Leaderboard

Popular Content

Showing content with the highest reputation on 07/26/19 in all areas

-

9 points

-

2 points

-

Rather than find the studs, locate the plasterboard screws with a powerful magnet. Far more precise.2 points

-

the optimum gap between panes of glass is about 16mm so typically 4, 16,4,16,4 = 44mm Our 3G units have the middle and inner panes as low E glass and all 3 panes are safety glass and low iron. I believe it's important in a 3G unit that the middle pane is toughened because of the unequal thermal stresses. Other things to look out for also apply to 2G units ie whether the gap is argon filled and whether the unit uses super spacers.2 points

-

We had a letter today saying that they had all the info and documentation that they needed and our claim will be processed over the next six weeks Then refund will follow within 14 days It’s a bit of a relief after reading recent posts Let me explain We had Counsul tax people sniffing around before we even had pre plaster inspection After much argument they told us that in there estimation we could finish the build six weeks after pre plaster inspection and we could be ready for that in two We tried everything Showed them that the German kitchen we had chosen that couldn’t be measured till plastered Had a twelve week lead time Go to Howdens or B&Q Get an off the shelf kitchen We’d no services or toilet Water was coming from an outside tap next door In short we where miles off Eventually we where made an offer 50% for twelve months then full amount Even though we where still paying on our current home Take it or leave it and risk having to pay the bill for the full amount that we already have By the time we moved in we had paid 12 months at 50% amount 3 at full amount We where able to get BC to sign us off 5 months after moving in By this time we had paid 20 months Counsul tax and lived in the house for 5 months before sign off We wasn’t sure if this would be an issue We where absolutely honest in our submission But no mention of the timeline from HMRC1 point

-

Looks like a cheaper/generic version of the "ComfoPost". This datasheet might give an idea of how well something like this might perform: http://www.alternativeadvancedenergy.eu/AAEnergy06/it/dwn.asp?ID=2431 point

-

The other thing is, house value if you sell/have to sell, the majority of people would balk at a house with no heating, at least get UFH pipes in if nothing else, worth the cost, then you can instal a Willis heater or ASHP at a later date if you require it.1 point

-

you could send stu gray an email, he is the panasonic dealer for the north of scotland and the islands "info@heatorkney.com" he would let you know how expensive they are, although i think they are ~£500 each so not exactly cheap1 point

-

Yes, when I looked at 21:16 BST (20:16Z that is, UTC or, if you must, GMT) weatherHQ was showing the last observation as 16:50 (whatever time zone they use, BST I'd guess). When I look on checkwx it gives a much more recent observation at 19:50Z (20:50 BST so about 25 minutes ago). You don't need an API key just to look on the web, only to use the API for easy programmatic downloads: https://www.checkwx.com/weather/EGPE/metar BTW, adding a bit of whitespace for readability, this is the JSON you get back from the checkwx API for Inverness: { "results":1, "data":[{ "wind":{"degrees":0,"speed_kts":2,"speed_mph":2,"speed_mps":1}, "temperature":{"celsius":21,"fahrenheit":70}, "dewpoint":{"celsius":15,"fahrenheit":59}, "humidity":{"percent":69}, "barometer":{"hg":29.76,"hpa":1008,"kpa":100.79,"mb":1007.92}, "visibility":{"miles":"Greater than 6","miles_float":6.21,"meters":"10,000+","meters_float":10000}, "elevation":{"feet":29.53,"meters":9}, "location":{"coordinates":[-4.0475,57.5425],"type":"Point"}, "icao":"EGPE", "observed":"2019-07-26T19:50:00.000Z", "raw_text":"EGPE 261950Z VRB02KT 9999 FEW035 21/15 Q1008", "station":{"name":"Inverness"}, "clouds":[{"code":"FEW","text":"Few","base_feet_agl":3500,"base_meters_agl":1066.8}], "flight_category":"VFR","conditions":[] }] }1 point

-

No as it transfers the building loads to the ground underneath. I imagine there is a depth where this could be ignored but it would be very deep and you would likely need an engineer / soil survey etc. and a large safety factor.1 point

-

1 point

-

I will be tiling our hall and utility room floor soon with slate tiles of varying size. I intend to model that on CAD so I have a worked out pattern to follow.1 point

-

The one I bought came from CPC in one of their special offers about 20 years ago. So I doubt it is still a current model. And yes it is noisy. The outlet comes with a semi rigid expanding hose and duct tape forms the temporary seal to the mvhr vent. This is just a temporary fix for now. I had not anticipated the need for cooling here so had made no provision for it. But thankfully our ASHP does cooling mode and there is an easy pipe route from the plant room to the loft to run pipes for 2 fan coil units which will be the eventual solution for bedroom cooling, though maybe not this year.1 point

-

I couldn't decide on the pattern for our drive paving, so drew up the whole drive in Autocad and made several different versions, with different angles and layouts. When I gave them to the chap that laid the drive he couldn't believe that anyone would spend hours drawing the layout of block pavers before laying them...1 point

-

1 point

-

We heat our DHW to 50C using ASHP. Our average COP (DHW and space heating) is around 4. I don't bother with electrical heating to 60C, the immersun will divert solar PV to provide a boost. Admittedly it means we hit over 60C in spring, summer, autumn but may not in winter.1 point

-

You should be able to mount the indoor unit straight on to this as they don't weigh much. For the large hole, you could make a 75mm inspection hole behind the unit with a hole saw, and refit the plasterboard if you caught a stud.1 point

-

That does not look like toughened glass as it would shatter into far smaller pieces with very few sharp edges.1 point

-

1 point

-

i have a T who temporarily disconnects the tumble dryer vent pipe, and uses that. F1 point

-

If i just uses resistance heating then probably no, though there will be some parasitic losses. Not so sure if it uses stored hot water. There may be a rare scenario where it pumps warm water back though the system for too long, and if it has had a very low CoP just before, it may dip below 1. I am starting to wonder if icing is a real problem. It may just happen when trying to raise the temperature to much for too long i.e. an undersized system.1 point

-

Plan A is very doable just needs an SE to design, especially as you are already using piles.1 point

-

That’s good news. Unfortunately the council tax folk have no idea how long a self build takes. You really grafted with yours but it still took much longer than their (IMO) p*ss poor and unreasonable estimates. They simply saw you as a cash cow. It’s inconsistent too. Our council wasn’t even bothered until well after we moved in. You applied for your reclaim at exactly the right time given that HMRC have had their arses kicked by the tribunal judges. Happy days, and start planning to spend the reclaim!1 point

-

Best of luck, I have just sent all my paperwork to a VAT accountant to do it for me (as I would probably make a mistake and be fined!). Also we moved in 10months ago but only just got BC sign off. I also copied the recent court case thread on here where HMRC lost their case to my VAT man who thanked me for the info.1 point

-

We built a 4 storey terrace next to a river. We piled down 25m but the nearest we could safely install the piles to the river wall was 3m, so the engineer cantilevered the ground beams. Lots of reinforcing near the cantilever, but this was a much bigger engineering challenge. The rear of the houses is cantilevered about 2m and the flood wall a further metre.1 point

-

By chance I know a little bit about that particular build. Looking that GD episode up, and paying special attention to the issue of the cantilever will repay the effort many times over. The lesson I took away from viewing that episode and talking to some of the people directly involved in the build is - get an SE who knows both the material involved in the build and has substantial experience with cantilevers.1 point

-

But even with defrosts, would the COP go below 1? Even if it's sometimes down to 1.1 it's still a win over using an immersion.1 point

-

1 point

-

1 point

-

In my case I could tee into that flow and return for anything. All my flow and return branches run to their destination with the 2 port valve at the destination, so in the case of the DHH tank, the 2 port valve is on the pipe feeding the coil. I could tee off below that if I wanted with another 2 port valve for any other circuit e.g another heating circuit. Just occasionally we could do with a little heat in the bedrooms so I will organise these FCU's in the bedrooms so they can do heating as well as cooling,1 point

-

As I've never seen an ASHP with a COP of less than 1, what's the advantage of using the immersion anyway?1 point

-

We certainly did!! (Full disclosure: that was my team mate videoing; 4-tandem bike relay team, we'd just done the final pull to get to the top of the pass and they took over for the descent, as he has stronger nerves than me. Here's a shot of us rolling into Kansas early on day 4) 4 years ago now so details are hazy, but... they definitely do work, but I just didn't like wearing them. Large problem is unless you regularly train in >100F temps, and train actually using them, they just add another unknown risk which is the last thing you want on race day. (So long as it's <100F I found the body can self regulate enough given a reasonable forward motion creating movement of air. It's above 100F things rapidly come apart. And this is the only thing Fahrenheit is any use for) What helped me more is various "cooling towels": we kept a stack of them in cool boxes full of ice water in the chase van, each change you could drape those over and cool down quick. And the old favourite: nylon stockings stuffed with ice wrapped around the neck like a french man carrying onions. Exploiting the latent heat of vaporization effect, I now know to call it (thank you, MVHR enthalpy exchanger!)1 point

-

The render board battens will be on the line of the studs. We have the same, battens on the outside that the cladding is fixed to. MBC usually chalk lines down the membrane on the outside of the house to highlight where the frames are for whoever fixes the battens, plus there is a line of staples running along those lines too. The outside battens have to be fixed to the frame studs as there's not enough "meat" in the outer boarding to fix to.1 point

-

A lot suggest the concept of heating the DHW so say 45 degrees with the HP then topping up with the immersion heater. That concept falls over for me as it would work fine on the first tank warm up. But then you draw some water, or the tank cools by losses, and it will drop to the point of the immersion heater coming on but will rarely get low enough for the HP to turn on. As @joe90 says just use the HP to heat water to 47 or 48 degrees, that is all you need and well withing the parameters for a heat pump.1 point

-

I agree wholeheartedly. I know I bang on a bit here about the risk of overheating, and how solar gain is a significant problem for a well-insulated and airtight house, but that's because I've spent far, far more time and money trying to resolve overheating than I have on heating. Heating is a complete non-issue for us, if push came to shove a small fan heater in the hall would keep the whole house more than warm enough in cold weather. The reality is that we have to cool the house, either by passive means, like the solar reflective film and window overhangs, or by active means like floor cooling and air conditioning, for a far greater proportion of the year than we spend heating the house. Every time I see a new house design that has acres of glass, the thing that immediately springs to mind is the overheating risk that may pose.1 point

-

From my photo memories, taken at 6.15pm on 26 July 2018. Going forward and with climate change I really think cooling/aircon should be something that gets as much consideration in the build as keeping warm. If I ever (bring on the white coats) do another I will have whole house aircon as well as mvhr etc.1 point

-

Interestingly we have some 6-16-4-16-6 units and they are notably poorer, thermally, than the 4-20-4-20-4 units, enough that we can feel the difference stood next to them in cold weather. All our glazing is SGG Planitherm, argon filled, with two low e coated internal panes. One thing I very much wished I'd done is specify a much lower inward IR transmittance glass for the outer pane, definitely not the low iron glass we have, which lets through loads of unwanted heat, so much so that I've had to apply solar reflective film to it.1 point

-

In no way does it match the local architecture and it is designed that way to be hidden behind the large Yew tree you can see behind it. The Conservation Officer (K__B) was a real pain and a bit of a bully to be honest but when the head of Planning in saw it at a meeting with architects to inform them what type of houses he would like to see being built he passed this one on the spot so I think we where fortunate. There is only a field opposite the glass wall in the photo and the other three sides are 12ft high walls as it used to be an orchard so most of the people in the village do not know of its existence.1 point

-

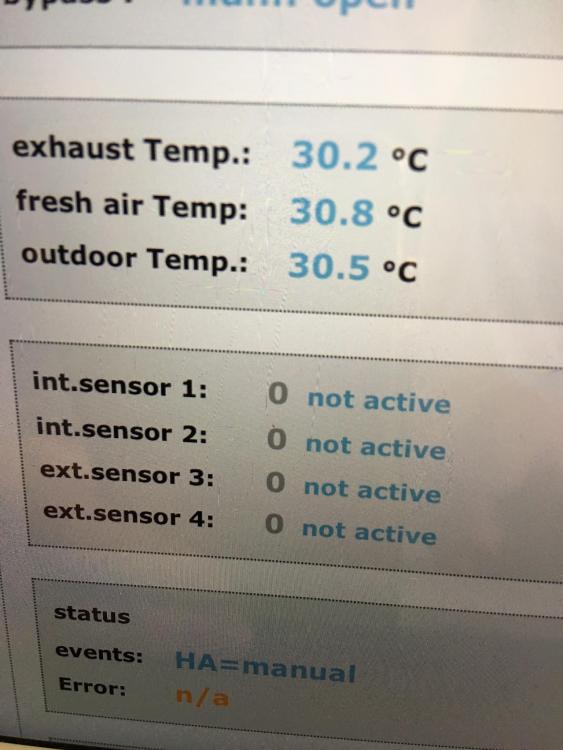

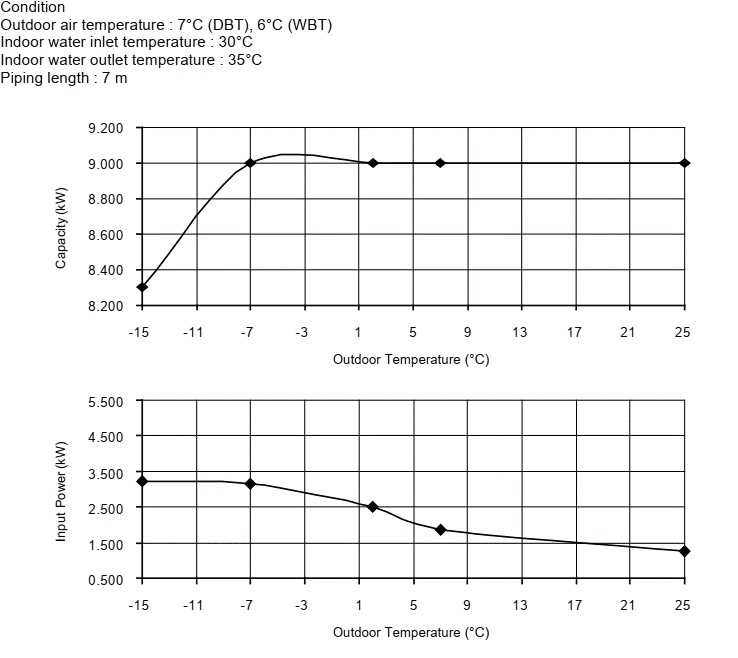

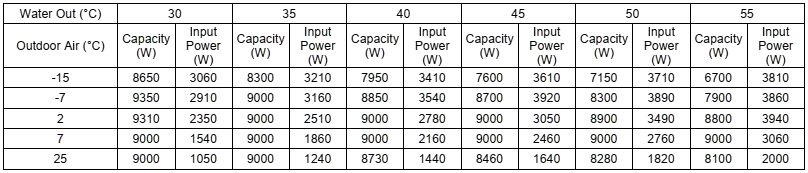

I keep my efficiency high by careful setting adjustment (fluke). I have a Panasonic Aquarea Generation H 9kW split which heats 2 x SnnAmp Pre UniQ PCM38 cells, it also cools the floor direct. I have a ΔT of 5oC set on the flow temperature and a target of 45oC, this is what the SunAmp requries to cease the call for heat. It usually takes a couple of hours to re-heat the cells so difficult to remotely monitor the CoP: (this display shows a tank re-heat (shower) and evening cooling) If the heating is running then it takes significantly longer as the majority of the heat will be taken into the slab and the system will run as long as the house is calling for heat. Whilst it is doing this it sits at 38oC for as long as the house is calling for heat as the UFH only takes water at 26oC but is taking most of the capacity of the ASHP, the SunAmp cells are taking water at 38oC, the PCM temperature, so the cells are being re-charged incredibly slowly as the house heats, this gives a better performance history as shown below: The first few hours variation are down to outside temperature, as the outside temperature rises the system drops down to a steady 1.2kW draw which gives a CoP of over 7, then at the end when the UFH has stopped calling for heat and the system finally ramps up to heat the cells (it cuts off around 43/44oC) the CoP drops again. I have numerous days when this can be seen. It also ties in with the stated efficiencies: In fact I am getting better than expected performance whilst heating to 38oC as the system is drawing a lot less power than expected. I suspect it is down to setting the ΔT of 5oC and not pushing it too hard, but letting it work relatively easily so as not to force the system. I have not had any defrosting issues either.1 point

-

? where's the "whoosh, that went straight over my head" emoji when you need it. Some people on this site are just far too clever (and I suspect I still wouldn't understand any of that if I googled the likes of API key, JSON, Python code or SQlite, never mind 'cron job'). ?1 point

-

Interesting. The thermometer seems to have stabilised at 22.9°C. Downstairs is therefore only 2.6°C cooler than upstairs, but subjectively it feels like an awful lot more. I suspect this is partly because the radiant heat off the walls and ceilings upstairs make it feel subjectively hotter, whereas the cold concrete floors make it feel subjectively cool downstairs. In any event, I'm about to walk half a mile to the pub. Shouldn't be any problem working up a thirst!1 point

-

I had same situation when i was renovating my kitchen 22mm copper comes out of floor to stop tap behind sink I had already found the main feed before it goes under slab was poly, it was by the side where i dug my pond I suspect it was the builders temp water supply for house as it did not come in a direct line from the main "Toby " I could move the copper pipe around like it was moving on the compression fitting in the floor--so I did not like digging up concrete floor to find where it was loose--so ran new pipe I was lucky enough to be able to run a complete new one from toby into house through garage . the thought of laying a tile floor in kitchen then a year later it all leaks -- no ,no ,no, had to move it1 point

-

I would, but then I like things done properly .1 point

-

1 point

-

0 points

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)