-

Posts

3193 -

Joined

-

Last visited

-

Days Won

9

Crofter last won the day on May 20

Crofter had the most liked content!

Personal Information

-

Location

Isle of Skye

Recent Profile Visitors

10771 profile views

Crofter's Achievements

Advanced Member (5/5)

553

Reputation

-

Wouldn't there be a risk in using somebody outside the UK, that they are not familiar with the relevant regs?

-

New Build In Scotland & totally confused on building control

Crofter replied to Andrew Jones's topic in Scotland

Well firstly, you may already be aware that planning and building control are separate. Sorry if this is all stuff you already know. The planners want to know what the building will look like and what it will be used for. It's all about the impact on the surroundings. So appearance, number of bedrooms, etc. Building control want to know the technical details of how it's actually constructed, to make sure that it won't fall down or fail to meet standards on things like disabled access and energy efficiency. The idea is to ensure that the supply of housing is off suitable standard, seeing as most houses will outlive the people who build them. -

I screwed all my battens. I like to know that I've actually hit the stud/rafter which I found impossible to tell with a nail gun. Long screws can be pricey, I watched the specials on Screwfix/Toolstation for weeks and managed to pick up some bargains. Note- I was exempt from building regs so I don't know if my approach would pass muster with a BCO.

-

I had to add some temporary support to my wool when installing from below. I had a big roll of polythene warning tape left over from doing the electrical supply, so just used a staple gun to tack on a couple of runs of that. It might confuse and alarm anybody who ever has to open up the roof in the future I suppose 😂

-

@Rishardare you going to build that from the top down? I e. osb on the inside, and then add the insulation layers from the top? My roof was osb sarking outside with breather felt, then wool between rafters installed from underneath (fun! Somebody needs to invent lighter than air mineral wool!), then 100mm PIR boards forming a complete layer on the inside, and VCL after that. I was mostly working on my own and adding the wool and VCL was one of the worst bits of the whole build. If I'd have been braver I'd have installed the wool from above but I wasn't certain I could get it done quickly enough to do it in dry weather.

-

First sketch of new house project

Crofter replied to Crofter's topic in New House & Self Build Design

Thanks. So, could that be MOE windows? -

First sketch of new house project

Crofter replied to Crofter's topic in New House & Self Build Design

Just revisiting this point. I'm not sure this is a BR requirement. Do you know otherwise? -

Upstairs, there's a lot of space given over to the hallway. Mostly in order to access that bottom left bedroom. Maybe that's a feature you want but it might be possible to tinker with things to make a more efficient use of space.

-

best paint for painting sanded down pallet wood

Crofter replied to lord mud of the flyes's topic in Doors & Door Frames

No direct experience but it's probably fine. I wouldn't use something like cooking oil, just a guess but it would likely remain sticky or wet to the touch, or might break down, encourage growth of mould etc. -

I don't have anything against the house itself tbh, I'm just curious about the legalities of building something like that.

-

I heard one of the finalists was in my neck of the woods (Skye) so I looked it up on iPlayer: https://www.bbc.co.uk/iplayer/episode/m002ckqg/scotlands-home-of-the-year-series-7-5-highlands-and-islands What I'm wondering about is what regs this building has to comply with. Does it really comply with normal building regs? No downstairs bedroom, no balustrade on the stairs, I'm sure there are other issues. However it doesn't comply with the caravan/portable definition either, because that would force a 10ft ceiling height limit. I suppose there is 'hutting', but again it doesn't comply because it's a permanent residence. Thoughts?

-

Galvanised gutter with timber cladding

Crofter replied to bluebellcottage's topic in Rainwater, Guttering & SuDS

I spent a total of about £200 on the guttering on the cottage. Childsplay to install. It's been up about eight years now and I can't detect any fading. I suppose it will eventually succumb to UV damage. But then again I'm the sort of person who buys all my kitchen appliances secondhand... -

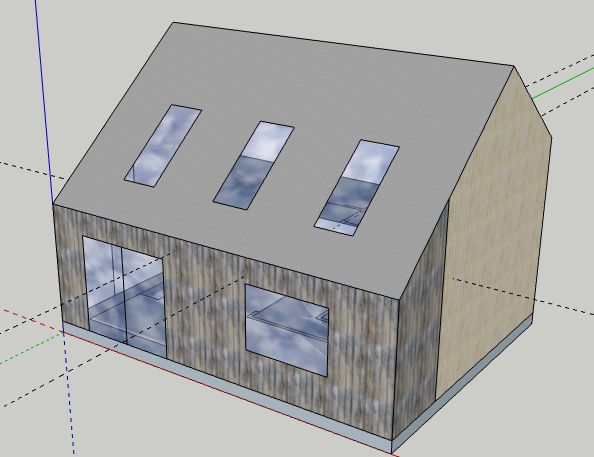

In order to create two different colours on the walls, we're going to use larch plus another lighter coloured material. In the attached sketch, I'm talking about the light brown section of the wall (I was just using the closest approximation I could find in SketchUp) At the moment I'm penciling in corrugated steel, because I've worked with it before and it's easy, cheap, and durable. I am a tiny bit concerned that a white or cream colour (which is what we want, and will likely be required by planning anyway) will show up every last speck of rust. Not that we expect that to be a significant problem as the plastic coated galv stuff has something like a 20yr guarantee. SWMBO isn't sold on the idea, she is fine using it for the roof but not convinced about using it on walls. What other options are out there? Essentially we want it to look like white painted rendered blockwork from a distance. So smooth and white is the goal. I don't really want to use blockwork as I'll be doing all the labour myself and I'm a pretty slow brickie. It just seems like a lot of work and cost for what is in effect a rain screen. @ProDaveused some form of rigid insulation board as his cladding, that sounds interesting. Another option might include fibre cement. Budget is pretty limited... last time I checked, corrugated steel was about £10/m² so I'm going to need some persuasion to spend too much on this...

-

Galvanised gutter with timber cladding

Crofter replied to bluebellcottage's topic in Rainwater, Guttering & SuDS

Can somebody explain to me why you would use anything other than plastic? It's cheap, it's easy, it's idiot proof. Agree on the point made above about galv nails in larch- I've seen this a few times and it looks awful. Stainless all the way. -

First sketch of new house project

Crofter replied to Crofter's topic in New House & Self Build Design

Thanks! Forgot about that. I had a play around with OnShape before I managed to get SketchUp to run, and I've thing I liked about it was the dimensions automatically appear on your drawings. So I might use that for floorplans.