Be sure to know the difference between the terms Client and Domestic Client . That distinction is critical. I am not an expert. I've just done the hard yards doing the research so others can benefit. Do not follow my advice as if it is expert advice. It isn't.1 point

-

If we were using joules most practical measurements in the current context would be MJ or GJ so always upper case wherever in the sentence it occurs!🙂1 point

-

Paul, [the following is neither advice, or legal guidance 🙂 ] I am self-building, quite literally. I consider myself to be the domestic client (although that could be SWMBO), and the principal contractor. I therefore know where problems may occur for pretty much everything I am doing myself and I don't do RA's fro each little job, and neither have I notified HSE. Three items so far I have not done myself - groundworks, erecting steel and pouring concrete. In each case I have met with the people carrying out the work, before they start, shown them the site, what I consider to be the "danger" areas and risks, and then asked them to confirm if they are comfortable with accepting responsibility for themselves and anyone/anything they bring onsite to perform their work. In each case they have, and I consider myself to be covered. I have experience only one accident on site requiring medical intervention - a gash to a leg from re-inforcing mesh. Others will be along shortly to tell me I've got it all wrong 🙂1 point

-

Yes I use A2A units in the bedrooms - originally fitted as A/C but I used them for heating over the past winter, works fine. Few items to consider - 1) It's a different kind of heat - not everyone likes warm air being blown on them so consider the position (or use the vane/flap adjustment) to direct the airflow in to the middle of the room 2) During the winter you may notice the defrost cycle - some units are smart and close down the internal unit whilst the external unit is defrosting to avoid blowing cold air about, but not all 3) Aircon remotes/programmers suck - it's like going back to programming a VCR sometimes. I found the wired wall mounted controllers seem to fare better in the wife acceptance factor department ...otherwise they 'just work'. Cheaper overall than an air2water heat pump. I'd highly recommend getting them fitted properly by an Fgasser - it's worth the money. I also have a no-name "easy fit" unit which worked fine for a year or two but has repeatedly broken down since Vs my 'proper' Mitsubishi units which are purring along fine. Strictly speaking that Telefunken unit above should be fitted by an FGas registered bod as it involves vac'ing down the lines and working with refrigerant.1 point

-

Let us know how you get on, if we don’t hear from you we know the worst has happened 🤣1 point

-

1 point

-

Not an expert enough to really known the answer.... But couldn't you construct the wall using 2 timber frames with the gap between for the sliding doors. As is, the 2nd timber frame would be on the inside and just be used to create the gap for the doors, effectively a larger service void. Yes that wall would be thicker but not really sure why it would be anymore complex than doing the same with brick wall.1 point

-

If you are going to pursue this, there is one word you need to understand. COMPROMISE. If you slide all 3 panes into a pocket on one side, that will take up a lot of the width of the frame of the house. Much of that width would normally be filled with insulation. By leaving a gap there (that is what you are doing, leaving a great big open gap in the wall occasionally filled with the doors) you compromise on the amount of insulation so that part of the wall will be cold. You might look at making that section of wall thicker to get that insulation thickness back? But the big one for me is air tightness. If as in your example photo just one pane slides into a pocket, then you might be able to design the window frame so it makes a reasonably air tight seal whether that pane is slid into the pocket or slid into normal closed position. But you want all 3 to slide into the pocket. Just how do you think you are going to get anything like an air tight seal around a hole in the wall 3 panes wide, when they are all shut, and only 1 pane is filling that hole? Find a real world example of 3 panes sliding into the same side and come back and show us how they did it.1 point

-

I have planning permission on a small plot in North Wales to build my own home. I will be moving on to the building regulation design shortly. I am hoping that I can get some help, I will need it! Cheers1 point

-

I had this issue - planners said my fence wasn't permitted (it's probably two meters back from the pavement/highway). They kicked up a fuss until I pointed out that I had planted a hornbeam hedge and therefore it isn't adjacent to the road. Eventually they backed down after I threatened to send them dozens of similar examples locally to investigate for enforcement.1 point

-

Phone the gas company and enquire if the property has been disconnected. I wouldn't touch that nut in your photo, looks more like a plug than a valve. Be aware than it can take a minute or more for any air to be purged from the pipes... But it does sound like you've no gas flow at all.1 point

-

We went for QuadCore KS1000RW Roof Panels thickness 137mm to give a u value 0.13W/m.K. https://www.kingspan.com/gb/en-gb/products/insulated-panel-systems/insulated-roof-panels/quadcore-ks1000rw-roof-panel This is our final finish - no plasterboard or additional insulation. We love it and it gives a nod to the industrial/agricultural steel barn that it used to be! Although the panels are not cheap it has saved us money on plastering! I will try and post a photo tomorrow so you can see!1 point

-

lots of people have a qualification, unfortunately that doesn't mean they are at the top of their game, nor even competent in that profession.1 point

-

@pocster The Quooker is definitely worth it. Stupid expensive, will never pay itself back but worth it. @joth I’ve only ever seen our Quooker draw 1kW after a cuppa however I’ve never looked to see what it’s drawing after filling a saucepan etc. Have they got 2 elements?1 point

-

We've using 150mm thick steel composite panels for our roof, hopefully finishing it this week. Then planned an additional 200mm layer of wool or cellulose underneath these/between the purlins. U value should be <0.10, but of course the devil is in the detail1 point

-

1 point

-

Hi. If you do not tackle ventilation heat loss, you can have a shedload of insulation and it will feel like you have 25% of what you installed. Fabric heat loss is relatively inconsequential, but ventilation heat loss is dire, so to build to a good standard, and then drill holes in the shell for extractor fans, and then fit trickle gents to every window would be barking mad IMO. With the house sealed and an MVHR installed, you can recover ambient heat, instead of pumping it out to the clouds, and reduce your space heating requirements. That then reduces the energy bills forever plus reduces ( scales down ) the heating system. All of these decisions have ‘knock-on’ effects, so you absolutely should approach this with a “fabric first” ethos, or it will be downhill all the way back to a swelling which slightly improved upon our fore UK BRegs. Get a plan as to how you will make the dwelling(s) airtight, eg as one airtight envelope, and reassess from there. If you cannot get under 1-2 ACH ( target 1 or less ) then MVHR is a waste of time anyways ( as natural infiltration will surpass the airflow rates of the MVHR ).1 point

-

1 point

-

Thermohouse do a roof system and I think Green Life Buildings do too. Not sure if these would work for you.1 point

-

We did something very similar to this. 200mm pavatherm EWI retrofit on existing 60s B&B cavity wall, and extension is 300mm blown cellulose TF with 80mm pavatherm EWI. Thermal bridge free all the way around Likewise the EWI is continuous up into the roof insulation1 point

-

If you are doing EWI on the old house you could build the extension as a solid wall ( block on flat for example) and use EWI on that also. This would make the cold bridge detailing a lot easier IMO. Then thin coat the whole lot.1 point

-

They're tongue and groove blocks laid on their side, probably just what they had to hand at the time! Assuming thats your party wall, id say that there will be no cavity between you and next door (on my street, 70's bungalows, some are like this and some are 2 blocks and a cavity in the middle, very bizarre the difference). Best thing you can do, aside from filling the gaps, and also putting a layer of soundcoat (https://www.british-gypsum.com/products/finishing-products/gyproc-soundcoat-plus), you could use a metal frame, pack it with acoustic insulation and then top with 15mm soundblock plasterboard, all depends how much space you can free up for it, if any. Take a look at my blog, i did a similar project in my living room, might give you some ideas.1 point

-

Hi. We've lived in our house for 20 years, but made minimal changes. It's a very non-standard, modernist house which had some very unsympathetic work done in the 1980's. We are hoping to be able to reverse much of that, and end up with something closer to what it was - replacing the PVC windows, stripping out the kitchen, and also making it much more themally efficient.1 point

-

Bought a 0.5 acre plot with an existing house 8 months ago. Will live in the house while we build on the plot and demolish once complete. House has water, waste and electricity connections. Want to build an energy efficient, accessible, modern (layout not exterior) family home. Selected Potton to work with and currently in the design phase. Targeting planning app by mid-June. ASHP/GSHP (not on gas network), MVHR and possibly solar PV+battery (EV arriving in Sept).1 point

-

1 point

-

Just installed a ground anchor. I bought only one as I was not sure they would work with our soil - it is littered with flint and other stones (when digging you are absolutely guaranteed to hit one with every entry of the shovel).On the 5th attempt, the ground anchor found a route through the stones and feels very firm (allegedly can handle 1.2 tons with the 900mm version I bought). I could fell it hitting stones, but I think it pushed them aside. Will now buy 3 more and the ratchet straps to tie the vans down. Will cost £250 in total but a small price to pay for peace of mind.1 point

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)