Leaderboard

Popular Content

Showing content with the highest reputation on 03/12/21 in all areas

-

The 300mu is 1200 gauge so will be fine for DPM. 125mu is 500 gauge and fine for the separation layer.3 points

-

I've just done the query. The daily averages (rounded to nearest kWh) for Sep..May are 2, 16, 17, 23, 25, 22, 19, 9, 5 kWh or 4,148 kWh total. I also run a small oil-filled electric heater on an overnight timer in my first floor study Nov-Feb with the hours per night depending roughly on the average external temperature. I estimate that this adds another 480 kWh so the total heating load is around 4,700 kWh with about 90% at E7 tariff. I just had a look at my "JSH style" initial estimate. The main error that I made in this was due to my assumption that all other electricity use ends up as waste heat which for heating days also warms the house: our new house electrics are more energy efficient so the base load is less than I estimated, and therefore we need more top-up. I also used a temperature set-point of 21°C rather than our currently preferred average which is around 22.8°C. Adjusting for both of these, the new estimate (to my amazement) was also 4,700 kWh . On reflection, it looks like my 10kWh mentioned above was just a measure of the thermal banking in the main ring foundations within the warm slab. It looks like the mitigation did its job. TL;DR: our as-built thermal performance is a good ballpark of the as-designed. I am currently on an OVO 2 year fixed tariff at 9.19p and 15.81p per kWh + VAT, so totals roughly £490 for my annual heating cost. DHW, cooking and all other use is on top. Given that I use little or no heating for the 4 summer months, I can cross check my total annual bill against the annualised cost for these summer months and this is consistent with this figure. Incidentally I estimate that switching to use an ASHP would only save perhaps 50-60% of this (at an average CoP of 3 say, but more peak rate tariff), say £290 p.a. That's why I find it difficult to justify the cost of installation of an ASHP. I am going to switch to an Octopus ToU tariff but the process is that you have to switch to Octopus on an interim single rate tariff until they switch your smart meter, so I am waiting until April because I want to take advantage of the OVO off-peak tariff in the meantime. I also have no components in the system requiring annual professional maintenance so I have no annual maintenance bills.3 points

-

I am a big fan of Charlie Luxton's Building the Dream and just noticed that Series 10 is starting on More4 on Weds 24 March at 9:00pm. Building the Dream - Episode Guide - All 4 (channel4.com)2 points

-

Like @pocster, with slight twist: .... it used to piddle me off . I now say "Yes, I am really lucky: I got used to the persistent sleeplessness after the fourth year." And smile.2 points

-

You’ll pay through the nose for that. You also need to hire a putz mixer as you’ll have no end of issues as whilst you “can” mix that much by hand you wouldn’t want to ..!! There is 4 hours solid of mixing - first stuff will be going off before the last is in, and that’s assuming you’re using a decent paddle mixer. By the time you’ve hired mixers etc, a crew would have that done and laid in a couple of hours. 75mm is also the bare minimum for sand and cement - ideally you would add fibres at that thickness. If you want to DIY quick then just use concrete - leave it 5-8mm shy and top with SLC. It’s less than a cube so £175 on a volumetric mixer.2 points

-

I think have spent the better part of 2 weeks trying to get council departments to see reason and logic, however I have failed and it has left me in a highly judgmental mood! They have consulted us for advice, they don't like the advice, so decide to proceed how they think it should be done but want us to "design" it to their spec. Makes one a bit annoyed to say the least.2 points

-

I've costed up the guttering etc in three different types. I had a full quote for it in Aluminium which was just over £4k, of which 54% was gutters and downpipes so I am scaling the other options on that basis. [NB: 84m guttering and 51m downpipe] Aluminium: inc. 125mm gutters, 76mm downpipes - £4,080 Brett Martin Cast Iron Effect: inc. 112mm gutters and 68mm downpipes - £1,936 FloPlast Cast Iron Effect: inc. 112mm gutters and 68mm downpipes - £1,319 Standard FloPlast: inc. 112mm gutters and 68mm downpipes - £341 It's amazing to see a factor of >10 in the price. On ScrewFix someone wrote in a review of the FloPlast cast iron effect: "This is standard plastic gutter that has been painted with a matt black textured paint to make it look like cast iron." I am tempted to have a go with some textured spray paint and see if I can make something that looks decent. Paint isn't ideal, but if that's what the FloPlast is then same compromise. I'm happy with black but my wife is set against it so painting may be the only option anyway. Is the Brett Martin cast iron effect moulded texture or painted as well? The big cost difference from FloPlast with Brett Martin is the cost of the downpipes as they look to have a connector moulded on.1 point

-

1 point

-

I built two DG with our build three years ago I allowed 15k for the neighbors no doors included Double skinned block work slate roof 20 k sounds about right to me1 point

-

1 point

-

50mm of PIR will reduce U-values substantially without taking up an extra 50mm of room size.1 point

-

Removing layer four would increase the U value and in theory make the SAP score worse but in practice may be to small to actually affect it.1 point

-

It certainly helps being in the building trade and knowing other tradesmen. You build up a mutual trust of each others work. You also get to know the ones you would not want working in your house. I can think of some plumbers and joiners i would not let loose here.1 point

-

1 point

-

1 point

-

Thanks Terry. Really interesting to see. We use a bit more and over the past 4 years it has ranged between 6500 and 7000 kWh for heating. We are achieving a CoP of 3.8 over the heating season, so an input energy requirement of between 1700 and 1842 kWh. At my current tariff of 13.44p/kWh I'm paying £228 and £247 per annum, to keep the house comfortably at 21.5C When I was deciding which route to go down I compared various different options and configurations and came to the following conclusion. If DHW and Heating requirement were sub 2500 kWh then direct electric resistive heating was the most cost effective. Between 2500 and 5000 kWh the balance started to shift to other solutions and over 5000 kWh then ASHP won out. Looking at your heating figures, and assuming you could get the same 3.8 CoP, would mean an input energy requirement of 1250 kWh per annum. Split 750/500 between night/day would cost you £147 per annum. Your in the realms of it making sense financially based on a ten year life of an ASHP (which is what I factored), but probably not enough for the hassle given you have a perfectly functional set up. Of course the real beauty of your set up is the simplicity of the willis heater and ease of repair. This brings us full circle back to what we concluded a few years ago when we discussed this, different ways to meet individual requirements (which of course vary but may be the biggest decision drivers) but ultimately, the overall cost balances out for a given energy requirement (for low/lowish energy requirements).1 point

-

Lucky, lucky, that I lived in a Freezing caravan through winter, up to my ass in flooded morass, working endlessly and never ending......don’t get me started (oh i did ?).1 point

-

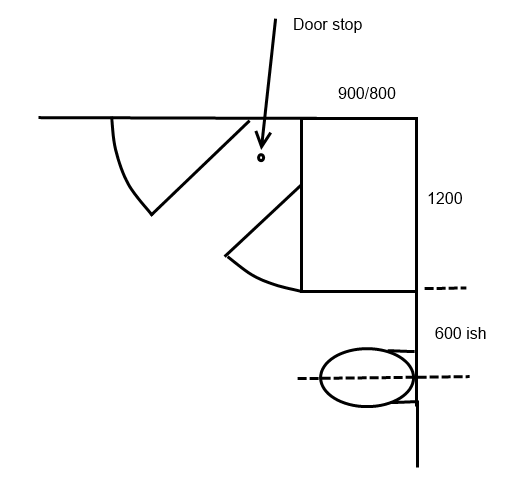

You have quite a large space. I would leave at least 50cm from the centre line of the WC to the shower screen. That gives you 1.3m ish for a tray in that direction. I would fit something like a rectangular 1200 * 800 or 900 mm tray with the door on the long side. Fit a door stop to the floor to prevent the bathroom door handle damaging the shower. Put the shower controls on the long side wall. You don't show a waste pipe but if that's low enough you can fit something like 18mm WBP to the joists and a low profile tray on top. I wouldn't go for an ultra low tray unless you are sure the waste pipe can cope with a decent flow rate eg its a short run to the stack. The position of the waste will depend on the pipe run so don't buy the tray until you know how that looks.1 point

-

1 point

-

indeed and we are having a combination of normal larch and charred larch. my curiosity was more to the longevity of the charring of Larch compared to the results of the charred Spruce in the article that was posted.1 point

-

I had that question for years even before the building work started, I remember somebody in the community laughing when I said that we need to convert a loft in my parents in law 's house to create a flat and then be able to save sufficient funds for the build. I have a bit of gripe now that the house is done and somebody 'says you are so lucky', like we won the house in a raffle.1 point

-

I backed the wrong horse and went for celotex.... what a melon when everyone else went for kingspan! (it's always funny to see what people take from the posts, seems you cannot be explicit enough)1 point

-

To be honest that is a myth a lot of kitchen retailers peddle. Kitchens are fundamentally not complicated of high-tech items. What the German manufacturers do very well in invest heavily in automation. Essentially play to their strength of being able to scale up manufacturing and provide a product to a good quality consistently and do it correctly. Right from the entry level German manufacturing to the top end ones, the one thing in common is a well put-together product, delivered to order. On time. and complete. It the the retailing that attaches the German tag to any German-made kitchen and tries a smoke and mirrors approach. There are definite differences in quality, detailing, materials, design between German manufacturers but this isnt immediately apparent unless you are in the business. This is something British manufacturers fail to do. Its all about cutting corners with a that'll do attitude. Inevitably that results in shoddy build quality, poor attention to detail, compromised quality and a shocking price driven attitude.1 point

-

Ok I would use 1200 gauge below the insulation, 300 is very thin for a DPM. The 20mm is edge insulation. 150mm below is good for UFH.1 point

-

It may worry you, lad ?. But I'll be dead or so out of it that I won't care by then Nothing.1 point

-

What about asking a shop fitter to quote. They should be able to handle all the standard carcass stuff, but utilise some fancy hafele ironmongery and bespoke materials to get a higher finish1 point

-

1 point

-

@patp Do you have any drawings from the architect or designer? If you have them on your computer as some form of file pdf for example you can attach them to a post. At the moment I still don't know if you have a solid floor built up off the ground? Beam and block or timber suspended? What the designer has proposed as insulation, how much and where? Without this guessing where to put a membrane is meaningless. If you can't post a picture or file, then describe in words how your proposed floor is constructed and what layers it has starting from the ground upwards listing every single layer, what it is and how much.1 point

-

Didn't I see something on tool share about the stapler thing which administers the clips to hold the pipes down?1 point

-

Well it will certainly add some 'thermal mass'. That should keep your house nice and cool. What happens when it leaks? How about condensation? How about vapour control? How about odour? How about rigidity? Will there be enough storage? where will the overflows go?1 point

-

Exactly that but the range Intu offer for tilt and turn windows are far less than for normal windows. Perfect Fit offered a huge selection but the white frame just doesn't appeal.1 point

-

Leicht is one of the best value kitchens that also offer great features. Effectively Siematic for a lot less. Almost all German products are better than the bog standard British kitchen, but not all of them add the clever features that Leicht offer.1 point

-

Hi Rob, welcome to the Buildhub site. I am a self-builder in Norfolk who is starting the build of something very similar to your specification (Four bed, 200m2, timber frame, traditional brick exterior). I am new here and a first time self-builder who has learnt a lot since finding this site. Finding the plot may be one of your biggest challenges ? Tips on finding the plot and evaluating its potential would be well worth looking out. Our plot came with full planning permission but it has not been that straightforward getting our minor amendments through planning. The other challenge has been services - we've struggled getting reasonable quotes for electricity/water and commitment to get them installed. The other biggie that catches people out is sloping sites and difficult ground conditions. Finding multiple companies that are prepared to guarantee the performance of the shell could be problematic. There is a lot of attention to detail required to achieve an air-tightness of 0.6 air changes per hour @ 50Pa (Passivhaus standard) compared with 10ach specified in Building Regs. This and the thermal performance of the build have a massive impact on the building comfort and heating load so it is worth looking at the trade-offs. Wall thicknesses will be 300mm+ with basic timber frame/cavity/brick skin so maybe consider other cladding systems or allow for the large difference between external and internal area in your planning. Most will suggest that taking a "Fabric First" approach and building to near Passivhaus standard will not add massively to your build cost and is worth the investment. Many self-builders here have used MBC (based in Gloucester but operate nationally) who provide the foundation/timber frame package you're looking for. Another suggestion for you is Flight Timber Solutions based near Colchester. Good luck with your plot search and self-build planning.1 point

-

1 point

-

I can beat that. I found a live mouse had made a nest in a welly left in the garage. And on another occasion, a mouse had collected peanuts from the bird feeders, and tucked them away as his winter store in one of my rigger boots.1 point

-

It’s strange - the stuff I’m using doesn’t look or feel like it’s sealed but it also does not rub off on your hands or clothes at all, char is about 2mm deep. I’ve seen quite a few other samples and some of them have a very soft char layer that feels very delicate and can be picked off easily and will rub off to a degree.1 point

-

Nah! Just do it, councils are too busy to notice and if the contractor looks “pro” who is going to question it . ?1 point

-

1 point

-

After self building for years we do virtually everything on a day rate but we tend to buy as much of the materials we can. It usually works out cheaper and if, and this happened, the quality or behaviour is not acceptable we can pay them up to date and invite them not to come back. A drunk roofer at ten in the morning is not acceptable. Exceptions are that we tend to get electricians to work on time and materials. With plumbers we buy all of the meaningful stuff and get them to do provide materials for the things like pipe fittings etc. If you ask someone to give a fixed price that person has to price for the risk of variation in the work content. Inevitably the price will be higher. Working professionally (I don’t do domestic work), the client always wants a fixed price. There are many times, with repair works for example, that it would often be far cheaper to issue a post measured order. Private clients may be persuaded but I worked for a good while in the public sector and there is no way you can get them to engage with the concept.1 point

-

Sharp sand 10:1 cement dry mix and the moisture in the sharp sand will let it go off. Paving expert recommends a resin grout, gotta admit I don't know what that is but I'm betting a grout gun, a sunny day and a cold beer will see you right?1 point

-

They are just ignorant. Get it spec'ed up properly and submit it, basically they are holding you back because they don't know. If they were smart, they would let you do it and learn. Typical public sector worker.1 point

-

0 points

-

When are passers-by going to finish asking me when we are going to finish? I know, they've just stopped for a chin wag - to be nice, to pay a compliment. Some even are interested in the answer. Sometimes I cant read the mood quickly enough and give the wrong type of answer: It depends [...] What do you mean by finish ? [...] Never. Five years [...] There's an online colleague I have called @Onoff : let me tell you a story about him [....] I had an instructor in the Army who told me I had two speeds; dead slow and stop. He was right. I think in future, I'm going to answer - "When you see me cutting the grass on a Sunday morning" (We have no plans for a lawn) How do you deal with the question?0 points

-

We look back on it as "character building" Ours was the winter of the Beast from the East. Thank god i put a WBS in the caravan. Keeping up the wood supply was challenging. The "highlight" of the winter was when the hot water froze, because a mouse had eaten about a foot of the pipe insulation, and lying on my back under the caravan at night, during a blizard with a hairdryer to thaw the pipe.0 points

-

made worse by most peole buying cheap -"black and round" --not first line tyres which have better sidewalls --but yes I do not like "drug dealer wheels " either -a new audi with 300 x30 X22 tyres bent 3 rims and they cost £750 per rim --only suitable for very good roads0 points

-

0 points

-

0 points

-

0 points

-

0 points

-

0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)