-

Posts

27638 -

Joined

-

Last visited

-

Days Won

224

Nickfromwales last won the day on July 10

Nickfromwales had the most liked content!

Personal Information

-

About Me

http://forum.buildhub.org.uk/ipb/index.php?/topic/38-hello-from-the-resident-welsh-plumber/

-

Location

South Wales.

Recent Profile Visitors

Nickfromwales's Achievements

Advanced Member (5/5)

5.6k

Reputation

-

Wet plaster or dot and dab for my self build?

Nickfromwales replied to Berkshire_selfbuild's topic in Plastering & Rendering

I always suggest to (tell) my customers to sit down with the builder, before they do anything, and set out your station. The builder will otherwise decide, if you appear to be a walk-over on day 1. They will assume fast=good; you can say "reasonable pace with a better eye of the quality and finish may cost another 5-10%, but I ACCEPT". Tell them that you're going to ask to have a framing level placed on the walls after they've been laid on, so they know that shite won't fly. Assume they'll do a good job, and you'll quickly find why folk say "assumption is the mother of all feck ups". Speak to the builders, they're human at the end of the day . Let the builder know that you're approachable, eg if more work needs doing to deliver a better end result. Employing a general builder, because their quote was the favoured one, isn't any means of a measure or guarantee as to what will be delivered, this needs to be managed (expectations from both sides) by you; if you wish to stand any chance of getting what you expect (want), then say this at the outset, not complain afterwards if you didn't ask what the quality / workmanship would be like. FYI, cement and skim are finishers not fillers, so a wall that's seriously out of plumb should probably have been dot & dabbed vs scratched and skimmed. -

Installing a woodburner in a SIPS house with MVHR

Nickfromwales replied to pedragon's topic in Stoves, Fires & Fireplaces

Use it well, for we are the chosen messengers. -

@GNB88, We could be neighbours, if England wasn't in the bloody way...... Welcome aboard.

-

Cylinder suitable for future ASHP

Nickfromwales replied to KOS's topic in Air Source Heat Pumps (ASHP)

Most modern UVC's have very low standing losses, and we are advocates here of a bit of oversizing so the stored temp can be around 50-550C, further reducing losses. Good advice if it's a thermal store for DHW though. -

MVHR and cooling

Nickfromwales replied to flanagaj's topic in Mechanical Ventilation with Heat Recovery (MVHR)

One that has a whacking great duct that has to go to atmosphere? 180mm on the one in my sons attic room, but it's so cold up there atm that you could keep meat; whilst the rest of us squelch about in the ridiculous heatwave..... No wonder my other kids go and kip up there when the sun finally shows its face. -

Installing a woodburner in a SIPS house with MVHR

Nickfromwales replied to pedragon's topic in Stoves, Fires & Fireplaces

If the house is open plan and 400m2 or above, I will retract 50% of that -

Installing a woodburner in a SIPS house with MVHR

Nickfromwales replied to pedragon's topic in Stoves, Fires & Fireplaces

Oh, lordy! Where have you been getting advice from? So..... IF your MVHR fan stopped spinning, there would still be a near-uninterrupted path for airflow through the MVHR system so that would allow the 'draw'. The MVHR doesn't close any valves or flaps, it's just a fan or pair of fans that are spinning or not. "Open a window or two for airflow"?, "No". A HETAS design would require an uninterruptable supply of airflow, not simply rely on you deciding to monitor this by opening things or closing them, that would never pass any regs. What you would need is as above, a direct to air WBS that isn't reliant on the room not being sealed. In a leaky house, one that's not airtight, and not the house you are making? This caveat allows for a consideration that adventitious air for combustion would find its way into the room through all the gaps, nooks, and crannies (natural infiltration); if you have MVHR, then the house won't have any.....so can't be applied here. Next, simply DO NOT DO THIS!! If you have an airtight house with MVHR then the heat output would be way above what the room it is in could ever dissipate, you'll just roast the room and have to leave it. A WBS has a place in a draughty bag-o-shit house, but not in any modern build with great insulation, airtightness, and MVHR (with subsequent minimal heat input requirement). This will become an expensive ornament. -

Porcelain patio grout staining

Nickfromwales replied to Hels13's topic in Landscaping, Decking & Patios

Yup. You can use a grout film remover, or patio cleaning 'acid' and scrub it with a stiff broom. Porcelain shouldn't need much in the way of sealing, but the installer should have cleaned this all up properly instead of leaving it to cure in sunlight. His problem, not yours btw, so tell him to get scrubbing! -

MVHR and cooling

Nickfromwales replied to flanagaj's topic in Mechanical Ventilation with Heat Recovery (MVHR)

The radial stuff comes pre-insulated if you want, so no other issue than the slight uplift in cost. -

MVHR and cooling

Nickfromwales replied to flanagaj's topic in Mechanical Ventilation with Heat Recovery (MVHR)

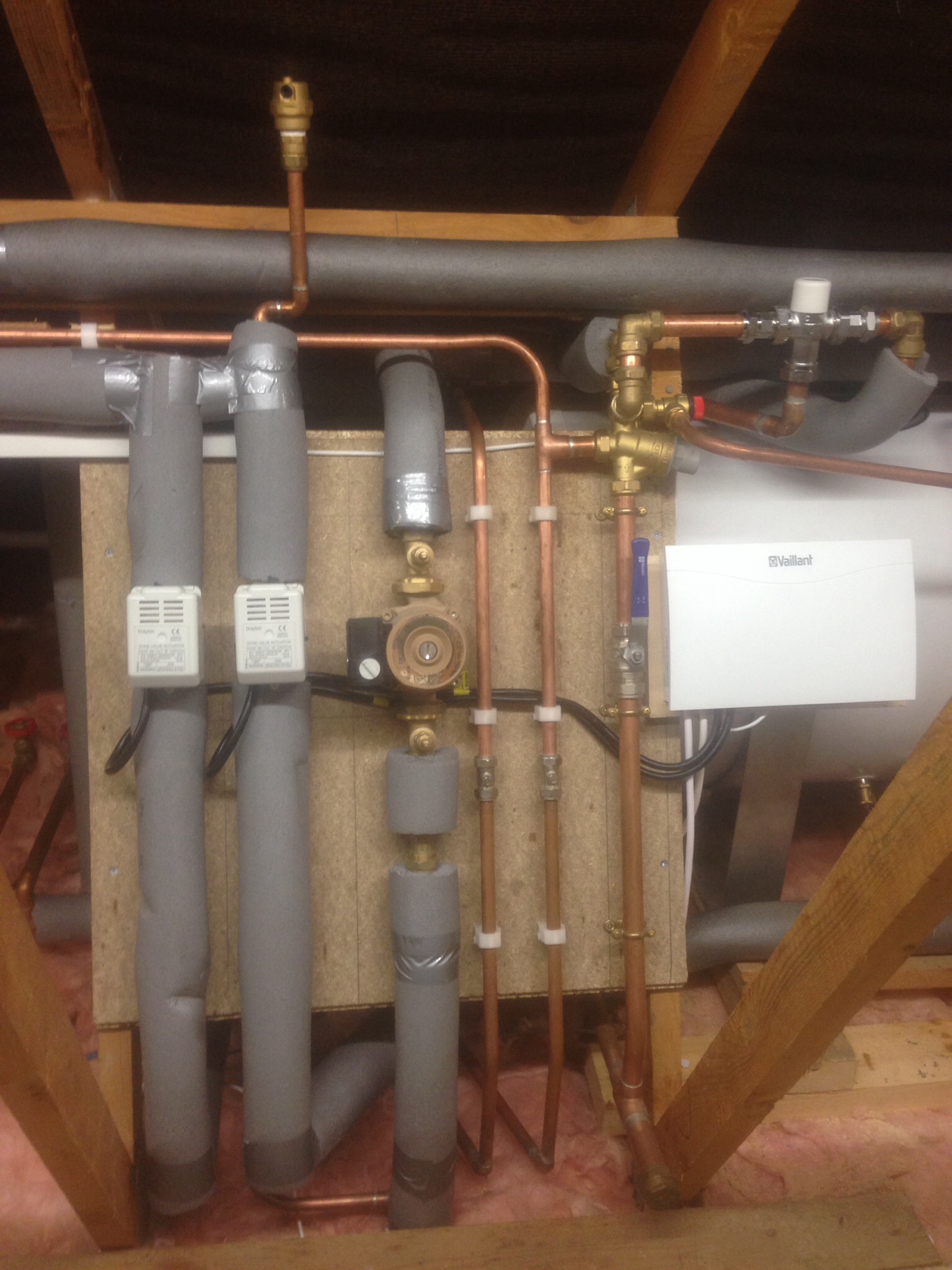

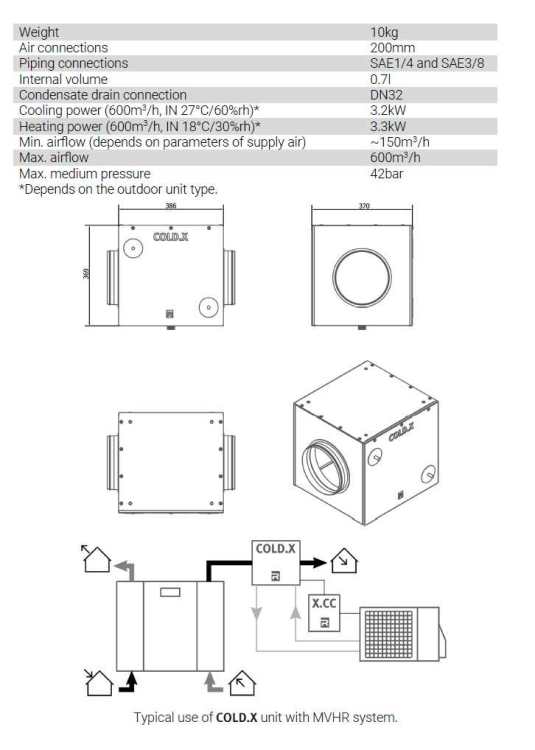

Yup, kinda. Refrigerant gas duct cooler, with external HP, which can heat and cool. If you want cool, it's gotta come from somewhere, so I am more intensively exploring options for these situations atm. There is also the Brink Air Comfort (AHU) but if you don't have a heat pump you're options are very much limited, hence what I showed you in that image. FWIW, I think if you want all electric space heating and cooling, with MVHR, then you'd be far better off going multiple A2A AC throughout. Space heating via electric radiators is pretty poor tbh, unless it's a PH+ spec build, and I think you'll come to regret that imho. I assume there won't be UFH then, so nowhere to implement slab cooling? This is the better option and far less aggressive means of heating and cooling, and imo the most economical operating costs/least impact the occupants. -

MVHR and cooling

Nickfromwales replied to flanagaj's topic in Mechanical Ventilation with Heat Recovery (MVHR)

-

Wet plaster or dot and dab for my self build?

Nickfromwales replied to Berkshire_selfbuild's topic in Plastering & Rendering

Which makes us both wonder why we got out of bed eh?? 😑 -

Hi James. I have been buying systems, and having support for (design and) installation of them, via CVC Systems Ltd (now also Air-Haus) for many years. There isn't a single instance where these guys have let me, or a client of mine down, which is a bloody rare quality. I can put you in touch with other BH members who will testify to this, via PM. I keep using them because of the great feedback, after-sales service, and robust design and support service that I have been given to date. May sound like sales-patter, but it's just based on facts

-

Wet plaster or dot and dab for my self build?

Nickfromwales replied to Berkshire_selfbuild's topic in Plastering & Rendering

I think a lot more people will start using AeroBarrier, and ditch the taping around windows and doors etc. One I’m working on atm is block walls, so I’ve recommended a bit of parge at the top 200mm of the wall, and leave to dry. Then some Passive Purple liquid airtight membrane over that. Then the AT membrane comes down the roof, drop vertically on to the wall for about 100mm, then tape goes from membrane to PP. Then all M&E 1st fix, then get AeroBarrier in. Happy days.