Leaderboard

Popular Content

Showing content with the highest reputation on 02/07/22 in all areas

-

Surely the appeal is not against @oxo. The "appeal" will be a judicial review of the Council's decision. So the appeal will be brought by Oxo's neighbour against the Council. Oxo won't have locus to make any intervention in the appeal and so shouldn't incur any costs.2 points

-

Not sure what the position is specifically in respect of planning, but generally, on an appeal there is no automatic stay of execution pending the appeal. That means that as long as planning rules follow the same rule that applies to general judgments, the current planning permission that you have is perfectly valid even though it is (or might be) subject to appeal. If that rule applies, you should get on and build ASAP as unless your neighbour has applied for a stay of execution pending his appeal, then there is nothing stopping you from building. If your build is largely finished it will make any appeal largely academic as it would pretty much be insane for the appeal court to overturn the planning permission and force you to tear down your build. So the first thing to check is: Has a decision letter been issued granting you your planning application? If so, then the courts have held that the issue of a decision letter is the step required to grant you permission. (R v West Oxfordshire District Council ex parte Pearce Homes Ltd [1985]) Next thing to check is whether your neighbour has actually obtained a stay of execution. If so, you would know about it as it would need to be served on you. I think this is unlikely. I wouldn't ask him/her for it, as you don't want to encourage this. Next thing to check is whether there are any other rules that might affect this, or whether the position is as the case for normal court orders, which as I say is that there is no stay of execution. Crack on!2 points

-

I've recently had the exact same problem on the same heat pump. E911 is the lack of flow error code - this is what you get if there isn't enough flow through the primary loop. E912 means the flow switch is detecting flow when it believes it shouldn't. I was seeing this error about 10 minutes after there was no call for heat. In my case a relay in the control board was stuck closed so the primary loop circulating pump was running even when the controller thought it wasn't. I could confirm this by turning off the power to the controller and turning back on - the primary loop circulation pump would start up immediately every time. You can also check by going into self-test mode (you'll need to hold down up and down arrows on the controller display, it asks for a code, input 0202). In that menu there is a self-test option which you can turn the circulating pump on and off manually. If the pump stays on when it has been turned off in the menu you'll know the relay is the problem. I was able to fix mine temporarily by powering off the controller, opening the box and giving the relay a tap which caused it to start working again. I got a new PCB under warranty from Freedom Heat Pumps who supplied the unit, which has hopefully permanently fixed the issue.2 points

-

In a way I'm glad that the post has generated such a healthy amount of discussion including some deep, somewhat philosophical arguments about what constitutes beauty and what's a good design etc. I'm going to stick to my guns and say I still really like the frontage. Not because I have to dig my heels in and back up my initial assertion, but because I truly do. My wife does, our families do and even some of our close friends we've shown it to. Some of that may be politeness but not everyone would collectively lie to us if they were that drastically bad. I will concede that none of them are self builders or immersed in the topic as deeply as the posters on this thread, and that was exactly the reason why I posted and kept coming back on this forum. Yes, I have seen better designs and I have seen worse designs. I would even put my neck above the parapet to say that I actually liked some of the designs on the McMansion website posted earlier. I see nothing wrong with designing a house that has a wow factor. Why shouldn't you feel proud of something if you're spending that much time, effort and money on it? It will still be built with fabric first principles - airtightness, thermal efficiency, MVHR, ASHP, UFH and now increasingly likely to include Solar PV connected to DHW. But that doesnt mean I want go for a bland square box or design only for efficiency. I am incorporating the feedback into my discussions with the architects and see where this takes us. Don't disagree with the fact that time spent now at the design stage will save us a lot of grief later, though its really hard to reconcile when every fibre of my being just wants to get the plans submitted so we can feel a sense of achievement for checking that box! Budget wise, my thoughts have been massively refined since the time I posted my other costing thread. 2 visits to the NSRBC and Build it Live this weekend lead me to believe £2-£2.5k/sq m is achievable and that's a much easier pill to swallow as compared to the £3.5k I was being quoted earlier.2 points

-

This is just such a no-brainer. Watched a TF company put a 300m2 build up, including passive raft foundation, all to passive standards, in 31 days. AT score was 0.27 ACH. If you want the satisfaction of self-building, go for ICF ( just not Velox ffs ), but if you want your sanity and marriage in one piece go turnkey TF. By the time you've buggered off to choose your bathrooms / kitchens and floor coverings, the house will be most of the way up.1 point

-

Then it will be a terrible benchmark and not apples for apples. Here people are mostly self / new building for themselves, developers cut any and every corner to make a fast buck. Even the "good" ones are not great. Premium is just the price the buyers paid for dwellings which were likely a load of shart.1 point

-

1 point

-

Your input has been incredibly helpful and it's genuinely appreciated. Without the help from this forum, I don't know what state we'd currently be in!1 point

-

They might have bought some fancy headed paper ... and swallowed a legal dictionary1 point

-

Could it be a bluff? I got sent a letter threatening an injuction, but it was to force me to sign a Covenant.1 point

-

go with timber kit i beams and blown celluose insulation, no blow outs and no cutting of woodcrete1 point

-

Heavy doesn’t bother me I’m big and strong, and the fact that it’s heavy is why it doesn’t blow out so easily like EPS, I’ve seen some of the disasters with EPS, even the woman on the TV who used Nudura had blow outs and walls buckling. Any system is only as good as the people building with it.1 point

-

Here’s my thread from a few months back. It depends I think on what type of suspended floor - mine was a ground floor, beam and block.1 point

-

1 point

-

1 point

-

That sounds expensive, but is to them too. Such claims do not reach the high court until reviewed at a few levels, and can even be thrown out at the last minute, on the basis that this is not a good use of the court's time/ should have been negotiated elsewhere. I would guess the court cost might be £10-20k if it goes that far, and you would get most costs back as long as you win. An expert lawyer should give you a forecast of the likely outcome. I would be surprised if a court over-ruled the planning appeal unless there was a blatant disregard of a written principle. Is it bullying or red mist? Has anyone said you must hold up the works? If so, then I think you can state that you will seek reparation for abort costs, when you win. If not then what happens if you lose?1 point

-

Keep fighting . Don’t quit . What are their reasons to object ? . Most neighbors are full or shit ; make lots of noise but don’t do much1 point

-

That’s ok saying that, but they do their research over the internet with a few pictures. Nothing like being on a site and watching the troubles unfolding in front of you. And it wasn’t my place, so no financial loss to me, just horrified at the grief it caused to the builder and the financial loss to the home owner.1 point

-

1 point

-

If you replace the PCB don't let them take the old one away. Most relays are pretty cheap and if they are through hole mounted types I'd have a go at replacing the relay so you have a spare PCB for the future. Edit: Heck you could probably even find a better relay.1 point

-

@Siggles I'm delighted that's solved the problem. I think there may be a batch of PCBs with a component issue (although no-one admitted this) so I guess not too surprising that we've had the same problem. I'm also pleased that anyone googling may find this thread as when I was looking there was very little information out there on the issue. Hopefully this will help others.1 point

-

Thank you again, you are a legend! ? I'll let you know how I get on.1 point

-

Actually turns out I already had a photo on my computer. The things I've circled in yellow are the relays on the boards - the black rectangles. I'm not sure exactly which one it is that controls the primary pump so I just gave them all a hard tap - like a flick with my nail. In my case this got the relay moving again. It is possible for the relay to have welded shut if there has been an arc across the contacts at some point. If that's the case I don't think you are going to be able to get it moving again and will need a new PCB or relay. Good Luck. Btw if you do need a new PCB then Freedom Heat Pumps are a UK distributor for these Samsung units and AFAIK also administer the warranty on behalf of Samsung. I still think you would be best going back to the people who installed it and asking them to help, but I believe Freedom told my electrician that a new PCB was about £180 if you need to buy a new one.1 point

-

I think we import the majority of our timber. They problem is going to be getting it out of the woods, those single grip harvester machines are amazing and I would think the operators are going to be on double bubble for a while. Those almond farms are insane. People are always surprised at how sterile the Sitka plantations are when you walk through them, you don't see whole lot of wildlife. There's about 30 acres of mixed forest at the back of our house and it's teaming by comparison, roe deer, red squirrel, foxes, badgers and loads of birds.1 point

-

An EPS ICF should be below £170/m2, based on external dims and for the sake of it, include all openings in the area calc. This would be supplied and fit, Inc concrete, rebar, pump, labour, props etc. Render on the outside may reach £50/m2 of wall. Plasterboard and plastering to finish internals, £40/m2. Of wall. Your 17x8 building is going to be in the region of 125m2 of wall so all in, less than £35k. Groundworks excluded. Shell is then £277/M2 of footprint. Or less than 15% of your 1800min budget. ICF over sips: one main advantage is that it doesn't support mould like timber does.1 point

-

Sounds sensible @Thorfun When you connect up the loops you can fill each one individually by closing off all the other valves except that loop. I found this much easier to make sure all the air was out of each loop and to pressure test each one seperately. Have fun.1 point

-

I reckon you can do an infill panel both sides and make it a feature, sort of framing the door (no pun intended). think of accent stripe1 point

-

If it’s a upvc frame, they do frame extenders. Will look a bit shite, but hey ho.1 point

-

That is so helpful Andrew, thank you very much ?1 point

-

Latest update, contacted the MD of the MHRV company, who had his top man contact me and replied back with a list of things that are wrong with the installation. The main one that could have caused the problem being the drain is fitted in the wrong position. The plumber fitted it after the T junction and it should be between the machine and the T junction. I sent the reply to the installation company, who have contacted me this morning and will let me know what can be done. Hopefully it will be working again soon as having to open windows when having a bath and then jumping out to close it when rain starts being blown in is a pain. The only place we have found any mould while the unit hasn't been working, is right at the bottom of the rear bedroom window. We shall see what happens! Cheers Dave1 point

-

Defrost cycle simply fires up the HP pump. only, and the water from the buffer is used "in reverse" eg it is then the HP which is 'heated' by the warmed water in the buffer. Pump flow ( direction ) stays the same, as confirmed above.1 point

-

@SteamyTea I think the Tee is a benefit here as it'll promote flow into the buffer, the UFH is only supping from that. @Nickfromwales no, circulation doesn't reverse during defrost.1 point

-

Do you think including building regs? My guess is 15k and *then* building regs lol I wouldn’t do 3Ds for free.1 point

-

Hey @Indy could you give us a rough idea how much the designers have charged you so far? I always find that really interesting and would love to know for when I do it myself.1 point

-

1 point

-

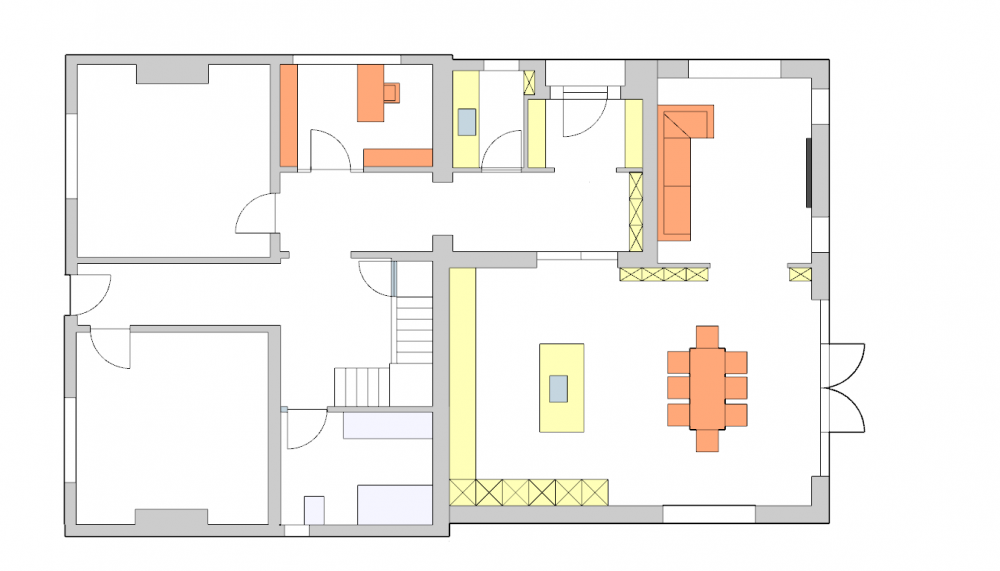

It's a matter of a couple of thousand maximum. Well worth it. Here's a similar effort to yours. I've made a separate utility and a walk though boot room/porch. I think this would be nicer than the design you had. More suitable for a main entrance. Your kitchen location might be better however. I don't know if the window to the north I've included will work with obstacles/views. A quick internet price up shows the French doors with fixed side panels costing 45% of the equivilant bifolds with much better performance.1 point

-

1 point

-

This is grand design kind of design and very pretty and modern but would it fit on the road and get planners approval easily and to everyone's taste, I am not sure about it as neither I dont know the road nor I know the personal preference of @Indy I.e. traditional/moderns etc. I know if you are even closer to conservation kind of area you would struggle as know a similar case. That front porch in OP is a quite overpowering and the too be honest comparatively I liked the original design and the recent update has made it worse. Why is that huge porch required. If you remove it you could alternate the roof design and designer will have more flexibility in respect of the front facade. If the porch has been recommended by the architect, I would suggest seriously consider the design approach and as other have suggested create a pinterest board with respect to design you like. For a project costing £1m or more as OP suggested, please dont rush the design phase. That's a key phase. The comments here have been brutal but given the amount of money OP is going to spend the thinking/designer need a good shakeup.1 point

-

I've gone for recirculating. Yet to install the kit (first week in the house) and 100% sure it'll do the job.1 point

-

We have literally just finished fitting aluclad from Allen brothers. Thier aluclad are actually manufactured in Denmark by their sister company but we only dealt with the UK side. Great communication, delivery and good products. We are very pleased with them, in my opinion great value for money which I guess is what you're looking for!1 point

-

1 point

-

Nice big fat 28mm pipe looping up over windows & doorways. That seems to be what Gas Safe thinks is the bees knees these days. I have a rental property where they insisted on switching out 15mm from the meter to 22mm when fitting a new boiler. Only way was round the side of the house but that was a shared corridor so they poked it right through a ground floor room and out the back wall. Then they ran it over the top of a brick barbecue I'd built against the back wall ?1 point

-

The rebuild cost influences the premium. My last 12 month premium was about £500 with £10k cover for the static caravan but no tools or plant hire insurance.1 point

-

you will need a completion cert and warranty.1 point

-

We are just asking for quotes Last time we covered public liability and the house and garage against fire and vandalism As soon as you start covering plant and tools The insurance seems to jump up £605 four years ago with Protect Be careful not to have to extend for a short period as they charged nearly the same for an extension of 6 months1 point

-

What does that include? Ours was about the same price and covered Site caravan and content, own plant but not hired. We bought our own telehandler, digger and dumper. We did it through ProTek At the time they didn't do the structural warranty though.1 point

-

It looks a nice site, and the floorplan layout is not bad, but the elevations give the impression of a design made to look quaint, but with no thought given to cost and complexity of build. I fear the present design is going to work out difficult and expensive to build while giving no obvious benefit over a simpler design other than looking quaint.1 point

-

I’m doing mine with a liquid dpm as the natural stone is not flat. so 3-4 courses of stone then painted on dpm then carry on up in stone.1 point

-

1 point

-

I believe we have a big problem in our heads about u value. The standard Nudura blocks on paper look terrible, but combine that with good build quality and an airtight building and it’s all you need. In my humble opinion.1 point

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)