Leaderboard

Popular Content

Showing content with the highest reputation on 11/17/21 in all areas

-

It’s true ! ? Not complete ( of course ) but after 7 years we actually move in tomorrow. What have i learnt ? . With infinite support and help from this forum you can build a non standard house built by an unskilled non standard human ? . I always felt my journey was a testament to this forum . If I were a plumber , joiner , brickie etc. then that would be a distinct natural advantage. Yet I am an ex software engineer who builds his house bit by bit ( had to get that joke in , sorry ! ) There have been mistakes a plenty ( not all mine ) - many wft moments . The build literally consists of blood , sweat , tears and indeed other bodily fluids . So thank you to all that offer help and advice . Those that tolerate seemingly stupid questions ( usually are stupid actually ) . But most of all to give time to help someone achieve more than they are capable of . This is the power of buildhub . I will now post some witty comments elsewhere ; or some obscenity that will get me a naughty boy badge .3 points

-

Greetings! Apologies for the crass title but I am still a kid at heart. ? After a brief delay due to Covid-19 the carpenters were able to attend site and erect our timber frame. Thanks to the accuracy I insisted on and ensured for the coursing blocks the sole plates were a doddle and were done in no time at all although we did have a bit of rain and I had to get the puddle pump out! We used Flight Timber for our timber frame and they have their own lorries with cranes built in and so each stage of the build was delivered by the lorry and then craned in to place. Here’s the ground floor panels arriving. It took them just 2 days to finish all the ground floor external and internal wall panels. The speed of it all is very impressive. Then the posi-joists arrived These took a few days to do but thanks to the 8mm designed deflection and 300mm centres they are rock solid even across the 6.2m spans. It’ll be a bit of a nightmare trying to run MVHR, electrics and plumbing but we won’t have any bounce on the floors! Plus when the sun shines through it creates some lovely lighting effects Next we had a weeks delay as Flight didn’t have any chipboard flooring in stock as they were let down by their suppliers. This was a frustrating delay but with the current material shortages not one that I should really grumble about too much. It was eventually delivered and the chippies got on with laying it and the first floor panel starter plates. And then it was on to the first floor wall panels. These took 2 days to do as well and so within a couple of weeks of starting we had both floors done ready for the attic trusses They were also a couple of days delayed due to Covid-19 but arrive they did They didn’t take long at all to go up and I love the symmetry of them Then it was another week or so getting the roof finished and building the vaulted ceiling in our entrance hall etc and then they were done! It was 18 days on-site from start to finish. Amazing to see. I took some time-lapse footage and you can see the video below: And so we have a superstructure! The roofer is not far behind so my next blog will be about the roof slates and Solar PV array. Thanks for reading and until next time…2 points

-

One thing is certain from the info I’ve picked up here is that our current vented drier will not be going into the new house !2 points

-

I could not agree more with this ~ the quieter the house the more accute one's hearing becomes!2 points

-

One of the mistakes I made fitting the ducting on my system was to fit an attenuator on the supply circuit and not on the extract circuit. I didn't think it would matter as the extract vents were only in the bathrooms, kitchen and utility. The rooms with supply vents were silent but the bathrooms etc had a slight background hum only audible in the room itself. If I ever design another system for myself I would use two attenuators. https://www.ductstore.co.uk/acatalog/Attenuators.html2 points

-

I have just specified and bought my MVHR kit. But I have not installed it yet. I purchased it directly from the manufacturer of the unit I chose. Great service from them, by the way, even including a site visit, when he was in the area visiting someone else (!) Like you I was keen on whisper quiet. First, I chose a PH-certified MVHR unit and bought the ducting from he same manufacturer. Choosing a quite unit I think is key to having a quiet system. And I slightly over-specified the unit too. There was a smaller model available that would have been sufficient but the price difference was small. To tackle the risk of noise, it wasn't required by the MVHR designer who did the calcs for me, but I chose to pay a little extra and double-up almost all the duct runs (other than very very short ones). I also chose to have 1m-flexible-silencers on both the supply and extract from the dwelling. And I have bought a supply manifold which has extra baffling inside too. The ducting is semi-flexible and radial, so no cross talk and I used the wider (90mm external diamater) ducts rather than the smaller ones (75mm external diameter). The expert who sold me the system said that my system should indeed by whisper quiet and the marginal increase in cost will be modest.2 points

-

Unfortunately you're wrong! ? Yours are wood screws plain and simple. Concrete screws have a much "rougher", thread with extra thread forms so it bites. They also need a Torx bit to drive them rather than a Pozi bit like your screw. This reflects the extra torque required to drive them in and that you don't really want to be slipping when driving them! PM me your address and I'll send you a sample. I think I only have 100mm long ones left though. Tbh I prefer (the grey) frame fixings for windows. If you hit a mortar joint with the concrete screws they'll likely just mince it up and not hold.2 points

-

No they're not. These are: By frame fixings they usually mean these. You drill a hole the same diameter as the grey bit and knock in. Bosch multi construction bits will drill through your uPVC frame and into the wall. This a 10mm one so you would use 10mm frame fixings. https://www.ebay.co.uk/p/1004205987?iid=3534576379422 points

-

Not specific to renovations, but generally lenders like to be confident that you've got funding in place to finish the job from the start, so I'd expect them to require the full deposit up front.1 point

-

https://www.currys.co.uk/gbuk/household-appliances/laundry/tumble-dryers/sharp-kd-hhh8s7gw2-en-8-kg-heat-pump-tumble-dryer-white-10194164-pdt.html I bought this from currys, the cheapest heat pump tumble dryer at the time and its been great. I monitored the energy usage and it is very close to the spec which is 1kwh for a half load and 2 kWh for full load. Like others have said a good chunk of that energy will stay in the house as latent heat.1 point

-

List here might be useful... https://www.gov.uk/guidance/goods-and-services-you-can-claim-for-under-the-vat-diy-scheme1 point

-

A quick update. Just finished attending to the Sunamp PVs and I now have hot water! I can only speak as I find and Sunamp have delivered with fantastic customer service, admittedly they could not recommend a local service engineer, but talked me through the process including FaceTime. Far too often support from companies are promised and often fall short, not Sunamp. Maybe I was lucky. Thank you to all here and I hope I have saved Nickfromwales writing lengthy instructions.1 point

-

Foam in the gap. Leave to dry. Remove excess. on The foam will shrink slowly unless covered so now is the time to put sealant on top! The skill using the foam is to foam enough to join the window to the walls but not run it too much into the cavity. I try to run about 25mm on the sides and between the top and bottom of the frame fill any gaps. Seal all 8 edges. Don't forget to seal under the cill where it meets the external wall!1 point

-

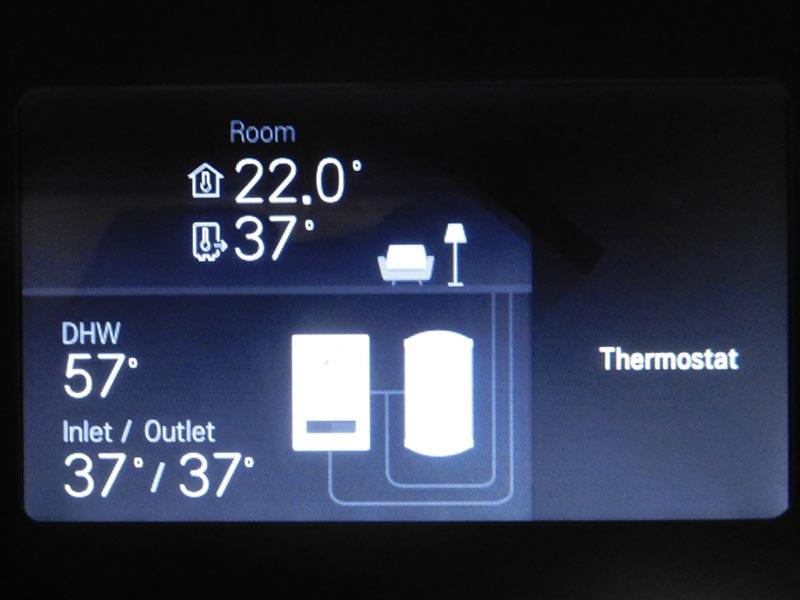

I adjusted some of the settings as per your suggestions as follows; Outdoor temp for auto mode: min -10º max 15º changed to -1º/15º Indoor temp for auto mode: min 16º max 21º changed to 18º/23º LWT for auto mode: min 20º max 50º changed to 30º/50º The house temperature at the time, according to the Hive, was 19.9. Having made the changes the system fired up and I took an image [below] of the LG controller. Moments later the system had evidently executed whatever it had been set to accomplish as stopped and I took another image. The Hive showed the house temperature = 20º The first 'real' test will be to morrow a.m. when I will note times and temperatures as per my initial post for comparative purposes. Thanks again for all the help.1 point

-

1 point

-

Definitely. So not Brookvent. Those sharks refuse to sell spare parts if, for example, one fan motor dies. (must buy entire MVHR unit)1 point

-

1 point

-

I am not one to add unnecessary work, but I would use these clips. You have some doubts about the build quality, so this would be a small insurance, and you can relax on a windy day. And fill the gaps in the PIR.1 point

-

Assuming insulation outside the polythene then no. For longevity use heaviest gauge polythene you can get (DPM).1 point

-

1 point

-

Sorry I never got any further with this. I did find that eurocell no longer sell the glass which allows 0.81U as per their brochure, they now use AG Glass which I think came in at around 1.0U, so its probably better to go to a wholesaler so that you can pick and choose frame and glass.1 point

-

Well done, we ex-s/w engineers do not make natural house builders as of all the engineering disciplines, s/w has the worst habits (you can't re-start building a bridge half way through and the client wouldn't think to ask). Good luck with the dungeon.1 point

-

1 point

-

Yup, well in a PH. If you're not pumping loads of heat in low down, how is it getting to the ceiling. The heat has to be coming from somewhere. If the UFH is only a degree above room temperature the gradient is shallow. If you have hot radiators there is a steep temperature gradient and the hot air travels upwards quickly, cooling as it goes, until it drops down for the cycle to be repeated continuously.1 point

-

Mine is in the loft but hung from the roof trusses, on rubber mounts so no noise is transmitted through the bedroom ceilings. Very quiet.1 point

-

Oh, and I positioned the MVHR unit as far away from the bedrooms as I could, even taking the precaution of placing it on the far wall of the plant room. In a well-insulated house, which is airtight and triple-glazed, and which therefore tend to be whisper quiet inside, even small sounds become noticeable, sounds that would normally blend into the background of a normal house.1 point

-

The two main sources of noise are (i) the unit itself and (ii) the high speed air in the ducts. And for (ii) especially the turbulence caused when the velocity of that air changes at, for example, the point where a duct joins a larger valve, such as at the point where air is supplied in to a room. (i) is addressed by buying a better quality Passive-House certified unit and fitting silencers. (ii) is addressed by slowing the speed of air flow in the ducts by increasing their cross-sectional area by doubling them up. The rule-of-thumb for noise in ducts is to keep the speed of the air below 2.5 metres per second on boost level. I went even lower.1 point

-

Careful what you wish for unless you can handle the celebratory Full Monty. There lies madness/blindness. Think Sam Neill/Event Horizon etc!1 point

-

I built my own silencer. worked very well. Next time i would combine and build my own manifold/silencer like @joe90 did. I would consider building a soundproof cupboard for the MVHR UNIT too. You can hear it when the door to the utility is open.1 point

-

You could have the ASHP, and just have flow and return tails blanked off at the house where the services will pop through to the extension.1 point

-

Who advised you increasing the size of a structure/building would constitute a NMA?1 point

-

That statement and the rest of this thread would not encourage me to buy an unservicable unit like this.1 point

-

Hi Jilly. Looks like you are really making progress... remember your posts about protecting steelwork.. Can you set up your LPG system based on you getting an ASHP later. Yes buy the LPG combi boiler but set it up to emulate an ASHP although temporarily running at a higher temperature. You can get a cheep boiler to see you through to the next stage, a regulator and a couple of 47kg bottles. Make sure you get it serviced.. may be able to sell on later second hand to another BH member? In the grand scheme you have taken a lot of time /care to insulate the house so even though you may spend a bit more on the gas you'll have no standing charge for a mains gas connection. The main thing is to plan it so you don't have to lift floors etc later? Also, if you do it this way you can enjoy the bathroom and so on.. waterfall shower with plenty water? filling a bath in jig time .. clean your teeth and not wait that extra time for the warm water to arrive at the tap..(yes there are some on BH that clean their teeth in cold water but I'm a philistine) it means that you can enjoy the things you have bought now rather than waiting till later.. yes it may cost a bit more on gas.. but you deserve a bit of luxury surely? Just thinking out loud.1 point

-

I would take that last line as a hint they are likely to approve it. No guarantee mind.1 point

-

1 point

-

There are small A2W heat pumps that heat just a water tank. There might be more than these. https://www.ariston.com/en-uk/products/air-source-heat-pump-water-heater/air-source-heat-pump-water-heater/ https://www.earthsaveproducts.com/products/ecocent1 point

-

Well at least you did it in manageable byte sized work packages. And glad to know I am not the slowest builder on the forum.1 point

-

There will be guidelines regarding overshadowing of garden, loss of aspect, loss of light into habitable rooms, overlooking and loss of privacy. Also in keeping (style, scale etc), following front and rear building lines, following the pattern and spacing of neighbouring properties. If you are doubling the footprint and demolishing the garage, it may be worth demolishing all and starting from scratch. At least it will then be VAT free.1 point

-

Hi, a truss clip can be used, as others suggest, just to be on the safe side but it is not strictly necessary. I'm a structural engineer and I work mainly with timber frame structures: we specify truss clips only when the wind uplift force is quite high (windy locations, shallow pitched roofs) and the dead load is low (e.g. lightweight roof covering). Otherwise rafters birdsmouthed to the top plate and fixed down with a pair of skew screws/nails would be providing an acceptable nominal connection.1 point

-

Yes, that was over 40 years ago! As I recall the house had one of those nice 1960s gas fires in the living room and some kind of gas heater on a quarter landing on the stairs! It also had a gas "geyser" water heater. This was my first house bought in 1979, just before a big upward price move in the market, so we were lucky (sold it two year later for twice the price). No doubt I would now find that house horribly cold, although it seemed fine at the time.1 point

-

Don't know what happened to my previous post above as it seems to have got included with the one I am quoting from, so repeating here: I've got one but sadly I am unable to "speak up for them" ! In fact may be the poster that contributor Jilly refers to in her post (5th Nov). Yes you will need a thermal store. My wood pellet boiler worked well as long as I was happy to regularly maintain it every 4 weeks (i.e. strip the burner assembly down and lubricate the moving parts) and get used to some of its quirky properties. Add to that the multiplicity of additional controls that I incorporated over the years. Both the installer and the manufacturer have gone bust so there is no chance of finding anyone locally to service it anyway and getting spares would be difficult to obtain now. I suspect mine is not a unique case as I know of others who have (/or are) waited/waiting for the RHI payments to come to an end before pulling out the old boiler and looking at alternatives. Sadly I have reverted to oil which is what we had in the first place but I wanted to be "green" so replaced it with a pellet boiler (we are not on main gas). Now of course I have come to realise that burning wood pellets is not exactly 100% "green" anyway and the notion that it must be, because it consumes renewables (i.e. wood), is false. My advice to the OP Mike 2020 would be not to do what I did and stick to the oil boiler until he sorts out the insulation and draughtproofing, observe the oil consumption for a year or two, and only then decide on the heating system.1 point

-

The real security wants to be inside in the from a ground anchor fixed into the concrete base. A thick chain/lock to secure bike to it, and I'd also put in a battery powered alarm (assuming you don't have power).1 point

-

Don't eff about with anything other than a proper foam gun and have a practice beforehand. This stuff is good but not in stock at SF unfortunately for some reason: https://www.screwfix.com/p/soudal-soudafoam-expanding-foam-gun-grade-750ml/5026d Be very careful using "foam". Aside from the mess, if you were to foam the gaps and leave the window open whilst it sets (and is still expanding), it can warp the frame and you won't be able to shut the windows. That's why I like the low expansion stuff. Another useful tip is lightly spray the gap with water from a plant sprayer. A damp surface takes the foam better. Low tack masking tape around the frame to minimise foam getting on it.1 point

-

Yup! 5mm gap is enough to squirt foam in! Makes a hell of a difference. All Form. No Function! Yuck!1 point

-

Have a look here at what may be the reality of any DG window install. I found a horror story. No Compriband or expanding foam used, oversize gaps, all covered up with trim, superglued on. Basically draughty, cold bridges. Your 5mm gap is a lot and you'll lose a lot of heat.1 point

-

Make sure that the manufacturer of the render system use confirms how they want it done NOT the contractor. Weber for example can be very particular that these sort of details are built to their specif detailing, they will be issuing the warrant on the system so you must meet their specification.1 point

-

1 point

-

I have had a search, but who would you use for a small new build to design and supply an mvhr system? thanks1 point

.jpeg.77f6f187df1b84a3b43742ed8ba3e04b.jpeg)

.jpeg.24c7fe065cc226241418ecbcc89d1325.jpeg)