-

Posts

10085 -

Joined

-

Last visited

-

Days Won

123

JohnMo last won the day on June 30

JohnMo had the most liked content!

About JohnMo

Personal Information

-

Location

NE Scotland

Recent Profile Visitors

28585 profile views

JohnMo's Achievements

Advanced Member (5/5)

3.2k

Reputation

-

That's a good suggestion - a pergola doesn't have to cost much. I just built one with 2x PV panels. So solar shade and generation in one assembly. Vertical just do 3x 500W panels to a 1kW inverter. Or as you say horizontal or any angle in between. It's also useful to have PV generation in winter, vertical will give twice the output in Dec/Jan. A 200m² new build to a half decent build spec, should only need a 4kW heat pump. CoP of 5 to 6 doing cooling, will generally be pulling less than 500W (modulated down). If the sun's out and you need cooling, PV is generating. Our two horizontal 500W panels in full sun the other day were generating between 800 and 900W, which is enough to run our 6kW heat pump.

-

Mine was a zero cost option, replace blinds with curtains if you want. Choose the right ASHP it will come with cooling out the box. Mine switches from heat to cool via a repurposed light switch. So £2 if you don't have one kicking about. Runs WC for cooling and heating so you don't even need a thermostat. PV - buy 2 to 4 500W panels, £68 each, string inverter £250 to £300, DC and AC isolation switch £100 for both. £100 for cable, MC4 plugs and sundry bits. Then you need mounts depending on where you locate. Panels make great fence panels, roof for pergola etc.

-

So do you use only AC for heating and cooling? How do you do hot water?

-

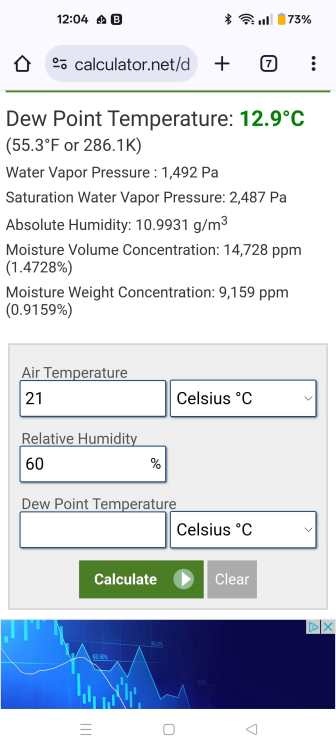

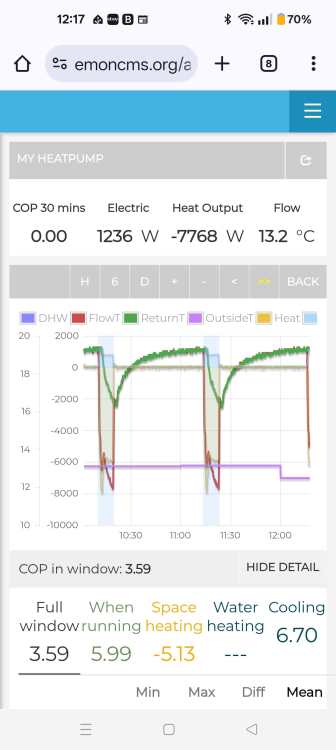

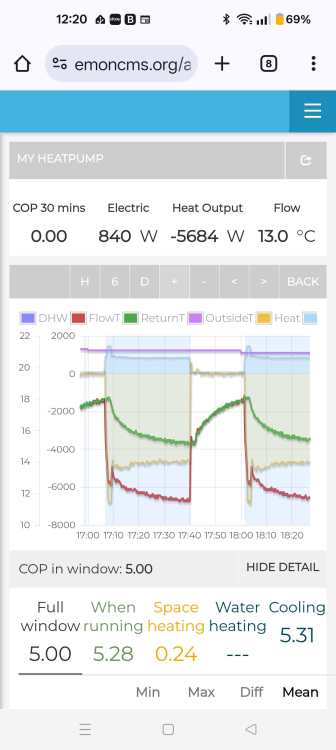

The way to operate is to run with a single flow temp for both fan coil and UFH. It means the fan coils are bigger for a given output in kW. But running everything above dew point, means no condensation, so no drains required. A quick look at an online dew point calculation, house kept at 21, RH 60%, dew point is 12.9. I set my target flow temperature at around that. I get no condensation on the UFH manifold. Floor surface temperature is around 19 to 20 depending on floor covering. So a mile away from condensation. The heat pump cycles based on return temp of around 19 degs. This is in the morning no solar gain So short 10 min runs then off for an hour or so. This it when we get solar gain Much longer runs. When we get to heights of summer, the heat pump runs several hours at a time. Our house internal temp almost all driven by solar gains, without internal blinds and UFH cooling our lounge l easily gets to 27 degs. Now it may go up to 24, but it recovers back sensibly levels quickly. But with a floor that is cooler than the air, it always feels cooler than it says on the a temperature gauge. Think old stone church always feels cool even when it's baking hot.

-

We have a long thin house, so way different from factor yourself, it didn't change our test result much when converted to ACH.

-

Your answer is pretty much 1.4 ACH

-

Are you sure, I think it's (1.4 x 479) / volume. So if house is 200m² and ceiling are 2.4m high is 200 X 2.4 = 4800. (1.4 x 479) / (2.4 x 200) = 1.4 ACH

-

Without knowing your house volume he cannot know that!

-

External blinds are best, internal blinds ok. UFH run in cooling mode. Fan coils.

-

The 4G ones apparently have just been issued, in the last week or so. Believe a few have been installed around us - near Elgin. Octopus are still playing about, insisting they attempt the smart meter install 3x, before moving to getting a SIM card meter.

- 12 replies

-

- 1

-

-

- utilities

- electric bill

-

(and 3 more)

Tagged with:

-

I doubt they would really know, they would have no idea if I did 5 miles a day or 500 miles.

- 12 replies

-

- utilities

- electric bill

-

(and 3 more)

Tagged with:

-

Ufh manifold, blending valve with ASHP.

JohnMo replied to Russell griffiths's topic in Underfloor Heating

Have you bought these heat pumps? -

1.4 is m³/h·m² . You know the m² figure You need to work out the house volume in m³. Now you have house m² and house m³. Multiple 1.4 by your m² area. You now have the air loss per hour atv 50Pa. Divide your answer by your volume. That should be your ACH at 50Pa

-

Ufh manifold, blending valve with ASHP.

JohnMo replied to Russell griffiths's topic in Underfloor Heating

What are you heating? That 26kW isn't enough? -

Self installed Air Conditioner

JohnMo replied to Annker's topic in Mechanical Ventilation with Heat Recovery (MVHR)

You need to find the R290 versions, these can be self installed, anything else is covered by F-gas rules and CANNOT be self installed. R290 is not a F-gas. Such as https://www.appliancesdirect.co.uk/p/eiq-9wminv/electriq-eiq9wminv-air-conditioner?refsource=apadwords&utm_source=google&utm_medium=cpc&utm_id=22547259545&cq_src=google_ads&cq_cmp=22547259545&cq_con=&cq_term=&cq_med=pla&cq_plac=&cq_net=x&cq_pos=&cq_plt=gp&gad_source=1&gad_campaignid=22550830981&gbraid=0AAAAAD9z1-3QTKHge6o0Ghos-COyYa2ow&gclid=Cj0KCQjwjo7DBhCrARIsACWauSlh7hYyhbBpFfYGkXsuY0rfa8ZEzg2dcAcbQv2hdl2iRtp-u5p6tyUaAo-qEALw_wcB