Leaderboard

Popular Content

Showing content with the highest reputation on 01/07/22 in all areas

-

5 points

-

2 points

-

Don't feel bad, every self builder has a similar story, if not ten. I spent a weekend removing and replacing board to get last minute UFH trunking in for the bathrooms but similarly forgot to do some things that would have made my life so much easier. The lesson we all learn is, put the duct in when it is easy and worry about what will get pulled through it later... In relation to 'home cinema audio' we put in cable for 4 wall speakers in the living room and hooked up a cheap LG home cinema / DVD unit which was ok but is now a bit flakey (volume randomly increases and decreases). Stopped using it and got a cheap Sony sound bar as the late TV audio is not great and it's fine for the vast majority of viewing. Now have 4 unused speakers on the wall and a vague plan to upgrade to a proper 5:1 av amp some day in the future. I've always felt that a lot of audiophile 'science' is just marketing nonsense (I remember the fad for 'oxygen free cables') and to persuade people to part with £££. By the time you're in your late 40s/early 50s I would suspect that your hearing range is suitably diminished so as not to be able to tell the difference - even though you 'know' it's better. Similar to those blind tests where the experts can't differentiate between £100 and £10 wine etc..2 points

-

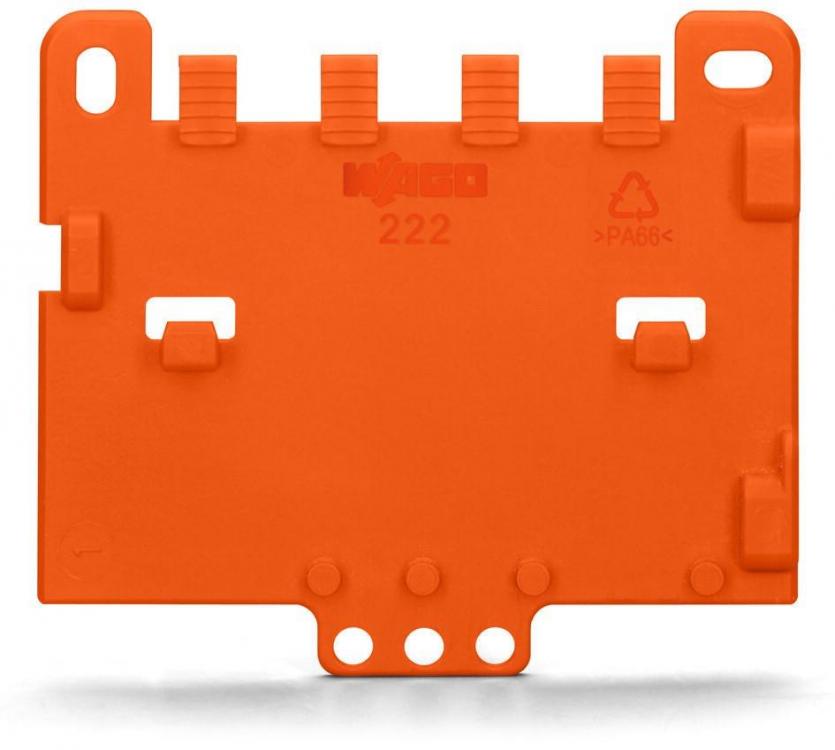

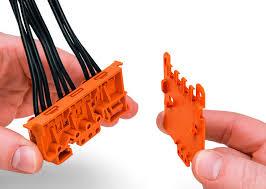

You can get a strain relief plate 222-505 which has holes in to screw down: https://www.wago.com/gb/installation-terminal-blocks-and-connectors/strain-relief-plate/p/222-505 To which you clip mounting carriers: Good old chunky 222 connectors in a 222-500 carrier: Or the newer 221s in a 221-500 carrier, so the same plate fits both: You can see with the 221s you can flick the lever still/access the wire. With the 222 you have to faff and slide them all out potentially to get to just one. Which is why I designed my grey 3D printed ones. Now if I had some orange filament...and it was fire retardant...? Tbh I find navigating the Wago website and part numbers only slightly less confusing than Geberit!2 points

-

We left you with a poured slab and we were chomping at the bit to get the ground floor Nudura walls up before the end of the year. Well, I am glad to report we got there - almost ? After getting the slab done, I figured I'd get ahead a bit and it would be a good idea to talk to someone about the waterproofing we would have to put on the outside the walls before we started backfilling. To cut a long story short using waterproof concrete in walls such as these is a complete non-starter, so Type-B waterproofing cannot be used. Visqueen's R400 Radon barrier is not an effective waterproofing method and so we now face having to use a Type A and a Type C waterproofing method - basically this will mean for us a waterproof screed being added to the floor with channel ducting where the walls meet the floor and the "egg-crate" plastic material across the screed and up the inside of the walls. That should eat into our contingency ? ? ? But also it meant a dash to get some waterproof slurry to paint round where the Nudura blocks would be laid the following morning and mixing and painting it on under floodlights (it's the dark grey stuff in the picture to the right). Oh what fun!! But, the following day we were up early to welcome out walls, the bracing and two fine chaps (Louie and Harry) from The Fell Partnership who would be helping us Day 1 to get the first row in place. We then scurried around unloading things off trailers and flat beds, and installing the waterbar between those pieces of upright rebar. By 10am we were ready to go. By about 2pm we had most of the first row in and part of the second row (see below). If it hadn't been for some non-standard corners in the design, we would probably have been at Row 3, but that's what you get for following a design religiously ✝️ (FYI - the T-corner is all to do with the design - don't ask yet) On the second day we were left to our own devices, I had to make a dash to collect some extra Nudura parts and some waterproofing equipment (due to the direction our waterproofing system now had to take) so we made a later start but still we were very pleased to get up to 4 rows installed. Day 3 we were ready to begin installing all the bracing system, and after hitting her head SWMBO was made to wear the Christmas present from her children. and on Day 4 it inevitably rained in Cornwall ? , but before our help arrived again we had managed to just squeeze a block on to Row 6 (the final row before the first pour of concrete) After the help on Day 4, we continued to finish things off on Day 5 by constructing part of an internal load bearing wall, and a wall with the only window opening at this level which will be for the family bathroom. FYI - the rest of that side of the house will consist mainly of windows into bedrooms plus some extra small sections of walling (to be determined) Where we were not able to complete things before the pour happened (time didn't allow) was where the internal wall meets the external wall and there are two doorways to construct (this is why I said we almost made it). I will have to do these in the New Year, mixing and pouring the concrete by hand (just under 1 cubic m) so that'll burn off the Christmas pudding ? A week later (during which we had some more high winds) I came back down to finalise a few bits (like lack of scaffold planks and bracing in some places) to be greeted by a snaky ? wall. so that was all straightened up, the rest of the bracing fitted, and the Nudura joist hangers inserted. (Between straightening and the pour we had Storm Barra, but my remedial work held up nicely) I won't bore you with pictures of hunky men doing manly stuff with concrete pumps etc. but suffice to say it all went very well, with no leaks or blow outs so "he who shall not be named from Channel 4" would have been very disappointed if he was allowed onsite. And so, last weekend (after a midweek pour in the remnants of Storm Barra) I was able to deconstruct the bracing and we are now the proud owners of some freestanding, high-wind-proof walls. Really happy at the attention to detail that Louie and Harry paid to ensuring the walls were straight and true before the pour began - right up my street. So now we have a tidyish site again (for a short while) ready for steels installation in the New Year. We have to finish off the internal wall, then waterproof and backfill outside, and install joists and flooring before we can continue with building the upper floor walls. We're hoping that by middle of next year we can start on those upper floor walls. So until 2022, and the inevitable next lockdown, I wish you all a very Merry Christmas ? and a Happy New Year ?1 point

-

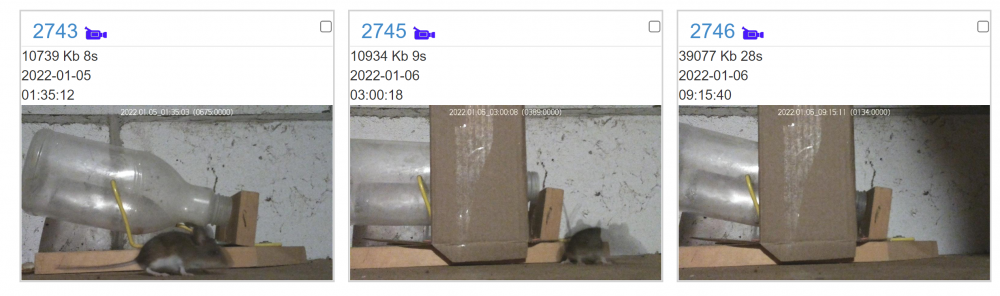

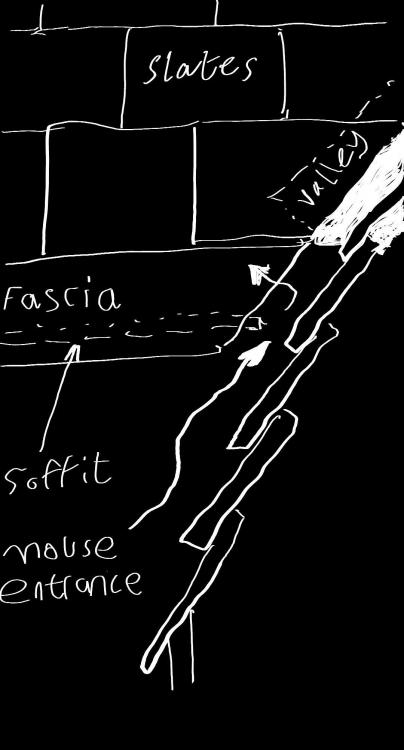

Every Winter we get at least one unwelcome house guest in the loft. This year is no exception.? The night before last, the little bu99er climbed on top of my DIY seesaw bottle trap locking it down with him on the outside. Look how he frantically wants to get inside to munch the peanut in there! How ironic. vi_2743_20220105_013504 (1)_Trim.mp4 So yesterday I made an arch out of a cardboard box to stop him climbing on top. At 3AM he got the bottle half way down by gingerly leaning into the opening, but it wasn't until later that he lost all will power and got completely inside. BINGO! Next stop, the back of Sainsbury's car park two miles away ? In the past we've released them closer to home (across a busy road) but on more than one occasion the same mouse has got back in the loft the following day so now we take them for a longer ride. Pure coincidence there's a nearby Owl sanctuary between us and the supermarket.? Ahem. At least we give 'em a sporting chance. But enough of that. I want some ideas how to stop? getting in. I think I know where as there's a very obvious entry point into the soffit box. This seems inevitable because it's where the eaves meets a perpendicular roof at a valley something like this: The cross section sketch shows the mouse entrance at the gap between the timber fascia and adjacent roof. The gap is necessary as water cascades down the GRP valley and down to the lower gutter. Looking at this junction from the inside of the loft I can see daylight here. The obvious solution is to spray foam the gap from inside the soffit box but this will bridge the fascia to the valley gutter and rot it out. The eaves have plastic vent trays all the way along the bottom of the first row of slates but stop at the gap no doubt for the same reason. Seems like a stupid design.1 point

-

Mostly satellite here, Terrestrial is not a good signal. While we do use IP tv for some things, it still just seems so "wrong" to be using precious bandwidth on a creaking poor internet system when that high bandwidth data at keast for broadcast tv is better provided with an aerial.1 point

-

Bloodyhell Peter Checked at 445 nothing Great spot Both of us where feeling really down Not sure what conditions are As there is no decision notice though Perhaps going on Monday1 point

-

I got a new supply from Anglian after much faffing about. The people in the office are mostly planners/administrators, I found the technicians very helpful once you get them on site. As mentioned, report it as a fault or even better, a suspect leak ...1 point

-

Go and buy 20 sheets of that cortex plastic £3.50 a sheet in wickes and cover the whole floor, tape it together with gaffer tape. You will save the 60 odd quid in the long run by not having to scrape the floor off and having problems with tiles sticking if it’s covered in plaster dust.1 point

-

Thanks, it's cedral on ground floor and standing seam steel on first floor and roof.1 point

-

I would be interested to know what they have done to make it a trickle. If still not resolved I would move into the caravan and report it as a "fault" Some heavy handed politics going on here with your water company I think?1 point

-

You can only buy online from Burncoose, although they do have some gardens you can visit.1 point

-

Some of us know a lot about very little. Some know a little about a lot. The above trades were people who knew very little about very little, but didn't know how little they knew.....they are scary... and they are out there now.1 point

-

I thought the anhydrite screed was gypsum based anyway? If you are tiling you need to lightly sand off the laitance and that should get rid of any other imperfections.1 point

-

1 point

-

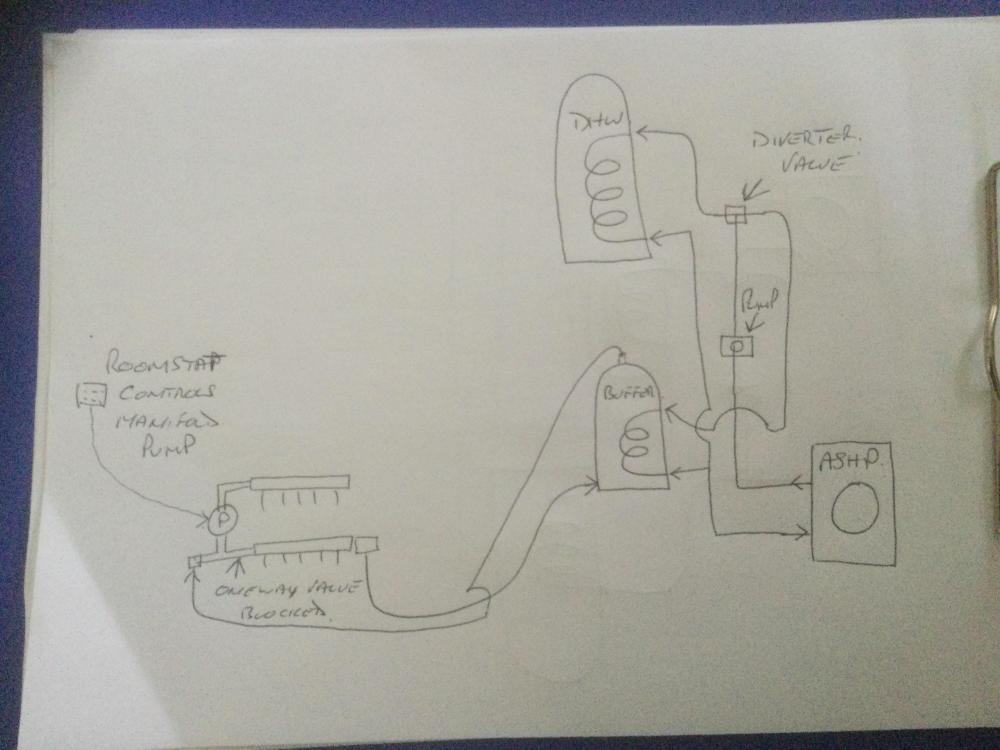

Monitor the temp of the pipe from the diverter valve to the DHW tank when the buffer is heating. It should drop to ambient. If not, the diverter *isn't*...1 point

-

Someone on here did a grid matrix of the various panels that may be worth searching out. A rot proof core is worth going for. Your call on the tray replacement. Now would be as good a time as any but if it does/will not leak you could leave it.1 point

-

As the other bloke said, why not make rough openings 70mm larger than windows 25mm insulation both sides and 10mm wiggle room and foam.1 point

-

Thanks, I've requested a quote from them just now so will see what they come back with.1 point

-

I would stick with multi panel, utilise good quality sealants and re do it again in 10 years. maybe invest in a shower tray with an upstand?1 point

-

I use British Hardwood https://www.britishhardwood.co.uk/ordering-and-faqs1 point

-

Get some echiums. https://outofmyshed.co.uk/tag/echium-growing-in-cornwall/ They grow very fast, and tall. So tall, mine fell over.1 point

-

From a financial point PV doesn’t make sense Unless like Dave you can pick it up cheap and self install Our predicated saving was £200-300 per year So we ignored planners and didn’t fit On our second Our sap guy is very much pro PV and stated as we will have ASHP we could save as much as £500 annually But conceded with batteries 8-10k install As PV installers are hiking up there prices Due to Covid Of course ?1 point

-

For such a small creature they don't half make a racket! I'll also swear I could hear our latest one snoring when I was working in the loft shortly before we trapped it. I find WiFi cameras extremely useful for aiding the removal of these pests. I have a Raspberry Pi camera permanently in the loft for this purpose. The Rpi Cam Control software has motion detection and I've set it up to notify my phone when triggered. I find with the trap I made I need to get to it asap as the mouse has nothing better to do than chew its way out. These days you can get a WiFi camera up and running for less than £8 each if you don't mind programming an ESP32. Makes for an almost disposable item!1 point

-

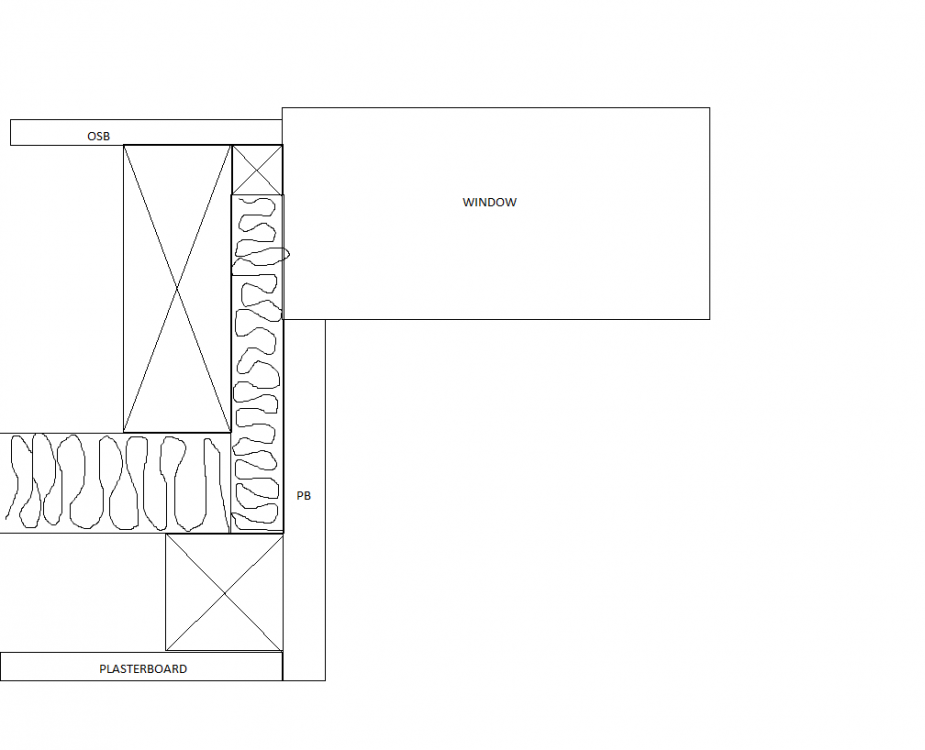

What is typical up here is for a 25x25mm batten to be fitted to the inside of the kit (at the outside) the window then sits on this and you can put 25mm PIR on the reveals and tape them to the internal PIR/ window to complete your airtight barrier, this relies on the window openings being made big enough though, your frame is already up so i think you will struggle to fit insulation in the reveals as there will not be enough room around the window1 point

-

HP12 Base Fibre mesh Then any K topcoat Alternatively LW1 6 mil then mesh Leave for three hours The 10 mil of LE1 Scape following morning If you need Something in writing Speak to Warren or Chris Or Kathia Vallester in the K rend office1 point

-

Right, been monitoring this fir a while, when the DHW tank calls for heat it’s topped up fairly quickly (fir an ASHP) with a flow temp of 50.5’ and the diverter valve fully open. When the buffer calls for heat (tank stat) the flow temp is about 40’ and the buffer never gets to the stat temp of 35’ despite running fir hours. When the room stat calls for heat which energises the manifold pump the temp at the manifold rises to 30’ but falls within the hour as tho the ASHP/buffer cannot keep up with the demand. I have tried slowing the manifold pump down but this makes little difference. I cannot understand why the DHW tank is heated fairly quickly to the required temp but it fails to heat the buffer fully and keep up with demand. Luckily the house rarely needs heat due to good insulation. Any ideas chaps? (I have checked/bled for air etc)1 point

-

another vote for beechwood here, they're just down the road from us.1 point

-

It's been a few years (10), but I purchased about 200 ish laurels from beechwood, via ebay at the time, all bare rooted. No problems whatsoever. I just heeled them into the vege patch in bundles when they arrived, and transplanted them when time allowed.1 point

-

Because these flints are quite thin as in not fist size "blocks". Many are basically conical. They've been selected for their feature face rather than suitability for a "wall". Just don't think I'll have the "sticktion" with straight mortar. Hence trying to find something super sticky. Flints are notorious for being impermeable. If you use a cement based mortar it will shrik away from the flint leaving it "rattling" around in there. Water gets in the gap between flint and mortar, freezes, blows and the flint falls out. A lime based mortar retains flexiblity which is why it's traditionally used. I'm using a part lime mortar mix with modern admix. Once in I'm going to overpaint the whole lot with some sort of a sealer. Hopefully that'll creep into any gaps and aid them staying there. Where no man has gone before etc!1 point

-

We used Hedges Direct at our last house and this one. Good quality and choice. https://www.hedgesdirect.co.uk/ Burncoose Nurseries in Cornwall also a good supplier. https://www.burncoose.co.uk/site/index.cfm1 point

-

Geocel Pro Flex Soudal Transpacryl. Everbuild Crystal Clear DL Chemicals Paracryl Some go on "cloudy" then cure transparent.1 point

-

Looks like a field/wood mouse. I'm sure it could scale the wall and get in as you suspect, but my money would be on it getting in nearer ground level and going up the cavity.1 point

-

Looking for anything specific? I've had some good hedging and small trees bought on-line at good prices from Beechwood Nurseries (3fatpigs.co.uk), and had a couple of hundred lavender plants from various places. Bigger trees from treescapenursery.co.uk, but delivery will probably kill it for you. Good to buy local if you can; it's surprising what you can get at wholesale prices if there are growers in your neck of the woods.1 point

-

They might go and die somewhere inaccessible and decay with a nasty smell. Also the poison can be passed up the food chain and do lots of damage to birds of prey that are quite helpful keeping rodents at bay. Simple traps or a cat maybe.1 point

-

Hi Joe we have used Sunnysidenurseries On eBay Quick delivery and plants have always arrived in great condition1 point

-

1 point

-

Any one with experience of taking the risk of self building while on a standard mortgage with usual high street lender (disclaimer: I am not in way encouraging this risk taking ?). It would be good to know hopefully not too stressful stories.1 point

-

1 point

-

just dropping back in after a good while away, saw this post, i agree with @joe90, can't see them unless looking hard. i had my roof hooked on and it's great. takes longer to set out but you save time in the fitting. there is also less chance of breaking due to overnailing as per another post asking how tight to nail. the other plus point is with having to double nail, replacement is almost impossible, however, bend a hook, slide out slate and replace. one thing i have found is that when replacing one, sliding it in on top of a slate ripper makes it easier to place the head over the counter battens. i would also suggest you don't need to keep the required overlap as the tail can't lift so would save in the quantities required.1 point

-

It was more frustrating than anything and we were kicking ourselves for being a bit naive but it worked out in the end. I can PM you details of a very good broker who we have used on every re-mortgage since the build if you like?1 point

-

1 point

-

Two BH members knocking lumps of one another: how about helping @CotswoldDoItUpper instead ?1 point

-

You can generally pick up an empty bottle from ebay or Facebook marketplace for £20-30 and then get it filled, cheaper than the alternative. Also your local tip might have a some "for sale"1 point

-

£120 for 2 bottles. Thankfully I moved out of the caravan and into the new house before Christmas so don't have to worry about gas bottles again! We are in West Sussex for reference.1 point

-

1 point

-

I was convinced it had to be a rat (if not a badger!) based on the noise. I sounded like someone loudly gouging out wood with a chisel.0 points

.jpeg.18753b8b9fc79accf3dcf1c663cecf3e.jpeg)

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)

.jpg.8c190979063ba43fe4ac51f7b323e311.jpg)

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)