Leaderboard

Popular Content

Showing content with the highest reputation on 10/25/21 in all areas

-

Sounds like a blocked condensate trap / discharge pipe etc. The "smoke" will be "plume", eg the steam created when excess levels of moisture meet the hottest parts of the heat exchanger. The condensate water is acidic, so is chewing through the steel case of the boiler as we type. Google the manufacturers installation guide and in there it will tell you how the service the condensate trap. DO NOT run the boiler with the trap off, as that being removed opens a clear path to the burner chamber and there is a possibility that products of combustion may escape. I'm not entertaining the covid jibber-jabber, but you need a plumber in ASAP to repair this, or one or two a little later to replace the rotten out boiler with a new one. Time to stop bathing with a thermos flask and get some degree of reality and a pragmatic solution to resolve this now.3 points

-

The COVID risk of getting a qualified plumber to fix this is minimal. Most of the risk would come from talking to someone not wearing a mask in a confined space. Open windows and leave him on his own to fix it if you are worried. Messing around with a boiler whilst unqualified is a lot more dangerous than COVID.2 points

-

Firstly make sure everything on site belongs to you. if the builder has been supplying materials then the supplier may retain the right to removal if not paid for. if you know who the suppliers are, it could be worth contacting them, … then again you could be opening a can of worms and end up paying twice! if the builder had any morals they would be speaking to you and working with you, sadly many companies going bust simply run with whatever money they can grab leaving you to pick up the pieces.2 points

-

One of those appliance trollies would work. I moved several lengths of kitchen worktop with mine. You can get a half decent one in B&Q for £41. Handy to have if you even need to move a washing machine or fridge etc. Do you have doorways to go through? You might have to shuffle through. https://www.diy.com/departments/mac-allister-hand-truck-250kg-capacity/1357679_BQ.prd Tho, you'll still have a challenge lifting it in place. Suggest you find an extra pair of hands for that bit.2 points

-

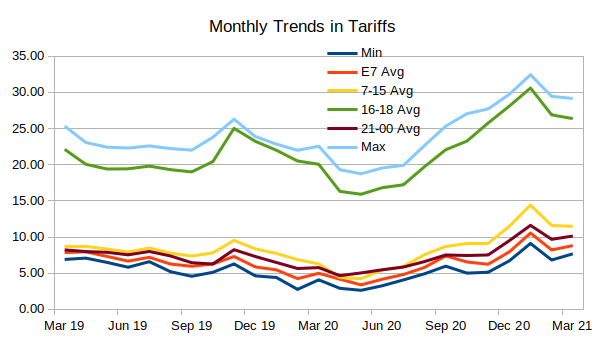

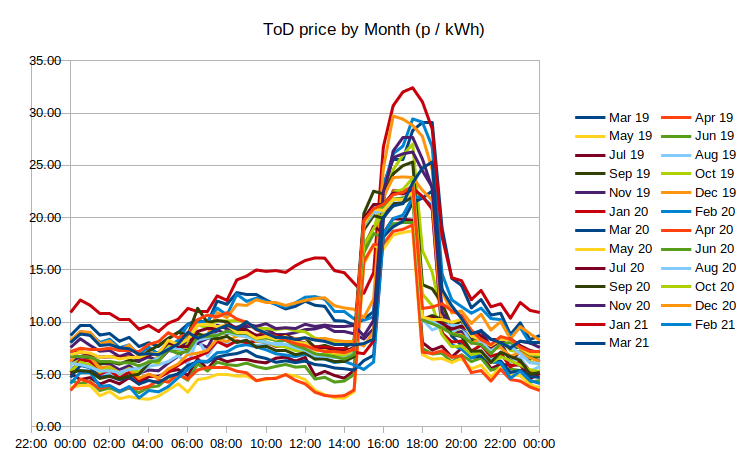

Not sure where to put this, but I thought that this might be useful for other members considering switching to a ToU tariff. I've been considering moving my Home system to use a ToU tariff and Octopus seems to be the only supplier offering one ATM. My main concern was that they have a spreadsheet for historic pricing for 2019, but no hard data on current pricing on their website. You can't get access to their forum until you have an account, which is a bit of a problem if you want the data to make an informed switch. Luckily they do offer and document a REST API where you can query the ToU tariff data. I used this to pull the data for the last 2 years, and aggregated this for time-of-day by Month. I've attached the quick and dirty scripts (minimum effort to write) that I used for this as a starting point if anyone is interested in doing this themselves. I used httpie and rs (because Octopus did and I couldn't be bothered to recode these; you can just sudo apt-get these utilities on most linux distros.) I've also added the main summary graphs below. My main conclusions are as follows: Electricity prices are rather high at the moment (winter; an increased demand due to Covid home working; and possibly a Brexit hike), and in my case I have a 24 month fixed E7 tariff from OVO which isolates me from this hike, and so the rates will need to fall somewhat for it to be worthwhile for me to switch. However the ToU tariff is cheaper in comparison to current single rate and E7 "flexible" tariffs, so long as you can stick to some basic rules: Use the Midnight - 6AM window as much as possible for high-load stuff. Avoid the 15:30 - 18:30 peak demand pricing where practical and move as much daytime use out of this window. About the only use we have in this window is for "always on" devices and cooking and this is rarely more than 1 kWh during this window. The price can fall considerably on an infrequent basis (11:00 - 14:30 on sunny days in the summer; anytime the wind is blowing). If you have a Home automation system and use the daily price forecast API, then you can reduce your electricity overall costs further. Analysing our past usage E7 saves us about £15 / week in the winter months and a ToU tarrif would increase this saving to £20-25. Be aware that you need a converted SMETS1 or a SMETS2 meter fitted to allow your smart meter to be switchable between suppliers. In our case, we have SMETS1 meter that is due to be converted in by July. (This OVO form post gives the back story.) Hope this is useful. These are all calendar monthly aggregates by 30-min pricing slot. Min and Max are the usual definition; the remainder are averages over different time windows. Get-tariffs #! /bin/bash BASE_URL="https://api.octopus.energy" PRODUCT_CODE="AGILE-18-02-21" TARIFF_CODE="E-1R-${PRODUCT_CODE}-C" TARIFF_URL="$BASE_URL/v1/products/$PRODUCT_CODE/electricity-tariffs/$TARIFF_CODE/standard-unit-rates/" W=~/Desktop/agile for ((i=0; i<$2; i = i+1)) ; do START=$(date -d "$1-01 $i months" +%Y-%m-%d) END=$(date -d "$START 1 months" +%Y-%m-%d) MON=$(date -d $START +%y-%m) echo Processing $MON http $TARIFF_URL period_from=="${START}T00:00Z" period_to=="${END}T00:00Z" page_size==1490 | \ jq -r '.results[] | [(.valid_from|capture("^........(?<m>..)T(?<t>..:..)")|"\(.m) \(.t)"), (.value_exc_vat|tostring)] | join (" ")' | \ sort > $W/agile-tariff-$MON.lst done Aggregate Tariffs #! /bin/bash W=~/Desktop/agile for ((i=0; i<$2; i = i+1)) ; do m=$(date -d "$1-01 $i months" +%y-%m) perl -ne ' my ($h,$m,$v) = /.. (..):(..) (.*)/; my $i = 2*$h+$m/30; $tot[$i] +=$v; $cnt[$i]++; END {foreach (0..47) {printf("%.2f,",$tot[$_]/$cnt[$_]);}; print "\n";}' \ $W/agile-tariff-$m.lst done1 point

-

1 point

-

My PV will generate up to 3.6kW My immersion heater on full consumes 2.8kW If the PV is running full chat on a sunny day, and nothing else in the house happens to be on, 800W could get "wasted" to the grid. I have one of these convector heaters set on it's 700W setting, and connected to a wireless controlled switched socket. If my home made (Arduino) PV diverter gets close to 90% immersion heater power, it turns on the radio controlled relay to send an additional 700W to the dump heater. It is of most use in the spring when we can have some sunny weather and it is still cool enough for a little extra heat in the house to be useful. In the summer it gets unplugged and we just have to let some go to waste.1 point

-

Re plug in heater. NEVER leave a fan heater running unattended. If the fan seizes and the over heat trip fails to trip, the plastic just melts as the element overheats without the airflow. Far safer are the cheap metal cased convector heaters with thermostats and variable power settings available in a variety of names for about £20 each. We have 3 that were used in the static caravan and one is still in use as an excess PV dump load.1 point

-

I know but, oil filled are a bit safer in a dusty, remodelling environment. I keep one on all the time ticking over on low in our joinery workshop to help keep rust off the machines/ prevent glues and adhesives getting cold etc so1 point

-

@saveasteading - 140x38 stud. Lintels are 225x50 x3. OSB on the inside to give me a good working surface to VCL, service void/batten out. Gutex board is currently fixed in place with 2 or 3 thermally broken screws Ejotherm STRH, these aren't structural. On top of this will go the breather membrane tapped for windtightness. This is all held back to the timber frame with 38x50 treated battens using Heco screws (Heco provide a fixing design but they were ££££). Cladding on top. ?1 point

-

1 point

-

Either it needs underpinning or it doesn't. Partial underpinning is an interesting idea, as you are undermining the building then trying to wedge it up tight again. It is rather a primitive process, and I always thought would cause a mm or 2 of drop. For the whole building evenly that wouldn't matter, esp as it is usually because the building has already moved. Not knowing the reason for the precaution, I wonder if there is another means of spreading the load away from the corner he is concerned about.1 point

-

Yes. While I don't buy into the "GCSE are easier than 'O' Levels" because they assess different things, combining subjects is not always successful. If we are to do that, we may as well just teach English and Mathematics. Then hand out all the other subject books at age 14 and let the kids decide what they would like to learn.1 point

-

The other thing to search for is "generation meters" sold for solar PV, same thing, different name.1 point

-

1 point

-

EBay is your friend for change of £25 https://www.ebay.co.uk/itm/Emlite-Landlord-Electricity-supply-Meter-MID-approved-100A-Short-Cover-/264926521552?mkcid=16&mkevt=1&_trksid=p2349624.m46890.l49286&mkrid=710-127635-2958-01 point

-

1 point

-

1 point

-

1 point

-

The DNO only allow their fuse to protect meter tails up to 3 metres long. If either your garage or house CU is more than 3 metres from the supply head it needs it's own fuse. Very unlikely your garage CU will be no more than 3 metres away.1 point

-

Put a sign up on the canal bank "Free tea and coffee in return for 5 minutes help"1 point

-

Get @pocster to give a hand. He now knows the value of getting others to help. Would have saved him hiring a crane and 3 strong men. Some say that he like to watch the greased male form.1 point

-

1 point

-

@Al1son 4 years is the short answer at which point the development is immune from enforcement action. The onus is really on you to evidence that the development has been there for that period, because the development is unauthorised (i.e. no planning / PD) However, just because it is immune from enforcement action doesn't change its status. It is still unauthorised. This may be an issue for you in terms of insurance (something an insurance company could use to deny a claim) or if you have debt secured on the property. If the planning Authority do not accept the evidence you produce, they may well proceed to an enforcement notice requiring removal. You would have a right of appeal which would be dealt with by a reporter. Just bear in mind that if a notice were served, anyone with an interest in the property, inc your lender (if you have one) will be served with a copy of the notice. Best advice I can give is to engage with the Planning Authority.1 point

-

As an update to this the BCO came out is is happy for the vents to go between the slips at the end of the beams as its 7N blocks. The new brickie has the headache of evenly spacing the vents between the beam ends along the wall and tying in with solid bricks Luckily it seems the new brickie has a sense of humour!1 point

-

Yeah, and the terminology gets pretty mixed up in those debates too. Totally, E F Schumacher in the 1970s who was known for highlighting that one of the big mistakes we make in international development is to focus on large-scale, high capital value, complex programmes that yield underwhelming results. This often requires expertise to be flown in to run the things and doesn't fit the local culture. Instead he said the development efforts need to be smaller scale and more appropriate for the local environment and population, which would not only be more effective but cost a lot less money. I think that your differentiation about where the waste happens is really important; they tend to lose at the early stage of production whereas we tend to waste at the later stage. The UN's figures are something like European and US populations waste between 95-115kg per capita but sub-Saharan Africe, South and South East Asia it's 6-11kg. I'm sure it'll happen one of these days in the not too distant future. A previous client of mine was involved in a tech startup attempting to raise funding and develop community co-operative solar energy generation within a couple of countries in Africa. But currently there are multiple & serious problems rolling this kind of thing out due to the complexities shall we say of regimes, wildly different jurisdictions and cultures etc. not to mention investment and investment risk (I also know someone who was quite burned by a solar investment in South Africa). My client was from an African background and explained to me that one of the problems with Western Aid and development is we assume Africa is some kind of homogenous mass of land and people whereas even on a small local basis, it can be pretty much the opposite. This has massive implications when doing work out there. He actually moved away from this work to lead solar development within a large established energy company. One positive side is that it is possible for many of these countries to jump a whole stage of development, with the right kind of approach. Lets hope. ?1 point

-

Just about everything that can be moved is locked in the house. I think I may change the locks just to be sure.1 point

-

New legislation came into force this month that in theory requires light fittings to be replacable with commonly available tools, and include instructions on how to replace the light source. https://www.legislation.gov.uk/uksi/2021/1095/regulation/6/made#top From my Lighting designers FB page: Good news! The Ecodesign for Energy Related Products and Energy Information (Lighting Products) Regulations 2021 is coming into force tomorrow (1st October 2021). This includes light fittings containing one or more sources and/or a separate control gear. From tomorrow lighting manufacturer's will have to ensure their products meet technical and legal requirements. 1. LED lamps and gears will have to comply which means more energy efficient products and higher colour rendering. 2. LED lamps and gear should be replaceable with commonly available tools and without permanent damage to the luminaire 3. Lighting manufacturers' must provide access to information on how to disassemble fittings for replacement of light sources and control gear, and for responsible disassembly at the end of life.1 point

-

Hi. I can only echo the above - it's the similar route we have taken. Rockwool Flexi between studs and 60mm Wood Fibre board over. Ready for rainscreen cladding / weatherboard. Flexi infill is very simple. Push fit, no gaps and has reasonable heat storage capability. It was under half the price of a sheep's wool or wood fibre flexi batt. A bit itchy to work with but I was actually watching two others do it whilst I started the Wood Fibre. One thing many forget with infill insulation only is that you end up with so few gaps to actually fill up. See the pic attached and note the amount of triple studs and solid lintels.... BP1 point

-

Yeh, all sounds nice, cosy and attractive but kind of veers away from what we (sustainable houses) are trying to achieve. Minimal impact on the environment etc.1 point

-

If you do go with that, many people in good quality houses end up looking at stoves for caravans or boats as anything else makes it unbearable in no time at all.1 point

-

1 point

-

I would not even think about a wood burning stove (my wife wanted one initially) if you are trying to target good insulation and air tightness values - in fact, building control may tell you not to do it (they did for me) and anyway, it was just a passing thought. Wood burning stoves burning in your living room is the equivalent of having a diesel truck in your house and will render the air quality rubbish and if you are putting in a MHVR to improve air quality, it is quite contradictory. We are just about to finish our 1930s bungalow and it wasn't for the faint hearted. Good luck.1 point

-

Looks to me like a jolly good example of why we have the planning system and building regulations.1 point

-

Both Airtightness and EWI are *all* about detail, detail, detail. EWI especially is also about careful planning. You need to be obsessive about it. I'm not sure I mentioned it in my thread, but you would need to specify deeper external windowsills so that they stick out over any potential EWI. Cheap if you do it when you do the windows; a pain if you forget.I think I specced either 200mm or 250mm. Also for door thresholds, which I detailed with support for when people stand on them. Inside a classical example of a cold bridge that gets forgotten when doing IWI is the wall strip between the two floors (does not apply to you, but remember you have similar potentially under your floor). One way to think about it is where your insulated envelope runs. In the Little Brown Bungalow I made it beneath the internal floor, and up the walls where I had CWI, and on the loft floor. So I actually ran the plumbing and electrical services under a floating floor to keep them fully inside it. That meant I maintained the airbricks to keep the joints ventilated and dry. In the end I did not do EWI, as it was already good without it, even though my walls had a poorish U-value. The only wall I dry lined was with the other half of the semi-detahced pair, and that was for sound not heat reasons. F1 point

-

I've not heard of anyone having trouble with these slumping. I think @ProDave used something similar. Apparently the better insulating ones (Slab 32) are better to work with. Rockwool would be better acoustically and maybe nicer to work with but it's expensive. Blown in cellulose is my favourite however. It is how a wall or roof delays the suns heat passing through it in the summer. It's also called decrement delay or phase shift. Don't confuse it with overheating caused by poor glazing/shading choices. It's well explained here. https://www.greenspec.co.uk/building-design/decrement-delay/ You're right to ask. I make tons of mistakes and often think I know more than I do!. It's here to create a service cavity which allows you to run pipes and wires through the walls around the house without puncturing the vapour membrane ( in most cases also the airtight layer).https://foursevenfive.com/blog/the-service-cavity-making-airtight-construction-easy-2/ This membrane is important, it stops air moving through the walls taking moisture into the structure where it will get cold enough to condensate rot the timber. It prevents cold drafts blowing into the house. It must be carefully installed, taped with airtight tape to all windows and doors, floors and ceiling membrane. All penetrations the same. You should aim to have no holes at all anywhere. Effectively hermetically sealing your house. Contrary to cranky old chippies opinions, combined with proper ventilation, you will have a much more durable, healthier building. Normally clipped to the service cavity batten AFAIK. I won't pretend to know this. Maybe an electrician will be along to help.1 point

-

I would just fit a conventional good quality one unless you end up with extract only ventilation. There'll be plenty of air in your house to feed the stove. No need to put in more holes. It does help. I'll try to show with some Therm simulations adapting my own 250mm eps cavity wall. An approximation of external wall insulation only. Total interior U value 0.49. Now with 200mm EPS in the floor. U value drops to 0.3 but still lots of heat escapes via the corner if insulation is not carried down. Bearing in mind this is with a wall U value of about 0.13 and a floor of 0.16 so the effect of the thermal bridge is dramatic. Look what happens when we carry the insulation 700 mm below floor level. U value drops to 0.2. A big improvement. The same but with floor insulation removed. U Value back to 0.34. Next I've added 1m of 100mm EPS horizontally. The floor U Value is now the same as with just the 200mm floor insulation and nothing externally below ground. (this is a simplistic example so they wouldn't perform the same in reality. BTW I've also accidentally removed the outer leaf here but it makes little difference) Finally I've done all I can to avoid digging the floor, Externally insulated with 250mm EPS 700mm below the ground. Included a 1m wing and added 25mm of EPS above the floor to take the underfloor heating pipes. U value is 0.27 overall. I'm going to make a crude estimation and say this is the equivalent of putting 250mm EPS in your floor and not taking any measures against the wall/floor junction. The lesson of all this is 2 fold, firstly if you can't or really don't want to dig up your floor there are other options. Secondly insulation is of limited use without getting a handle on thermal bridges. If you search for "french drain" I did some posts recently about them. I think everyone should have one. It'll be a pain with the insulation already installed and if you put in batt or roll insulation you'll never fix it right again after putting in the ducts. Hope this helps.1 point

-

All evidence helps but you can't be sure it will be enough. Find as much as you can. Letters from other neighbours or family confirming when it was built would also help. If they accept that it's more than 4 years old you won't have to change the size.1 point

-

That's fair comment - it's a 3 year old (2018) article. But the article is actually about saving money first - was a response to someone with high bills, and switching has been the lowest hanging fruit for the last decade at least. It was slightly slugged when the Energy Cap came in, as that effectively balanced the market towards non-switchers to an extent. And obvs at present it is not re-applicable until the market loosens. It's really up there for people who are just starting, and for me to link to in random comment sections etc on any old site.1 point

-

Set them out in piles so they are ready to be used roughly 1m back from the wall. 4 in a row then 4 on top at 90 degrees and then again till it's 5 high. Cover them with some plastic sheeting so they stay dry. What's left over can sit on the ends of the slab resting on internal walls so the weight is down through onto the foundation.1 point

-

20% hydrogen can be run into standard boilers without any changes. Green hydrogen at 20% blended gives about a 7% reduction in CO2 due to the lower calorific value of Hydrogen. The Gas industry is lobbying the government hard to get Hydrogen as an option for heating homes, without it the gas network asset they own has no value. Blended grey Hydrogen is being pushed as a stepping stone to, blended blue hydrogen (made from gas but with CCUS), and on to 100% green hydrogen (produced from electrolysis using renewables). The lobbyists are pushing hard for a door to be left open for Hydrogen "ready" boilers. A recent unofficial press briefing is suggesting they've got their way. My view is this is a disaster for Net Zero by 2050 if they have. Blue hydrogen is being mis-sold and over-promised by the gas industry. The process releases more climate change gasses than burning natural gas directly, when you include the fugitive methane released. Heating your home with green Hydrogen would require 6 times more renewable energy than heating it with a HP. We will struggle to build the amount of renewables required to achieve Net Zero by 2050, without needing 6 times more of them for the heat in buildings part of the equation. (Unless the Unobtainium catalyst is discovered mentioned by @SteamyTea) Green Hydrogen is definitely needed, to replace the 70,000,000 tonnes of grey hydrogen current produced plus de-carbonising the industries that are hard to electrify. Unless there is a breakthrough in green hydrogen research that significantly reduces that amount of energy it takes to produce it, its going to struggle to replace the existing uses for hydrogen, let a lone find new uses. If a door is left open for hydrogen ready boilers, in the hope of a research breakthrough, there's going to be a very low take up of ASHPs in the existing housing stock, and ASHPs are the only current clean technology that can get close to the the day-to-day running costs of a gas boiler.1 point

-

This is what I did I needed an additional 100mm, so I cut short pieces of 47x50, fixed these at 600mm centers, then further 47x50 were attached to the short pieces. In my case the whole lot was filled with spray foam. Then a reflective Air tightness vapour control layer and then a further set of counter battons.1 point

-

I am sorry to say the whole house heating upgrade topic is being completely miss handled by the government. They think (at least this is the impression they give) just swap all the gas boilers for heat pumps and the problem is solved and we have all gone green. WRONG. The most fundamental issue with a very large amount of the UK house stock is the fabric of the houses are lousy, no or poor insulation and poor air tightness meaning they need a massive amount of heat to keep them warm. Easy to throw lots of heat into a house with a large gas boiler running on (what used to be) cheap gas. Not so easy ito do with a heat pump. Yes if you do the heat calculations a very large heat pump might work, but what about the radiator sizes? what about the hot water tank? What it the HP needs to be so large you need 3 phase but can't get it at your house? Offering £5K is just going to feed the cowboy "swap a boiler for an ASHP and do nothing else" brigade, result in a lot of poor installs that don't work, and give heat pumps a bad name (which many think they have already) WHEN are we going to tell the general public the truth? If you want your old poorly insulated house to go green, you are going to have to spend a LOT of money upgrading the fabric of the house first and properly insulating it, which will be costly and very disruptive. THEN it might be a good idea to heat it with a heat pump.1 point

-

You would normally shot fire a sheet a 2400 x 600 mesh under the steel The lift and rap the face of the steel Then plug and screw to the block about 300 above Or as above cement board but you would need to add a movement joint where the board joins the block1 point

-

In that case, count your blessings and speak to them, make it a joke … you may seem a bit fussy but it’s your home and you would like …xyz! we are all human, we all have good and bad days and we all want our days to go smoothly. to quote the Advert … It’s Good to Talk.1 point

-

1 point

-

A mechanical mortar gun which works like a giant mortar syringe is one possibility, trouble is these require a wet mix and the whole job becomes messy. The other option is to us a thin pointing trowel but this is a fiddly job on the vertical perps. With my brickie team this was a 2-stage job. First is the usual extra 3 seconds a block to butter the end with mortar then the brickie's mate went around pointing up both sides of the block wall within the hour and filled in any voids. The cavity had a rougher finish but was still better than your example.1 point

-

1 point

-

Make sure you don’t go off the straight line when laying or it’ll quilt up and then you’re into cutting out sections and patching. It’s quite hard to spot too, so keep checking back on the previous runs to ensure they’ve stayed down. A cheap 9” roller will help to lay it smoothly. FWIW, I’ve laid Christ-knows how many floors without Ditra / other and not lost any of them ever. My golden rule is prepping and never laying onto a dry / dusty / contaminated subfloor. I have seen others lay directly onto screed which has been too long on site / not laid quick enough and the tiles + adhesive + top skin of screed has come up one one big sandwich. Screed needs to be sound, prepped properly, and bingo. I’ve only ever used a mat over unknown sub base or liquid screeds.1 point