-

Posts

1818 -

Joined

-

Days Won

6

IanR last won the day on August 16 2024

IanR had the most liked content!

Personal Information

-

Location

Essex

Recent Profile Visitors

9519 profile views

IanR's Achievements

Advanced Member (5/5)

751

Reputation

-

Connectivity Plan - Approved Document R

IanR replied to Caroline's topic in General Self Build & DIY Discussion

If you have "Superfast" then I assume you have a temporary location for the Network provider's ONT box, perhaps on the mobile home side, or a kiosk. If that's the case you need to contact your ISP and ask for an "ONT shift". This is chargeable, so they should arrange for the Network Provider (OpenReach etc.) to come and survey and quote them for the work, which the ISP should then advise you the cost of. You may not get much detail of the works to be completed, but a cost from the ISP for an ONT shift, will confirm to BC that the new poperty will have FTTP. BC are then also asking for you for a schematic that high-lights the ONT position in the new property, they'll want to see provision for any ducting required to get to that position, a power outlet in the close viscinity and your network distribution (Router and Switch) close by.- 1 reply

-

- 1

-

-

Bring down the lower edge of the cladding to the top of the ground floor windows, so you can put the top boxes for the ground floor blinds behind the cladding also: +1 for external blinds with automated shading control.

-

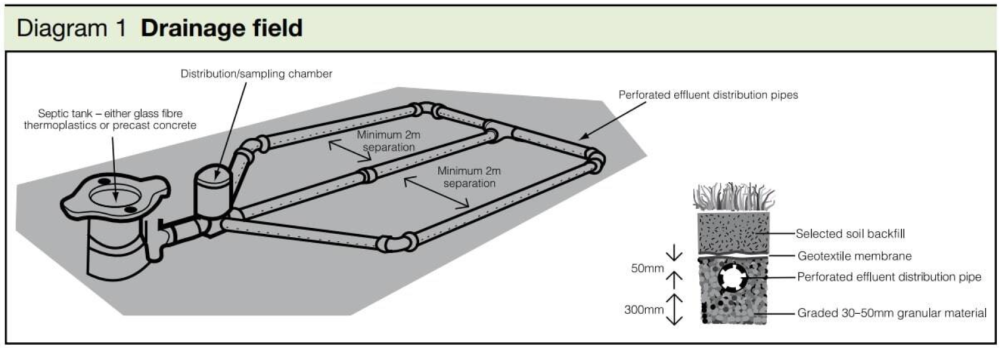

I'm not sure what you mean by "infiltration tunnels" is it a specific product? However, it's not a Council decision, it's a National requirement. If you are going to have a private sewage system in England then you as the operator have to either meet the General Binding Rules or get a permit from the EA. Building Control should require you to do one or the other as per your local council. As the "Operator" of an STP without a permit, you are criminally liable for the STP meeting the GBR's. The wording as been softened in the 2023 version of GBR's to now say they will only bring a criminal prosecution if your STP causes pollution AND you do not meet the GBR's. If the "infiltration tunnels" can be used to construct a drainage field and meet BS 6297:2007, there should be no problem. Edited to add a relevant previous post:

-

It's not unfortunately, in codifying the requirement natural options have disappeared for perforated tubes with their fixed cross-section and calculable flow-rates, so something more like Still relatively simple, but a second chamber is required for an STP, the first being a settlement chamber to seperate the solids (that needs emptying every 1 - 2 years), then the aerated liquid chamber with a filter media.

-

That's a misunderstanding. While the discharge has low toxicity, if it is allowed to build up it can get to a hazardous level, so the GBR's require their discharge to be controlled either into a drainage field or a water course.

-

Then to meet the General Bing Rules you'll need a Drainage Field that meets BS 6297:2007 I'm not sure if that document is available free of Charge, but if you ask Gemini, it gives you a good idea of what is required: Edited to add what looks like a good reference to clear up any confusion on what a Drainage Field is: https://www.homeseptic.co.uk/drainage-field-size-calculation-and-design/

-

If your site is in England you must meet the General Binding Rules, otherwise you require a permit from the Environmental Agency. The GBR is the far easier route. For a new discharge you can not use a soakaway, for discharges to ground it must be via a drainage field. Both STP and Drainage filed must be in line with the relevant British Standard. See Rule 9 for the specifics Ref. https://www.gov.uk/guidance/general-binding-rules-small-sewage-discharge-to-the-ground Lots of rules, make sure you meet all of them. Under the GBR you can discharge to a Water Course in some circumstances, so when you say "cannot discharge to a water course" I assume you mean you do not have access to a suitable water course.

-

Essex Highways require gates to be a minimum 6m from the highway to avoid a vehicle stopping on the highway in order to open the gates. Footpaths are part of the highway.

-

100mm PIR would bring the 9" solid brick wall down to 0.25 U Value from around 1.9 The ubakus site allows you to try different build ups, although uses German products. https://www.ubakus.de/ Of more a concern through would be ensuring moisture can get out of the wall. How old are the walls? Is there a damp proof course?

-

For some PU resins, voc's would be released during the curing process, once cured there is no further off-gassing whether or not heat is applied. That statement doesn't cover all PU foams where a foaming agent is used. Good ventilation is recommended during the 5 days of curing. There are also low-voc and zero-voc options that reduce off-gassing during the curing phase. Wouldn't that be epoxy based for cement repairs, or are you referring to a PU sealant to fill cracks? Epoxy resins do continue to off-gas after curing, although at a much lower rate than during curing.

-

-

That's a complete misunderstanding of the product.

-

Hi and Welcome. SIPs = don't do it, go for a twin wall or I Joist structure and cellulose blown insulation MVHR = great benefits, but only if combined with a < 1.5m³/m².h @ 50Pa infiltration rate. UFH = no regrets Best Flooring = Hmm, subjective one, but combined with UFH I'd suggest PU poured Resin. Good Luck!

-

"DWG" is the native format to Autocad, so if the house plans were authored in Autocad the DWG may include templates, macros, metadata etc. that the Architect feels is their intellectural property and may not wish to hand that information over. But, DWG can also be a neutral file format exported from other CAD systems and contain only the Vector image of the house plans that you see when you print them out. Depending on what "he" intends to do with them, a vector PDF will/can provide the same info as a neutral file DWG.

-

No harm in requesting, but likely the best you can expect is a vector based PDF. Some architect's seem to get prickly about handing over their native CAD files, unless you have agreed it prior. This is defintely one to agree up front. "CAD" means different things to different people, what are you hoping to do with the file(s), a vector PDF may well be sufficient.