Leaderboard

Popular Content

Showing content with the highest reputation on 11/17/23 in all areas

-

After some debate, Jan and I decided that we could press out the sag in the cells if I made a suitable jig, so I made up an H frame that is held against the side of the SunAmp by some tape strapping, and which could hold a pressing plate (a square of OSB3, and with two bars that allowed a set of folding wedges to apply the pressure. I then brought the SA to temperature and used the wedges to load up the pressing plate and push the cells back true. All that remains is to allow the cells to cool back to solid phase and then I can reassemble the SA. A bit Heath Robinson, but simple, very cheap and effective. Job done. Here is a pic (note that the wedges are pretty much at the end of their travel as the cells are back in shape and position :5 points

-

There have been four apprentices on my site. Two were treated really well by their journeymen especially the joiner. The other two were from the two different roofing companies. The standing seam apprentice did nothing but moan and was obviously not interested in learning much so just laboured mostly. The flat roofer apprentice was constantly berated and bulled mostly for the quality of his work but also for how he looked (was called, and I quote, “you are the ugliest (expletive deleted)ing guy I’ve ever seen”) I went say something but the electrician advised me to stay out of it. When they came back to fix some of the problems with the roof they told me the apprentice was fired in part for the workmanship on my roof. However, my view of this was they just scapegoated him because ultimately it’s the lead guys responsibility to check the work as they go and at the end. Now it’s only four examples but I suspect a lot of apprentices aren’t treated or trained very well.3 points

-

Sod the courses though Steamy, it's all about just giving a damn about your work3 points

-

I can't tell you how many times I've had this conversation in the last few years. We just don't respect tradespeople enough in this country. It's (wrongly imo) seen as something that kids who weren't any good at school end up doing because they aren't good for anything else. Absolute bollocks.3 points

-

2 points

-

My builder was great 😁 Jokes aside, I was pretty lucky with the few contractors I needed. The plasterer was brilliant. He had come up to the island for a job which was then cancelled, and was staying in his campervan while looking for work. Took one look at the site and said he'd get it done in five days. It actually took six, but he didn't charge any extra. Top bloke. One of my favourite quotes is that the difference between an amateur and a professional is that an amateur does the best job they can, and a professional does the worst job they can get away with. Definitely applies to building (and many other walks of life).2 points

-

Probably best with anything Chinesium, to work on half the given current rating.2 points

-

Not always, in my experience. There were times when we went for what we thought was a higher quality outfit based on the price and professionalism of our interactions with them, but I don't think they did any better on average than the cheaper ones.2 points

-

Well how about her managing me then .... we all know @Pocster's a bit , well, you know ...... ??2 points

-

I had plastic bags tacked to the walls throughout the house and they still chucked empty crisp packets etc on the floor. My other half collected it all up and put it in their van 😂 They never did it again.2 points

-

I guess 'our' kind of houses are, unfortunately, few-and-far between, so there's simply little exposure to good building practice or a lot of the more modern equipment, materials, and techniques we use. I think most customers for building trades don't have any idea of what quality they're getting - they tend to judge by contractor's politeness, cleanliness of their vans, how much they tidy up, how well written their quotes are etc etc. So, as we're leading the housing quality race, it would be right that central and local government cut us some slack e.g. like restricting Part O to the high-rise flat builders and the modern estate builders.2 points

-

@MortarThePoint Here are a couple of images showing how our oak beam was fitted. When installed, it came with two large "bolt" type "pins" protruding, which were then drilled into the concrete lintel. The surrounding area was then plaster boarded. I have to say in the past 5 years we have not suffered any shrinkage or cracking or either the beam or plaster. The beam was sourced and fitted by the approved stove fitter!2 points

-

We often have this discussion about skills - it runs something like ' We need more skilled people for for trade xyz' And I always suggest that skills are just the icing on the cake. We need to give tradesfolk parity of esteem with their non-trade colleagues. Until there is a rigorous and universally accepted Apprenticeship Scheme - one that engenders respect in the pub and the building site, then we'll continue to suck our teeth with irritation. The German model isn't perfect. But it's better than ours. And Apprenticeship depends on an excellent education system: one where those not going to University have the opportunity to get highly respected qualifications as trades people. And there's less than no chance of that.2 points

-

That is quite interesting as when I was studying climate change 15 years or so ago, Hungary was a case study for future weather extremes. Under any of the climate models, your part of Europe was going to get a lot hotter in the summer. As you are still at the design stage, are their things you can do to mitigate higher temperatures i.e. window shading, tree planting, body of water as a heat dump, PV on a roof and side walls (it can suck up 20% of the incidental solar energy). I lived on a 'tropical island' that often had sustained 35°C+ temperatures, luckily it was permanently windy, but large land masses do not have that affect. You may find Air to Air heating and cooling is better than slab heating/cooling.2 points

-

I’m glad it’s not just me! It’s harder for women as some of the chaps are so sexist, I hated those conversations when I wanted something done correctly and had sleepless nights before deciding to let them go. I don’t know how people can be off site with their build. Everything is soon covered up…2 points

-

Its why, for almost everything, i just do it myself now. Its easier and less stessfull Cant even be worrying about building control anymore. That hopeless too. I can do it right and have no cert, or i can have it done wrong, but get a cert. Lots to do at the new place. Will continue on a DIY basis on almost everything. The lack of pride in your work is the real issue. No one cares anymore. A sad state of affairs.2 points

-

I like a self leveling laser level to cast a line around the top of all the units. You find if you move a standard level around the top of the units it changes. With the Lazer you can average out the errors in the units, and it's so easy to level front to back at the same time .1 point

-

1 point

-

Make sure you obscure access to the isolators in the cupboard by placing lots of tins and packets in front of them...1 point

-

You can get manual air bleeds. https://www.screwfix.com/p/flomasta-end-feed-air-vent-cap-15mm/524511 point

-

Yes, and I am not criticising your work. The point is, that for every talented person, there are a lot more that are not skilled enough, do not care enough, and work for companies that are run by fraudsters (I worked for someone that would claim that his 'engineers' were all qualified plumbers, electricians, SEs or whatever needed to be said to get the sale or fob off an angry customer. He prided himself that he got a Physics 'O' Level by failing his Physics 'A' Level). Is that such a bad thing. Builders are modifying buildings that can cost upwards of £120,000, often £million. I have seen some dreadful treatment of staff in some companies. I was lucky that I was treated very well where I did my apprentice. Not so in all cases. In my current sector (catering), work place bullying is still very much accepted. It is not acceptable anywhere. I blame Gordon Ramsey who has made million out of being a horrible (expletive deleted) that likes to belittle everyone else. I don't know what the answer is to improve the attitude towards work and improve the level of skills needed. It is a hard job, some people just do not want to be told anything. They are the kind of person that if you offered them a tenner, they would refuse it because they would think there is a catch somewhere. They are also, in my experience, the type of people that prefer conspiracy theories and reality TV.1 point

-

I have never been on a building course of any sort (tho BT taught me electric basics). Yes I do think apprenticeships are important but in my years being a builder I agree with @Tom the level of care amongst most is very poor, so even if you did do a “course” if your level of care is poor they will never be good.1 point

-

Exactly I had that whole debate with sparky on-site. I said we’d either need to have access to them from the cupboard beside the ovens but it’s a pull out larder unit so you’d need to cut the back out of the unit. In the end I suggested putting all the switches in the utility room which is immediately behind the ovens and fridge.1 point

-

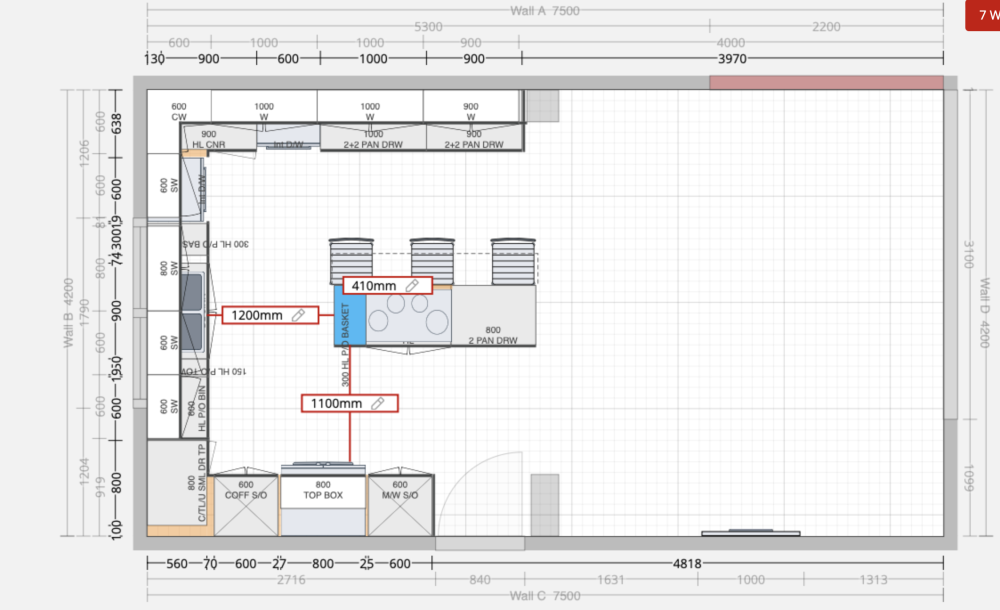

Thought I'd have a stab at flipping the island around so that; - Cook can see out of folding doors across the garden - People won't be brushing past anyone sitting on stools at the island (unless they want to get into the drawers behind which will be for cutlery pots/pans etc) It keeps the triangle nice and tight and I think it works pretty well. Thoughts?1 point

-

Remember to turn your level 180 and check again in case the kids have used it a baseball bat.1 point

-

And a weather forecast, though energy usage and weather are generally closely related.1 point

-

1 point

-

Hessian wrap. Others may correct me but I am not aware of asbestos ever being 'implicated' in connection with this. It's not just anti-squeak - it is thermal insulation, and I sometimes use it as a wrap when I cannot get plastic sleeve on the pipe(s).1 point

-

To fit our shower trays we removed a section of insulation under the tray. Then dry fitted the shower waste pipe and the lower part of the trap so it's in the right place. This was loosely supported in position at right height but in a way that allowed it to move vertically bit. Then fitted a frame of pressure treated 2*4 or similar and 18mm WBP ply to support the tray at the right height. The WBP had a clearance hole in it that allows the trap to sit at roughly the height of the top of the WBP/underside of tray. It should be possible to pull the trap up about 0.5" further to allow for the thickness of mortar/adhesive used to fix the tray down. Test you can fit the tray and screw the top part of the trap through the hole into the bottom part. Remove tray and plywood and glue up the pipes. Replace plywood and put rags in trap to stop debris getting in. Screed floor to top of plywood. Fix tray (with mortar/adhesive) and immediately screw in the top of the trap to be sure you can before adhesive sets. Check it level. The heights need to be planned carefully to take into account of the screed and tile thickness plus fall to the drain. It's a bit different for a linear drain but a similar amount of planning and prep is needed before screeding.1 point

-

@jack got it that all makes sense. Sorry you've ended up explaining each point 5 times lol. Our UFH is in just 75mm screed which is pretty good to freewheel a constant temperature through the day, but also fairly fast responding when we do heat it so boosting the room setpoint does work ok for cheap rate. It's a fairly simple regression analysis to work out the daily kWh input needed for a given outdoor temperature, so sooner or later ASHP will have learning thermostats that solve this in a nicer way.1 point

-

1 point

-

yes indeed. and i was inspired by the buildup from MBC which was on their website. yes but, for me, it was a cost i couldn't justify so late in the build as our budget has well and truly gone out of the window. 2"x1" battens can split but we piloted and countersunk every single batten. i bought a cheap table drill and we setup a system from chop saw to drill which worked quite nicely.1 point

-

1 point

-

Yes, Certainly take structural precautions here as you'll loose a lot of strength. You could just insulate between the joists well as normal too. It wouldn't make much difference thermally.1 point

-

Looks good. @Thorfun among others have the same buildup. It's quite common. I think MBC offer it as a factory spec. The OSB behind the plaster is a cheap enough addition for a much more robust wall. You could drop your service cavity to 20mm using 20*70mm strapping. 20*45mm battens tend to be a bit weedy and split. If you do this you can spec outwards opening windows and wrap the jambs etc and overlap the frames from the inside. One point of care with the airtightness will be the band joist area that will require a membrane wrapped around the end of the joists for the first floor connection. Likewise any buttressing internal wall. Nothing that can't be overcome however. Note the insulation outside the band joist too as this will be a weak spot otherwise.1 point

-

We also have B&B first floor but used 50mm insulation. You can run water supply pipes in the insulation but best sleeve them with conduit. Maintain insulation on hot pipes. Can also run them up walls in slots cut in block work, we did this for wall mounted basin taps. If you have lots of space you can even build a false wall/service void with battens and Hardi backer board or similar. Waste pipes need a fall on them which will mean they need to run in both insulation and screed. 50mm diameter pipe is recommended. If you want a wet room or low profile shower tray (eg walk in with no raised plinth) the waste pipe to the trap needs special planning and prep before screeding. It might even need to go through the floor and run to the stack in the ceiling of room below. Our's didn't... More info on request.1 point

-

Yes that’s my plan B, but the Reed works on the bench and I am going to protect it like @Onoff posted above, the new Reed will be inside the waterproof casing of the motor box. 👍1 point

-

1. At any high point where air can accumulate. 2. As long as it becomes a new high point, pipe always slopes upwards to vent point.1 point

-

not got any concrete above ground! and for the basement i'll probably metal frame the walls so will all be plasterboarded anyway.1 point

-

Search this forum for "polyphase" it's been covered many times. So long as you have a SMETS v2 smart meter vector sum metering is guaranteed by the standard. If you have an old installation with separate import and export meters, good luck: the suppliers often don't know how it should be setup, and the installation contractors often fail to set it up properly even if told. https://forum.buildhub.org.uk/search/?&q=polyphase&search_and_or=and1 point

-

The simple answer is, there is no simple answer. Every house is different Nd every owner has different expectations of house temp. Generally good rules are 1. Always flow from the heat pump at the lowest acceptable temperature. Acceptable meaning gives the house internal temp consistent with your expectations. 2. Run heat pump for long periods, this goes with 1. allowing low flow temps. 3.Try to have house at a consistent temperature, don't allow to cool down to much, if you want it cooler at night only set back the temp a couple of degrees, otherwise the heat pump can't catch up with heat demand. Weather comp allows point 1. (Lowest flow temp). Fixed temp maybe not, depends on the house time temperature constant. Normal house with rads or UFH weather comp.1 point

-

I'm running weather comp but reduced the step on the curve, was set too high a temp, so now max flow temp is 35c.1 point

-

Reminds me of all those happy summers with the family. Only 285 quids.1 point

-

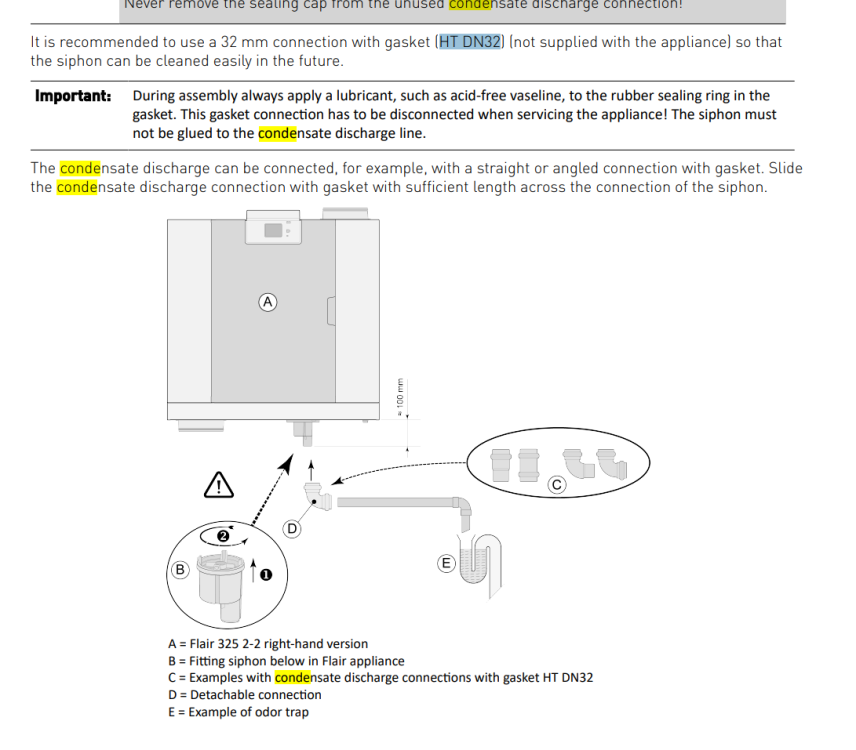

According to the manual the outlet on the siphon is 32mm OD and they suggest DN 32 HT You need something like this to get from 32mm OD [German Spec] to 32mm ID [34mm ish OD] UK Spec. McAlpine 1 1/4 inch to 32mm European Pipe Connector S28L-ISO - 40005071 - Plumbers Mate Ltd (plumbers-mate-sales.co.uk) Best to take the syphon with you - it looks like it comes off.1 point

-

Is timber frame not such a 'thing' in NI as it is in Scotland? I'm pleased with how ours went, using stick-build and would absolutely do the same again. There now follows a strong opinion. I must get along to a self build exhibition and maybe see why so many people go for ICF and the like. As a designer/ contractor I tried hard to give eps blocks a chance but couldn't make it 'stand up' commercially. The parameters may change for self build / beginners. In the construction industry there has never been any excitement about ICF. The suppliers (other than a few eps, for a while) did not even target the industry. Stick build also reduces exposure to large deposits. And there is more wood down at the BM whenever you need it. A major advantage of wood frame also seems to be the ease of cladding, both internally and externally. Any shape or size. I cannot find any open costing comparisons, but stick build must be 20% cheaper, maybe 40% cheaper, and less risky, than ICF. I'd actually love to be proved wrong, ie that ICF is a great and affordable thing.1 point

-

Some People don’t realise that low voltage often needs bigger cables !!! (Less volts = more Amps)1 point

-

After 35 years experience buying a multitude of garden furniture......it's not about the price you pay it's ... about the time and effort you invest and spend in preserving them.1 point

-

We're soon to install an oversized Zehnder CW12 duct cooler in the supply, taking a feed from the reversible ASHP. All supply ducting will be well insulated and has been optimised for low air resistance so we can potentially increase the fan speed if needed without too much extra noise. Not expecting huge cooling power, but if it can discretely drop a few degrees across habitable spaces we'll consider it a win. We've also made sure to have external blinds/solar control glazing on the south elevation, but don't want to risk that alone being enough. I'll report back on how it performs next summer. 😅1 point

-

Thanks, and agreed. My ethos is prevention vs cure, so where some designers will give you the option to go 'full throttle' to cool a home, I prefer to simply work on preventative methods to stop it getting hot in the first place. With successful management ( by using controls with a tight hysteresis ) the runaway should never be more than a degree or degree and a half, eg the uplift over the time taken for the controls to recognise that occurrence and for the system components to have kicked in to respond to tackle said unwanted uplift. A correctly designed system, in a relatively relaxed state, should not struggle to bring that back down in a reasonable timeframe without having to become too aggressive in its response. To cool a house down that has been left to runaway to, say, 24oC would almost need air con to drag it back down, given that by then the fabric surroundings would have had time to achieve that new ambient and would be holding on to that heat energy for a much longer / extended period of time, ergo the 'response' would need to dialled up then from a whisper to a shout. Each dwelling / instance is different, so I review each case uniquely, and on its own merit, in my day to day business. Comments here, however, do sometimes generalise a little, but it is a widely differing crowd on here with varying dwellings / installed systems / wants / needs, so we do our best to cater for all.1 point

-

Just one MVHR unit (Zehnder ComfoAir Q600 ERV). The supply splits for the ground floor and first floor, with the ground floor manifold in the plant room and the first-floor manifold in the loft. The Comfopost is in the plant room on the first-floor branch. This doesn't present any issues with balancing the system, no. There will be a small amount of pressure loss through the ComofoPost, but if the system is balanced/commissioned with the Comfopost in place this won't be an issue. I've been proponent of Comfopost for "trimming" first-floor temperature when overheating has already been designed for via overhangs and automated shading, and I still beleive this is a realistic approach in combination with ground floor heating/cooling via UFH. But, in practice, for some reason the heating/cooling power to Comfopost (measured with a heat meter) doesn't appear to come close to what was in our M&E spec or the manufacturers data-sheet. I'm not sure what the issue is and need to look into this further, but the delta-t is very low .1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)

-2023-11-1716_59.thumb.png.2278941a78e6434e805239f2784b9fbe.png)