Leaderboard

Popular Content

Showing content with the highest reputation on 07/10/19 in all areas

-

We've just finished our standing seam roof using a roof from Blacho Trapez. The roof cost less than half the quote we had from Catnic for a Tata Colorcoat Urban. At around £15/m2 for the roof sheeting it represents good value. Buy the time you add eaves and barge detail you can add another 1/3 to this figure. Transport will add significantly as a lorry from Poland will cost nearly 2k so sharing transport is important. This post is to let others know how we got on with the roof and hopefully help when they are considering which standing seam roof to go with. This is our first self build and we have no first hand knowledge of any of the other standing seam systems on the market. We came across the roof by chance when another buildhub member @Patrick posted that he was looking for other members who would help share transport costs. Patrick knows far more about the roofing system that we do and is now in the process of formalising an agreement with Blacho so that he can help others order and import roofing products from Blacho. Blacho are based in Poland where steel roofs are far more main stream than here. They have many roof designs, we selected their Retro 25 system which is very similar to the Tata Colorcoat Urban system. Once you have selected the roof style, you then select from a range of 8 input sheet materials. These range from a basic sheet offering just 10 years to a Krupp Pladur sheet offering 50 years protection. Included in the range is Tata HPS200 ultra. The price of the Pladur sheet is not a lot more than the HPS200 and it was our first choice. However the Pladur product is not a know quantity here, so we selected the Tata option which has a 40 year warrantee and widely known so won't cause any undue questioning form building controls and insurance. Here is a link to the roof catalogue:BT-Katalog-2018-EN inch revised.pdf Ordering a roof is more complicated that you might think, with soffits, barge boards , eaves edges, pitch, etc to consider. After a couple of iterations with Patrick doing the communication with Blacho we ended up with a roof order. The roof comes palletised, so you need plenty of hands to help unload if you don't have plant on site. Installing the roof is pretty straight forward, I'm not going to attempt to duplicate the resources provided by the manufacturer. The following is a condensed “lessons learned”: You may think your roof is square, it's not. You can lose small inaccuracies when dealing with tiles. Big sheets of fixed size show every millimetre of any discrepancy. Check you can get the sheets to the area of roof they will be installed on. We didn't and three 7200 sheets we had for the rear roof ended up being cut and joined. If we did it again we would not have any sheets over 6500, they just get too fragile. Get your datum lines right, check and recheck. We used the time honoured and infallible 3-4-5 rule to get our datum lines. For the most part this worked fine but on one section of roof where we started with a thin strip to get the even sheet distribution, we failed. This resulted in a 10-15mm error over 3500. It was the area round the roof lights, which themselves turned out not to be square in the roof either! Avoid sheet joints if you can, they are fiddly to make and add to the installation time. Use string guide lines. We didn't and paid for it with small discrepancies that could have been avoided. The apex of the roof is one area that we found difficult. It looks OK but does not bear close inspection. Use a sheet nibbler. Unless your really skilled with tin shears they make getting an acceptable finish achievable. The devil is in the detail as they say..getting the barge boarding and eaves edges right takes quite a while. We opted for a “Swedish eaves” edge that involves folding the roof sheets over the eaves former. Great for preventing any wind getting under the sheets but makes getting the guttering correct difficult. The rain runs off the sheets at quite a rate and can easily overshoot the guttering edge or get caught by the wind and blown over the back edge. We ended up running flashing to the inner gutter edge. It can't be seen and should be a belt and braces solution.4 points

-

2 points

-

Thoroughly enjoyed that. Not a f***ing Scooby what he was on about mind. Head hurts.2 points

-

Aldi special. Easy to return if crap. https://www.aldi.co.uk/workzone-cement-mixer/p/086066228031800?gclid=EAIaIQobChMIxbavsNWq4wIVRPlRCh2AzQqNEAkYBCABEgKeXfD_BwE&gclsrc=aw.ds2 points

-

Disagree on the dreamer part ?. Dreams and determination will get you where you want to be.2 points

-

We have three floors in our new build and I need to find a quick and relatively cheap method of constructing staircases. I was thinking of constructing three basic L Shaped staircases using a box steel stringer with tread fixings welded to the spine. These will then be covered with timber treads, similar to the photo. Has anyone got any experience of constructing such things, any design pointers, best practice and indicative costs?1 point

-

Looks like we are going to have piled foundations with a ring beam and an insulated block and beam floor. I've been gathering quotes for the piling, which has been challenging as there doesn't seem to be any local piling contractors. The only quote I've had which wasn't clearly a 'we don't want to do this' price seemed fine for the piling (at about £220 per pile + £900 mobilisation) but the price for the ring beam was higher than expected at almost £9k. The length of the ring beam is approx. 85 linear meters and the cross-section size is 350mm by 450mm. I make that around 14 m3 of concrete which SPONS tells me should be around £150 per m3 - £2100. There's the cost of the rebar, which SPONS prices per tonne, but being really conservative with my estimates that's an extra £1.5k. Which leaves £5.5k of labour. I should also mention the quote specifically says it assumes the concrete can be poured into a neatly dug trench (prepared by others) without the need for any temporary formwork (formwork is an extra £2,210 if required). So with that in mind, I'm looking for any thoughts on whether my feeling that the ring beam quote is expensive is valid or not. I'm trying to get more quotes but it's difficult in the piling black hole of South West Cheshire.1 point

-

This post is a brief interlude in my "Accessible Ablutions" mini-project, and will be followed by one more post reporting the costing and sourcing detail of the project. I found that I needed to hold a hinged shower screen firmly in place against a slopoing ceiling, and needed a custom part. Through the good offices of Buildhub and @Temp, that was able to be done in a few days to the custom design required. This is a short description of the process, taken from the thread. The Problem I have repurposed the former hinged bath shower screen as the end screen of my walk in shower, as it is under the stairs. A side benefit was to be that the narrow 450mm entrance gap would you be opened a little wider for horizontally more extensive people, or putting a shower seat inside more comfortably etc. Due to a need to reposition the shower closer to the stairs, there is now such a minimal gap that I need to fix the screen in place, rather than let it move. So I need a part with a 42 degree upper surface and a slot to fit over the top of the 6mm hinged screen, which I can then glue or silicone in place. Pics and a diagram are below The Answer We came up with a design incorporating a toblerone shaped 3d-printed "thing", which could be glued to the top of the glass screen, and glued and screwed to the ceiling. After creating a "prototype", which was nearly but not quite right due to a measurement inaccuracy, it works beautifully. The full story is in this thread:1 point

-

That really is fairly shit on the shitometer.1 point

-

1 point

-

Having looked at companies house I can see the sole director of E R Aluform is Mr Edward Brent Rigby who was until December 2016 also a director of Velfac so there is clearly a relationship........ I would get on to Velfac and ask them to give you some names of alternative installers in your area. From what I know when we were looking with them your install contract will have no direct connection to Velfac themselves, separate company etc. Focus on your build if your windows are delayed knock on costs may escalate.......I would get your windows to site asap then at least you have them safely in your possession. I agree on Velfac being a slightly different install to other windows but with a comprehensive manual from Velfac other fitters should be able to get them in if you can’t get a Velfac approved one. It will be months before any creditors see anything if ever.....loss of 50% of install fee is better than 50% of cost of windows, I know it wont be a small sum but it is not a huge one in the scale of things.....our resin drive installer ‘went bust’ owing us nearly £2000. Sadly no assets to speak of...Ltd company of course....what little available taken in fees by liquidators as usual. There is an address for Mr Edward Brent Rigby on the Companies House data. He also has a linked in page. Might be worth exploring a little. I uncovered some interesting things about our drive man ....things he had withheld from his statement to wind up the company....ripples can have far reaching effects and though I may not get my money I will see he never holds another directorship.1 point

-

Interesting as Aluforms director used to be the Ops Director of Velfac... I would push them hard to help you here ..! https://beta.companieshouse.gov.uk/officers/kCCZuqYUPmpgbqj_hbBUxX3OfI0/appointments1 point

-

Once you have checked that the windows are safe - assume you have done this, perhaps get a list of installers from Velfac and start phoning around... F1 point

-

If the company has gone bust you could try phoning them to see if any of their installers would be able to do the work directly for you. The Velfac style of window is a bit unusual as the inner timber frame and the outer aluminium sash are the same size. There is normally a gap around the windows of about 12mm which is sealed with Compriband tape. They also do not come with an outer sill as standard and if a sill is needed the windows are factory fitted with a timber packer and aluminium cills are soursed elsewhere. I assume someone has done some drawings / window schedule and accounted for this.1 point

-

@zoothorn just post up what your planner replies with, also can you do a rough section sketch with rough dimensions of the stream, bank, Slope and where you want your Cabin, we can go from there.1 point

-

Have you paid up fully for the windows. As in if you still have something left to pay them and assuming they are already made you could hopefully use this as a bit of leverage to get velfac to step in and sort you a new installation company out. The windows sitting in their factory will only be any good to you so with a bit of tears over the phone and some good will from them you might have a chance of coming out not to badly damaged.1 point

-

I hope it’s that and not the windows too as that would be much more tragic!1 point

-

Sorry, I missed that entirely - ignore me!1 point

-

I read into the OP’s message that the windows themselves are safe and due to be delivered but the (separate) installers who had been paid 50% of the installation cost upfront have gone into administration.1 point

-

What does "ceased trading" mean? I assume they're in administration? You could find out whether they'd paid anything to the factory. If so (and even if not), I'd be in direct contact with Velfac at the earliest opportunity to explain what's happened and the see whether there's anything they can do. If they've received any of the deposit, it's possible they'll honour at least that amount. Even if none of the deposit reached Velfac, I'd be sobbing over the phone asking whether there's anything they can do to help you get back on your feet. If they've started production of the windows (and you'd hope so given the due date), they have a strong vested interest in you continuing with the purchase, so you definitely have some leverage. I feel for you - we didn't have this happen during our build but I spent a lot of time lying awake at night worrying it would!1 point

-

Did you pay the deposit by credit card? If so you should be able to get the money back from the card company. Contact them asking what you need to do to claim under Section 75 of the Consumer Credit Act. Keep copies of any paperwork or email you have and from now on. If you paid by any other means it will be difficult to recover anything. You would need to find out the name of the administrator/receiver and contact them to register a claim but you would be an unsecured creditor so probably last in the queue. You should also find out if they really have gone into administration yet or are just telling you that hoping you will go away (not unheard of). If they haven't then you need to wait until they fail to install. Then give them written notice that if they don't install in say 2 weeks (by date) you will hold them in breech of contract. Finally after that you can go to small claims court and possibly escalate it, ending up with you sending bailiffs (or whatever they call themselves) to try and collect the money. However you do have to give them the opportunity to hold up their end of the contract before you can hold them in breech and go to court. There are fees and hassle going this route and it can be like throwing good money after bad depending on how much is at stake. Sorry but unless you paid by CC it doesn't look hopeful.1 point

-

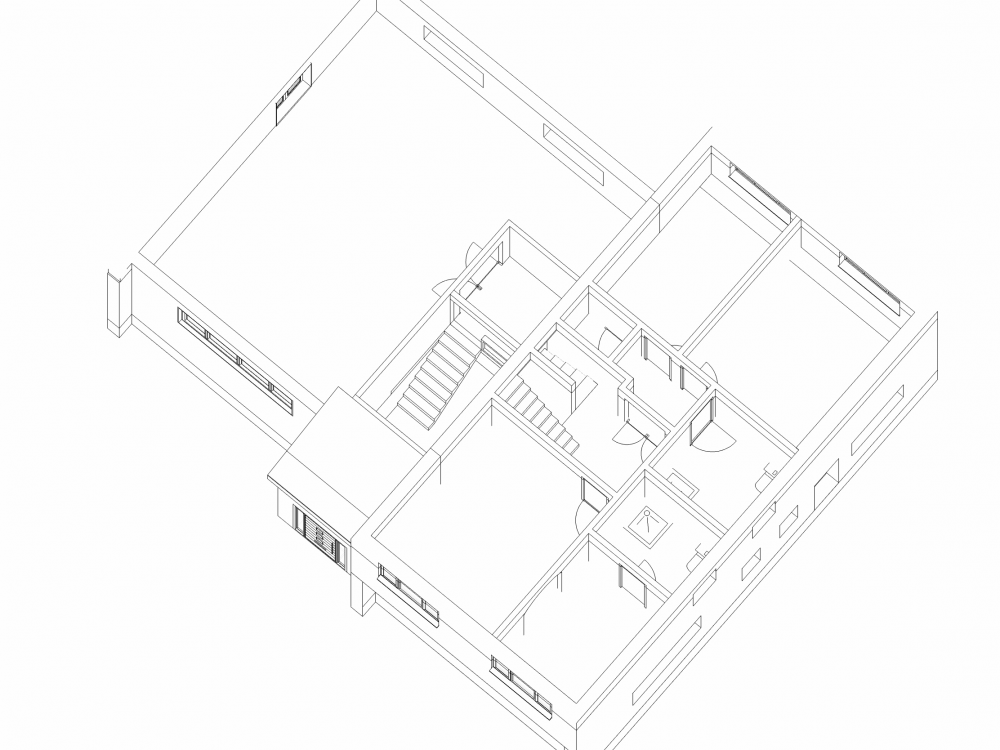

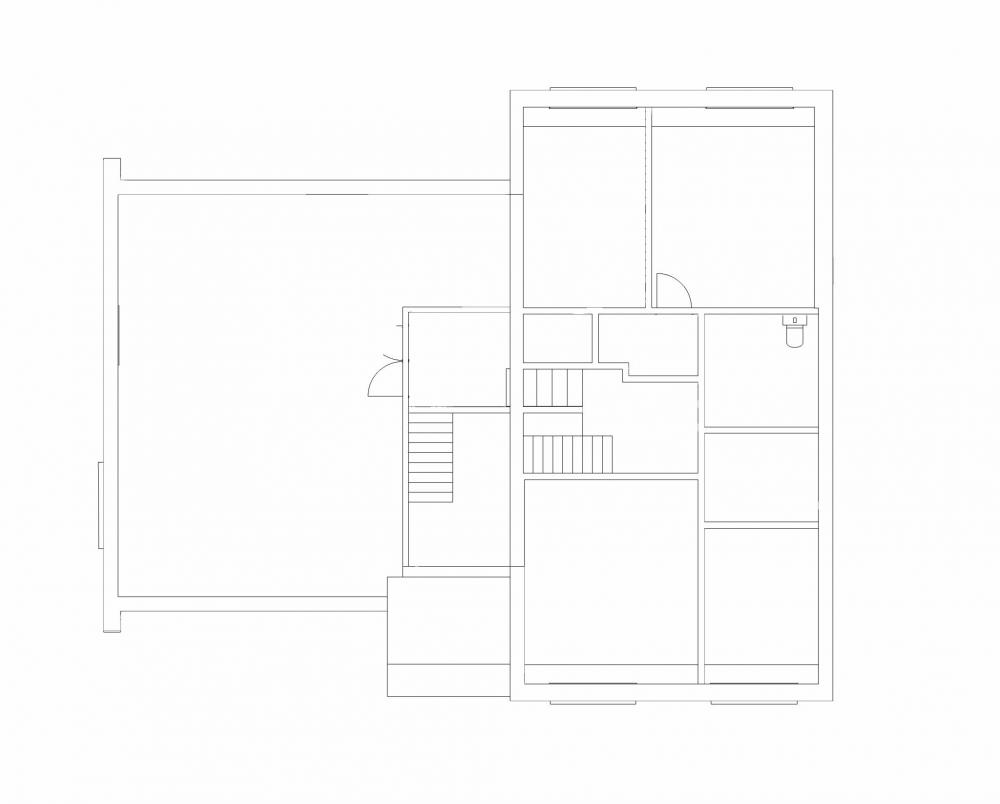

Yes, go down from the kitchen to the playroom under the stairs to the bedroom. There are a few structural issues to overcome but all possible I think. We thought about putting a long window in the spare room facing south but it would change the whole look at the front. It’s a nice idea to split the rooms as well but, having lived there a few years we like the room layout the way it is. One extra piece of information. Some time in the future I’d like to put a loft conversion in. With your idea I think loft steps would work well up from the +2 level as shown below.1 point

-

Welcome I would spend some time properly learning all you can about building physics and planning law. If you really want to make a difference, get on the local parish council and work your way up the political ladder. There is a serious lack of 'young' people involved in local politics. Failing that, how about a houseboat.1 point

-

Yes - but we need to recall that the Clapham omnibus is now mainly packed with middle call Millennials traveling into work from their £500K Pied a Terres in Tooting and Balham up to the big smoke - their views might be interesting. (I mean that - interesting)1 point

-

Welcome. (Currently choosing not to get into the debate as I only have half an hour). I don't quite get the concept of your own terraced house not feeling like yours. It is. If you move out of London, doer-uppers can cost very modest amounts of money. It is probably worth pointnig out that now is probably the best time for decades to have a mortgage, since you can get 10 year fixed money at less than 2.5%. And that will leave you with something at the end if you want to spend some time exploring alternatives. I would also mention that a lot of people who head off into, or are icons of, the "deep green lifestyle" actually have a foundation in a more conventional lifestyle that is a permanent Plan B should they need it, or are quite well off, or have the backup of strongly-rooted families. eg the famous "Hobbit House" of Pembokeshire was built on the family farm. Throwing a wildcard on the table, if you are still 'searching' in some ways ... for what you want to be and do ... you might enjoy an experience for a time of living in, or attached to, a community. The value is in being exposed to something 'other' as a contrast, and in offering service. I am familiar with communities such as Little Pilsdon and Iona, based in historic traditions, but there are many other forms and some which are secular, and some which are networks. I was for a time involved in a setup called the Othona Community, which has a dispersed membership of hundreds, but a base on the Blackwater Estuary near London. Imo the advantage of the older communities is that they learnt how to manage themselves already, and are full of older people with decades of experience from whom much can be learnt. Find people who have been marching to a different drum for 30 years or so, and buy them a pint of Stout. Just thoughts. Ferdinand1 point

-

@Carrerahill I’m not making any assertions on the structural rights or wrongs,just relaying my past experience as a foreman & dealing with NHBC,who as you said don’t like all that. Even known some building control to get funny about it. Anyhow, @epsilonGreedy‘s garage is fair faced (I believe?) so not an option for him.1 point

-

Forgot this was the garage. If its 100mm, just crack the end off a block with a bolster and then turn the cut end into the cavity. Three or four whacks and job done1 point

-

Worth saying that it’s been down 3 years now and is wearing very well - quick mop and it’s back to new. Was about £100/m2 so not much more than a large format tile when you include the labour1 point

-

1 point

-

1 point

-

1 point

-

And did I read right in that the shorter these intake/extract intake pipes the less need for lagging/insulating? Note @pocster has a warm roof type setup but i'm asking for future reference1 point

-

The APS is a self appointed membership body that is all around CDM2015. I’m assuming he is taking full liability for the requirements of CDM in this instance - has he suggested he provides a construction site plan as part of his work..?? If not, who is he advising will be responsible for CDM2015..?1 point

-

I think for the initial part of the build Basement and party wall It would unreasonable for him to be held to a schedule With so many variables that he may have no control over Though I would pin him down to how many hours he will be there each day Once the initial work is complete it will be much easier for him to give you an accurate schedule for the rest of your build1 point

-

1 point

-

Yes, I think this solves the head height issue as you can move the landing past the entrance to the kitchen. The upper floor picture looks correct, not sure what you have done with the levels on the lower floor, are you thinking of having the door level with the kitchen then going down from the kitchen to the playroom under the stairs that go up to the bedrooms? That would work well I think and gets you down to just three sets of stairs. Realistically you won't get a lot of light from the front door to the playroom either way, there isn't that much glass and it is quite far away, so I wouldn't worry too much about it. Is there something stopping you putting a long narrow window at head height in the spare room facing south? Then you could split the space with a north south wall rather than east west, you could have the small room with one north facing window next to the kitchen and the large room being dual aspect running front to back. Even without an extra window at the front, this room would have west facing windows now, although I don't know how much sun you expect them to get. TBF this may not be there best se of space as you would need a small extra hall, depends how much you want extra light. With an infinite budget I would be tempted to make that whole area a new kitchen/family room/dining room with windows all round.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

You may want to consider cross battening under the trusses with 25 x 50 or 38 x 50 at 400 ctrs for your plasterboard and your electrics.1 point

-

1 point

-

Reviving an old interesting thread. What about rising heat? I imagine that hot air from the rest of the house would also accumulate in the loft. Even if you carefully shuttered the rooflights, would this be an issue? Putting it differently, assuming no rooflights at all, and good insulation, is it almost guaranteed that the loft will be fine? (I was even thinking of going for a Velux Cabrio, but I wonder if that can even be shuttered.. or are there awnings that could work on a pitched roof?1 point

-

1 point

-

1 point

-

We had a similar issue a few years ago. Both HDMI leads within a month of each other. I googled, I watched you tube then we hacked away at part of the wall and fed through the new cable where we could. It was a nightmare.1 point

-

Also google "repair hdmi" without quotes for other ideas. Crimping is probably best but the tool isn't cheap and might be connector specific?1 point

-

There are solder repair connectors available but I've never used them. Will need a small iron with fine tip. https://www.ebay.co.uk/itm/HDMI-Male-19-Pins-Connector-A-Type-Solder-Termination-Repair-Replace-Kit-5-Pcs/162962886822?epid=1538358618&hash=item25f15850a6:g:jyUAAOSwfuBazLNs I don't see any instructions. edit: or a backshell?1 point

-

Never seen one. A very fine 19 core cable and very fine pitch connector would not be easy even if someone sold one.1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)