-

Posts

524 -

Joined

-

Last visited

Personal Information

-

Location

Cumbria

Recent Profile Visitors

5014 profile views

le-cerveau's Achievements

Regular Member (4/5)

150

Reputation

-

Duct compatability

le-cerveau replied to Chablais's topic in Mechanical Ventilation with Heat Recovery (MVHR)

They are compatible, see the end of my blog entry. -

I can't answer the details of your questions, but we have 3-phase and this is the meter so no spinning disks, and this was second hand, ie installed with an initial reading greater than zero. Our PV generation meter was new though:

-

Yes, our house was built with Econekt/Izodom 2000 ICF blocks. No issues with them and my builders managed fine with the blocks.

-

I did a custom setup as have most here. My pipes were installed by warmafloor but the setup and control is all custom designed and installed.

-

I don't have a defrosting issue and have a ΔT of 5oC, details in my CoP post: It is teh difference between flow and return temperature in an ASHP, the system will modify the compressor and/or pump to the differential flow temperature, my system alters pump speed.

-

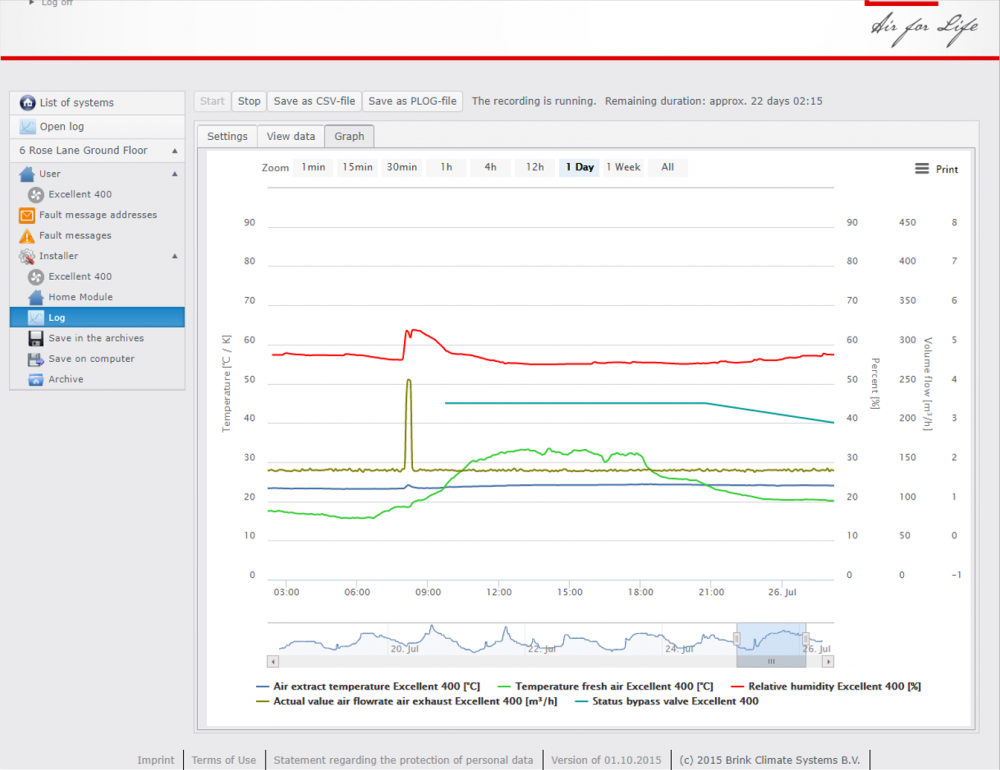

Yesterday in Cumbria: You can see my mothers morning shower (RH increase and MVHR ramp up and down) and the bypass close as the outside temp passes the inside and open again in the evening as the temp drops. The house has remained at a pretty constant 24oC and yesterday the cooling didn't come on (it is set at 25oC). It was on the day before.

-

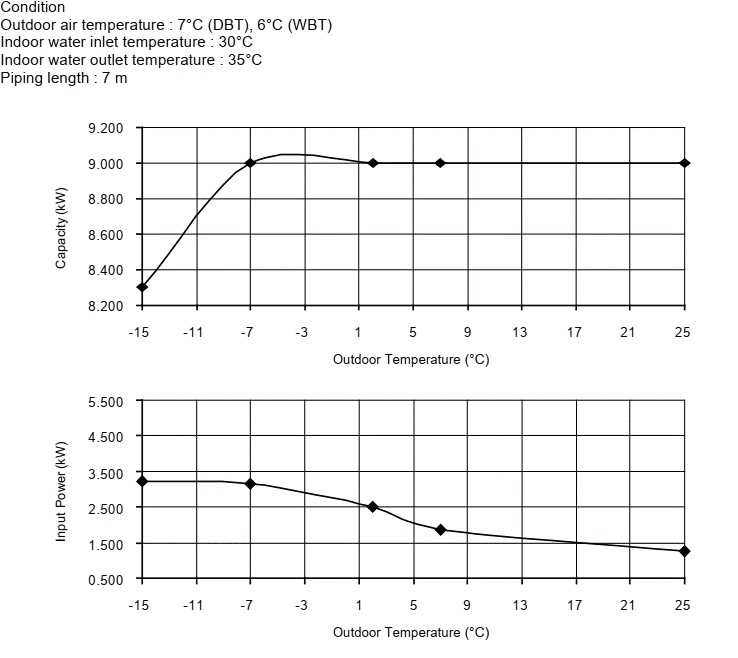

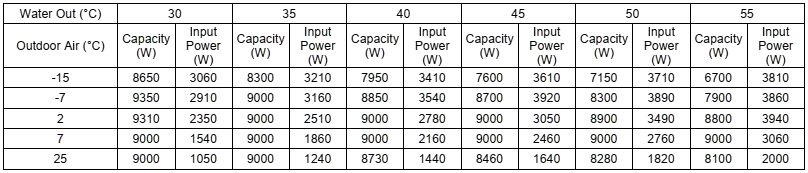

I keep my efficiency high by careful setting adjustment (fluke). I have a Panasonic Aquarea Generation H 9kW split which heats 2 x SnnAmp Pre UniQ PCM38 cells, it also cools the floor direct. I have a ΔT of 5oC set on the flow temperature and a target of 45oC, this is what the SunAmp requries to cease the call for heat. It usually takes a couple of hours to re-heat the cells so difficult to remotely monitor the CoP: (this display shows a tank re-heat (shower) and evening cooling) If the heating is running then it takes significantly longer as the majority of the heat will be taken into the slab and the system will run as long as the house is calling for heat. Whilst it is doing this it sits at 38oC for as long as the house is calling for heat as the UFH only takes water at 26oC but is taking most of the capacity of the ASHP, the SunAmp cells are taking water at 38oC, the PCM temperature, so the cells are being re-charged incredibly slowly as the house heats, this gives a better performance history as shown below: The first few hours variation are down to outside temperature, as the outside temperature rises the system drops down to a steady 1.2kW draw which gives a CoP of over 7, then at the end when the UFH has stopped calling for heat and the system finally ramps up to heat the cells (it cuts off around 43/44oC) the CoP drops again. I have numerous days when this can be seen. It also ties in with the stated efficiencies: In fact I am getting better than expected performance whilst heating to 38oC as the system is drawing a lot less power than expected. I suspect it is down to setting the ΔT of 5oC and not pushing it too hard, but letting it work relatively easily so as not to force the system. I have not had any defrosting issues either.

-

Different duct sizes

le-cerveau replied to bissoejosh's topic in Mechanical Ventilation with Heat Recovery (MVHR)

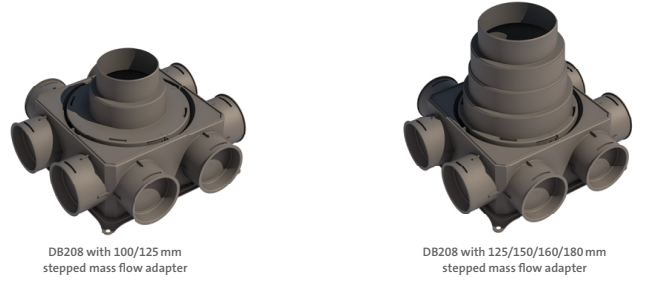

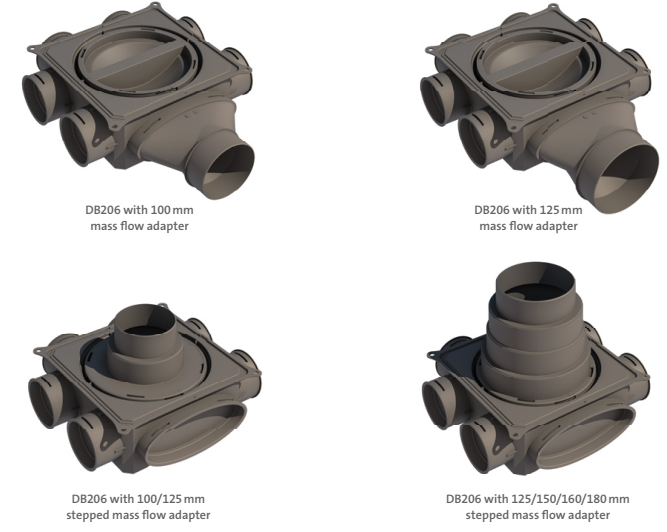

It may be possible to mix systems. The issue being that the kitchen lounge diner requires both extract and supply. Extract by the kitchen and supply elsewhere. It is possible to convert from semi-rigid radial duct-work to large bore by using a Ubbink DB208/DB206 distribution box in reverse depending on the size of duct-work: Simply connect the galvanized duct to the distribution box the run as many semi rigid lines as as required for the correct flow rate, flow limiters to balance teh system as inserted in teh main distribution box or in these adapters if required. Then run semi rigid elsewhere, doubling up as required. Not as it was originally designed but would work.- 7 replies

-

- 1

-

-

- mvhr duct

- galvanised

-

(and 2 more)

Tagged with:

-

Just got my EPC figures

le-cerveau replied to joe90's topic in Energy Efficient & Sustainable Design Concepts

I went from 84, pre PV (FiT requirement) to 103 with 9.7kW of PV. -

Which ASHP are set up to cool

le-cerveau replied to Triassic's topic in Air Source Heat Pumps (ASHP)

I can see why you would infer that from the article, but I do not think that is what it is claiming. It is saying that the heat emitter is sized to heat at 25C above room level, but only cool at 12C below room level, which accounts for 2 of the 8 times less efficient claim. The rest is about solar gain etc which is right but is the reason why you are cooling. So a daft conclusion made based on sensible factors. In a low energy house you would not have 45C heating with ufh, ours runs between 23 and 30C depending on external temp. An Ashp is less efficient cooling compared to heating, but you are talking about a drop of COP from 4 (heat) to 3 (cool), so still efficient. There are some fundamental issues here: a ΔT of 25oC for 'normal' operation is for a house that leaks like a sieve. In a house that leaks like a sieve solar gain is not such an issue until the outside air is above about 20oC. A house that leaks like a sieve will not have MVHR (or is fitted but completely ineffective). A cooling ΔT of 12oC(below required temp) in a leaky house would probably work for an external temperatures of about 30oC. This is all based about heating/cooling the air mass as it changes so fast in the leaky house. In most of ours well built houses (not leaky) the air is only a part of the problem, not the whole problem. We maintain the structure (not Thermal Mass) of the house at around the desired temperature and the air follows suite, assisted by MVHW and structure. I have found that most UFH companies cannot get their head around low temperature UFH in passive style houses so do we really expect cooling companies to be any better. They are geared around provide to the mass market (garbage houses) a common system that a simple instillation man can install (I didn't call them engineers). I had similar issues trying to convince MVHR companies (modern technology) to deviate from their standard patter (2 x MVHR units, cistern extract, multiple vents, specific routing) -

Which ASHP are set up to cool

le-cerveau replied to Triassic's topic in Air Source Heat Pumps (ASHP)

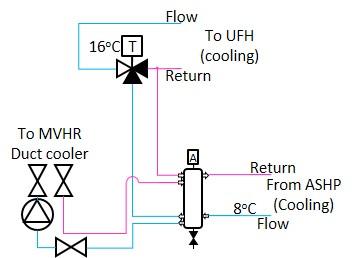

When I was designing my system (3 years ago) I looked at adding a duct cooler as well as slab cooling and to overcome the problem of condensation I planned on running the ASHP (in cooling) at about 8oC but using a thermostatic to provide warmer 16oC to the slab. Doing this by providing the UFH return to the hot side and the ASHP to the cold side, and utilising a hydraulic separator to balance the pressure. This was one of my original layouts. The TMV would draw enough cooled water to reduce the return to the desired level, whilst allowing the duct cooler maximum power. The ESBE TVA572 series of valves have an option down to 10-30oC control which would work (confirmed with them) or could utilise an electronic controller I use a CRA110 controller on a VRG 130 mixing valve to control my UFH (I run it at 26oC), but it goes down to +5 so could be used as a cooling control. It is a complication but to maximise duct cooling whilst avoiding floor condensation it is an option. -

Which ASHP are set up to cool

le-cerveau replied to Triassic's topic in Air Source Heat Pumps (ASHP)

By utilizing a Duct cooler example: https://www.bpcventilation.com/cold-water-duct-cooler-range . It will only have a limited effect though due to the relatively low air volume movement. -

Which ASHP are set up to cool

le-cerveau replied to Triassic's topic in Air Source Heat Pumps (ASHP)

My set up is very non standard. My ASHP is effectively dumb and the control system does all the heavy lifting. My ASHP heats my buffer (Sunamp PCM34 blocks, pre UniQ) these are used for DHW pre-heat and domestic heating. The UFH continuously circulates through a Low Loss header (LLH), if heating is required an EBSE motorized valve switches the flow from the LLH to the buffer, drawing heat through a Thermostatic mixing valve set at 26oC (buffer at 34-40oC). When heat no longer required valve switches back. The Sunamp is connected to the ASHP and defaults it to cooling mode, a second relay connects to the Heat/Cool/Live of the ASHP , normally it connects the live to the cooling thermostat and if a call for cool comes in then the thermostat completes the circuit, switches on the ASHP in cooling which alters the ASHP supply valve from Buffer to LLH.. If however the SunAmp needs heat, this relay is switched, isolating the cooling thermostat (ending call for cool is active) and calling for Heat, also the first relay switches the ASHP over from cooling to heating mode. This prioritizes DHW pre-heat. My ASHP is set to 45oC for heating the buffer and 12oC for cooling. 45oC works well as I have a ΔT of 5C set so it takes it's time re-heating sitting at 34oC whilst the PCM melts, usually finishing off at about 43oC, currently it draws about 1.2kW (9kW split ASHP) for the majority for the time at it's most efficient CoP of >6, dropping to above 4 in winter.