Leaderboard

Popular Content

Showing content with the highest reputation on 11/25/22 in all areas

-

I think we need to stop a bit, because we are missing the exact regulation. I was under the the impression that the section immediately in front of the door has to be flat not sloping. So you need a 1200 square dead flat before your slope. I have heard of someone in the same boat, I would cover that whole ramp in plastic sheet going up the wall, then pour a very weak mix of concrete screed on top and get the height you want. After it’s inspected smash it up with a hammer and lift the plastic.3 points

-

2 points

-

Remove the panel it’s fitted to and do away with it or put it inside the opening instead of outside. Watch out for bare terminals behind that could touch the metalwork2 points

-

The correct thing to do would be to ask your window supplier to manufacture the windows without trickle vents being drilled. And supply the trickle vent plastic bits separately. If the building inspector insists on fitting them, then screw them on to the frame, but don't actually drill to provide ventilation.2 points

-

Not sure if this has been mentioned already, but you could try an optical sensor, something like this https://paraquatics.co.uk/product/tunze-osmolator-5017-replacement-optical-sensor/ I used exactly this for an auto top-up for a reef aquarium. Worked faultlessly - though would obviously trigger the pump when the level fell too low - but sure it could be reversed so as to trigger an alarm or similar if it sensed water. Worth thinking about as a back-up.2 points

-

Just a few progress photos of the inside and how its been moving along since the builders left after completing their work: First job was the warm roof, literally just to get some of the 100mm boards used up as i had no where else to put them I was also trying to get as much of the dusty bits out of the way before opening this room up to the rest of the bungalow, so removed the outer bricks from under the bathroom window (the blocks will be done later down the line, as the new bathroom needs creating first so i'm not without showering and toilet facilities). Cleaned up under the floor and removed the old kitchen window, door and brickwork. 2 new windows went in, triple glazed, with just the bow window to swap out for a standard casement window later down the line. Next task was to get a firm floor to work off, so I set about getting all necessary pipes in, and also got the electrician in to sort the sockets out, and finally another load of insulation, trying my best to use up all my bits rather than skipping them A further 50mm to the roof and 20mm under it: Followed by airtight primer and tape round all of the edges Started working on the box section at the top of the roof which will house the ventilation pipes and cover up any thermal bridges from the timber wall header At this point the building inspector came, and asked me what on earth the pipes were for?! Told him they were for the mechanical ventilation and he looked nonethewiser, but otherwise was happy for me to carry on Another satisfying job using up all my odds and ends of plasterboard this time! Before the front of the box goes on, i need to cut out the 125mm holes for the vent pipe to come through, and install the plenum at each end. Also found a use for the spare render beads i had from doing the dining room (part 1), trimmed them down with the planer to 11mm, which will give me a perfect level base to work from when i put the bonding coat on. Fingers crossed the next time i post, it'll be more or less done, minus the bathroom end.1 point

-

You've got to show these things who's boss! Seriously, if the socket is the type I think it is, then the back of it will have a wiring loom going into crimped receptacles. There may be some slack in that loom to allow you to dismount the socket and lay it flat. Is the recessed plate holding the socket riveted or screwed to the chassis?1 point

-

I think you're right about ratings. They're usually the highest output you can expect, which will generally be when it's warmer outside and you're generating relatively low temperature water. I have a 5 kW unit. With a well-insulated house, I never particularly felt the need for anything bigger until the cost of electricity went up and we went onto Octopus Go. On very cold nights it's realistically going to be more like an average of 3 kW when you take the lower output and periodic defrosting into account. Stuffing all of our expected 24 hour heat loss into a 4 period with Go isn't realistic, especially when I'd ideally like to also heat up our hot water tank at the end of that period. Realistically, a more powerful heat pump would give me more options. I may think about that if and when the current into needs replacing.1 point

-

I wouldn’t worry Jilly It won’t even get a mention from BC Planners are to short staffed to get involved The lady we bought our first plot off Her house is listed She wanted me to fit Ally bifolds at the back of her house but planners wanted them replacing with timber Like for like with the rotten French doors that have only lasted ten years She just applied for Ally doors and lantern No problem as long as they are round the back of the house1 point

-

1 point

-

A drip for a week is probably within the realms of a DIY dehumidifier & heating on job IMO for a few weeks (dehumidifier for longer). I had over looked the 7 days statement, I have to admit.1 point

-

1 point

-

1 point

-

Do grid tied inverters cost that much more? For me, ignoring any export payment, the benefit of grid tie is not discontinuity when the battery runs out; a transfer switch is never instantaneous. Also it means (potentially) 100% of household can be powered from PV + solar in summer rather than having to segregate the house into 2 consumer units 1 of which can never get the benefit of PV. Also, I'd imagine the battery inverter is not instant response so I bet the lights dim when you put on the kettle when on it, but that's a minor niggle compared to the other issues.1 point

-

So much for a bespoke solution. What's their problem? Obviously I think you should find a more accommodating joiner.1 point

-

Sorry I am thick again I see the socket in your picture and the plug that has to go into it and see no reason it just won't plug in. Just what is in the way?1 point

-

How far is it away from actually fitting? The cable group going into the plug is overwrapped with heatshrink tubing. Might you be able to soften it enough to fold it over with a hairdryer or heat-gun? I'm not really understanding what space it doesn't fit into.1 point

-

Thank you all for your advice. I’m now waiting for the planning officer to come out to view. So will update here once I’ve got an answer.1 point

-

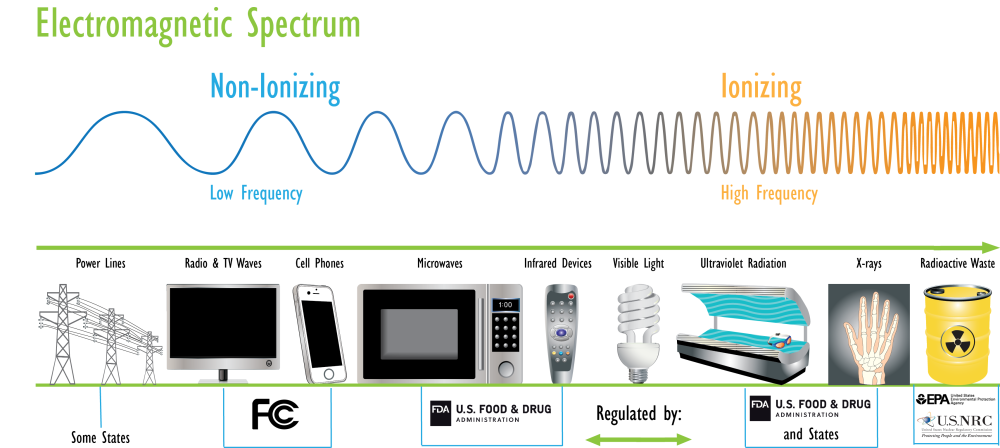

It also reinforces the concept that frequently is important, it uses it as the z-axis after all. Much better to explain it as small packets of energy (quanta) hitting the atom. The more packets sent to the target, the greater likelihood the electron is displaced. This can also explain efficiency quite nicely as most quanta will miss. Common language breaks down in this realm as it is hard to describe a continuous bombardment of massless sub atomic particles without using the term frequency. Even E=hv uses frequency to describe the energy. I wish quantum physics had been explored before Newtonian Physics. We would have a lot less confusion.1 point

-

Remember the level entry requirements stipulate a flat area in front of the door, so a wooden ramp on top of that, would have to have that flat are first before it starts to slope. That is NOT a "level entry" door. If it was it would not have an external cill like that, just a threshold strip that floor inside and ramp outside tuck under.1 point

-

Dead simple. Telford TS, 28mm DHW coil, no other coils. Oil > TS primary water. 22 or 28mm circs, depending on size of boiler, 21-26 will be fine on 22mm circs. Set the stat and boiler flow temps to suit and away we go 👍🏴 You’ll want high and low stat pockets in the cylinder to be able to better reference / respond, vs the one cyl stat. Will give you guest mode then, more stored ( heated ) primary water for sporadic higher usage. A bit like the old “basin / bath” setups on the old E7 / E10 cylinders of yesteryear.1 point

-

IME, even with the recommended buildup tarmac without edging (curb retainers) will only last 10 years or so before cracking and moving. Have you thought about using gravel mats for retention?1 point

-

that's some good research! and if the Ebara pumps don't work out then i'll revisit the Zoellar pumps. can't break the hole wider. it's fine as is. message understood. both pumps will be at different levels and floats will not be near/facing the other pump so free movement should be possible.1 point

-

Here is a simple graph. Oil has a lower condensing temp compared to gas1 point

-

As I understand it, all houses require it. It's possible there's level access around the side/back where you can't see it - it just needs to be accessible from a parking spot. There's no requirement for you to maintain level access, only for it to exist at the time it's signed off. Do something cheap and temporary. Get hold of some bits of wood and build a ramp on top of what's there. Or lay plastic over your existing ramp, and lay down some cheap (even second hand) pavers in a weak concrete mix (or even just siliconed/glued to bits of wood of the right thickness underneath). Be creative - you might do it for something close to free. We did something similar with ours when the inspector noted the absence of level access on his final visit. We bodged something up with some concrete council pavers we had lying around, sent him a photo, then dismantled it as soon as we got the certificate.1 point

-

1 point

-

It's a huge shame about the last minute delay (and other challenges along the way), but your parents must be chuffed to bits with the result. They should be proud of you.1 point

-

Just had a preliminary air test on masonry new build flat roof bungalow before I start plaster boarding...Is 1.03 airtightness and 1.3 ACH good at this point? Is it financially worth pursuing lower?1 point

-

Put the obvious bits right and ask him to do a free secondary report. Then offer to sell your services as a quality manager.1 point

-

It is strange how frequency always causes the 'damage' rather than energy levels. Ionising means removing the electron from the atom, leaving an ion. It happens all the time and at different energy levels how we make plasma). Frequency has very little to do with the process, other than the speed and quantity of the processes. It is all to do with the amount of energy needed to knock the electron into a higher orbit. Ionisation is a useful process as we can create molecules that would not normally exist in large quantities, or decay into the constituent parts very quickly. Ozone (O3) is probably one of the most common ones made and has many indirect advantages (sterilisation), though in large quantises can be damaging (it makes the body 'rust').1 point

-

Yet Geocomposite drains are used for drainage in clay environments - sometimes in preference to gravel. I personally feel that the larger the surface area you can present to the silt as a barrier, the longer it will last as a drain. Without it, the silt will quickly find its way into the perforated pipe.1 point

-

Gravel or clean crushed concrete - should be £25/tonne loose or £40/tonne bagged - that’s decorative slate and I wouldn’t be burying it !1 point

-

Gives pretty much constant, instant hot water production. Oil + TS is a very good solution for DHW. Same with gas, but gas starts to throttle down as it nears the set temp, oil doesn’t.1 point

-

40mm clean limestone is what is used around here (West Wales) for land drains, it depends on your local availability what is used, here pea shingle is twice the price of limestone.1 point

-

was thinking of using this will be sitting on chalk around French drain with non woven between chalk and slate any views welcomed Grey Slate Chippings 20mm - Slate Chippings | Gravel Master1 point

-

I wouldn’t use a membrane in clay. Can clog up the membrane. Could put membrane on top if soil on to of that.1 point

-

I looked at plots endlessly on plot finder etc before eventually settling for knock down and rebuild but I’m based in Dover and at the time ( less so now) you could get a detached on about 1/3 acre for about 300k.. These days I notice the small developers around tend to favour the infill plots, buying houses with large gardens and then splitting up the plot, renovate sell up and then build their own or in the opposite order of their cash flow allows.. Disadvantages are that plot size might be a little constrained and the neighbours can be rather annoyed and object to planning applications but usually this is surmountable.. especially if you are replacing a single dwelling with a single dwelling or maximum of two…services tend to cost far less… Deffo won’t get the 1/3rd ratios on plot cost:build cost and profit doing it that way.. our plot ( demolished house) cost just over 1/3rd of likely final value but we were able to live there for 5 years before demolishing and retained the large garage so not so bad I guess … build costs..that’s another story! Sounds like you have been looking for a while for a suitable plot..just outside the m25 might need some flexibility and compromise1 point

-

1 point

-

will run it by SWMBO and see what she says exactly!1 point

-

10mm Pea gravel is too fine and easily gets clogged with silt and mud. 20mm gravel is best for drainage. Limestone is going to end up like a subbase! Use a non-woven geotextile.1 point

-

About 100W when left on standby, give or take. Our bedroom does have an overnight overheating issue, and the only heat source is the two bodies in it. Having cats means we keep the door closed, and a nearby trainline means we keep the window closed, and MVHR really doesn't move much heat around. I've installed a fan coil the actively cools the room in summer (cold water from the ASHP), and assists in passively cooling it in winter by circulating air from the hallway and guest bedroom (generally the coldest room in the house). I guess at the moment we're now providing about 4kWh from body heat, vs about 8kWh from electrical gadgets and 10kWh of active heating out of the ASHP, per day. So not an insignificant contribution.1 point

-

50W per m2 on standby; 100W when powered up; 200W when working hard. Average male.of the order 1.5-2m2 A small plug in radiator is about right. SWMBO says when I'm away the towel rail is needed to maintain the same indoor temperature. At least that's how she claims it's maintained...1 point

-

Combination ‘appliance’ traps are horrible gurgley noisy things. Can you get a washing machine up stand in there to take both discharges? Link You simply fit a compression T into this and create 2x up stands for both discharge hoses to ‘poke’ into. You can go ‘posh’ and fit one of these; Link on top of that single up stand to be completely silent ( very close to ) during discharge. A client of mine has recently employed a 2nd fix plumber, and he’s connected their washing machine to a combination waste and it’s noisy as feck. 👎. A good reminder to never do that.1 point

-

I think that'd lower the trap outlet too much. Personally I'd remove the current setup and replace it with a McAlpine SSK2 double bowl space save kit: It gives two appliance inlets and a third universal inlet should it be required for something else. It also pushes all the gubbins out of the way (often to the back wall but obviously you've got pipework there already but it could sit in front of that) thus freeing up loads of cupboard space.1 point

-

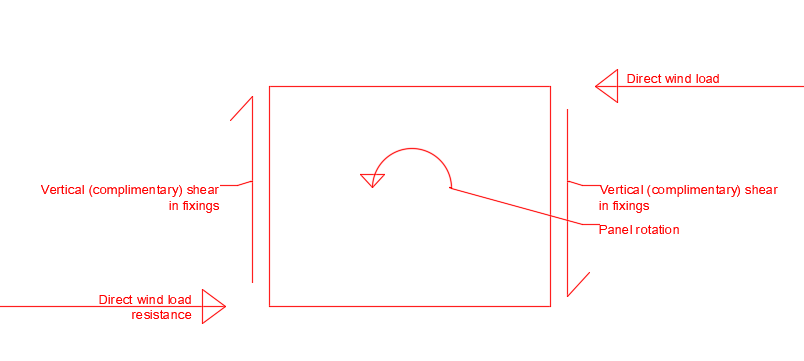

Unfortunately it often partly ends up that way, a non load bearing racking wall can catch you out. Advise you stick with your SE's specification. In written form you have a timber frame panel that carries no vertical load but it needs to stop things moving sideways. Say the top of the panel is loaded horizontally. This horizontal force gets transferred to say the floor below that resists the horizontal force. Now you have two forces acting in equal an opposite directions but they are separated vertically. This introduces an overturning effect into the panel. We call this a complimentary shear force. The static laws of physics say that for a body to remain still every force has to have an equal an opposite force. Thus even though your panel is not carrying a vertical load.. only a wind load the vertical fixings at on side will be subject to uplift and at the other side a downwards force. That is why you may wonder why your SE has come up with what may seem an onerous spec.1 point

-

make a cheap wooden ramp. get completion cert. burn ramp and do patio as you like.1 point

-

Updating on outcome here. I ended up using an Europlast EER125 single room heat recovery which I got on eBay for £110. Fitted today. Easy fit, like an extractor fan. Works by reversing directions of air flow every 70 seconds. There's a ceramic heat exchanger inside which presumably collects the heat on the exhaust cycle and reuses it when it pulls the air back in. Two modes of operation fast and slow. Slow is not too noisy at all. You wouldn't want fast in a bedroom but fine in a bathroom/kitchen. Only issues I can see. You have to in theory wash the filters every three months so that means unclipping the grille and pulling out the heat exchanger. How many people will be bothered to do that in reality I don't know. Second issue, you definitely need a 127mm hole not a 125mm one, and you need the hole to be dead straight. I had a bit of a small bend on the hole when it crossed the cavity (was reusing an existing hole) and it caused the plastic tube to bend slightly which meant that the fan caught on the edge and made a noise. Needed to remove and expand the hole slightly. Will wait for real world performance in the winter but so far so good and certainly a step up from putting in an extractor fan. Hope this helps somebody considering a similar option.1 point

-

Actually I had mentioned to the lawyer I don't know if I should buy it or my parents should be buying. I would just be organising it. Hadn't thought of the VAT issue., Using a main contractor and with a lot less bespoke stuff than in my house most stuff will be zero rated, but it is definitely worth thinking about. I guess I am in a different situation to most people, I can afford to retire and earn way more than I spend. In that situation I think I may as well make other people's lives better so frequently pay for things for family members and friends. I enjoy it and they do too. I even paid for my wife's friend's divorce lawyer when her husband hid all their money and she was at risking of losing her kids. I prefer direct action, to giving to unaccountable charities. My parents are 71 and 72. Their health is fine and I'd like to hope they will be around for a few years yet. They could afford to buy the land and build the house, although they probably couldn't lay their hands on the cash next week to finance the plot. But they wouldn't know where to start to organise getting a house built. If I can make their life easier then I think its the right thing to do, I am sure most people would want to do the same if they could.1 point

-

0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)