ValleyBoy1958

Members-

Posts

15 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

ValleyBoy1958's Achievements

Member (3/5)

5

Reputation

-

Automatic bypass valve

ValleyBoy1958 replied to ValleyBoy1958's topic in Central Heating (Radiators)

Pump speed now reduced from 3 to 1 and has had no impact on heating up time of all rads, so will leave it on that setting. By-pass valve set to 0.3Bar on a try-it-and-see basis and am currently monitoring the temperature of the by-pass pipework using my datalogger to check its efficacy. -

Automatic bypass valve

ValleyBoy1958 replied to ValleyBoy1958's topic in Central Heating (Radiators)

Thank you Marvin for your thoughts and confirming that my understanding is correct. I have a an oil boiler, brand new, which has replaced my wood pellet boiler. This does not modulate (unlike the pellet boiler) and yes, the pump has 3 speeds, and is currently set on speed 3 as we have a large C/H system (15 radiators all bar one with TRV's) with a manifold system terminating in longish runs of 10mm microbore pipework. I intend to play around with the pump setting as I'm not convinced that it is necessary to have it running at top speed, not least because it is not one of those newer low-energy pumps and consumes about 60W on speed 3. I guess I should look at pump speed first before tinkering with the by-pass setting? -

Automatic bypass valve

ValleyBoy1958 replied to ValleyBoy1958's topic in Central Heating (Radiators)

Thanks to the three of you for your replies. Perhaps I should rephrase my question: what pressure should I set the by-pass valve at? I'm thinking I could set the by-pass valve to the maximum and then close all the TRV's. Then gradually reduce the by-pass setting until the by-pass pipework gets hot? -

Automatic bypass valve

ValleyBoy1958 replied to ValleyBoy1958's topic in Central Heating (Radiators)

Have I answered my own question here or is it such a difficult one that no-one is able to answer? ? I'd be grateful if anyone has an opinion on that!! Thanks. -

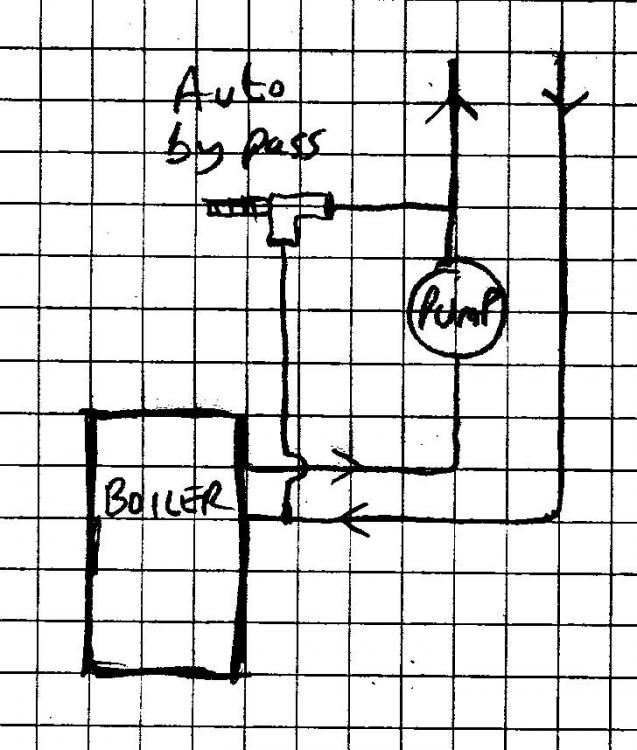

I am trying to get my head around how the automatic by-pass valve on my oil fired boiler works. I understand the principle: on a C/H system where all the rads have TRV valves then the situation could arise whereby all the TRV's close and the pump would be struggling against a closed system. This is almost the case with our system but there is one rad (a bathroom towel rail) which has no TRV and therefore is always open. Nevertheless the boiler has an automatic by-pass valve fitted - schematic attached. My question is this: the adjuster on the automatic by-pass valve is calibrated from 0.1 to 0.5 bar in 0.1 bar increments - what does this mean in reality? For example: if the valve is set to 0.3 bar does this mean that the valve remains closed until the pressure in the C/H system exceeds 0.3 bar and it then opens to allow the by-pass loop to come into operation? Thanks.

-

Don't know what happened to my previous post above as it seems to have got included with the one I am quoting from, so repeating here: I've got one but sadly I am unable to "speak up for them" ! In fact may be the poster that contributor Jilly refers to in her post (5th Nov). Yes you will need a thermal store. My wood pellet boiler worked well as long as I was happy to regularly maintain it every 4 weeks (i.e. strip the burner assembly down and lubricate the moving parts) and get used to some of its quirky properties. Add to that the multiplicity of additional controls that I incorporated over the years. Both the installer and the manufacturer have gone bust so there is no chance of finding anyone locally to service it anyway and getting spares would be difficult to obtain now. I suspect mine is not a unique case as I know of others who have (/or are) waited/waiting for the RHI payments to come to an end before pulling out the old boiler and looking at alternatives. Sadly I have reverted to oil which is what we had in the first place but I wanted to be "green" so replaced it with a pellet boiler (we are not on main gas). Now of course I have come to realise that burning wood pellets is not exactly 100% "green" anyway and the notion that it must be, because it consumes renewables (i.e. wood), is false. My advice to the OP Mike 2020 would be not to do what I did and stick to the oil boiler until he sorts out the insulation and draughtproofing, observe the oil consumption for a year or two, and only then decide on the heating system.

-

Have you done an interstitial condensation calculation of that thickness of IWI? I only ask because I went through a similar exercise recently assuming 75mm Celotex as IWI and the calculation showed that there was no risk of condensation but 150mm might be a different kettle of fish!

-

Why aren't A2A ASHP more popular

ValleyBoy1958 replied to RomyD's topic in Air Source Heat Pumps (ASHP)

A2A was never eligible for RHI payments, so I think that would be the main reason. I looked into it and it worked out much cheaper than an A2W system but our place, being a dormer bungalow, was not suitable due to the tortuous and quite lengthy pathways that the pipework would have had to make. -

Heat pump latest government offers

ValleyBoy1958 replied to nod's topic in Air Source Heat Pumps (ASHP)

How much is very little? I must have spent at least £1000 on IWI (Celotex 3") and associated stuff like plasterboard, battens and VCL plus additional quilt for the attic spaces. Well worth it though as we slashed our heating oil consumption from 3000L to 1500L p.a. -

Heat pump latest government offers

ValleyBoy1958 replied to nod's topic in Air Source Heat Pumps (ASHP)

Spot-on! Typical lazy (or not understanding) newspaper headline. The ASHP system cost them £14K (but with £9K recouped via RHI admittedly) and they were quoted as having "already spent a lot of time and money insulating the house". No details of the insulation were provided. -

Gravelld - can I be cheeky please and ask what cost you were quoted?

-

Thanks for your reply. Is that the usual rule of thumb i.e. 80% of fuel used during the 4 winter months? Your response has prompted me to look at the monthly pellet consumption figures. I have kept a daily usage record since I had the boiler 7 years ago, so on a wet afternoon I could plug the data into spreadsheet and see what I find! BTW we have solar thermal which provides all our DHW from late May to early September which helps.

-

Apologies for the basic error in my maths! I had a senior moment there and took the 5000 kWh figure rather than 15,000 kWh when calculating the cost for gas ....doh! So ProDave's calculation is nearer the mark but still approx £140 difference between the 2 fuels and assuming a year-round COP of 3. This could be optimistic with what is likely to be a high flow temperature requirement (high for an ASHP that is) without bigger radiators. Even so I believe the capital cost of an ASHP will still frighten off those who currently use gas to heat their home, without some generous subsidies. Re: electricity price: I was paying 15p per kWh until recently (with Bulb until the price shot up) and it is now 18p (after switching to Octopus). Like Joe90 I agree that the cost of an ASHP will definitely reduce in the future but that is no good for me right now! I have had my one shot at RHI with my wood pellet boiler which I now much regret getting. When we first moved here we were using about 3000 litres of oil p.a. but by improving the insulation and eliminating draughts we got this down to 1500 litres before changing to biomass; thereafter we used approx 3000 kg of pellets p.a. The reason for reverting to oil is because the Danish pellet boiler manufacturer has gone out of business as has the installer, and so spares is a major problem, coupled with the fact that my wife would not be able to carry out the routine maintenance of the boiler if anything happened to me. At nearly 75 years of age my time is running out and I might not be around when ASHP's are affordable! It was not an easy decision to revert to oil, as Steamy Tea says, hardly in keeping with decarbonisation. However as it is likely that HM Gov will prioritise those on oil/gas when it comes to ASHP subsidies, maybe those who buy my house in the future will be able to take advantage of that (or even me if I am still around at the time).

-

If I had an ASHP and it managed a COP of 3 all year round then it would use 5000 kWh of electricity p.a. to heat our house, which at an optimistic 15p/kWh equates to £750 p.a. If I was on mains gas currently, then at 4p/kWh I would be paying £200 p.a. If the installation cost of an ASHP is of the order of £7000 - £12000 and having one caused my heating bill to increase almost 4-fold where is the incentive for me to change? I am playing the devil's advocate here of course as I do not have mains gas, but rather a wood pellet boiler. I will be getting rid of this shortly and have looked into an ASHP but the cost is out of my league. Hence going back to oil at a fraction of the price.