Russdl

Members-

Posts

1601 -

Joined

-

Last visited

-

Days Won

6

Russdl's Achievements

Advanced Member (5/5)

594

Reputation

-

@mjc55 I used foam glass for our detached garage slab, which may be relatable to your pod. Basic details here:

-

We should have installed air conditioning… now what?

Russdl replied to Adsibob's topic in Other Heating Systems

Alternatively, find the nearest location to you on the Weather Underground map https://www.wunderground.com/dashboard/pws/ILONDO538 and that will be a personal weather station near you, probably in someone’s back garden, and that should give you a better idea of the local air temperature. if the temperature defaults to F you can change it to C, settings are accessed via the three bars, top right corner. -

We should have installed air conditioning… now what?

Russdl replied to Adsibob's topic in Other Heating Systems

Preventing the heat getting in is a great plan, but don’t open up to ventilate until the outside temperature is below the required indoor temperature. If it’s pushing 30 degrees outside after when you open up to ventilate it will soon enough be pushing 30 degrees inside and your shading would have been for nought. -

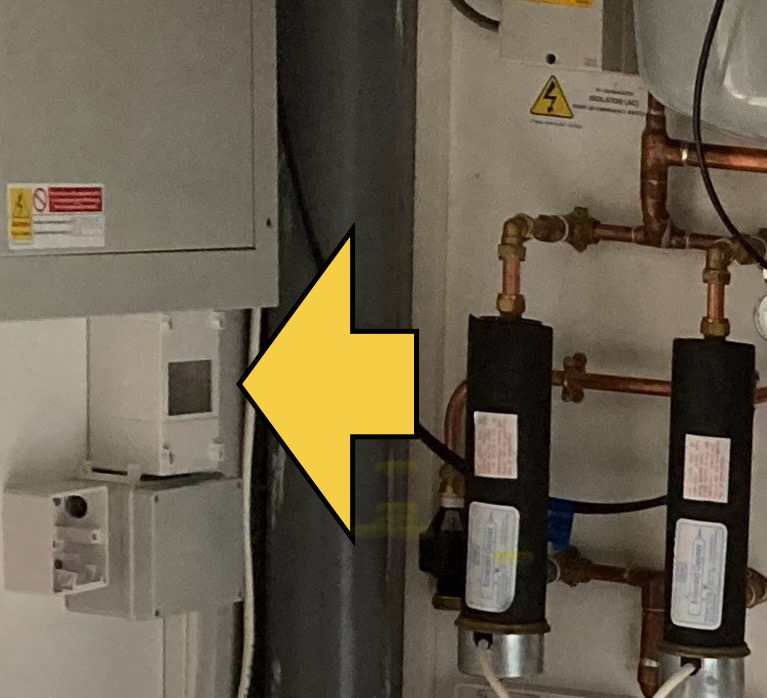

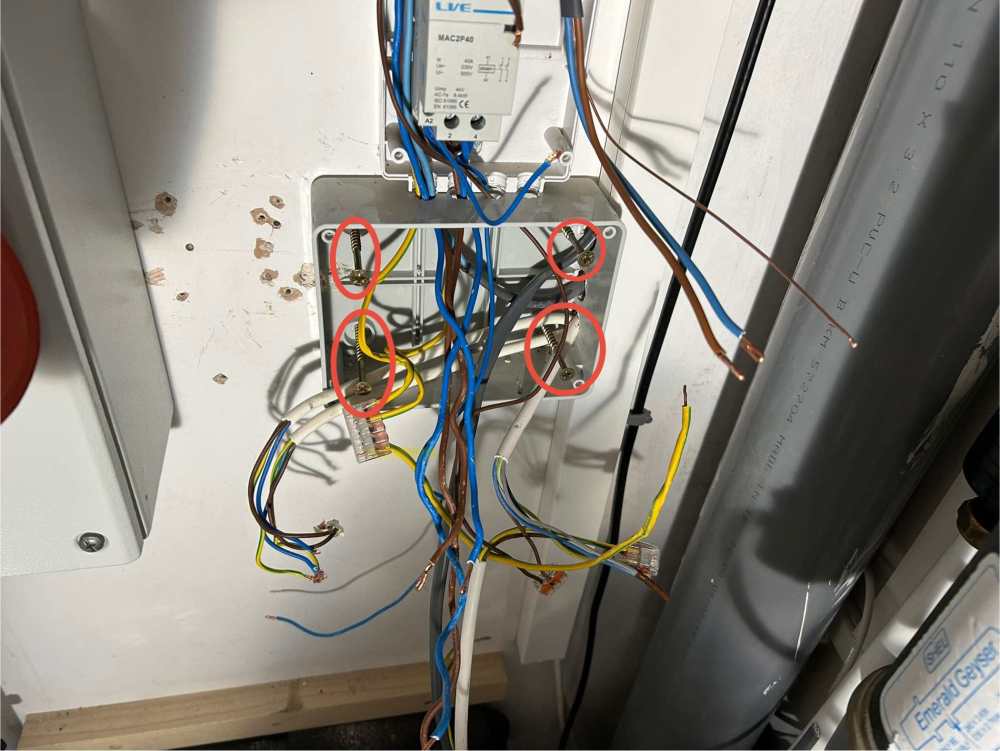

Crikey, that was a long story and similar to ours in some respects but so wildly different in others it must be a completely different situation. For example, I got on very well with all visiting trades - except for one who was described to me as a high functioning sociopath (I had to google that, but it is absolutely spot on). The distribution board in the photo looks just like ours except for down in the bottom right hand side. In those images ⬆️ there are 2 MCBO’s not connected to anything. In our distribution board those 2 MCBO’s are the power for the two Willis Heaters ⬇️ work that was completed on the 28th Nov 2020. Another major difference is you say you’re owed £1100. We are owed £4787 in an unpaid CCJ so clearly a completely different situation. The Last time I looked there were 3 unpaid CCJ’s against the individuals Limited company totalling £26,887, I can post images if you’d like? That may have changed by now but I can’t be bothered to spend another £8 to check, it may be a worthwhile investment for others?

-

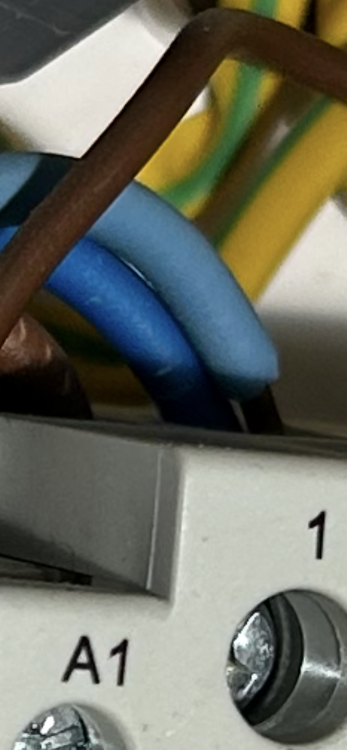

The original electrian sourced by the M&E contractor was a top notch professional I would say. When the original electrician became unavailable the seemingly less professional replacement was parachuted in. On the face of it you wouldn’t know the difference, under the covers the difference is more obvious. Thanks to the wonders of modern technology (phone cameras, text messages, emails, site diary etc) I know exactly when this wiring was done and who did it. Just looking at the wiring in the distribution board you can tell this wiring was done by a different electrician. The original electrician’s wiring was incredibly neat and ordered, the replacement electrician’s work not so much. Perhaps he wasn’t fully qualified? It never crossed my mind to ask.

-

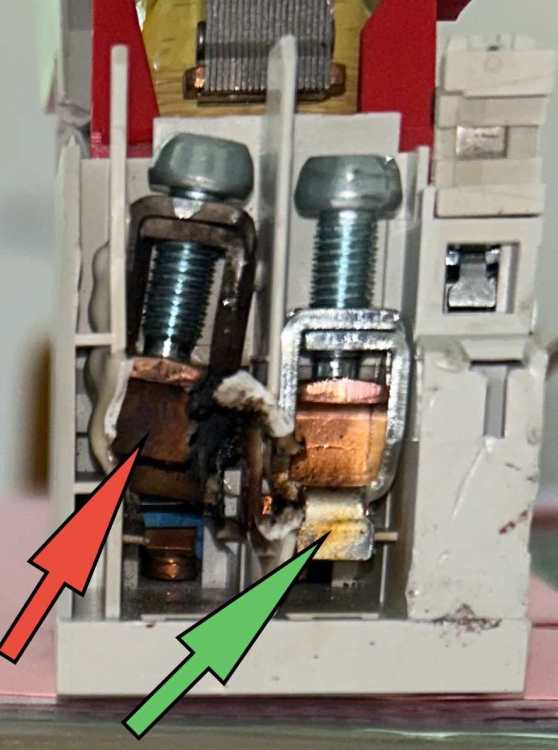

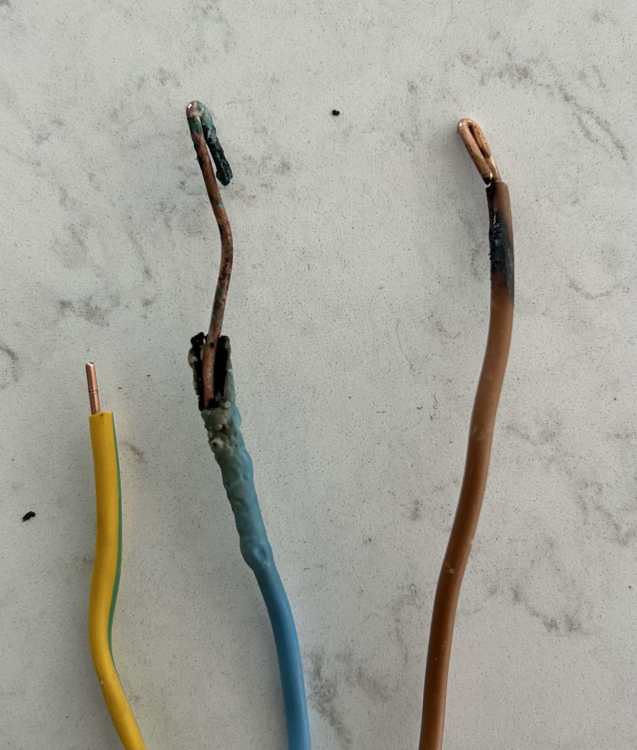

I’ve just pulled the damaged contactor apart, the burnt terminal is done up as tight as a tight thing - there is no way there was ever a cable clamped in there. It must have just been wedged along side or something? The red arrow is pointing at the heat damaged terminal (obviously!!) in the fully closed position, the green arrow at a fully open terminal (with only minor heat damaged). I can’t believe this, I can’t get my head around how a professional electrican could leave wiring in such a dangerous condition.

-

Well it’s all back together and working, nothing has gone bang and nothing (apart from the Willis heaters!) is getting hot. I think I’ll chalk that up as a good result. ~~~ I’ll keep hold of these two in case the installer or his boss wants them.

-

You’ve got to start with external shading, prevention being better than cure and all that. East/west windows could be equally problematic. I’m sure you’ll be building with high levels of insulation and air tightness, in which case I would have thought that without shading/cooling the recent brief heatwave would have been unbearable. We have no cooling per se but we do have external blinds, the last few hot days have been a non event as far as internal temperature/comfort goes but that does require a very much non automated heat purging strategy of an evening (opening doors/windows, ramping up the MVHR etc).

-

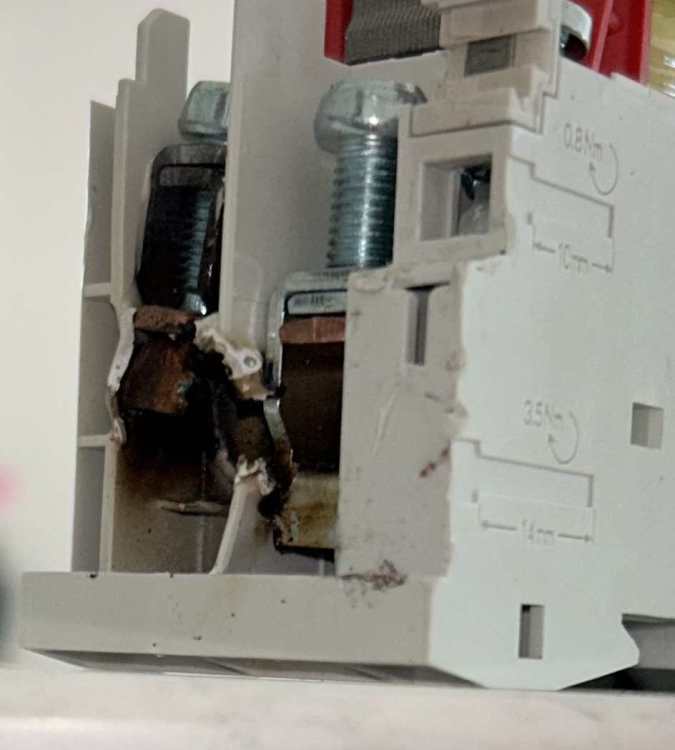

I’ve got the new contactor now but before I start putting it all back together again is it ok that the top of the contactor junction box (for want of a better name) has been cut out? I was under the impression this shouldn’t happen. This open end is mounted snug to the distribution board, so it’s not open to the elements/fingers etc.

-

No, I’ve replaced the obviously burn T&E and that ends up at the right hand Willis heater that wasn’t working.

-

Likewise, I’m confused. Something I hadn’t spotted before, in the first picture I posted on this thread ⬆️ where I was concerned with the overheating on the right hand contactor you can clearly see the light blue neutral into the left hand contactor is definitely not properly inserted. I can’t understand how the Willis heater was working and, as you say, why that left hand neutral wasn’t all burnt and crispy like the right hand neutral?

-

I’m amazed and confused. I’ve just removed the good contactor and was stunned to find the neutral for the Willis heater did not appear to be connected at all, and this is the one we normally use. I thought I may have dislodged it but looking back at a photo from a week or so ago, despite the shadow I think it’s fairly clear to see that the neutral is not properly inserted into the terminal. How on earth did this Willis heater work? I guess the neutral must have been just inside the terminal and just tight enough to stop overheating but not tight enough to stop it coming out completely when I removed the contactor?

-

I thought I’d try and tidy up the numerous cables in and around the contactor whilst I await the arrival of the replacement. It looks like the electrician used a machine gun to attach a couple of back boxes to the plasterboard during the original installation and then used some bloody great big screws to attach the junction box. At 70mm those screws are just the right length to go straight into the airtight layer. Nice. None of the above is the end of the world but on top of the poor/dangerous contactor installation it is mildly annoying. Anyway, all the heat damaged T&E is now replaced so I’m pleased about that.

-

Thanks for that detail Dave, mildly alarming though it is. I’ll definitely be in the market for an electronic nose to sniff out any future problems. As nothing trips out, what would have made the connection fail in the end? Is it just a build up of crud on the neutral wire?

-

That contactor did get really hot. How come nothing tripped off? Is that indicative of other problems? T&E from the contactor to the Willis heater switch easily removed. ~~~ The terminal screw is at such a jaunty angle I can’t even get a screwdriver on it. The electrician must have been aware what was happening. Surely?