Leaderboard

Popular Content

Showing content with the highest reputation on 01/22/23 in all areas

-

I would have a word with your solicitor, providing them with as much info as you can. Get them to draft a watertight letter dispensing with the architects services. Maybe even claiming moneys back for services not provided. If you take this approach the liquidators will probably put you at the bottom of the list of cases to deal with, probably just write you off. It'll cost a few £100 but a good solicitor will leave you pretty well protected. Put the rest down to experience and try to move on. There's always hiccups along the road, be it ground conditions, ill health etc. Ob the plus side you have permission for something. That's 90% of the battle. Maybe start a new topic, post some plans and drawings and go from there. We had 3 sets of planning before we built.3 points

-

Why do you say that? The house clearly has poor air quality, insufficient ventilation at the moment. So some improvement is necessary. Dehumidifiers will remove most of the excess moisture so will cure the most noticable issue, the condensation, at the expense of needing electricity to power them and generally being noisy irritating things. But that does not cure the poor air quality. for that you need proper ventilation. I keep seeing people recommend DMEV or PIV for this, but all that does is blow in fresh cold air or suck out stale air with the same amount of cold air being sucked in any way it can. Neither have heat recovery so while they will improve the air quality, they will cool the house / increase heating required. Yes for sure for best results you want an air tight house. But I don't understand the logic of saying mvhr is a waste of time if the house is not air tight. If you do fit mvhr to a leaky house, at least some of your ventilation will benefit from the heat recovery. Balance the system properly so you are not pressurising or depressurising the house and little else will enter or exit through all the leaks except perhaps on a windy day. I would certainly say if you get the chance go ahead with mvhr. Since I appear to be in the minority here, I await incoming.3 points

-

What did you commission him to do, full project management or just drawings and and was this all specified on the original quotation. In other words do you think he's done more than the 35% that you have paid him for. If not then just send him a letter / email / text / carrier pigeon to say that you no longer require his services and if he responds with a bill ask him to specify exactly what the bill's for. Also, surely if you commissioned the company, which no longer exists then you would have heard from the insolvency auditors if you owed him money as they would have looked at the debts he had and the monies owed. He must have had debts otherwise he wouldn't be bankrupt. You could try asking the citizens advice bureau as well. As you have said you need to be well clear of him to progress in your build, I hope you can at least use some of his drawings and good luck2 points

-

Ok, free electricity is an unachievable utopia. But where we are now is bonkers. And yet, even on here, this month ive seen the statement its too cheap. I know 3 people who have closed or are closing the doors on their business because the energy costs have increased so much. And set to increase more in April when subsidy ceases. Taking to the guy who runs the nearby pub. They are 3 days a week max, and kitchen for 2 hours in the evening only. Simply cant afford more. No idea what he will do come April. Close up for good i suspect. Theres a lot worse to come as more buisness realise they cant cover the costs. And thats before the crazy rates rises. Prob best for another thread. So i would suggest my statement is not out of context. Its just a statement. Does anyone really think that at the current level any good can come from where we are heading? For those who say its too cheap, welcome to a situation where stuff cant be done anymore because energy costs are crippling. Meanwhile, seems everyone elses (other developed nations) costs are significantly less. As i said earlier, pegging electricity to gas prices is an artificial construct whgich the government allows to continue. And no one is challenging. Only Ripple energy look to be doing something, and thats way to complicated. I get that the demographic on here is probably in the top 10% of countries population, and so can probably afford to shrug their shoulders and pay up, but most of the country cant, at least not without a significant drop in living standards. Energy is NOT to cheap.2 points

-

A problem we have at the moment is just about every heat pump has a TOTALLY different way of connecting to the required controls and by default only operates from it's own supplied controller which tends to be a non intuitive grossly over complicated and awkward thing to use, such that the average home owner has no hope of even adjusting the time settings. In my own case I left the manufacturers controller as an object of curiosity in the plant room and integrated the system to a standard central heating programmer on the wall of the utility room. A user interface that most home owners are familliar with and they can easily turn heating and hot water on and off and program on and off times just as they have always been able to do with any heating system. But to do that was not easy as there was no hard wired hot water on and off input with my heat pump, so I had to fudge my own interface to allow the hot water to be enabled or disabled by something else. And the wiring is totally different between one make of heat pump and another. So an electrician going to wire the system if he has not done that one before he first has to read, digest and understand the manual. Only then can he work out what cable is needed between the inside and the heat pump sitting outside. You don't have this problem with a gas or oil boiler, they are virtually all the same control interface, permanent supply, call for heat, call for hot water etc. It would be good if the heat pump manufacturers could bang their heads together and come up with at least some standardisation.2 points

-

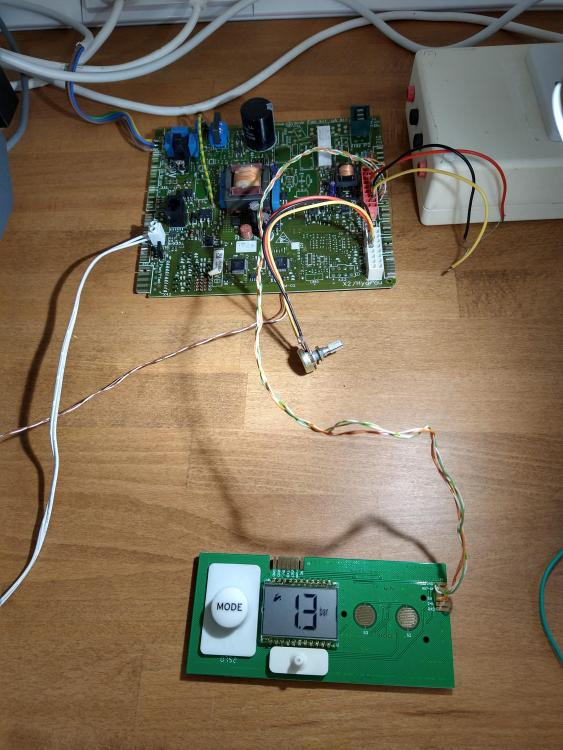

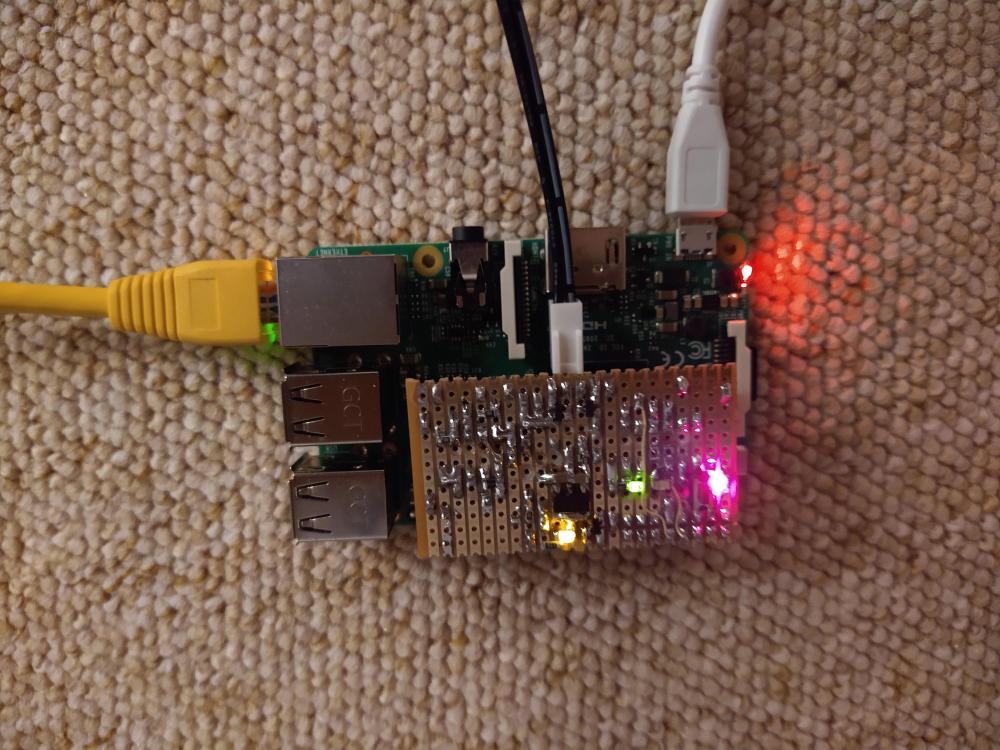

I guess this post doesn't really belong in Boilers & Hot Water Tanks so I'll offload it in this subforum. The central heating system in our house is fired by an ageing Glowworm Flexicom 30HX (heat only) condensing boiler. It's probably on its last legs but while it still works I'm keen to squeeze every drop of life out of it. The main drawback with it is that there's only one flow temperature (set on the front panel display with a couple of pushbuttons) for both heating and HW, with only one demand switch input. Because of this limitation I have to set the flow at around 65oC minimum in order to get anything over 55oC into the HWC so I can't have a lower flow temperature separately for the radiators - which would improve efficiency. Not without investing a few hundred quid in Glowworm's own external control kit that is... this kit talks over a proprietary serial bus called "ebus" and combines a switching unit with inputs for HW cylinder stat and room thermostat(s) for CH temperature and scheduling. Luckily for me, Glowworm were gobbled up by Vaillant before the Flexicoms were released, so under the sheet steel it's pretty much a Vaillant ecoTEC with some budget component choices so while Glowworms don't get much attention, plenty of people like to integrate Vaillant boilers with the HomeAssistant OS. For this reason I set about seeing if I could adjust the flow temperature over ebus using the RaspberryPi that already runs my CH system. If I can make it emulate the external controls, I can set a lower flow for radiators and UFH and implement an X plan scheme. The first step was to pick up a spare main PCB and display panel on ebay to mess around with (too cold to risk messing up the real boiler). Here it is dangling precariously on the bench: It's powered from a 240V isolating transformer so not quite as lethal as it looks. Not quite. The first thing I noticed was that, in its former life, it was a combi boiler (Flexicoms come in three flavours: CX (combi) SX (system) or HX(heat only) like mine). For giggles I stuck some 10K resistors on the NTC sensors and water pressure sensor to see how it would run. It still kept throwing faults until I did some googling and found out that the pump is tested on power-up by looking for a small increase in pressure when running. This was fixed by manually tweaking the pot a bit and kept it happy enough for me to play with the serial interface. That's about as far as it will go without an fan and ignition unit though. But at least I could connect it to an ebus interface and talk to it. There are some PCB's out there to interface ebus to RS232 but it's a simple enough thing to design so I built one on some stripboard that plugs onto the Raspberry Pi header: The two wire link is going off to the main boiler PCB (although the wire magically changes from black to white along the way!) If anyone's the slightest bit interested I can put up the circuit diagram for the interface board but it's just a dual comparator and a couple of opto isolators. Incidentally, this interface and topic in general might be of interest to anyone looking to integrate Vaillant boilers with other control systems as they don't talk Opentherm. The awkward thing about this particular hack is that ebus timing can be quite fussy when doing bus arbitration and the UART in the Pi has a fifo that gets in the way. However someone already fixed this with a kernel module called ttyebus dedicated to reading/writing directly to the UART. Then there's the oh-so-handy daemon for linux called ebusd which can interpret a wide variety of ebus device comms and access it all over TCP, HTTP, MQTT etc. On putting all this together, the automatic scan performed by ebusd instantly identified the boiler and loaded the appropriate configuration files for it resulting in access to a great many parameters: bai AccessoriesOne = extheatingpump bai AccessoriesTwo = storagechargingpump bai ACRoomthermostat = off bai averageIgnitiontime = 1.3 bai BlockTimeHcMax = 18 bai BoilerType = 6 bai ChangesDSN = 0 bai CirPump = off bai CounterStartattempts1 = 3 bai CounterStartattempts2 = 0 bai CounterStartAttempts3 = 0 bai CounterStartAttempts4 = 0 bai currenterror = 75;-;-;-;- bai DateTime = nosignal;00:00:00;-.-.-;- bai dcfState = nosignal bai DCFTimeDate = (ERR: invalid position for 3108b509030de500 / 072b080101010150) bai DCRoomthermostat = off bai DeactivationsIFC = 0 bai DeactivationsTemplimiter = 0 bai DeltaFlowReturnMax = 22.69 bai DisplayMode = 2 bai DSN = 8193 bai DSNOffset = 1 bai DSNStart = 8192 bai EBusHeatcontrol = yes bai EbusSourceOn = on bai EbusVoltage = on bai errorhistory = no data stored bai expertlevel_ReturnTemp = -1.81;cutoff bai ExternalFaultmessage = on bai externalFlowTempDesired = 90.00 bai externalHwcSwitch = off bai ExternGasvalve = 240 bai ExtFlowTempDesiredMin = 0.00 bai ExtStorageModulCon = no bai extWP = off bai FanHours = 1250 bai FanMaxSpeedOperation = 5780 bai FanMinSpeedOperation = 1500 bai FanPWMSum = 58260 bai FanPWMTest = - bai FanSpeed = 0 bai FanSpeedOffsetMax = -580 bai FanSpeedOffsetMin = 210 bai FanStarts = 30964 bai Flame = off bai FlameSensingASIC = 709 bai FloorHeatingContact = off bai FlowsetHcMax = 82.00 bai FlowsetHwcMax = 80.00 bai FlowSetPotmeter = 45.00 bai FlowTemp = 25.88;ok bai FlowTempDesired = 45.00 bai FlowTempMax = 116.06 bai Fluegasvalve = off bai FluegasvalveOpen = on bai Gasvalve3UC = off bai Gasvalve = off bai GasvalveASICFeedback = off bai GasvalveUC = off bai GasvalveUCFeedback = off bai HcHours = 901 bai HcPumpMode = permanent bai HcPumpStarts = 29164 bai HcStarts = 4500 bai HcUnderHundredStarts = 0 bai HeatingSwitch = on bai HoursTillService = 3100 bai HwcDemand = no bai HwcHours = 263 bai HwcImpellorSwitch = no bai HwcPostrunTime = 80 bai HwcSetPotmeter = 62.00 bai HwcStarts = 22600 bai HwcSwitch = on bai HwcTemp = 116.06;circuit bai HwcTempDesired = 0.00 bai HwcTempMax = 62.00 bai HwcTypes = 0 bai HwcUnderHundredStarts = 0 bai HwcWaterflow = 0.19 bai HwcWaterflowMax = 11.57 bai Ignitor = no data stored bai InitialisationEEPROM = no bai IonisationVoltageLevel = 72.2 bai maintenancedata_HwcTempMax = 116.06 bai maxIgnitiontime = 2.1 bai minIgnitiontime = 0.2 bai ModulationTempDesired = 33.0 bai OutdoorstempSensor = -60.44;cutoff bai OverflowCounter = yes bai ParamToken = 3 bai PartloadHcKW = 19 bai PartloadHwcKW = 30 bai PartnumberBox = 20 00 46 39 50 bai PositionValveSet = 0 bai PowerValue = 21 0a 50 18 64 1e bai PrAPSCounter = 0 bai PrAPSSum = 0 bai PrEnergyCountHc1 = 3291922 bai PrEnergyCountHc2 = 0 bai PrEnergyCountHc3 = 0 bai PrEnergyCountHwc1 = 994043 bai PrEnergyCountHwc2 = 0 bai PrEnergyCountHwc3 = 0 bai PrEnergySumHc1 = 776243897 bai PrEnergySumHc2 = 0 bai PrEnergySumHc3 = 0 bai PrEnergySumHwc1 = 383284736 bai PrEnergySumHwc2 = 0 bai PrEnergySumHwc3 = 0 bai ProductionByte = no data stored bai PrVortexFlowSensorValue = 0 bai PumpHours = 2157 bai PumpHwcFlowNumber = 0 bai PumpHwcFlowSum = 0 bai RemainingBoilerblocktime = 0 bai ReturnRegulation = off bai ReturnTemp = 25.75;65123;ok bai ReturnTempMax = 0.00 bai SecondPumpMode = 2 bai SerialNumber = 42 30 36 30 33 34 35 33 bai SetFactoryValues = no bai SetMode = auto;69.0;68.0;-;1;0;1;0;0;0 bai SHEMaxDeltaHwcFlow = 27.81 bai SHEMaxFlowTemp = 83.31 bai SolPostHeat = (ERR: invalid position for 3108b509030d7304 / 00) bai Statenumber = 98 bai Status01 = 25.0;25.0;-;-;-;off bai Status02 = disabled;76;38.0;80;62.0 bai Status16 = (ERR: invalid position for 3108b5040116 / 00) bai Status = (ERR: invalid position for 3108b5110103 / 00) bai StatusCirPump = no data stored bai Storageloadpump = 0 bai StorageLoadPumpHours = 630 bai StorageloadPumpStarts = 21447 bai StorageLoadTimeMax = 45 bai StoragereleaseClock = yes bai StorageTemp = -14.94;cutoff bai StorageTempDesired = 62.00 bai StorageTempMax = 0.00 bai TargetFanSpeed = 0 bai TargetFanSpeedOutput = 0 bai TempDiffBlock = 0 bai TempDiffFailure = 0 bai TempGradientFailure = 0 bai Templimiter = off bai TemplimiterWithNTC = yes bai TempMaxDiffExtTFT = 0.00 bai Testbyte = 3 bai TimerInputHc = on bai ValveMode = 0 bai ValveStarts = 12893 bai VolatileLockout = no bai VolatileLockoutIFCGV = no bai VortexFlowSensor = 0 bai WarmstartDemand = no bai WarmstartOffset = 0.00 bai WaterHcFlowMax = 0 bai WaterPressure = 0.974;ok bai WaterpressureBranchControlOff = off bai WaterpressureMeasureCounter = 231 bai WaterpressureVariantSum = 65534 bai WP = off bai WPPostrunTime = 5 bai WPSecondStage = off broadcast datetime = no data stored broadcast error = BAI broadcast hwcStatus = no data stored broadcast id = no data stored broadcast id = no data stored broadcast load = no data stored broadcast outsidetemp = no data stored broadcast signoflife = no data stored broadcast vdatetime = no data stored general valuerange = no data stored memory eeprom = no data stored memory ram = no data stored scan id = no data stored scan.08 = Vaillant;BAI00;0202;8001 scan.08 id = 21;10;31;0010005484;1300;021068;N6 So far, so good. But the fact this PCB was obviously out of a combi was bothering me so I went about finding how to change the ID. This turned out to be a simple matter of searching around for the correct button presses - which kind folk had already posted details of how to do it. Now it has a new personality, the same as my current boiler! Then things get a bit more hazy. Some people were looking at the ebus traffic coming from Vaillant controllers with the objective of emulating them but nobody was doing the same for Glowworm controls. It's an open question whether or not Vaillant controls could be used with Glowworms but I'd be surprised if they could. However, after adding an extra configuration for the Vaillant external controls I seem to be able to affect some of the registers relevant to flow temperature. For example, sending: ebusctl write -c bai SetModeOverride '0;50;70;-;-;1;0;1;-;0;0;0' results in being able to read back the following from the board: ebusctl read -f -c bai FlowTempDesired 50 ebusctl read -f -c bai StorageTempDesired 70 The first parameter for SetModeOverride is listed as 0=auto, 1=off, 2=water but the pump relay actually responds differently 0=off 1=on 2=on so I'm not sure what's going on. The second parameter seems to be all I need to set in order to adjust the flow temperature maximum and also shows up when using the diagnostics menu on the LCD in addition to being read back over ebus. I have no idea of the significance of the third parameter (listed as StorageTempDesired in the configuration file) but it seems only relevant to HW in the combi models. Maybe someone familiar with the Vaillant room controls might shed some light? CXdump.txt1 point

-

Then a harder hit with a larger tool. Well at least your are happy to get the tools out and give it a go. We like that.1 point

-

@jayc89 that will all depend on how high above the window the gutter is. In our situation the window in the main bedroom is on the side wall, gable end and no gutter. When it’s chucking it down the big drips hitting the metal cill is like a drum. When it happens I generally move out to the spare room where the gutter is just above the window head and the problem is almost non existent.1 point

-

Agree with all of the above. Ring the ARB and let them know exactly what has happened. As a Registered Architect your experience astounds me and gives the professional a very bad reputation. Can you post your original drawings. I’d love to help out in some small way if I can.1 point

-

Pump speed is just a tool to get your required flow rate. Speed is adjusted to over the system resistance, if you have the flow rates you want and speed is to high you are just wasting electric. Nothing to do heat transfer, except providing the motive force to move the water at your set flow rate Temp, on its own isn't the whole story, it's the combined outcome of flow temp and return temp, so the mean flow temp that sets the kW output. Flow rate alters the mean flow temp. You also have floor covering u value to add to the mix. The more resistant the higher the mean temp needs to be for a give kW output.1 point

-

It's all one big experiment. And the golden rule of experimenting is change ONE thing at a time. I would start increasing the water flow temperature. Start with say 35 degrees. Let that settle for a couple of days. If your return temperature is not much lower than the flow temperature then you don't have a problem with flow rate. Is the UFH on 24/7 or on a timer? Is it a case of taking too long to get warm, or never getting warm enough?1 point

-

Pump speed should really depend on how many loops you have and how fast you need to pump the water around them to achieve your target delta T (generally 7c with a flow below 35c). I keep my pump speed as low as possible providing my delta-t looks good. As far flow temp, really depends on your heat loss, which will dictate the air temp. Keep the flow as low as SWMBO can tolerate.1 point

-

You would normally just tamp the foundation concrete with a rake. No need to vibrate. There is no problem having steps in the foundation. You can build on 300mm depth concrete as long as it is far enough below ground so the bottom is protected from frost. Depends on ground conditions. Definitely leave at least 225 bgl. May need to be lower for drainage etc.1 point

-

The Brexit charges are not crazy. It is what the crazy half of this country voted for: an abolition of free trade. i have ordered from them since the apocalypse and didn’t get charged, I think because they still have a UK distribution centre, but not sure. Just email them and ask.1 point

-

Sounds awful - very sorry to hear this. No contract no payment seems like a plan to start with and report to ARB.1 point

-

Did what you said. Water from the flush going past the rodding point at speed. Looks like there's no blockage after all. Thanks.1 point

-

Report him to the regulators, the ARB. If you don’t there may be future victims. He may well already be under investigation already. If you feel bad about this on a personal level, don’t. He could be ripping people off. If he’s not at it, the regulators will establish that either way. Innocent professionals have no issue whatsoever with being investigated by regulators as it allows them to prove they are indeed professional.1 point

-

This looks fraught with troubles. Loosing a downstairs W/C could make your house very hard to sell in future not to mind unusable if anyone becomes unable to use the stairs. Can you post plans of the house. Maybe the collective wisdom could come up with a clever solution that didn't involve so much upset.1 point

-

https://www.vpsunderfloorheating.co.uk/product/prowarm-pro-digital-remote-silver/1 point

-

You have a rodding point, take the cap off and get someone to flush the loo (don’t use it first) if the water rushes past the hole then you don’t have a blockage issue1 point

-

So I would level the run of gutter and clip a 90 degree bend on the end then it would pour down onto next doors garden. That might focus their mind a bit.1 point

-

There is on your roof, couple of £ and an hour or so and you can add a dropper into your roof and forget about it.1 point

-

We've the same size house (355m² gross, 315m² net), and our 9kW heatpump is more than up to the job. Floor U value 0.1, walls 0.12-0.15, roof 0.15, 3G throughout, airtightness 1.7ach. that's not exactly ultimate spec or performance compared to some here, but mucher higher than regs. We need your numbers. Glazing and airtightness matter a lot as well as just all I sualtion.1 point

-

Can the design you have be adapted so that it buildable for reasonable money and still satisfy the planning application you have? It’s another huge expense in money and wasted time (which is also extra cost) to go through planning again. Post up your drawings removing any identifying information.1 point

-

Hi @francis0990, I don't think there's any substitute for structural engineering advice, whether from an independent SE or from the timber frame co.'s SE. As @markc states the doubling suggests load-bearing, and it is not worth taking risks.1 point

-

As @jack says without heat loss calculations you are just shooting in the dark. I am installing a 6kW heat pump and it will heat our house 192m2 and a summer house, 16m2. I expect it to be using around 50-60% of its capacity even on the coldest day. Sounds good, but doesn't really mean anything as far of how much your house is expected to require in terms of heating. There is a calculation spreadsheet in boffins corner on buildhub1 point

-

They do, but your house already has its own heating system which is likely to be more efficient (or certainly no less) than that provided by one in/around an MVHR. Even at relatively low supply temperatures (eg 16C like you say) I've never noticed a cooling effect from the system. It must of course being doing so, but it's not noticeable in terms of cold draughts etc.1 point

-

I would say the water marks on the roofing felt are just run off of water coming down the wall and around the pipe. The damp areas at the lower end could well be condensation forming on the pipe in the roof space. I would bet there is nothing wrong with the pipe itself, more the detail of how it’s. Fitted wrapped etc.1 point

-

Just be careful of air pockets in the tube. We used these a lot in Germany and they were very good for getting in and out of rooms. You can’t beat a decent laser though.1 point

-

You don’t need syringes and no need or reason to measure the amount of fluid. You simply hold the tube in a U shape and add water to an inch or so from the top and it’s ready.1 point

-

We fitted ours after completion. I had quite a problem getting the right register plate to go from the stove pipe to the chimney because the company I used kept sending the wrong parts. Apart from that it wasn't too hard.1 point

-

If you need to pour concrete above ground level at the lower bits you will have to fit shuttering to contain the pour.1 point

-

ooh, that's a nice shiny bit of kit which HID would want instantly if he saw it1 point

-

Attached is a rather long description of the ground source heatpump that I built at the end of 2021. It's completely diy - two 2nd hand fridge compressors(one for vacuuming down, one for the HP itself), bits of bent copper pipe, etc. I've encapsulated it as a pdf so that it hangs together in one thread, and should be an easier read. Thanks buildhub for a big filesize limit! I started out knowing vaguely what I wanted to do, then watching every youtube on R290 compressor systems several times, googling it, reading stuff on "Ecorenovator" etc. The youtubes are especially useful, watching people do things right - or wrong! I've been quite nervous about the safety aspect of R290 (propane) as the working fluid, and anybody who tries anything like this should be too. Propane is a great working fluid - it's not an F-gas, it has a GBW of 3, while most F-gasses are 1000+. But it burns well, so must be treated with great respect - used outside and kept away from flames and electrics. It was quite a steep learning curve - I'm ok at soldering copper pipes for plumbing, and regular electrics, but there was a lot to learn to make it work. Which it does, and we are happy with it - Mrs RobL doesn't accept any low temperatures in this house! There have been minor niggles (a fuse blew, lots of weeping compression joints in the water circuit before I watched a youtube on how to do them right). All the issues have been easy to fix, and I'm comfortable with the idea that I can fix them rather than wait for somebody else. DIY-GSHP-RobL-June2022.pdf1 point

-

Just to update/bring this full circle. I managed to find a local builder who uses "Thor" Helical bars and they have (I hope) sorted this with two long helical bars above the whole window and eight separate bits coming up through the arch. Felt I'd reached the limit of what I was comfortable doing myself and pleased/reassured we've had it done. Next job working out what we put on top. Hugely appreciate the advice on here.1 point

-

I’d keep quiet if I were you… why would you want an uncontrollable hole in your new, sealed, window?1 point

-

The problem is that heating system design work appears to require trudging about in mud and rain on a building site. My architect, structural engineer, lighting designer and MVHR designer some how all sat in comfy warm offices and did a perfectly good job. But my ASHP heating engineer, despite having the exact schematic I wanted supplied to him by the manufacturer *and* by me in my tender pack, still turned up with a bag of different parts, spent a while trying to convince me the design in his head was better than what they tendered, struggled to even read a plumbing schematic, didn't have couplers for the parts being installed, installed some parts upside down and other things like pumps in completely the wrong place, installed a mid position valve rather than 2 zone valves, required 6 returns to site to debug it all into working, etc etc etc the list goes on. So for me the issue is not that the installer wasn't smart enough to do the design: I'd already paid the smart people to do the design. The issue is that the installer is attempting to be smarter than they really are by doing redesign work on the hoof rather than meticulously follow the design given to them. It's like a builder deciding to alter foundation depths and move some supporting beams or change insulation thickness on the fly. Bad practices that used to be the norm but are being slowly pushed out the industry. My hunch is the scalable central design will only be financially viable if coupled with a monitoring and maintenance contract, probably with capital outlay financing rolled in. It's not impossible, but will take some major players to make it happen. Octopus are closest now, but BG HomeCare + Hive surely has to be planning how to pivot into this1 point

-

Hi @Drellingore Daily results for our 5.12kW system this January: Date energy 01/01/2023 1.36 02/01/2023 12.24 03/01/2023 0.45 04/01/2023 1.07 05/01/2023 3.00 06/01/2023 2.52 07/01/2023 3.00 08/01/2023 1.54 09/01/2023 8.42 10/01/2023 0.22 11/01/2023 4.33 12/01/2023 0.00 13/01/2023 12.31 14/01/2023 2.17 15/01/2023 7.52 16/01/2023 6.63 17/01/2023 2.62 18/01/2023 11.80 19/01/2023 14.16 So as @jack points out: its not a constant flow of energy. We looked at off grid and keeping our lifestyle... ho ho! Forget it without massive storage. If we covered all the roof both sides, the front and back garden and everything there would still be inadequate panel surface to supply what we require in the winter. I am with @Radian and wait for decentralised generation and more importantly decentralised storage. I also agree with @ProDave philosophy about self use being king.1 point

-

Is there any particular reason to specifically target "covering our own usage"? I get why it's a target conceptually, but it's actually pretty arbitrary - there's no logical reason to assume that this is the optimal target when you take costs into account. I assume you're going for batteries too. Have you modelled how changing battery and array capacity changes the numbers? Is it possible that a smaller array with more battery capacity allows better usage? Where are you going to put the array? 22 kW is physically huge. For comparison, we have 8.5 kW and this is what it looks like on the (flat) roof of our house. For reference, the house footprint is roughly 160 m2: I assume have three phase? If not, you'll struggle to get approval to connect an array that big to the grid. Apologies if you've already worked through all of these questions, but 22 kW is the largest domestic array I've ever heard of!1 point

-

Thanks for the data! Yep, this works out perfectly. Our average daily consumption is 22kWh (we have two electric cars, family of four). If we extrapolate your generation to our size array, we get: (171kWh * (22kWp/5.12kWp)) / 31 days == 23.7kWh1 point

-

Interesting, I put my GPS logger on today, drove 600 miles, parked back in my drive and the altitude gap was 2' (600mm). But I think a simple water level is the easy way for house stuff. There was a 'thing' in Google Earth were you could run the cursor over an area and it would work out the heights to quite good accuracy. Can't for the life of me remember how to do it. May have been this: View Path's Elevation Profile https://support.google.com/earth/answer/148134?hl=en I am too tired to try it now. Actually, I tried it. Dead easy, but not sure how accurate it is.1 point

-

I wouldn’t make any decisions on renewables based on SEG or any other scheme the Government sees fit to come up with. My plan is still to consume as much as we can generate/store. Any payments for excess will just be a variable benefit.1 point

-

Not from large suppliers that offer reliability and flexibility, but small domestic suppliers are probable a pain to them. As well as that, domestic suppliers are often trying thier hardest to not export. The idea of SEG, FiTs and previous schemes (ask @DamonHD what he has) was to help start an industry, not reward purchasers. The UK is currently trying some very complicated and difficult schemes (just look at what Octopus are doing) to understand. This is mainly because we are trying to shoehorn a distributed generation system onto a centralised generation system, and the easy way to do that is to cut usage, not increase generation.1 point

-

Great stuff. I think the question I would ask if whether at the end of that your house can be easily operated by a random person you sell it to in the future? We have various people around (or no longer around) who have doo-dah-diddled wonderful things that work great, but only potential with themselves as embedded maintenance engineer. One of our members looked at the great thing he had created, and then wrote a manual for his partner for when he popped his clogs. I wrestle with this as a small LL making houses as efficient as possible but still suitable for tenants, and needing to be "tenant-proof". Do you have strategies for *that*? My strategy is to keep it very simple, work to long time lines, make sure I have enough money to employ engineer or handymen, and to have done most things myself at least once so I hope I have a clue.1 point

-

Pump speed is low . Have the self regulating actuators so flow and return don’t deviate much . I guess it’s the SWMBO factor - which is hard ( impossible ) to define ….0 points

-

You are doing that backwards. Dig the trench to the depth required, pour the foundations, build the wall and THEN fill in any low ground to build it up. Remember building up ground inside the building that will support a floor can't be done with any old spare soil, it must be inert and clean and something that will compact well in layers. Your general "spare soil" pile is only of use for landscaping outside the building. We bought in several lorry loads in inert non organic infill to build up the solum and used all the spare excavated soil to level the garden.0 points

-

Excellent. Roughly the same delay as mine. Spent it already though 😕. Lend us a fivver will ya?0 points

-

0 points

-

Found this quote on Google: but the associated link does not work. "ZIPLEVEL® is a high precision pressurized hydrostatic altimeter. It works much like an aircraft altimeter that measures the weight of the air above it except that ZIPLEVEL does not use the atmosphere to measure elevation."0 points

-

Theodolite, which is a challenge to spell or even say, hence the common term ... which I don’t know the origins of thinking about it ...0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)