-

Posts

2799 -

Joined

-

Last visited

-

Days Won

5

joth last won the day on June 11

joth had the most liked content!

Personal Information

-

About Me

Completed UK's third "Enerphit plus" retrofit, during the pandemic

-

Location

Hertfordshire

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

joth's Achievements

Advanced Member (5/5)

941

Reputation

-

Further to what @jack lists as challenges, a variation is to do weathertight + airtight shell, so include windows and roof in the shell-builder's contract. This way you can specify airtightness and weathertightness requirements on that shell. Although they've lost some popularity, MBC Timber Frames offer this service. I'm sure others do too.

-

Just to expand on this, I had a trawl through the legislation and think you're fine (unusual disclaimer, IANAL etc): your options 1-3 are all allowable under the BUS. https://www.legislation.gov.uk/uksi/2022/565/regulation/9 my emphasis: (2) A heat pump meets the suitability criteria in relation to the eligible property F2... for which it is installed where— (a)it provides heating— (i)solely to that property, or to both that property and any related property, and (ii)for the purpose of both space heating and hot water heating, using liquid as a medium for delivering that heat, (b)it is capable of meeting the full space heating and hot water heating demands of that property, and The key thing here is whether the outbuildings (workshop, annex) can be defined as Related properties". So "The/That property" is just the main house, and the other buildings are related properties. AFAICT the main criteria for related properties is they are not covered by the main property's EPC https://www.legislation.gov.uk/uksi/2022/565/regulation/2 “related property”, in relation to an eligible property, F6... means any building or swimming pool which is used by, or available for the use of, an owner or occupier of that property and where the building, building unit or swimming pool is not covered by the valid energy performance certificate for that property;

-

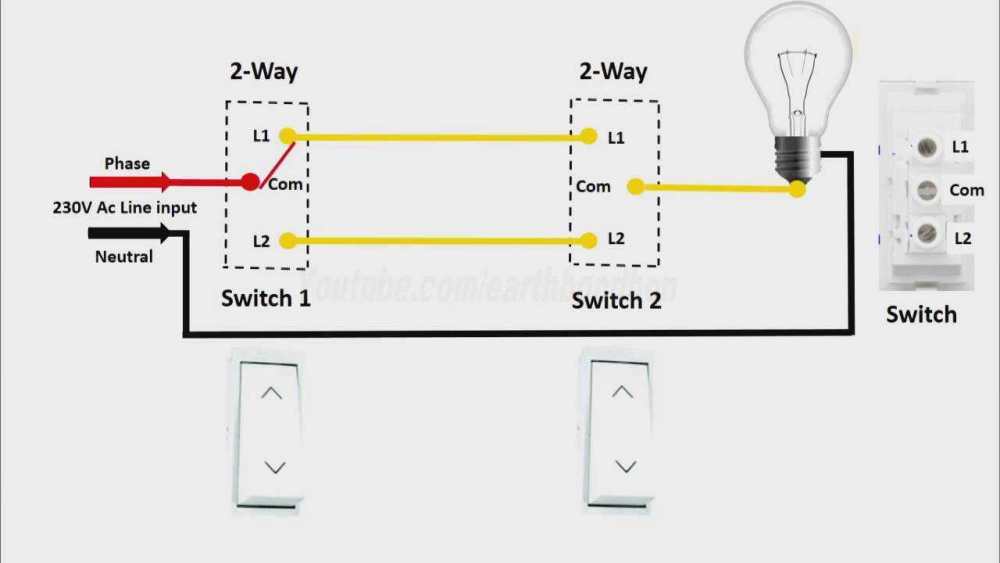

If you want proper 2-way switching without replacing the cable, wireless is probably the way to go https://www.tlc-direct.co.uk/Main_Index/Quinetic/index.html replace indoor switch with a "Quinetic Wireless Switch c/w Built In Receiver". Add one (or more) "Quinetic Kinetic Wireless Switches" wherever you need them.

-

The grant covers supply and install under a single contract for heatpump(s) sufficient to space heat and provide all dhw for "the entire property". I think the clearest out if you want a modular system is to discount the garage or workshop as being part of the property. (If they aren't built / converted yet then clearly at this point you'd be fine)

-

The difference is single vs double pole switch (SPST Vs DPST standard abbreviation). If the inside is a double pole it's probably an isolator switch: if the outside unit had a fault (water ingress) it might trip an rcbo by leaking neutral to earth if only live is disconnected, so for total disconnect both live and neutral are disconnected in an isolator switch. Normally adding a second switch you want a double *throw* switch (SPDT) and fully connect the two switched poles This means either switch can turn on/off the switch at any time regardless of position of the other switch. If you put a SPST inline (in series) as you describe it will act as a disconnector, so you can turn lights off from outdoors but then can't turn them back on from inside without going out and toggle the outdoor switch back to the on position again.

-

ASHP without Boiler Upgrade Scheme?

joth replied to timhowes's topic in Air Source Heat Pumps (ASHP)

Interesting my experience was very different, they refused to talk to me because I'm not a registered installer. -

ASHP without Boiler Upgrade Scheme?

joth replied to timhowes's topic in Air Source Heat Pumps (ASHP)

Not so much "want" as compelled to: Ecodan manufacturer instructions mandate the use of a low loss header and registered installers won't deviate from that for fear of violating the warranty Obviously "don't use Ecodan" is easy retort but I'm primarily answering why existing ecodan installs like nod's will have it. -

Carefully planted and maintained trees can block summer sun but still let in some winter light. That tech is beyond me though (and takes time). You could add brise soleil to the plans, gives you the approval to install them if you ever want to in the future Else +1 for external shutter blinds, it's what the rest of Europe uses surely only time before we wake up to using them more here.

-

Self installed Air Conditioner

joth replied to Annker's topic in Mechanical Ventilation with Heat Recovery (MVHR)

I got one of these https://www.appliancesdirect.co.uk/p/eiq-12wminv/electriq-eiq12wminv-wall-split-air-conditioner electriQ Easy-Fit 12000 As other say R290 so no FGAS engineer needed. (But clearly, needed someone more competent than myself 😂) It's in the garden room / gym so currently doing nothing as it's too hot to consider an indoor workout. But I might go sit in there later with a cold drink and set it on 100% -

Self installed Air Conditioner

joth replied to Annker's topic in Mechanical Ventilation with Heat Recovery (MVHR)

There's two types of self-install, the all in one with a large external duct (effectively the same as the "stick a pipe out an open window" portable AC unit), and the pre-charged minisplit with a length of refrigerant pipework you hook up between the indoor and outdoor unit. I went for the latter, but even though I used the soapy water leak test, I did a poor job tightening down the the compression fitting so the refrigerant leaked and I needed to get it professionally recharged. I couldn't find a local AC engineer that would touch R290 so I had to go via the distributor (appliances direct) and pay an arm and a leg for it. It would have been cheaper to have it professionally installed in first place I expect, but hey, learning opportunity! The monoblock hole in wall solution is much more idiot proof, but puts all the noisy gubbins indoors and obv needs a much larger hole core drilled. Whichever you choose the electrics is simple, plug into a 13A socket. The minisplit you do need to connect a flex from indoor to outdoor unit, but it's like two screw terminals - no harder than wiring a plug. -

A2A + A2W ASHP or a more powerful A2W ASHP?

joth replied to puntloos's topic in Air Source Heat Pumps (ASHP)

We had ufh downstairs only. If we needed heat upstairs the fcu could do it, but it's never been necessary (quite the opposite even in winter the master bedroom overheats. The guest room does dip to 18C when unused but warms up as soon as a body is sleeping in it) We're passivhaus retrofit and no issues with the grant. You need to tell your installer that room by room satisfaction is the mcs recommended method but it's not a requirement of BUS so long as whole building heat demand is met, using the passive house phpp Vs group floor emitter power would also satisfy this. -

A2A + A2W ASHP or a more powerful A2W ASHP?

joth replied to puntloos's topic in Air Source Heat Pumps (ASHP)

@puntloos went for option A I helped out with the Loxone programming for it, and I went for option B in my own install a few years before, so I can speak fairly well to the pros and cons. In my experience: Benefits of option A (separate a2a and a2w) - redundancy: still have heating (and cooling) even if one ASHP is out of action. - greater maximum output (if house gets way off target you can run both systems together to get back). (also can heat/cool while doing DHW cycle) - cooling is more effective. A split system using refrigerant can make 5deg C air, vs about 14degC with A2W (due to condensation). (of course, not everyone likes/wants such cold air blowing at them) - relatively easy to phone up an ASHP and an Aircon supplier to have the fix it Benefits of option B (a2w does everything): - lower capital cost (and potentially lower labour cost, esp if you're doing the FCUs yourself) and lower maintenance - slightly easier controls, possibly. In the sense only one setpoint per needed to control both systems, and no chance of heating and cooling fighting each other. - somewhat lower risk of creating uncomfortably low humidity house (as keeping cooling above dew point) - less room needed for outdoor units. (also slightly less planning permission hurdles, although these were recently relaxed somewhat) However finding a supplier to install option B satisfactorily (with FCUs) may be the deal breaker. -

Fancoil - Best invention ever no contest!

joth replied to Dave Jones's topic in Air Source Heat Pumps (ASHP)

One thing to note is sizing depends on the air source going into the FCU. My 2 FCUs are in the loft, so pulling fairly warm air in summer (and cold in winter, if I ever used them for heating. I don't). So my FCU have higher realized output power than if the air coming into it was already "pretty cold". (Output power is determined by the delta between air inlet temp and the water temp, and air flow rate). If you have the FCU in the room being cooled, and down at floor height (where air is naturally cooler anyway) it will not have as much effective output than if you are drawing in hotter air from higher up. Hence why split aircon units are normally installed up high. (but rads installed down low) -

Fancoil - Best invention ever no contest!

joth replied to Dave Jones's topic in Air Source Heat Pumps (ASHP)

Yes I originally ran my FCU at those sorts of temps, while all the pipework is well insulated the snag is all the valves, pumps, mag filter, flow sensor etc etc. There's a lot of extra "gubbins" inline in an ASHP install (at least, there is in mine) and it's really onerous so lag all those components, not to mention makes maintenance of them harder. And even when I tried I found condensation was forming due to tiny gaps and then e.g. the pump gate vales starting to corrode over. So on balance I now just run mine at dew point. (some stuff still gets a little glistening with beads of sweat but no river of condensate running everywhere) This point was easily avoided in my installs: ecodan has two zones with independent setpoints, using an electronic mixing valve, so with the loxone load/weather curve the UFH generally ticks over at 18C flow temp while the FCU at around 12C (due to GF not needing as much cooling as upstairs) -

My answer is very similar to @Dan F I'd already decided on Loxone, was originally desiging the lighting myself but my electrician thought I wasn't putting enough fittings in (from the usual one spot per 1.5m2 grid of approach lights school of thought) so I got a designer to review and then improve the design. The main benefit there is she modelled the lighting to determine if it was sufficient, the alternative would be over provision and dim. Also having loxone I wanted layers of lighting in main spaces, either for reflected atmospheric lighting or direct working lighting, and the designer helped a lot in details to make that work well - e.g. placement for fittings to give and optimal shaped "scallop" of light projected on walls, and suggesting details like small markers inside window reveals. She also had discounts on a few manufacture products she passed through, which against MRP probably paid the fees on its own. I'm really happy we went professional designer route, but it isn't for everybody