-

Posts

2094 -

Joined

-

Last visited

-

Days Won

6

Moonshine last won the day on March 13 2024

Moonshine had the most liked content!

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Moonshine's Achievements

Advanced Member (5/5)

540

Reputation

-

How to tell is textured ceiling is asbestos laden

Moonshine posted a topic in Plastering & Rendering

I am looking at an older property which has a number of rooms with textured ceilings, and others with textured wallpaper on the ceilings. In a couple of rooms the ceilings are heavily cracked and will need repairing / replacing. How is it best to find out if the textured ceiling is asbestos laden? I could overboard but i think my prefered option is to remove the ceiling completely before boarding again. -

Also bear in mind MCS guidance has changed and in September 2025 new lower noise criteria will apply, maybe making installs more challenging. https://mcscertified.com/mcs-has-published-an-updated-version-of-mcs-020/ It now allows two heat pumps for detached houses, but noise criteria has dropped from 42 dB to 37 dB. If you are not going to go the MCS permitted development, your LPA may ask for a noise assessment of the unit for planning.

-

I-joists pre notched for support beams?

Moonshine replied to Moonshine's topic in General Construction Issues

So they actually are manufacturers notches (from Staircraft), saves time having to put individual noggins in between joints if a single piece of timber can be fixed in https://staircraftgroup.com/kb-post/i-joist-notch-installation/ -

I-joists pre notched for support beams?

Moonshine replied to Moonshine's topic in General Construction Issues

Cheers Nick, just to be clear it's not my site but one a visited for work related reason's. I have been to a lot of sites too and have never seen this. It is a neat hole and that what made me think of the manufacturer. May ask the SM about it. -

I was on site yesterday and saw a standard i joist, but with a notch taken out to allow a support beam. Is this allowed and done by the I joist manufacturer, or done on site? Seems strange to be cutting into the main beams of the I joist.

-

fecking scumbag

-

This is not what you want for this thread, but some points about the East Hertfordshire methodology (https://www.eastherts.gov.uk/planning-and-building/planning-sustainability/heat-pumps), this looks like an copy of the IoA / CIEH calculation with some interpretation of background noise levels and urban and rural locations, also a fixed 6 dB for tonality/intermittency (which is not always the case). It shoud be noted that the IoA / CIEH calculation which has 6 dB for 'Character adjustment' states 'The numbers shown are examples and are not associated with any particular installation'. https://www.ioa.org.uk/heat-pump-briefing-notes-calculation-sheet-ioa-cieh I think that the East Hertfordshire methodology is a high level screening tool, that finds installations that are definitly not going to be a problem, rather than where they may be an issue, but could be o.k. Their guidance states 'Environmental Health do not require that a noise assessment is carried out by a third party, but should the applicant wish to do so, this must be carried out by a suitably qualified person'. I can certainly see scenarios which would fail the test in the spreadsheet, but with proper assessment (which Environmental Health would accept) the installation can be found to be suitable. btw i thnk your rural areas criteria should be 20 dB(A) based on the East Hertfordshire spreadsheet. Also the permitted development limit is 37.8 dB (to 1 d.p) if you don't use the table in Note 7, and do proper logarithmic calcs 😁

-

Mortar on indian sandstone slabs

Moonshine replied to xtianaudio's topic in Landscaping, Decking & Patios

They look bad, i would have used easy joint as above, and its what was used on our porcelen tiles. How about a small sample area, with brick accid and an angle grinder with a wire brush to remove the mortar. May damage the tile under neath but could weather in. -

Advice Regarding Materials & Amounts Needed

Moonshine replied to BGoldey's topic in Building Materials

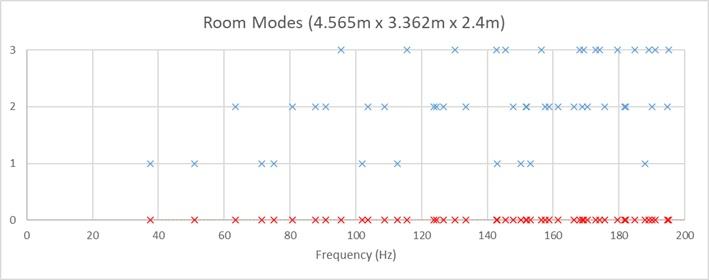

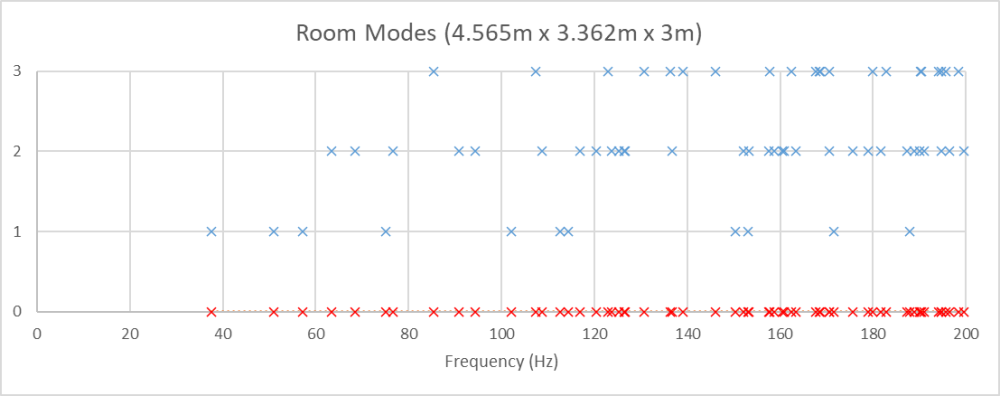

It looks the room size (assuming a 2.4m ceiling) meet the criteria of Walker (BS 1116) and Cox (Room Sizing and Optimization at Low Frequencies), so i presume that you have put some thought into it 😀 Room model density looks good (0 is all modes, 1 is axial, 2 is Tangential, 3 is Oblique), though you will need to watch out for the 38 Hz and 51 Hz modes and make sure they are nicely controlled. Edit: just seen its 3m high, thats not great, doesn't meet the criteria of Walker (BS 1116) but does for cox. You get more low freq modes, and bunching around 75 Hz, you may want to think about reducing its height -

Advice Regarding Materials & Amounts Needed

Moonshine replied to BGoldey's topic in Building Materials

What is the cavity going to be in the external wall, whatever it is full fill it with mineral/glass wool, though note that building regs may need to be considered for thermal and peneratating rain. You may need to go up a cavity size for thermal performance. What is the roof / ceiling buildup as the sound insulation of this will need to be considered. I presume that you have looked at sizing of the room and potential room modes? You rear absorption / diffusion isn't going to act as a very good bass trap as it looks only 100mm thick, maybe set up a corner bass taps in the corners behind both of the rear speakers (both so that the path difference of each speaker is equal). Are the Rw 46 dB door sets individual or Rw 46 dB both together? It looks like there are vision panels in them, so i presume they will a specilist studio door set, with price tag. For reference lorient have test data for Rw 44 dB doorsets without vision panels, with pretty standard (cheap) threshold and jamb seals https://www.lorientuk.com/acousticsearch/results 103.pdf Edit: what is going in the green areas, these could serve as a base trap. -

https://www.knaufinsulation.co.uk/products/dritherm-cavity-slab-32 Just phone the technical department (01744 766666 ) and ask to be emailed the certification, send that to the BCO, get them to confirm its acceptable in an email. Send that email to the architect, then crack on.

-

We did 150mm ecotherm batts fully filled, with render. Building control and architect were fine about it. Only think I would say is I am in the south West, as you could it be an issue with wind penitrating rain? Have a look at the building regs, lso maybe worth a chat with the local building control officer. This document only recommends full fill in sheltered areas https://www.gov.scot/publications/building-standards-technical-handbook-2019-domestic/