Leaderboard

Popular Content

Showing content with the highest reputation on 09/26/23 in all areas

-

3 points

-

Could you ask them to mirror their proposal so the gardens are next to your house rather than the new bungalows. Would be low cost to the builder.2 points

-

Fell it, get it cut into planks, use it for very rustic garden furniture. It will end up being the most expensive timber you have on site by the time you have paid to get this done.2 points

-

Power is in watts (W, not w, and not Watt, that is the man it is named after). A watt is a joule per second, (a joule, J, named after Joule, is the unit of energy). To make life difficult, power is multiplied by 100 and then by time to end up with the kWh. So energy is now in kWh (not KWH, KwH, kw/h or anything like it). The kWh is a horrible unit, especially as we have a unit for energy, the joule.2 points

-

2 points

-

Double sheet the plasterboard 1st layer hides the expansion gap1 point

-

1 point

-

1 point

-

1 point

-

Have you called these companies? They might not have 1500 width in their standard stair builders but should be able to customise for you. I used TK Stairs, nothing of that size but they seem quite adaptable.1 point

-

Basic 1:2:3 mix would do the job (roughly 20n.) It's probably only a couple mixers worth.1 point

-

you don't need anything special, so forget 40N. neither do you need readymix unless there are several m3. yes to postcrete, or any diy mix.1 point

-

1 point

-

If the trees are badly affected by Hymenoscyphus fraxineus, the new name for Chalara fungus, then you need to get it disposed of correctly. Hanging it on an outside wall will not be a responsible way of using it.1 point

-

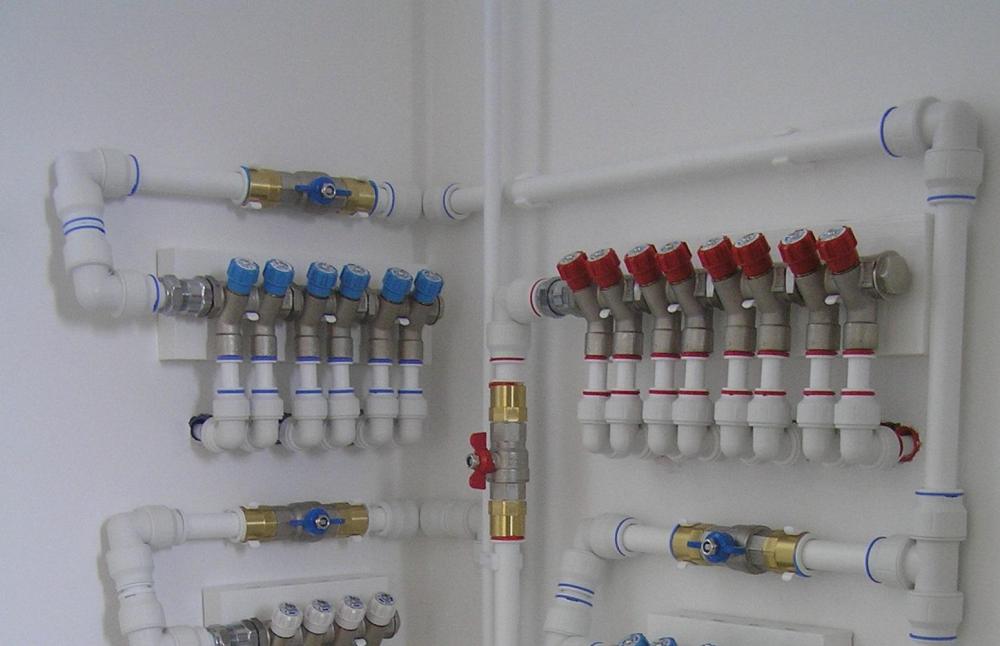

The boiler flow (48) is mixed with the UFH return (26) to produce the UFH flow (36). We can even work out what fraction of each the mixing is using to make the UFH flow.. 48X + 26Y = 36(X + Y) X + Y = 100% Solving these simultaneous equations gives.. X = 45.5% Y = 54.5% So the 36C UFH flow is made up of 45.5% Boiler flow at 48C and 54.5% UFH return at 26C.1 point

-

No, it doesn't care, mine was run through insulation space by the gas engineer.1 point

-

Certainly looking at the annotated photo, you have hot water going through the flow meters and return water at the bottom. How the mixing occurs doesn't matter as @ProDave says. It looks to be doing what it should be. With all UFH mixers there will be a higher temp going into the mixer than out to the UFH loops, 10 to 15 degs is pretty normal and that's what you have. The mixer takes some hot water from the boiler, adds some return water. So if you have 10l/min around the loops, you may take 6 to 8l/min from the boiler supply, the rest is reused return water. If you want to remove the pump and mixer and direct couple, you would put the flow in at the top and flow out at the bottom. Switching the pump of will give you zero flow, as the pump pulls the water through the mixer, the mixer acts as hydraulic sepereration.1 point

-

Ive been studying the local timber industry in NE Scotland. Timber is felled, cut into standard trunk lengths (wasting a lot if the trunk size is long), and stacked locally for a year. Mills buy it to suit their market and product. At sawing, they lose a large proportion which goes for firewood or mulch. For stud, they can't compete with imports. Timber, when sliced up, bends all over the place, as stresses redistrubute. If you want it straight, then it has to go through a fancy grading machine, with more waste. Sell it to a local firewood dealer.1 point

-

Pick a better icf system and they will recommend the engineer. Same with the insulated slab, pick a good product and they will have details of engineers familiar with the product. The worst thing you can do is pick an engineer that isn’t familiar and is over cautious because of this, could cost you thousands in over the top reinforcement.1 point

-

Looking good the retaining walls will be rendered so exterior paint as soon as they look dry, couple of damp patches visible on the longer wall. Sand/cement doesn’t breath anyway so paint spec directions should be followed as some paints should only be applied in minimum temps and above dew point etc. whereas others are tolerant of cold temps and damp conditions. interior really needs to be left until windows are in and you can see the plaster is a uniform colour1 point

-

I should clarify. It will be 100W extra heating needed only when it is cold outside. Not in summer. Cash payback is only a part of the equation but it will certainly pay someone back over the lifetime of the house, maybe even your kids or theirs.1 point

-

The brief answer: don't. It's too much effort and time (three years minimum) and needs significant amounts of space - level hardstanding . Thinking through the stickering (level storage) process is also important. Get that wrong and you build in warp. Bought the chainsaw (DIYmax) - about as powerful as a motorbike - and the chainsaw mill. Went to the local (50 miles) decent saw mill (T K Knipe in Cumbria) , bought a couple of oak trees : French oak. Why French oak? Because it's straight grained. I could have bought any amount of local English oak - but the local wind and turbulence round the local hills causes the oak to twist and adapt (to stay upright). That makes it completely unsuitable for cladding - OK for other stuff, but not cladding. I also bought a Chestnut tree - high tannin content. (Ash is relatively low) The issue is the milling to thickness, drying time, cut and trimmed straight run length. There is a huge amount of waste. (Which I used for shakes). We finished up buying Siberian Larch (pre- Ukraine war) from ProWood in Bolton. Haulage cost £100. It took three days hard work to store it all perfectly level and covered properly (so air gets to it, but it stays reasonably dry) . I ducked the issue of chamfer by having an 8mm shadow gap between each plank - no additional processing. Board on board would solve that problem another way. This is the result. The 8mm shadow gaps are now 12mm shadow gaps. Lots of little things in the house are made of off-cuts: window sill, stairs, kick-board, skirting, window reveal lining, toys for the grandchildren, birdboxes. I really really oathe throwing it away in the skip. If you consider getting it felled and sawn, get a survey done first - it might be rotten internally. Then work out how much straight run timber you might get out of it. Balance my somewhat gloomy, Eeyor approach with a local chippy - a drinking mate. Cheerful, gentle man-mountain. He's building his own house ... "Ya've jus' clad yer ouse mate" I grin. "Yer, got meeself sum larch, an' did it lark" he says "Ooo djer buy it off ? I ask "Went down 't estate, felled meself sum larch and jus' did it" "Wot? His nibs (Duke of Westminster) trees?" "Yer - looks awraght dunnit "..... "Dja dry it then ?" He splutters into a pint of Wainwright's .... " Yew fookin' self-builders - cut, milled an' purup in 't same week " Yeah, right. 🤨 But I took the point. By the book needn't ......1 point

-

Outdoor acrylic sealant (aka window frame sealant). I wired up the fitting then filled the conduit hole with sealant and fitted the light etc.1 point

-

I used nothing . But I insulated the hot feeds - which achieves the same ‘identification’ task .1 point

-

By 1000 to make it a k (kilo, thousand)1 point

-

Not quiet. You'd need an extra 100w running continuously (all day everyday) to maintain the extra temperature. For example of you got an old incandescent bulb and left it on or a large TV that would make up the difference. Otherwise the house would cool down. Ok ballpark payback is 15 years I'd say. Proper plan. You could use seconds PIR to make it cheaper.1 point

-

You asked for / contracted for a cover fitted. You have a cover fitted. That's the sum total of your arrangement. Not a leg to stand on unless you're being explicit with what you ask for / the counterparty has sound commercial reason to do better. You used checkatrade. As you now know that's mostly for the disreputable trades who aren't busy by word of mouth; plus a couple of newbies just starting out. I'd buy the correct manhole and a sack of cement and watch a couple of Youtube if I were in your position. Chalk giving £1000 to the lads to buy oats for their horses up as school fees/learning the hard way how not to contract. If you do decide to silicone your existing mess; lift it, silicone the seat, then wrap the lid in cling film before placing it gently in position until your silicone sets. This way you'll have half a chance of removing it in future. Checkatrade are entirely complicit in the game if you read their T&Cs.1 point

-

These two companies offer multiple carcass colours. We used DIYHomefit for our dressing room with walnut effect carcasses to match our doors and flooring. https://www.larkandlarks.co.uk https://www.diyhomefit.co.uk DIY Kitchens offers 7 cabinet colours which can match door colours.1 point

-

Insulation is a strange thing, and often misunderstood. For every doubling in thickness, you generally only get a 50% improvement. While not ideal, you may find that adding just 25mm of just about any sheet insulation greatly improves the place. Before you do, start by finding all the air leaks. Sorting them will make the biggest difference.1 point

-

Go with oak, adds a nice finishing touch to open units. No kitchen supplier supplies caninets in more than 3-4 colours: white, grey, oak, cream.1 point

-

1 point

-

As I was clipping the pipe up anyway, I opted for blue/red pipe clips.1 point

-

1 point

-

Just though it would look great, but I can't find any at a decent price so will be reverting to coloured insulation tape 🙂 and a labelling machine1 point

-

Internet connected smart thermostats (there isn’t anything smart in a hive, it’s and on/off stat) all require cloud functionality to operate. Thats because they communicate over port 80 which is always open, and it doesn’t require any ddns setup to tunnel back directly to your house. The best option is to chuck it all in the bin, move to boiler/hp manufacturers modulating controls, and set/forget the temperature.1 point

-

Yeah cheers Once I’ve air tested I’ll get my wife on it 😁1 point

-

@nod Don't forget that the new building regs require that all the hot pipe, (even within the heated envelope) are lagged now.1 point

-

1 point

-

No amount of damp products will fix that, sorry. Please don't add insult to injury and get drawn in by their sales pitches, those products just don't work (not for long anyway). The source of the damp needs fixing, not the symptoms.1 point

-

I think generally most of us shudder when you say "Damp Specialist" They want to sell you their solution to solve the problem. How many will be blunt like I was (sorry if I offended you) and tell you that what you have is a total bodge, has been done completely wrong, and needs ripping out and starting again with a proper conversion of the building. That is not something some magic damp solving product will fix. It wants a fundamental re design and rebuild. If you did just adopt some damp specialists solution and continue as it was, you would still have a very substandard very poorly insulated, cold and expensive to heat room. Is that what you really want? Or would you like to do it properly and have a nice warm dry kitchen?1 point

-

Yeah of course. Sorry I didn't mean to come across as too negative but without more information it's not appropriate for forum advice. If just boarding out for light storage I wouldn't be particularly concerned. But a high point load could cause deflection, cracking and slipping tiles.1 point

-

@irondezi I fitted NuLok back in 2011. I fitted it to an easy area myself and found it straightforward. I had the main roof, with dormers, tiled using NuLok recommended installers. I didn't use the NuLok PV tiles. I've since moved house but didn't have any problems during the seven years before moving.1 point

-

But, if the planners are going to demand that there is no increase in height then will you even have enough roof space for those stairs. Would you be better looking at extending into depth for future, even down to laying foundations. My brother had a catastrophic house fire and the house had to be rebuild, not from nothing, but definitely 70% and his insurance company were happy for them to extend into the side return so just ask them. They can only say no.1 point

-

Going "deeper" doesn't mean the ridge would automatically be higher - it's a function of span and pitch so turning the direction of span across the narrower width may actually result in a lower ridge. Planners are almost certainly going to want you to respect the nature of the surrounding properties in scale, form and materials but that doesn't mean an exact copy. As to the insurance company the first step I would have thought is to ask about the potential for "betterment" if you contribute the balance. The conversation has to start somewhere......1 point

-

In relation to question 1 and in some instances, LPA’s may look to retain certain design features that other properties incorporate. But each application is determined on its own merits.1 point

-

Fresh air is about 20% oxygen, a tiny fraction of a percent is CO2. It takes days in a sealed room for O2 levels to get low enough to affect you badly but rises in CO2, even though very small, affect us quite quickly. I think that's why there's little interest in measuring O2 levels - it's very hard to run short of it simply from breathing, even in a highly airtight house.1 point

-

0 points

-

0 points

-

Sickeningly neat . Wasting time looking pretty whilst the build lags …0 points

-

I’ve been planning a suitable punishment lol. @nod, please tell me that you’re going to put all the locking collets onto every SINGLE fitting?! If not, the punishment will have to be quite severe, sorry.0 points

This leaderboard is set to London/GMT+01:00