Leaderboard

Popular Content

Showing content with the highest reputation on 10/15/22 in all areas

-

Yes - it would help. You need 2 things - a wide air gap and a good seal around the edge. It will not cut other noise routes, however.2 points

-

I would look at your contract as that little picture shows a fair old mess, appreciate that you might find difficulty in getting another builder but if you continue down this route what else will they mess up, and you will have spent more money on them and then on further trades to rectifying issues, which is generally destructive work. Best to get it right the first time.2 points

-

Well I went with @Temp's suggestion and ended up with sand from Cornwall. With the shipping it cost a fortune but I had already bought the bricks and had them approved by Planning so no way of going back. I bought 2 tonne bags. Material was about £80, shipping £175 (2 pallets). I will need 2 more. I think it will dry a bit lighter than the photo but you can see in the foreground the colour of mortar made with our local sand would not have worked.2 points

-

The window is just hitting the dew point temperature, while also being is the path of humid air. https://en.wikipedia.org/wiki/Dew_point You run a risk of condensation forming inside the shower room as colder, external air, will be mixing with warmer, internal air. Remember that we tend to measure relative humidity, not absolute humidity which is the actual mass of water in the air. So while the temperature and AH may seemingly only drop a small amount, it is enough to cause condensation. You can get condensation forming at high temperatures, think of that puff of steam that comes out when you open an oven door. The local air temperature may be 120°C, and the kitchen temp 22°C, but there is enough difference to cause a phase change from vapour to liquid, in a fraction of a second.2 points

-

You can get a good idea of the typical prices online, but local supply should be better. Go in to 2 or 3 of the local merchants and talk to the lead salesperson. They will remember you and take your first enquiry for a quote very seriously. Be perfectly straight that you will be comparing suppliers. A good merchant will be aware that they might not get all the job, as there are some areas where they can't compete. But a good relationship with one is ideal, for cost and service. For example, our drainage supplier advised that prices were about to double overnight, which they did, and so saved us a lot. Wickes is great for cost guidance. If they can sell 1 piece of wood/ ply etc at their published price, then you know your target is below that. And all their prices are published, to their great credit. And keep discussing here as someone else will have recent knowledge of best prices. BUT always remember that efficient design and avoidance of waste is worth more than any last few % you manage to extract.2 points

-

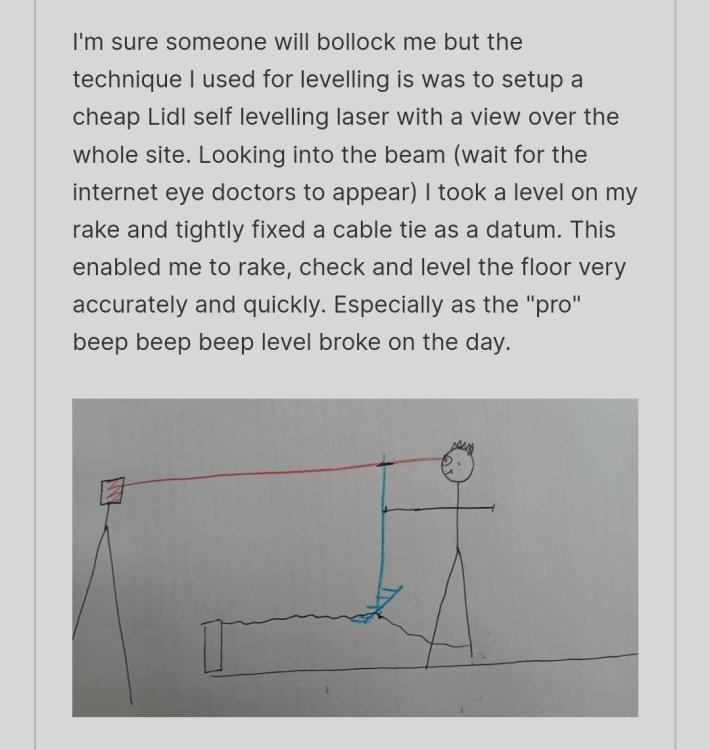

A sturdy metal rake is the top tool for concrete, forget shovelling. Wellies and gloves too, it's nasty on one's skin. I wouldn't worry about having it a bit wetter for what you're doing, it's not a skyscraper, the slight reduction in strength will be more than compensated by having it a bit more workable. Tamping it down with the rake will work fine to remove air at the scale you're at if you want to avoid a poker. However a couple of pieces of rebar are cheap and will make it infinitely stronger. Keep them about 50mm from the bottom of the trench, supported on chunks of brick/rubble. If you have it I'd be tempted to use lengths of rebar instead of timber pegs. You can just leave them in the concrete when you're done. The string will just get in the way I reckon. Here is my technique for one man concrete. Mates and concrete goes the same way everytime I've seen it. All first timers start really enthusiastic until about 10 minutes in. Then they start leaning on tools and grumbling about the heavyness of the work. Self scheduled breaks start appearing, totally unaware of the time limited nature of the job. The couple of seasoned concrete workers meanwhile be pushing on, steely eyed and sweating. Have a power washer setup if you have one. If not a couple of large tubs and stiff brushes. The job isn't finished until everything is cleaned down. Best of luck!1 point

-

It can work very well. When our house was being built we were on site with the architect one day and suddenly a huge racket errupted from over the boundary about 10m away. It turned out to be a large swimming pool behind a blockwork wall, in a building at the bottom of an adjacent garden. It had been built in the field on which our house now sat (and it turned out they also emptied the pool once a year into the field - now our newly turfed lawn, but that's another story). Anyway, archy immediately specs up secondary glazing on that elevation, a simple batten frame put up just inside the window reveals with a plastic framed glass pane with rubber gasket on plastic hinges at one side. and with a little sliding latch on the other. Very effective with a gap of about 10cm to the original DG unit. The noisy family dissolved away and we have since taken the secondary units out as new owners of the property are much more considerate.1 point

-

My house was already insulated when I bought it, but yes, that's sound advice to anyone wanting to save money on heating.1 point

-

I’m sorry to hear that, very depressing. We used secondary glazing in our previous house to try and dampen road noise, it worked to a limited extent, sadly for your situation I suspect it will only turn the noise down a little bit but you’ll still be able to hear the little erks. IIRC I bought a kit online (it was a long time ago) not too expensive and easy to fit. Good luck.1 point

-

When are telescopic air vent required? I can’t understand why he needs to use them as the external air brick is under the suspended floor level. I have been reading they are only required when external ground floor is above internal floor height1 point

-

Good luck, ask a few mates for help easier with a few bodies.. hire a vibrating poker, gets the air out the concrete, turns it from an aero bar consistently to a solid chocolate foundation of goodness1 point

-

Christ on a bike and I thought I had seen it all, I would not have them on site.1 point

-

1 point

-

1 point

-

Got our big ones 2x1x1m from a builders merchants, but we'll also got smaller ones about 300 deep various lengths from B&Q.1 point

-

We have just finished building some gabions. I bought ours from Fine Mesh Metals. I have some more to build next year and from the experience I have gained I will build my own baskets by crimping sheets of galvanised mesh. It should be a lot cheaper and the crimping tool and fittings are easy to buy. I faced the baskets with sandstone from the garden and backfilled with concrete blocks from the demolished garage. https://www.gabionbaskets.co.uk/gabion/gabion-design-and-prices1 point

-

lovely. thank you. the bosses on those are 60mm. should I get the 50mm ones or the 63mm ones? I presume the 50mm as it looks like they'll expand to fill up the 60mm hole?1 point

-

He clearly forgot or didn't know the void should be ventilated. Got to question what else he doesn't know or will forget.1 point

-

Lots of builders around us are starting to slow down, cost of heat and mortgage is keeping people's money in their pockets, so may be easier now than it was a couple of months ago1 point

-

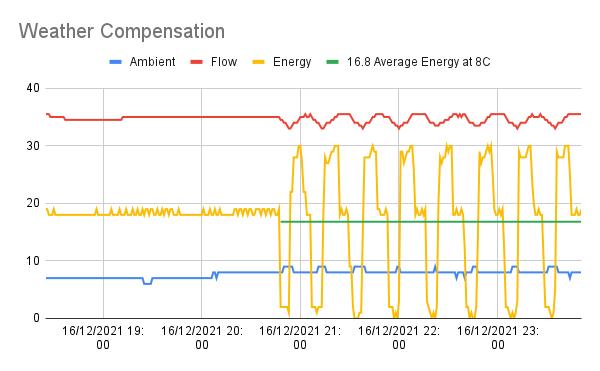

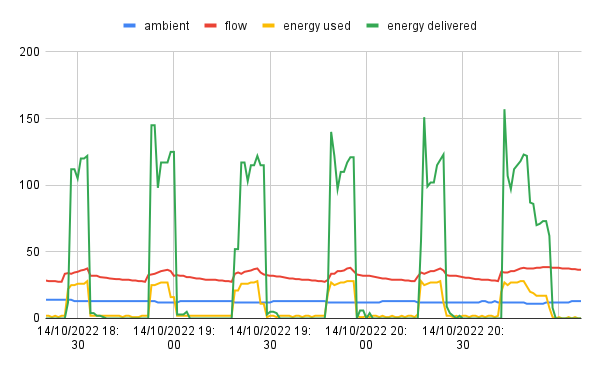

If you want to see what cycling looks like here are some graphs from my 14kW Ecodan. The first pic is from last year and you can see as the outside temp reaches about 8 degrees, it starts cycling at about 3 x per hour. The Y axis scale for energy is joules per minute. The minimum the ASHP will use steady state (no cycling) is about 1.1kW so maybe 5kW delivered. The second picture is from yesterday. I now have my MMSP monitoring working so can show energy delivered. It was more like 14 degrees and the heating was barely needed (it's running on weather comp only and keeping my whole house at about 20 deg). The cycling is a bit less frequent, maybe 2x per hour. The COP for the 3 hours or so is 3.9 and it's delivering an average of 2.2kW.1 point

-

You’ll thank yourself later. Cost of a months re t to find another contractor would soon pale into insignificance when retrospective repairs either stopped you moving in anyways, or cost several thousands to correct whilst you were living in it. Bite the bullet, not great news I know, but these guys are just crap.1 point

-

A good place to start with another contractor. All the nasty work is done. Now the standards need to improve.1 point

-

That would be a good price. I don't need any but was so surprised that I searched, but £30 without feet is the best i have seen. Obv not on orkney. A cheap alternative for a longish length is whatever local fences look like. Post and 3 wires? Then put scaffolding mesh on it.1 point

-

I do agree. But I am not sure what to do. If I sack the “builder” (which is the right thing to do) how long before I find another. I’m living in rented accommodation whilst the work is on-going so it will cost. I’ve paid the builder up to DPC level. Just thinking out loud here. Might have to bite the bullet and let them go. thanks all1 point

-

By having the window open, you're cooling the inside pane of glass (imagine a waterfall of cold outside air pouring in through the open window). This is enough of a drop for condensation to be formed. Better off having the window closes and having the fan womed for longer.1 point

-

Easifill is a finisher. The bulk of the work, including bedding in the tapes, needs the joint filler Get that as flat and smooth as possible and use Easifill to complete, sanding and adding more as required. Easifill goes off much quicker, so only mix up what you can use, making bigger mixes as you get used to using it / workable “open” time.1 point

-

Wasting your breath. Continuing with these clowns is a suicide mission. If you’re happy with these idiots then on your head be it sorry. You’re being given sound advice here, what you do with it is up to you. Pretty much why I instructed my clients in Leicester to sack their ‘builder’…… complete buffoons of an order of magnitude. Causing more harm than good, and covering it over hoping it wouldn’t get seen / discovered. Even staged ‘photo shoots’ for BCO then didn’t carry on with the same standards. Far from it.1 point

-

Whether it’s ridiculous or depends on your attitude towards air tightness. If you go to the trouble and expense of applying an air tight barrier with great care and attention to to detail then two tests is a tiny fraction of the overall cost. Moreover, if the first test shows up a number if areas to fix then it will pay for itself in the long run. It’s about £250 for a test. £500 well spent I reckon.1 point

-

Where the two bricks are length wise should that be a lintel? But generally - see above, a two year old could do a better job.1 point

-

That’s a bag of 💩. Stop them now and part ways immediately. This will NOT get better, only worse.1 point

-

1 point

-

Weren’t you curious as to whether any improvements were made ( or the opposite ) since the primary test? I’m rectifying every defect / not great bit of taping / improving the AT detailing on my current clients PH build and I’m going to look meagrely to getting the final “as built” test done tbh, eg to see how we’ve improved things. 0.59 ACH when provisionally tested, but since then I’ve gone to the enth to rectify / improve this. That’s included having 2 pairs of large french doors taken out and re-fitted by a much better window company ( Simon Chadwick of SMC, great guys if anyone needs a nationwide window supplier / fitter ) so, now I can no longer see daylight through them!! Should be a good place to start, lol 1st general builder, since discharged, had not helped things at all. I’ve hopefully found and rectified all the damage his crack team of AT membrane assassins caused 🤞( through ignorance as well as what they KNEW they’d damaged, but then immediately tried to cover over and hide vs repair, ffs ), so am hoping to get this project down to 0.3 or thereabouts when done. Sub 0.3 I think would not be impossible. The challenge will be to retrospectively seal the house when the installed systems are in and the bathrooms and kitchens ( fouls and wastes etc ) and MVHR are fitted and functional. I expect I’ll use some drain ‘test balloons’ to seal the outgoing FW connections immediately after they leave the insulated raft foundation and appear at the first chambers, and just make some EPS bungs for the 200mm MVHR fresh / exhaust exit the exterior walls. Add to this; the whole frame has since been blown full of densely packed cellulose Warmcell, entire ground floor has been tiled and the adhesive now holds the wall to slab AT tapes firmly down ( there is a huge amount of linear meterage of that, and then add my 20+ penetrations for external lighting / sound / WAP / power etc, and curiosity is, as usual, eating me alive! Ergo, the second test is 100% happening……..even if it was NOT required My plan is to use the sticky clear membrane ( the one the AT crews use over the keyholes / duct ends etc ) to seal the windows / doors / keyholes etc ( from both the inside AND the outside so they cope with both the negative and positive blower cycles without coming detached ) for one specific ‘build fabric only’ test, and then quickly remove those for another ‘final / actual’ as built test. I’ll leave the wastes and MVHR plugged for that test as I really want to know I removed the obvious major issues from the poor initial window and door installations.1 point

-

With our Austrian supplier, at a certain glass size it is automatically recommended. If it fails due to nickel sulphide inclusions. It’s tough luck, buy a new one. I’m at the stage now that heat soak on toughened, is standard on all sizes.1 point

-

1 point

-

Welcome. There are some very helpful people here but just remember, the only silly question, is the one you didn't ask. Marvin1 point

-

Getting BC approval for an installation in one position does not allow you to move it where you want, the wording may say it is installed in the property without being specific on location. that aside there are loads of pre made protrusion sealing cowls/shrouds for flues, downpipes etc.1 point

-

But reading your posts, they don’t seem very rational. You have said it is nothing to do with the heating, and maybe you are right. But you have not explored other factors in any meaningful way. i do think you need to experiment with a few humidity readings in the building (both the extension and the original house), record some data over a week, then if humidity is higher than about 49% hire some dehumifiers and get it right down to 35% and keep it at that humidity level for at least a week. Meanwhile, remove all mould, airtight and insulate the house and install MVHR. Once that’s all done, switch the MVHR on and return the dehumidifiers to the hire shop. That’s what we did with a 95 year old very damp house and it worked. If you can’t do that, then either do what you can and accept there will be some mould, or sell up and buy somewhere less mouldy.1 point

-

Correct. It becomes a lighter colour, harder and brittle in daylight esp sun, over 2 of 3 years. I think brown is just a cheap default colour, and grey is more expensive to make but more attractive.1 point

-

Very hard to predict at the moment, I've heard Network Rail are trying to lock in prices on some of the more specialist work by not going to competetive tender, on the other hand on the domestic side I'm inclined to think things might cool off significantly. In any event having been in the construction industry for nearly forty years, about half that time being a contractor it seems that every seven years or so we get a big down turn.. you set yourself up, maybe buy some plant, even a bigger yard!.. employ more folk and just as it seems you have cracked it and made a little money it all goes downhill fast! That is me using the seaweed test, and if you believe in that we are due for a downturn anyway. Good news ahead for the self builder.. but problem is you can't rely on the plot / house value increasing to make the finances look good. If you do it right though and spend the time on good design and cost control you should still weather most storms.1 point

-

The 11.2 has a scroll compressor which gives a much flatter efficiency curve (COP vs ambient) than the twin rotary compressor in the 8.5, so better efficiency at very cold temps. Power delivery is constantly variable down to around 30% of full power so it can deal with low loads really well. Also I very much agree about the desirability of having the extra headroom for the really cold nights.1 point

-

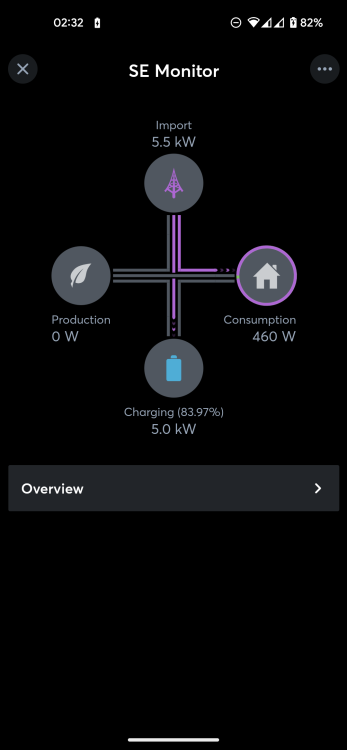

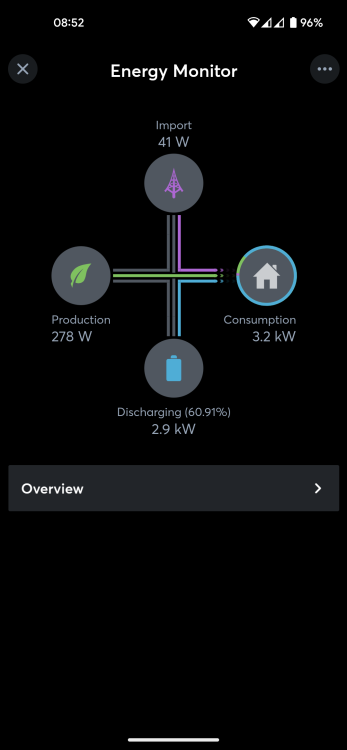

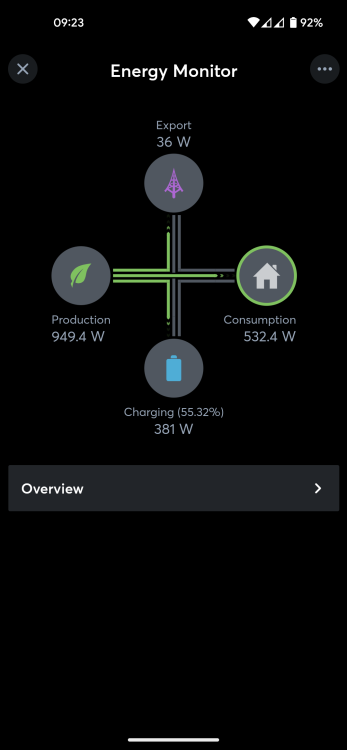

This was super helpful. I also found the solaredge example on Loxone knowledge base which was slightly helpful (the author unfortunately did not understand basic additive mathematics), and some pointers on the Loxone discussion group, and I got the full monitoring/reporting integration working! Direct Loxone to inverter over TCP, not external servers or cloud involved. It'd be fun to do charge control from Loxone too, but first I need to try and address the glitchiness of the scale factors changing (polling them races against the value being scaled), and also figure out what units the accumulated energy meter is in, it claims watt hours, but looks more like joules to me! Images show overnight cheap rate charging from grid, discharging this morning, then charging from PV.1 point

-

Hardcore, type1 or clean crushed concrete, compact that with a whacker plate then blind with sharp sand or fill sand which is cheaper if you can get it. then DPC then insulation1 point

-

Mitsubishi Ecodan R32 (PUZ-WM112A). It's similar to most other latest brands/models using scroll compressors with R32 or R290 refrigerant. I was lucky to find an installer who really knew their stuff and did a fantastic job.1 point

-

I still love this pic as I think it is the only time in 25+ years I’ve seen the collets used correctly and the correct colour per pipe … It is the only time I’ve seen JG used and installed as per MIs..1 point

-

Google can find very expensive white sand but most seems to be much further north, like Scotland. There is grey/silver on ebay from Cornwall.. https://www.ebay.co.uk/itm/Fine-Building-SAND-in-a-Bulk-Dumpy-Bag-NATIONWIDE-delivery-from-Cornwall/264718480404?mkcid=1&mkrid=710-53481-19255-0&campid=5338624526&toolid=20006&customid=a73f1d7d0c7be307511759f94c6d873c&pageci=50c334c0-58c6-4b6e-b669-048735570dc9&redirect=mobile But I would try and find the quarry and buy direct rathe than through ebay.1 point

-

Or just get a really good builder who will know other trades you need locally, I only used an architect to put my pencil drawings on CAD (and he still got it wrong!) No QS, No SE, i was PM to keep an eye on detail. 👍1 point

-

With hindsight, with my barn project, I would have got a pour in, and offset the extra costs of doing so by working extra hours / days at my job on the days I ultimately spent DIYing it. You could probably work out the cubic meter age you’d need and how much aggregate, cement, sand etc you’d need if DIYing it, add in fuel or electric costs of your mixer, etc etc. bad back etc etc. if those costs were £thousands less than a pour fair enough but I doubt it would be TBH. good luck.1 point

-

That's a harsh thing to have to do. We did the same. We refused to pay the final invoice of £8000. That caused ructions. They subsided the moment we sent them filmed evidence of extremely unprofessional behaviour to substantiate our claim. I bless @Stones for his advice - years ago - to install a video camera . Actually worth more than its weight in gold . I made sure I got witten agreement to take video images of everyone on site.1 point

-

0 points

-

0 points