Leaderboard

Popular Content

Showing content with the highest reputation since 04/07/24 in all areas

-

We had our first air tightness test today and achieved 0.25 ACH!! 🎉 Absolutely chuffed to bits with that. We have spent a lot of time taping every possible penetration, but I was still anxious in case we hadn’t quite been as scrupulous as needed.20 points

-

I installed the MVHR unit this week and got someone to commission it. It’s very quiet. You can hear a gentle hum from the kitchen terminal when standing underneath it but the others are silent. The external terminal isn’t as bad as I thought it was going to look but it’s still by the front door. I regret a bit not changing the whole floor plan of the porch/lean to bit of our house putting the plant room on an end elevation. In hindsight I ought to have combined it with the utility room with a wall separating them. The benefit of where it is that’s it’s right in the middle of the house though. The other small issue is the board on board cladding creates a void behind the terminal where the inside cladding board is which could allow rainwater to sit. I’ll need to add a block to fill it in. The board on board cladding has caused similar issues like this across a few areas of the house. Worth thinking about for anyone else considering board on board. Downstairs bathroom nearly finished. The Aqualisa shower was straightforward to fit but we pulled the speed fit hose out of the connection inside the rail which was a bugger to get back in. Bit concerned it came out so easily. I’m not massively impressed with the Aqualisa Optic Q shower control given the cost of it. It all feels a bit loose and plasticky. We have two and both the same. The rest of it is well made. The mixer and diverter are in the coomb upstairs making it really easy for future access as I made the coombs slightly wider and higher by removing the coomb completely on the opposite side of the roof. We gained a bit of floor space and it allowed me to widen this coomb by 150mm. I did this to make fitting the shower controls up here much easier. It would have been very tight otherwise. Doors and skirting fitted. Doors and hardware are by LPD. Unfortunately they don’t do smaller doors to fit the wardrobe. However Deanta do a very similar door (looks identical in the pictures) which can be custom made. Not cheap unfortunately and the lead time is 20 weeks. Also removed all the dust protection from our lights in the vaulted ceiling so it’s the first time we’ve seen them up properly.7 points

-

After my horrid time earlier this year I am now going to post something more positive. As of yesterday, I was offered a job, not ideal (is any job ideal), rather than working from home I must go to the office which takes 40mins each way and hubby is disappointed that he will be left on his own all day. That said even with time out for funeral 250 miles away and wet, wet, wet we have progressed. Some pictures. hardcore & binding (take 2 after previous issues) now the expansion foam around the sides The heave protection next then taping next was the rebar here is the pour on top of the rebar - 200mm drying concrete slab with no hint of everything underneath, typical building, lots of expense and nothing to see. the first row of outside blocks added showing the cavity first blocks over DPC with all the rain we have created a bit of a swimming pool It was at this point that we purchased a puddle pump as hubby really didn't like having to kneel and build low in water going up with some windows & doors framed insulation going in joining the existing walls to the new part this is where some of the kitchen cabinets will be hung, so although internal we are using heavier blocks to take any necessary weight On the left hand side you can see part of the existing barn that will be staying. The roof is currently being held up with barrels and wood building from scaffolding is a real milestone, makes it seem like we are getting somewhere. To protect the insulation, we have the original insulation from the barn roof cut up to provide a 'roof' over the cavity. Having made the frames for the remaining to windows these need to be placed in situ for building around. This area will be our front hall and snug. Of course, the front door will only be used by visitors, but we will go through the hall internally to get into the snug. With all the cavities it is smaller than I hoped, but with all the insulation it will be much warmer than our single skin house. Hope you enjoy the pictures, next time I hope to be at lintel and wall plate level, but we would like the weather to improve. Thanks for reading Jill7 points

-

Hiya. I'm Scottish base and have family that live on one of the inner Hebrides and have lot's of experience dealing with BC on the Islands. Also I deal with Scottish Building Standards on a regular basis and have done so for the last 40 years. Some of the BC officers I know quite well, we have a chat on the phone about our careers and reminisce on how good the old times were. In other words they are folk just like us.. there is the odd exeption but that is life. In the round though BC officers actually do have your best interests at heart. It would be great to have a BC officer or two join BH! On the Islands there is a lot of politics. Some Island builders are really shite, cut corners in a big way, some are better / good. BC know who they are so maybe you are getting a heads up and not just seeing the wood for the trees about the work that has been done by others. Now you are doing a bit of work yourselves.. well how much and when did you start doing a lot yourselves? It is in your own interests to build your house right? There is always friction on the Islands... BC know this but are not corrupt at this level. There are loads of other Islanders and folk moving there that do DIY projects so you are not the first and last. @JWHIT "surely this is trespass" My advice.. get this right out your head now. If the BC officer can access your site then you have a Health and Safety issue and they can hammer you on that. The HSE law is quite clear on this all over the UK, if your site is accessible then you are on a hiding to nothing. Have a looked at your site security? Don't pursue this route as you will likely regret it. Too late for that, BC can hammer you much earlier. There is no argument in law for shoddy HSE by saying.. hey I'm insured. Insurance is for when you have tried to do your best and things still go wrong. If they can see bad things from outside the site boundary then surely.. you may be making a cock up? If you try and play hard ball with them then they will pull your trousers down and you won't get to pull them back up until they have run you ragged. Now you may feel that the BC officer has turned up with no appointment.. but they are allowed to do this under UK HSE law (not just Scottish law) .. part of their remit is pubic safety.. they can hammer you on this too! To lay it on a bit thicker they may start to ask if your project should fall under CDM regulations., just to give you the run around. In summary: 1/ Yes there is Island politics, don't worry too much about the main Island Contractor not getting the job. 2/ Phone the officer up and ask when they are next on the island and arrange to meet them in person. This is so imprortant. You are on an Island.. you must get to know folk.. the emails you get from BC only show a snap shot.. sometimes they write stuff that seems really daft / aggressive.. but they are pushed for time and under funded. Cut them some slack and cut yourself some slack too. Keep an open mind as while you see this as a personal opinion then they may be able to give you good advice? Also if you hit it off with them then later on when you apply for a completion certificate you'll probably find that part of the process much easier and not get hit with a load of things that don't conform. 3/ Build a rapport with the officer.. recognise that they may be trying to help you rather than hinder. You may have a young and inexperienced BC officer. Be very careful here not to bully as their boss will then give you the big stick! Listen to what they are saying.. put forward your ideas and have a bit of fun.. seriously they are just folk. To finish @Kelvin may be able to give you some advice about how you deal with BC when relocating to the north of the UK ( Scotland) 4/ Some of my family live on Tiree. Clocked this at the end! Well it does.. Some of the building regs are open to opinion / discussion / detailed design. BC officers often hold professional qualifications / have great experience. They are entitled to question. As before one big stick they do hold is the public safety issue (I do it too as an SE) . Lot's of folk on BH think that this is their house and they can do what they want. BC say and I.. that house has to last for 50 years at least and you may sell it to a family in a couple of years time. Our duty is not just to you but all the folk that come after. Just copied this right at the end. The above is misleading as if it is deemed to be a risk to public saftey then the LA can effect immediate access as what they do will call on the Fire service, the Police , gas board and me as an SE. You see.. who knows what building regs have been compromised? Is it just an extractor fan of a serious structural defect that could cause a gas leak? If push comes to shove and I'm acting for the local authority.. I'll find a legal way of getting into your property if I feel there is a safety issue. You are pissing in the the wind! If you have nothing to hide then you should be relaxed about all of this.7 points

-

Well it's the second day on week 4. The ground floor screeding is being done as I type this. To date all the walls are up (they come fully glazed, partially rendered and plasterboarded). The roof has been tiled and guttering fixed, the first fix electrics are done, the first fix plumbing is done (wastes and supplies for basins, wc's etc come ready installed in the panels), the underfloor heating is in and the MVHR ducting in place. In the service room is the cylinder, expansion vessel etc for the ASHP and the external unit is here wrapped, sitting on it's pallet. They started on the 8th April and expect to hand over at the end of May. We elected to use Dan Wood as a "half way house" - it's our original design (although with a nod to that sort of style). We didn't go extreme, much as we would like as I wanted a smooth planning experience, which we got. So, some of the standard Dan Wood bits we omitted. They can finish right up to carpets; handing over complete, save for the kitchen (too many choices apparently). We wanted a UK stair with closed risers so it could be carpeted. DW use bare wood, open riser and being aimed at the German market, the pitch is lower so the going messed up our internals too much. We also left out the doors (odd looking with the leaf rebated and closing against the face of the frame) and floor finishes save for the bathrooms. Those are now down to us. We had to provide the foundation (insulated raft for us) and drainage/service connections. However, it's been a dream not having to organise anything once they sign off the slab as ok. Men turn up at 7.00am sharp and work to between 5 and 6. Saturdays 8 till 1 ish. All materials are either brought with them or turn up on time. Electricians, plumbers, and scaffolders are woven into the work and are here at the correct point. The electrician was here until 11pm finishing off first fix because the next trade needed it done. Every single day it progresses. It probably isn't the cheapest way of doing it ( about £1730/m2 ex foundations) but the joy of not having any arguements with individual contractors makes up for it and there is no doubt the polish crew working on this house work damm hard and do a good job. You have to credit their attention to detail too. They obviously do this all the time as all the membranes are properly taped and sealed, the windows being inserted in the factory are done properly, etc etc. It's clear they have designed out issues over the years and have come up with solutions that work - hence the 20 year guarantee. We could buy the plot but needed to sell our house to fund the build. We are in a static caravan at present on site. Having reached retirement the certainty of getting the build done in a sensible timescale so we could get on with enjoying life was a big driver for this approach. Hopefully it'll be a family Christmas settled into a house this year instead of renting a cottage to escape the cold and damp of a 32ft static!6 points

-

I see a few mentions of the expense of MVHR. I self installed a simple system complete for less then £1500 in a 260m2 house. It has no sensors just manual boost which we use occasionally, otherwise it stays on trickle rate 24/7, even when some doors and windows are open. Really happy with the air quality (which I monitor with sensors), best value for money in the whole project and a no brainer in a new house IMO.6 points

-

I appreciate that I am most likely speaking to the converted regarding this topic, but we are currently renting a property on a large Persimmon built housing estate, and I honestly find it so depressing and cannot understand why anyone would choose to purchase one of these houses. Not only is the build quality shocking, but each house is orientated 180 degree relative to the house in the parallel road. Eg, you would never sit in your back garden, as you are overlooked by about 6 houses. You have to always be mindful when looking out your windows, for fear of staring directly at someone who is looking directly at your house. If nothing else, it will make us get on with our self-build, and make us appreciate that we are fortunate enough to be in a position to do a self-build.5 points

-

Hi, I’ve been a member for a while but have been mostly sitting, getting frustrated, waiting for our planning decision. 2 weeks ago we finally got our approval for a strawbale house in the village of Minard, in Argyll and Bute. Now we’re moving into the building warrant stage and at least this time, we’re prepared for a wait - our planning took ten months after being told ten weeks. I’m a bricklayer by trade and this one is going to be the last house I build. 61 years old and I’ve had enough, but definitely looking forward to getting stuck into this. Graham Walker5 points

-

I thought these photos might interest you ..... the first one taken a few minutes ago The slider in the kitchen has been open all morning - right hand side of the image is to the North, and thus the Winter Garden is in wind shadow (wind NW) , but in full sun (it was raining when I took the photo) There is a 2.5 meter overhang for a 'veranda' shown here earlier in the build. We call it a Winter Garden - yet to have anything in it , but won't be long now. SWMBO intends to fill it with - knowing her - a jungle or as close to that as she can get. There's one episode of Grand Designs where Kevin WotHisFace showed a similar design, but he calls the area a Breeze Corridor. The look of triumph on Debbie's face was a picture. First time she'd ever been 'on trend' she remarked.5 points

-

We leave the window in our bedroom for much of the summer. I support we could turn the MVHR off but it's so cheap to run and as it guarantees fresh air regardless we don't bother. Despite my statz-esque approach to kids leaving the entrance door open I try to remember a house is there entirely for our benefit and and enjoyment and not as a science project.5 points

-

Thanks to the relatively mild weather this winter i decided to start chipping away at the bathroom project, which is being extended into part of the extension which was finished over a year ago. This gave me the opportunity to install the bath, sink and toilet in the new bit, at which time I’d totally disconnected the old bathroom allowing me to strip it out and that’s worked really well for my as I struggle to do more than 4hours in a single day so I could keep doing a bit and stopping when I’d had enough. didn’t fancy tackling the ceiling for plastering in the new bit so got a pro in to do this bit for me, all done in a couple of hours which was nice. and made the most of the space and got the painting done after putting a layer of 10mm marmox board down ready to accept the underfloor heating mat Next job was to start making a frame to hold the toilet frame and the sink and cabinet Decided on making my own cabinet rather than paying silly money for an MFC one, got pine furniture boards, a pocket hole jig and a new router and came out with this which I’m pretty happy with that all got painted and the sink installed, wall mounted tap and the wet room panels that I’m using both for this and for the walk in shower area all installed. got to work cutting the OSB backing and wet room panel for the toilet in prep for the final big push to disconnect the old and commission the new, that was a hard days work! And then bath and toilet all installed once the shower area is complete the bath will be disconnected again to lay the underfloor heating, self leveller and the flooring before being put back in place, and eventually building the wall and plastering it. Made a start on stripping the old bathroom out Next job is to patch up the loft insulation where the old spotlights were, new wiring in place for a single light fitting this time, airtight membrane adhered to the walls and then battens before reboarding it ready for plastering. Floor is coming up also to be replaced with 22mm chipboard to match new bit.5 points

-

I've gone through the whole "elderly parent" thing, watching them struggle with sockets just above the skirting, or having to let go of their walker and reach up to "high" switches. Most sockets or switches I fit or move now are put in / back 450 - 1200mm. Seems very practical to me.4 points

-

4 points

-

The pros and cons of using a main contractor v individual trades are not just financial cost. A brilliant main contractor with a good reputation could end up cheaper than individual trades. If something goes wrong with one trade it could have a knock on effect on others. Any £ savings could be written off if you need to redo work if you subcontract an end up with a bad tradey. a good main contractor will use good tradesmen. however if you have a good knowledge of building work, and a network of good trades, you can project manager yourself and save some money. My advice would be to apply a sliding scale of building knowledge to your decision. The worse knowledge you have slide that scale towards a main contractor. The more knowledge slide towards sub contracting. if this is your first rodeo: Ensure sure you have a written contract or at very least detailed correspondence emails quotes etc. Having an email chain that asks “is there anything that is not included” can be helpful to you. Eg waste disposal. Utilising a trade or contractor without due diligence is risky. Online / social media reviews should be treated as fake unless you have verified them. A good tradesman will have no problem in you wanting to getting references. look after your tradesman. I pay mine immediately as they’re tidying up. They tend to come back. Keep out if their way as they do their job. If you’re delighted with their work drop them a line a week later saying so. trades are not cheap if you get good ones. If quotes are noticeably cheaper than others be wary. don’t forget if you think OMG he’s getting £40 per hour or whatever, I only get paid £15 per hour working at my company / I went to Uni / blah blah, he’s ripping me off. Don’t forget he only gets paid that when actually at the job, not all the other stuff he has to do when he’s getting £zero per hour. Pays for expensive tools. And he’s probably not in a workplace pension scheme, gets 28 days paid hols etc etc. yes some tradesmen are doing ok but few are super wealthy. This forum is good for advising if your quotes sound fair, when you get them in. Oh, and where I say “he” I include the great female tradespeople that are coming into the industry,4 points

-

4 points

-

We made a last minute change and added a rooflight for the hallway. I considered a light tunnel instead but we decided that making a feature of the rooflight would add some interest to otherwise flat ceilings. It has a created wonderfully light airy hallway. I love the being able to see the sky when you walk in. There’s a glazed door to be fitted giving you a view to the hills beyond.4 points

-

4 points

-

4 points

-

I don't mean to be harsh, but don't you think you kinda brought this second mess on yourself? You actively chose to get back a tradesperson who you already know made a potentially life-threatening mistake and he wasn't even able to fix it when told about it originally! What made you think his second-fix plumbing in your bathroom would be any better? If he didn't provide a quote, what did he agree to? What do you have in writing? Did you take detailed photographic evidence of his mistakes before you fixed them? If you've got pics, ask him for an itemised bill, and then you can prove that he didn't actually fulfill those things properly and therefore you're not paying. But to be brutally honest, I think you partially brought this on yourself and might need to chalk it up as not-too-expensive life lesson.4 points

-

Sorry but I can't see ANYTHING in that kitchen that will make it £55K. Howdens could replicate that, or any other kitchen supplier for that matter. Choose the best of their range, and fit yourself, Get good stone worktops and splashbacks, and buy the same top end ovens and hobs and other appliances as the German supplier is proposing. (yes this is an answer from a man)4 points

-

You must get to the bottom of this before parting with your cash. I see this a lot.. the vendor claims no knowledge.. but I know they know that they are not offering a clean sale. Ask this.. are you the first punter that has pitched up or have there been others who have clocked that the vendor is not playing the game? I have seen this over the last 40 years.. If you can't get a rural plot soakaway or similar to work etc then the plot is often only worth the agricultural value.. it's a fact folks and there is usually no magic bullet. It may be that the plot is worthless.. you don't want to be the idiot that buys it. It may be that you can do a deal where they give up more of their land and you share the soakaway say, now the plot has value. It's time to say to them.. look we need to sort this out or we are off. If you are not firm now you could lose your shirt. Forget CCTV survey for now and get the big stuff sorted. Who owns what and what rights of servitude exist. Understand that first.4 points

-

Ventilation, ventilation, ventilation, stick a living, breathing, cooking person inside a box wrapped with plastic and you are going to get damp and mould.4 points

-

4 points

-

I find this comment a touch patronising to be honest. You are fortunate enough to be able to build a house for yourselves. I don't know your ages but look around you on your estate, and ask yourselves are you the "target audience" for this type of residential living? I would suggest you are not - we lived on such an estate for 30 years before embarking on our self build and I have to say, the location, convenience, price and a certain degree of "maintenance free" work, were very appealling to us as we were a young family. Obvioulsy no one "wants" to live in the type of house you have described but unforunately the choices can be limited - Just for the record, "Residential living" worked extremely well for us, until we found ourselves in a position to move on.3 points

-

I have a passive-class house with a 70 tonne MBC "warm-slab" within the heated fabric of our build. I went for the deferred option of putting in the 6mm radial from the CU to an outside wall box and a insulated double pipe run from the UFH cupboard to where I would put the ASHP, but held off installing an ASHP and used a 3kW Willis as an interim means of heating the UFH loops so that we could size the ASHP based on a year or two run rate. The issue that we have is that going from using the Willis (plus Oil filled rad top up Dec/Jan) on an Octopus Agile optimised heating schedule to an ASHP at an average CoP of 3½ say might save us perhaps £300 p.a. in electricity costs. (We have a handful of days a year when we put in more than 30 kWh heat.) I'd want at least a 10 year payback so would want my install costs to be at most ~£3K. And then you have the issue that the typical life of an ASHP can be ~10 years. It's just easier to pay the extra £300. 6 years on, and I still can't make the investment case.3 points

-

Cracking insight from Jilly here.. so much info in seven lines of text.. Folks read every line of Jilly's text, learn and digest the deep knowledge she is imparting. To get the best out of this you'll need to go and do your own work.. Jilly is saying.. here is where you need to look out for your own benefit. Just a quicky for any doubters here.. Jilly talks about underpinning.. she has been there and worn the tee shirt in terms of piling etc on her domestic project.. she knows her stuff. Or bluntly.. if you don't take her advice then don't come back on BH complaining later if it goes wrong.3 points

-

You need specialist advice. Sometimes crown reduction is advised instead, to prevent heave which could happen if the trees were removed, due to the sudden extra water under the house, so they may have got another opinion? Could it be in a Conservation Area and the trees have TPO's? Or they don't own the trees? Removing the trees might ruin the character of the house/area? Lots of houses have been underpinned, it's not the end of the world, but it scares people and lenders. If you proceed, you must stay with the same insurance company, the policy can be transferred and you must confirm this will be the case as part of your due diligence. Other insurance companies won't touch it.3 points

-

Brilliant news! I've past Building control! Best news for a very very long time. Thanks everyone, could not have done it without you!3 points

-

The whole charging structure changed on 1st April 2023 - you have to pay for extension assets (connection) but should not have to pay for reinforcement assets (cable and transformer upgrades). https://connections.nationalgrid.co.uk/significant-code-review/3 points

-

With any self build, unless you can afford an Architect/Builder to oversee the whole project, you're going to be chasing people, materials, answering questions and more. My own project is up to roof stage, timber frame is finished, roof finished but outer brick/block leaf is next, then soffit, fascia, gutters, then porch, then windows & doors. Each have their own challenges. On top of my day job! I've a delivery of lintels tomorrow and I only thought to ask what size rigid truck is it to find out it's a full Articulated Truck with a moffet (look that up in goggle!!). Won't fit in my housing estate!! cue plan B, C and D !! We're going to offload it to a footpath outside my house on the other side of a council wall and I'll use a hand truck to get them one by one into the site through a gap some teen made wider last year and it was never fixed by the council! I'm sure each self builder has a raft of such stories. My house needs 2500 bricks and 1280 blocks. The brick supplier I'd booked and paid for in full, was meant to deliver this Friday along with the block supplier providing all the blocks, sand, cement etc. They gave away the bricks to another (assume larger) customer and it's 2 weeks to get a new order in from Belgium. I tried the other supplier I found in google for the same bricks and got through to the same woman I'd been dealing with, same company, one's a shell I'd say. Tried the supplier and they only supply to this one company in Ireland. Anyway, as a one off house they can bump you down the list so I tend to like to get things onsite a week or two early to avoid this added hassle. I've very tight for storage but if you have a brick layer onsite and no bricks you'll be forced to buy something, anything and have to live with it forever. Time management - getting answers to questions is one thing, learning on the job is another. I want to nail in about 200 nails by hand but after realizing my initial attempts were leaning tower of Pisa'esque, I purchased a first fix nail gun, my first! Wow! 200 nails in 3 hours, all batons attached to the window openings. I can sell it later but the right tool for the job for sure! I've to install my first express nails tonight after learning about them from a neighbour - fixes wood to concrete. The roofers left 6 Velux boxes behind with BBX on them. What are they for? An extra? Do I need them? I think they are to act as a vapour barrier and possibly air tightness according to initial google searches. Something else I've to figure out later on. The roof has turned out well hasn't it! They had to finished the Oriel Window Metal / Trocal flashing before they finished roof tiling. It has a ventilated ridge and those plastic covers at the edges all the way along the roof line instead of cement they used to use. I've about 40 spare tiles stored away! The outer brick/blockwork is my next major hurdle. There's a few items I need to buy, figure out and get onsite: 100mm DPC for above 1st course of blockwork above foundation 18" DPC for around windows Expansion ties - Ancon PPS200 ebonded Safety Tie - box of 250, at least I have spares! I can return the unused ones. Wall vents - using Timloc Cavity Wall Drill Vents - you drill a 25mm hold angling upwards and then plug this into it. This absolves the brick layer from having to install them as they go Wall ties - the timberframe supplier provides 4 boxes of these and marked up where the studs are to get good purchase Stop Bead and Drip Bead (plastic) for render, Weber OCR, Weber paint (I'm doing this job once the blockwork is finished), Mitre bond glue (2 part glue) Gutter Brushes for later Expansion Joints - I've two 10 meter gables, each require two expansion joints. There's an awkward window and ESB box on one end of one side so thankfully we're putting the expansion joint past both of these even though you should have one every 6 meters and within 1/2 of this distance from the corner, ours will be 3.8m from the corner. the timberframe amazing team marked up the best positions for expansion joints and identified this one before the Structural Engineer signed off on it. I've taped up all the Solitex on the outside of the Timber Frame, plugged the side door up with timber, OSB and more Frontex WA. We're still installing a lintel in the blockwork but will ignore it otherwise for the block course and if someone wants to open it later they can with an angle grinder! It saves wasting a lot of space in the utility room having a door there with no purpose. There's no sink = reason to not make it a boot room really. I'm lining all the window openings with insulation over the next week or so and adding batons to take the window straps. They want a strap within 100-150mm of any corner and no more than 700mm apart. The Straps are 1mm thick and come inside the window about 100mm. I've sourced wood to exactly match the insulation thickness which can be hard but avoids trying to plane / table saw wood onsite. This Friday I've to hope everything fits onsite as it's delivered and we've room for a telehandler afterwards for when the brickie's start! That's a snapshot of my week! I'll do a post about powering electrical devices onsite without a generator using an Electric car & Anker 2kW battery soon I think, some lesson learnt there!3 points

-

Best to put the intake upwind from the exhaust relative to the prevailing wind direction for your location (usually westerly in the UK). And ensure the intake and exhaust are both on the same building elevation to ensure even wind pressure between them. Separation: I would suggest 1.5 lateral metres minimum if you can.3 points

-

Ok to finish. Cracking part of the world. Keep posting about your bale house as very interested. Would love to have sight of your warrant drawings to see how you are dealing with the loadings, movement etc. wishful thinking... Fundamentally though if you keep the straw dry, well ventilated and the perimeter drainage around the house clear it should last a lifetime or more. If you go and plant loads of trees close to the house then it won't last so long. Are you local to the area and know the climate well? Lastly.. depending on where you are there may be a bit of salt from the sea in the air.. make sure you specify the right fixings. I have family that live on the islands and it can play havoc with fixings etc if you use the wrong ones.3 points

-

HW cylinder £1k to 1.5k incl vat Depending on ASHP £2 to 3.5k incl vat Plus another £500 for misc bits and pipe.3 points

-

Yep that’s the way to do it. don’t do little bits of ply though. cut a 250mm wide strip the length of all the cupboards.3 points

-

I would walk away. There is no way you can build a garage on top of next doors drainage field, even before you think about distances to the house. Unless an off site drainage solution was available for both houses I would say the plot is not viable. The minimum needed is permission from the land owner to the south for drainage fields for both properties to be installed under that field (assuming it is a field not other houses). If I was the vendor I would be looking for such permission, and then thinking of installing a large TP to serve both houses and the drainage field for it, then sell the plot as a serviced plot. That is about the only way I think it is viable.3 points

-

Now that I’ve looked at the block drawings I’d walk away. I wouldn’t want any aspect of my house relying on someone else’s land but nor would I want any aspect of someone else’s house relying on my land. Everything to do with our house is in our land. It’s easy to get over invested in a plot of land as you can start to see your finished house etc. It’s what I did on a previous plot but my wife hated it. We found a much better plot that very day. My dad used to tell me that if there’s doubt about something then there’s no doubt. So I’m with Russell, walk away.3 points

-

I've heard a lot of stories from bcos about incompetent work from self builders....and people expecting a free design service, Deliberate bodging and cocealment, usually by contractors Rubbish work by supposedly experienced builders. Promises to remedy a problem, only to find it ignored or concealed on a quick return. I don't fancy the job.3 points

-

This guy is a legend! Designs them and gives it away for free. Currently printing this ... SWMBO WILL HATE IT! 🤣 https://www.instructables.com/Time-Slider/3 points

-

Typically needles penetrate the building in the room above the room where the steel is being installed. Yes they are disruptive and result in more remedial works but they are a significantly more robust and safer method of providing temporary support vs strongboys particularly in wide openings such as yours. No doubt strongboys and back propping joisting is used also by some, ultimately it's your call.3 points

-

MY view on this is similar to few others, I arranged a Kick-off site visit with My BCO, this for me has always been a way of getting a positive relationship with the BCO officer, in Scotland with the Warrant the work is very formalised anyway. My invitation was open the discussion similar to "I'm planning on doing X, Y, & Z over the next few weeks, do you want to see any certain aspects? want me to send photo's? etc. and an open offer to visit whenever they were passing. I have nothing to hide, their experience and help is more valuable than then turning up ad-hoc IMHO. This worked to my advantage on the build they did call in one day and I went through the progress, all good, then when It came to pouring concrete, They were unable to visit due to other commitments so I sent photos and moved on with no issues. IF I was a BCO, and the client got twitchy with me turning up, I'd be suspicious. If its purely Insurance etc, I'm sure that could be worked around with a site visitors book for signing in etc. @JWHIT "it also seems to be the case that because we are doing a fair amount of work ourselves, and not using any of the main island contractors, they have sparked a particular interest " My View on this is simple, they don't know you or the quality of your work, so for me it's up to you to A: help them understand your ability and quality - i.e. let them see your work, your passion for the quality etc, B: be cryptic, evasive with them, and expect them to look under every stone to make sure their happy with the progress.3 points

-

Go to band p eps, they are a manufacturer not a re seller, save a fortune they will cut what thickness you want so you could go 100mm eps 90eps 80mm traditional sand and cement screed. good thickness to keep the ufh pipes well covered and a good lump to use as a big radiator.3 points

-

Just to complete this with pictures. The top picture is the Diy online kitchens under sink drawer. The second picture is the U shaped Blum under sink drawer that didn’t fit as it fouled the bottom of the sink and the Quooker wouldn’t fit behind it. The bottom picture is how we fixed that problem with the two half depth drawers one of which I cut down at the back to get it to clear the sink.3 points

-

Why are you doing it that way? I'm assuming it's PIR insualtion on top of a concrete slab? Pumped liquid screed would be around £2k.3 points

-

Another point, I stayed in a passive house many years ago before I knew much about them. And like you, thought it was stuffy. The house was empty and we were offered it as workers accommodation for a few days. It was well into the stay that we realised the mvhr unit was turned off, probably because the house was empty before we were given the keys.3 points

-

Don't get hung up on the density of insulation for sound proofing. The main job of fluffy insulation is to dampen the reverberations or "drum effect" in a cavity. Concentrate on sealing each and every air path. Perimeter, board to board, wiring holes. Downlights are a disaster. The add some fluffy insulation for reverberation. Then add mass. Denser insulation of course helps but it's an expensive way to add those extra kgs. Standard plasterboard, soundbloc and OSB are all about the same price per kg and mug cheaper than insulation. If you're feeling really cheap sand in bags or plasterboard off cuts will all help if shoved between joists above the ceiling. Finally decouple the floors although this is more important for impact noises. Strips of carpet or rubber above the joists and resilient bars underneath.3 points

-

There’s no advantage to you in fitting a GSHP. Loads of installers have pulled out of the market and are just installing ASHP now. They may make more sense in larger installations or community heating. For near passive house specs it’s a lot of cost for no benefit and more likely more downsides. We looked at it ourselves as we happened to have a spare borehole that we never paid for so I thought it might have been a way to use it. But it was still expensive, added a degree of extra complexity, was possibly too close to our water supply borehole, and we had limited space inside for the plant needed. Arguably even an ASHP was overkill for us. I heated the place for months with two small radiators. Took a while to get it up to temperature but once it was there it was fine.3 points

-

I think we've developed too much of a bias about degrees and the value they actually bring. I've met plenty of non-degree, non-formally trained engineers that will blow the socks of many engineering degree holders in both theoretical and practical knowledge. I also think we've developed a problematic prejudice towards manual work versus the degree holder. I hold a Master's degree, I studied aerospace engineering at degree level (but changed course during the degree as I got bored with the extent of mathematical modelling in front of computers) and then also studied acoustics, thermodynamics and fluid dynamics during a period where I designed exhaust systems. Now I am a heating 'engineer' installing heating systems, gas boilers, doing reparis and servicing part time - I actually find quite a lot of it very rewarding. Now, with all that being said, I do have an issue with the level of training and certification in the heating industry - I think it's appalling. But the problem with that is that is turns from protect to protectionism which becomes counterproductive. There would need to be some careful definition of what engineer actually meant and recognise various routes that can be taken to achieve this. Am I an engineer if I can take a lump of metal and form it to become a useful component part of a machine, whether as repair or new design, or am I an engineer only if I can sit in front of a cad/cam and produce design drawings along with some calculations?3 points

-

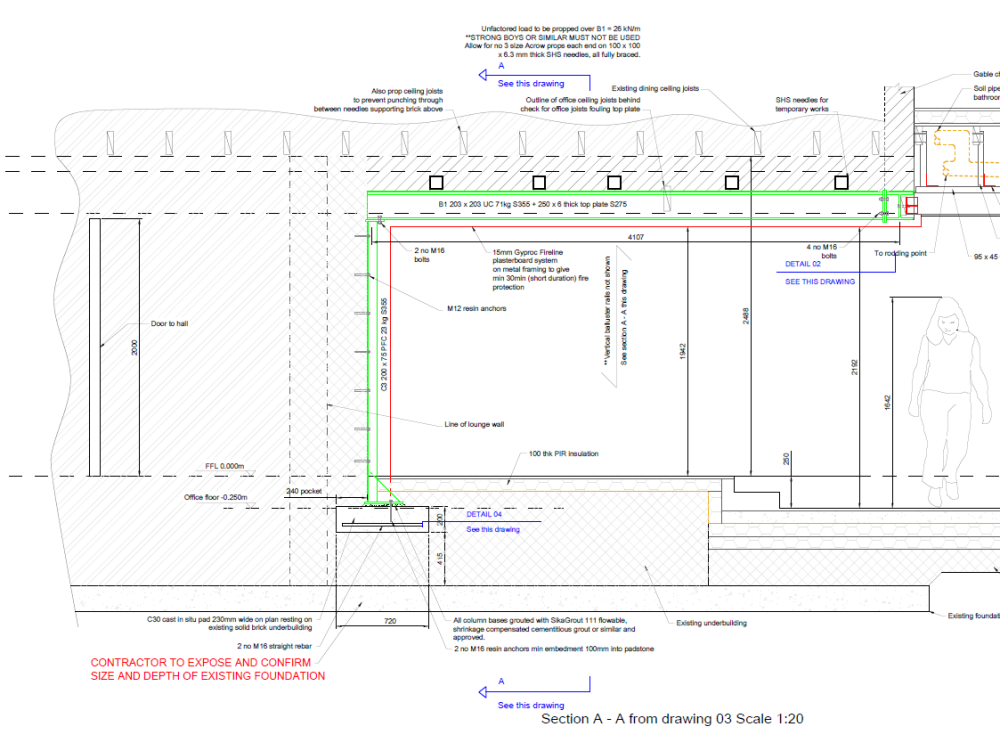

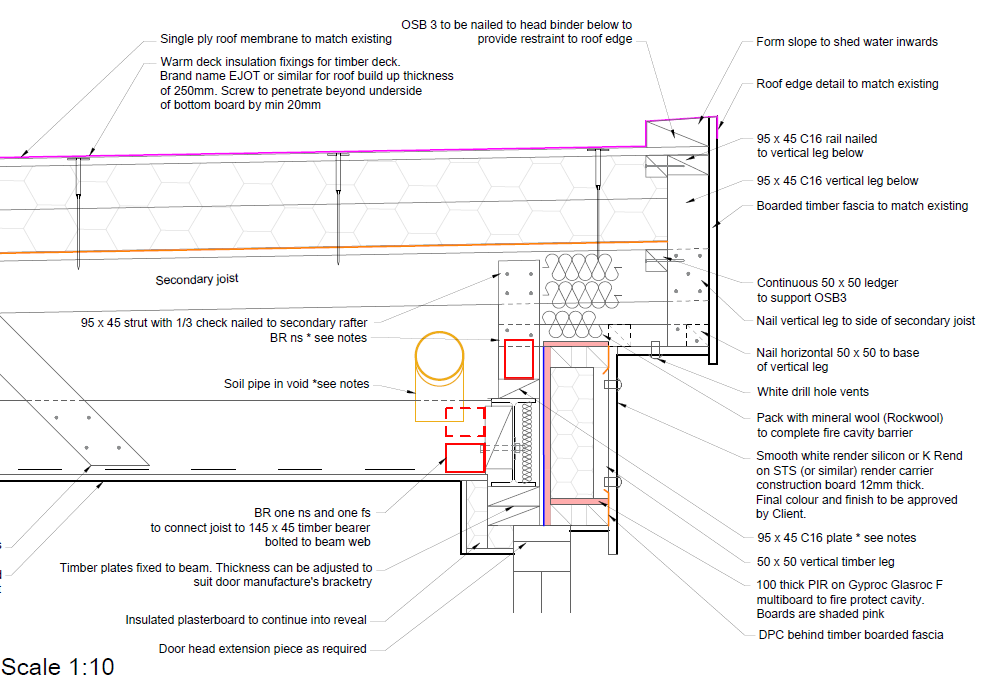

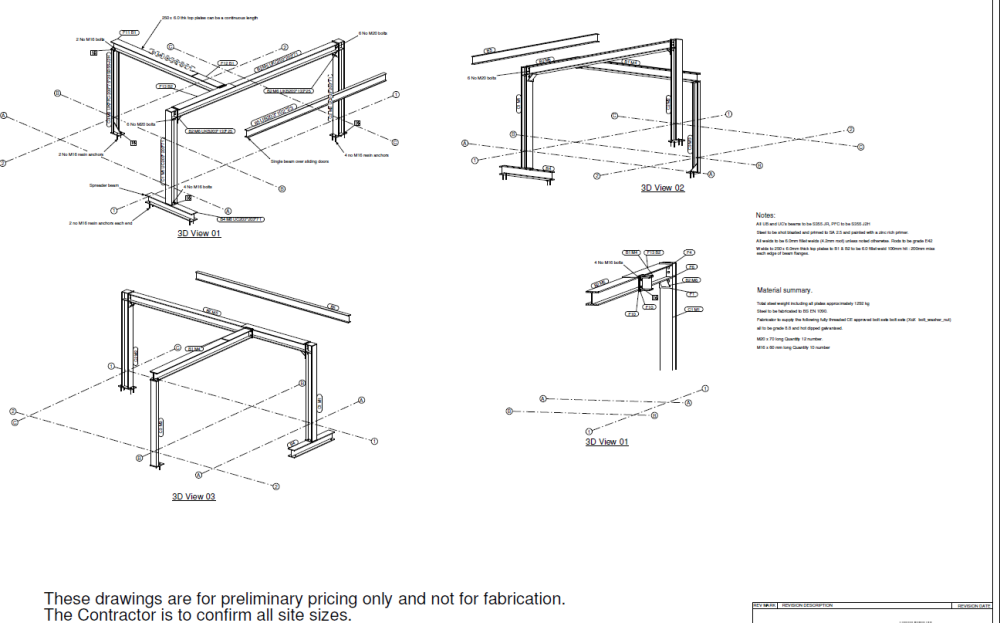

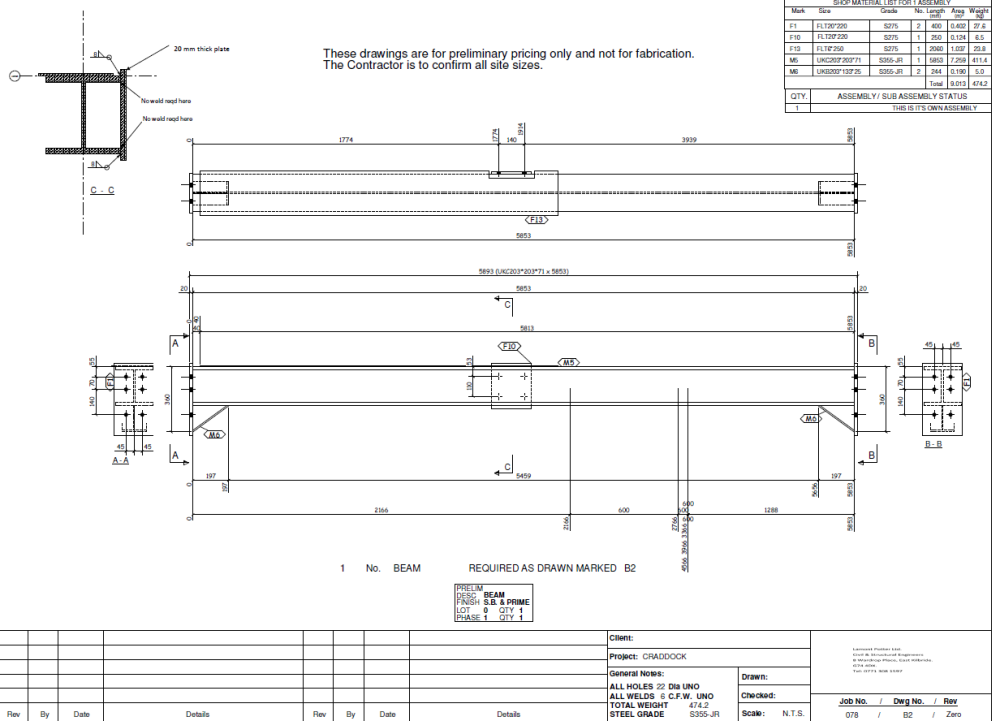

Well done you. As @ETC says annotate this up. Admire what you are doing, if you can get handle on this then the world is you oyster. Here are a few quick comments, some are obtuse but you'll learn this as you go.. don't be disheartened mind. Have a look on the internet for some of the terms I use if not clear. 1/ On the curtain wall where the glass comes down you show a flashing to shed the water outwards. Flashings need a safety lip. Show add that as the manufacture of the flashing will recommend it as a standard, so folk don't get cut on the sharp edge and it weathers much better for example, also stiffens the edge of the flashing. 2/ Make sure you show any mastic and note it as say flexible polysulphide mastic or similar and approved. BC can pull you up on this. Contractors will love you as it gives them room for manouevre. 3/ Your concrete anchors look a bit off SE wise. The two near the glazing are too close together (causes anchor spacing problems at detailed SE design stage, you could have to redraw it all!) and too close to the edge of the concrete.. all will trip you up later once the SE gets going. The two holding the I shaped section down are too long. Show them embedded into the concrete by 130mm. Also show the thread of the bolt extending above the nut by 5mm unless you are using expanding anchors. 4/ I think your mansard roof is too close to the box gutter as: (a) You'll need to get a drill etc into fix it... buildability. (b) The box gutter will have a run on it.. how do you achieve this and make all look tidy at the end of the day. (c) It will choke with debris / moss as the cladding is too close to the bottom of the box gutter (d) You will get spashing back up the cladding which could void the manufacture's warranty. BC regs in the spirit of things like to keep things 150mm above the spash zone. Simple solution.. just lift the cladding clear of the box gutter by 150mm? Ok don't get too hung up on the above. The best advice I can give you is to be brave when drawing. If you don't know something just put a note " to be confirmed" and then say why it needs to be confirmed.. it's ok to say you don't know! Below is a screen shot from a section drawing from one of my jobs. I use red colour to flag up a big structural safety issue and softer colours to pick out the bits that make the drawing easy to read. At the top there is a note where I say "also prop the ceiling joists to prevent punching through.." here what I'm doing it to try and communicate why I want something done in a certain way and what other folk need to do to make it all work. You'll also see how I'm flagging up stuff about temporary propping ect SE wise at the top of the drawing, no strong boys etc. This drawing also has a figure of a person.. bit odd .. I do this as soon as you open the drawing you get a feel for the scale, yes it's not true SE / technical detail stuff but my job is to make it easy for everyone to read an understand what I want them to do. I also dimension where I can the height of the person to avoid later "complications" and accusation that I may have shrunk / increased the figure height to make things look bigger / smaller. @ETC? surely not sir? But other's are not so honest as we know.. some folk alter the drawing aspect scale for planning purposes. The drawings above are telling a storey and targeted to the reader who will be a local builder, BC, the checking SE and the Client who has a technical background. The real objective is.. yes to provide the technical detail and that is what @ConnerR you'll probably get assessed on. But run this by you lecturer and see if they will add marks by using colour, adding explanatory notes which shows that you understand what you are drawing and how someone can take your drawings and build something from them. The annotation notes on a drawing are often as important as the detail. I'm not talking about the massive long text list down the side of the drawing.. more the annotation. I use arrows as the reader can see what I'm pointing at! It takes a bit more time but helps avoid errors. Contractors are busy folk and don't have time to read pish. Below is a bit of a fascia detail from the same job. Again I'm using colour and notes to try and pick out the important bits on this drawing. Also see how I offer alternative warm roof fixings to the Contractor but make it clear how I want them to penetrate the timbers. I use a technique to denote things on the near side and far side.. steel fabrication drawings often have this annotation. But if you do this you need to have a text box that explains the annotation.. It can be a good tool as it declutters the drawing if the annotations gets too congested. Below is a totally different style of drawing from the same job but using a specialist steel designer software package. It's two fabrication drawings for the steel fabricator..who take no prisoners if you get it wrong! The first is a general arrangement 3d drawing, the second is what is call an assembly drawing of beam B2. Beam B2 I hope the above gives you and insight into how we communicate by drawing what needs to be done and the different syles / ways of doing it. Keep posting as you make progress with your studies and all the best.3 points

-

Only for offsite systems or kits. Stick build is a load of timber from the BM and will come on account or with credit card guarantee. Plus it is from stock so can be bought just in time. ditto masonry.3 points

-

Very pleased with our wood floor upstairs. It’s not as dark as the picture shows. The second picture is how it matches against the top tread of the staircase which is yet to be oiled. It’s clearly going to be different but I’ll get it close based on some trials I’ve done. Also just about finished the bathroom downstairs. I have the loo, sink and vanity unit to fit this week then the complicated looking shower! The doors, linings, architraves and skirting arrive this week so we are getting close! End of May is the plan for moving in. Stupidly we are also doing the Cateran Yomp (54 miles in 24 hours) which is on the 8/9 June. We did it last year and I can barely walk for two weeks after it!3 points

This leaderboard is set to London/GMT+01:00