Lift span

Members-

Posts

98 -

Joined

-

Last visited

-

Days Won

1

Lift span last won the day on May 28 2022

Lift span had the most liked content!

Personal Information

-

Location

Up North, now West Sussex

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Lift span's Achievements

Member (3/5)

24

Reputation

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

Is that due galvanic corrosion? I used treated pine in the end. But, depending on what they are treated with I suppose it's the same issue. My intention is to protect the bracket/timber from the electrolyte (water!) somehow.- 33 replies

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

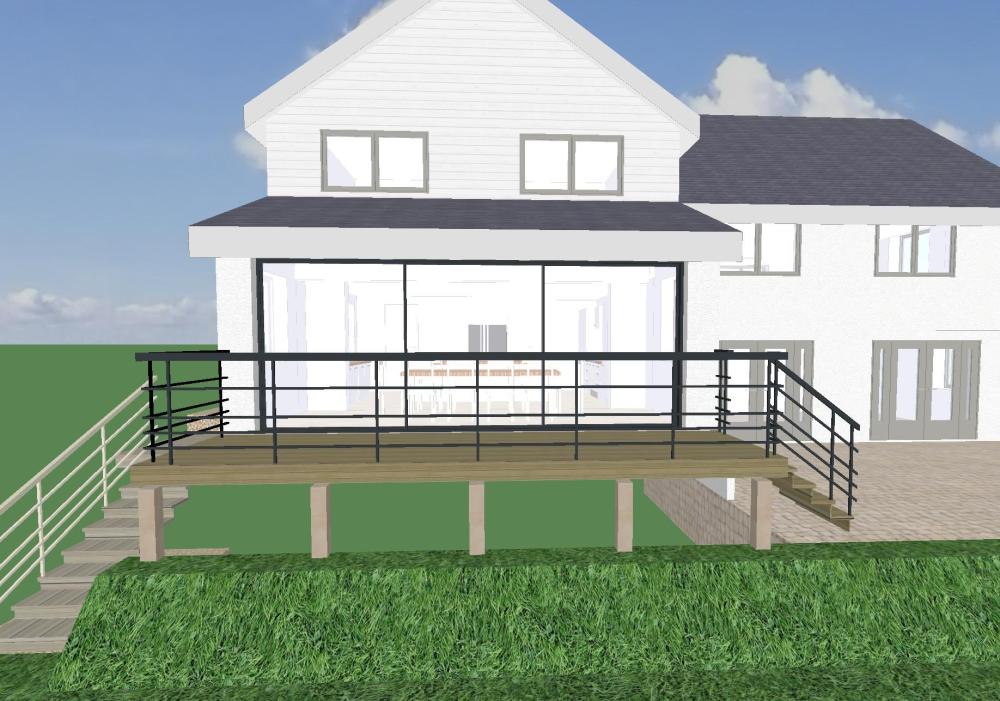

Well, in the end, I built this out of timber with composite decking. The footings also tie in horizontally with the building footings. Next question. I'm looking to do some kind of DIY glass balustrade. Something like shown below but with a handrail (drop>600mm). ie. timber posts (fixed properly in the frame), with stainless steel brackets. Anyone done this?- 33 replies

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

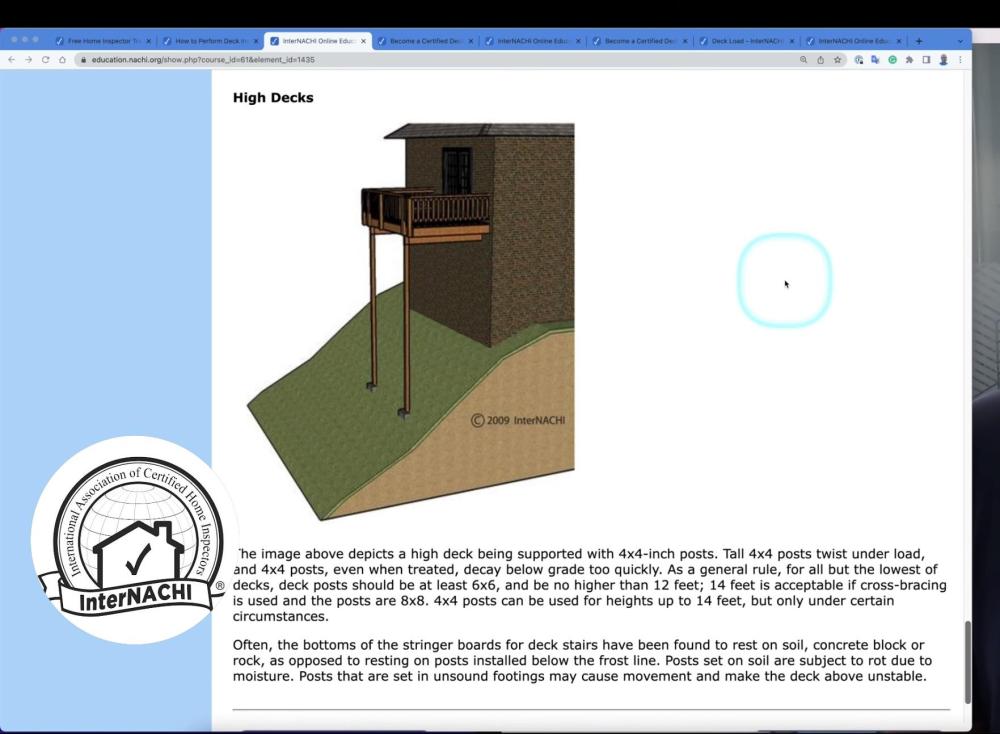

You may well be right! I'm a chartered engineer myself so I'm generally happy with the numbers and I've had mixed success with structural engineers in the past. With a timber build I'm happy all the information is out there eg. The TDCA Code of Practice - Raised timber decks is pretty comprehensive. Yes, no timber is the ground thanks! It's just the alternatives I'm looking at. No doubt I'll just end up with 150mm timber posts (probably oak) on steel brackets in concrete with a standard timber frame above with lots of cross bracing. I will ask my local SE though to see what they say. Different view points are always appreciated though!- 33 replies

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

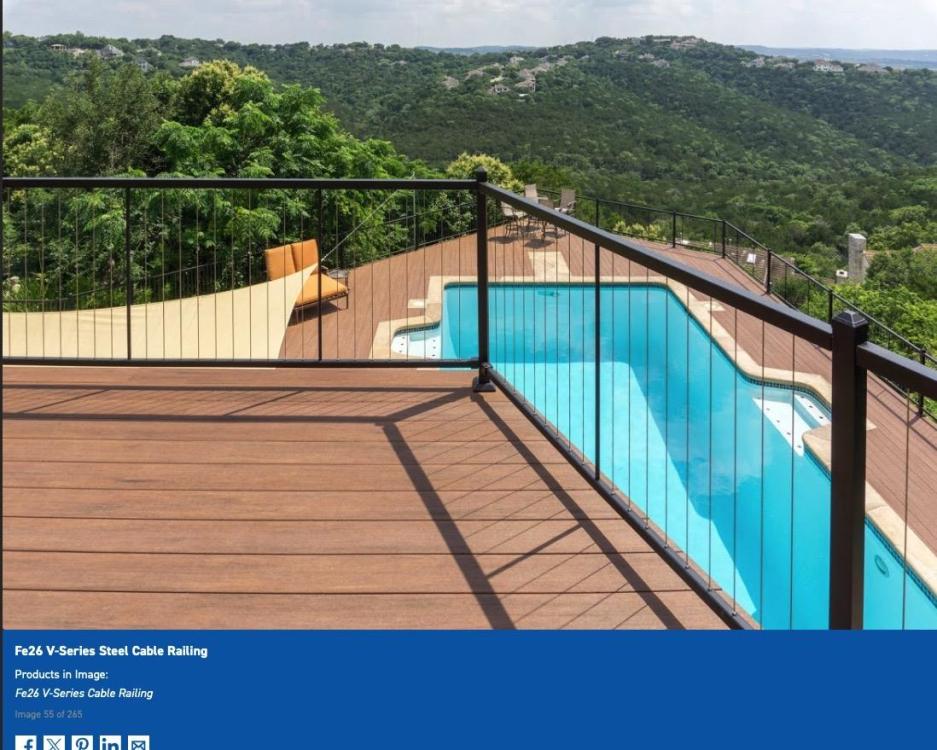

How did you attach your balustrade? Seems that there are lots of ways to do it and some are a bit dodgy for raised decks. I'm after this style of rail below but not sure if it's acceptable just to screw down into the frame at the bottom of those posts. The second half of this video shows some common issues:- 33 replies

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

I'm going round in circles with this! I've contacted two manufacturers of plastic posts. One says you can't use their posts in raised decks over 1m and the other says you can with diagonal bracing. I just don't see any evidence of anybody using it which puts me right off. The other issue that had come up is the balustrade. A manufacturer advised it may be better to fix into steel at that height. So, I've started looking at steel frames as you say Crispy. This is all turning into a massive time waster! I can see why the pros just concrete timber in the ground and let the home owner worry about it in a few years!- 33 replies

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

- 33 replies

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

- 33 replies

-

- 1

-

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

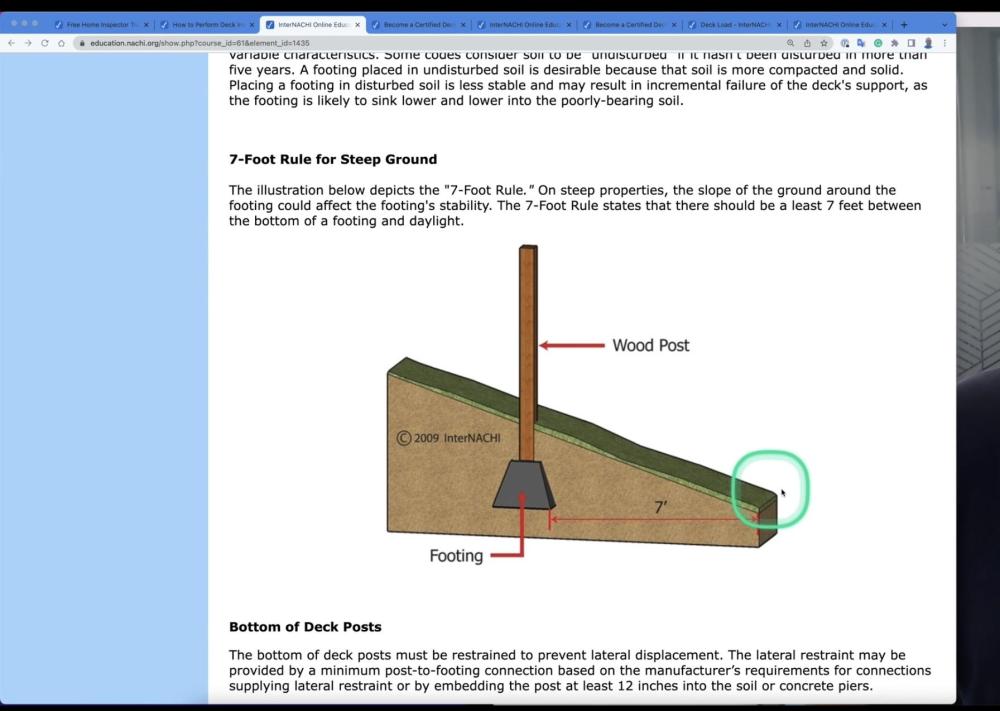

The underneath is going to be open like below with a weed barrier and gravel directly under the deck. Yes, the maintenance of the wood is a concern. I’ve just seen you can get 100mm square plastic posts so maybe they are the answer after all! That way I’d be able to dig footings to be level with the lower level of ground and simply concrete those posts in therefore eliminating any issues with the slope.- 33 replies

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

Here are some photos just to give some perspective. Vertical supporting posts would be around left hand side of that scaffolding.- 33 replies

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

That’s a good idea. Something I’d not considered. Maybe some kind of hybrid where it’s self supporting but with a ledger that’s “weakly” connected just get the level threshold.- 33 replies

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

The more I look at this the more I like it! What’s the maximum height of those columns in your deck? Thanks.- 33 replies

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

Building Control have signed off the plan already. They were only interested in the Balustrade height. Doesn’t need planning permission. Lots of other work did but when the planning officer visited he confirmed that the 30cm rule was from the ground adjacent to the start of the deck. Even with a structural engineer I’ve found in the past the conversation starts with “How do you want to do it” So I’m just looking at options so thanks for all your ideas!- 33 replies

-

- 1

-

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

I did wonder about a steel option. At 1.5 m high I’d be looking at a beam rather than a plate though. Again, just looking for best practice.- 33 replies

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

I’ve no doubt it’s a good job! I’d be interested in any photos! I would like to find some info that would have these as part of an official spec. The Timber Decking and Cladding Association https://www.tdca.org.uk say 140mm posts. If I could find a spec for 100mm I’d do that as they are obviously much easier to come by.- 33 replies

-

Posts for raised decking: timber or plastic?

Lift span replied to Lift span's topic in Landscaping, Decking & Patios

I was looking for some cardboard tubes here in the UK and they seem remarkably expensive for what they are. I have some plastic barrels though which I thought by cutting the top and bottom off I could achieve similar.- 33 replies