Hastings

Members-

Posts

273 -

Joined

-

Last visited

Personal Information

-

About Me

First time self-build, off-grid, airtight, low energy renovation.

-

Location

Argyll

Recent Profile Visitors

2128 profile views

Hastings's Achievements

Regular Member (4/5)

27

Reputation

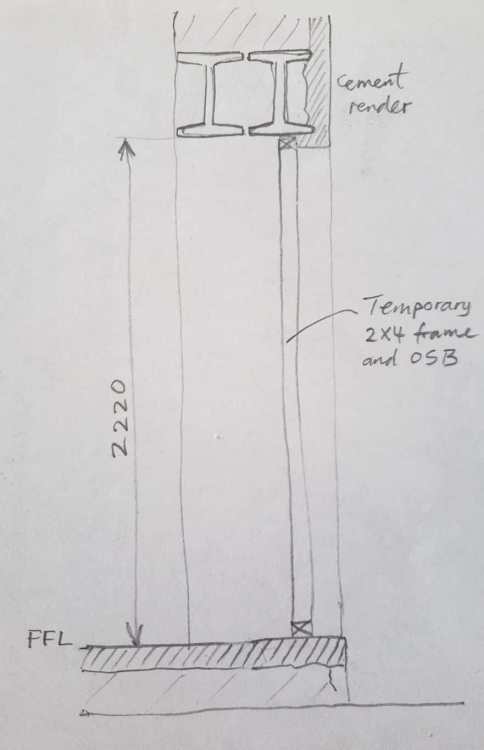

-

Are there any special precautions to take when fitting an aluminium d/g 3 door bi-folds unit into an opening (2360x2200) that has an RSJ over it? I expect to fit packers between the steel joist and the bifolds frame so they won't be directly touching each other but wonder if the fixings that connect the two will create enough of an electrical connection to cause the aluminium to corrode prematurely? Environment is fairly high humidity (West coast Scotland) close to sea. Wind blown rain regularly contains salt. My 5-year-old timber front door handle and lock made of aluminium alloy and stainless steel parts is already showing signs of corrosion. The bi-folds will be installed in an attached uninsulated, unlined, random rubble stone workshop/store. The opening currently has a temporary timber frame and OSB panel in place with new cement render finishing up against its outer top and side face edges. The new bifolds would be fitted in the same position.

-

DC Battery circuits - drawing 12V from a 48V battery bank

Hastings replied to Hastings's topic in Electrics - Other

So no need to disconnect each battery from the others while I'm using it? Doesn't the charge spread out gradually between all the batteries in the group when connected back together? -

I have 8x 12V 200Ah AGM batteries arranged as two 4x12V strings connected to each other in parallel to make a 48V supply. They power a 5kVA inverter/charger that powers the house. The inverter/charger has died and I wondered if, to let me charge laptop and phones while getting it repaired/replaced, I can temporarily connect a small 12V 300W inverter I have to one of the 12V batteries while it is still connected to/within the 8 battery bank setup? Or must I disconnect it from its neighbour first? I could of course disconnect each battery completely before using it but the connectors are secured by nuts and bolts and it's PITA to do so frequently. I want to keep the entire bank connected as a 48V unit so that I can continue charging it with my 48V wind turbine and its own charge controller.

-

EU greenhouse gas emissions see significant drop in 2023

Hastings replied to SteamyTea's topic in Boffin's Corner

This seems like a better perspective than the EU's agency blowing its own trumpet: https://www.energyinst.org/statistical-review/energy-transition-tracker "...Country Transition Tracker annually assesses progress across a range of energy sector indicators and highlights those nations that are most advanced in decarbonising their energy systems." The score cards are also very nice to look at. -

EU greenhouse gas emissions see significant drop in 2023

Hastings replied to SteamyTea's topic in Boffin's Corner

The very latest tomato growing greenhouses in the UK use natural gas (as well as heat pumps) to heat them, using the plants to capture some of the CO2 (source: https://energyadvicehub.org/giant-low-carbon-greenhouses-could-grow-12-of-uk-tomatoes/). I don't know if they change the fact that UK tomatoes grown in heated greenhouses in winter have a higher carbon footprint than tomatoes imported from warmer countries, like Spain, even after you add in the food miles. -

EU greenhouse gas emissions see significant drop in 2023

Hastings replied to SteamyTea's topic in Boffin's Corner

Even when adjusted to include imported emissions? -

Copper or Aluminium nails for slate?

Hastings replied to Construction Channel's topic in Roofing, Tiling & Slating

I think it may be important for the nails to be of a softer material than steel, so that they can be 'cut' with a slater's ripper, when a broken slate needs removing & replacing. Is this true? -

Newbie borehole-related water questions

Hastings replied to Kevin Dawson's topic in General Plumbing

Yes. The drillers are well regarded by people locally who have used them. The rainwater system we have now is a much better solution for us - lower cost (up front as well as year to year), lower energy, probably lower CO2 emissions overall. It was what we originally planned and we only drilled the borehole because of the council's very strong opposition to a 100% rainwater supply. -

Newbie borehole-related water questions

Hastings replied to Kevin Dawson's topic in General Plumbing

Our new borehole tested 7x ammonium level. The pass level in Scotland is 0.5 mgNH4/l (required for a renovation/newbuild). Pumping it all day for weeks through most of a summer didn't alter the result. There is no known source of possible contamination. The considerable investment in treatment processes required for removing high in iron, manganese and hardness in the borehole water might have cured the ammonium issue too but none of the many specialists we contacted could say it would do so for sure so we installed a rainwater collection system instead. If you manage to deal with your ammonia successfully I would be very interested to know about it. As Jeremy Harris says, I found GAPS Water to be the most helpful and knowledgeable and their quotes were £1000s less than the borehole driller's quotes for the treatment kit. -

Difficult to answer that precisely at the moment because at this time of year the battery bank stays fairly well-charged all of the time and there is mostly only me occupying the house and using water. But looking at the power meter when water is flowing I can see that maximum power draw (1200W) appears to be rare and even then very brief. The filling of the toilet cistern which is the most frequent demand draws a maximum 450W or so. The shower running is about the same. A slow flow from a tap settles at about 350W. Compare that with the previous situation (pump running in reverse) when the pump always ran up to 1200W for every and any level of demand and you're talking an improvement in power saving of, I am guessing, at least 4 or 5 fold. Never mind the all-important but now almost non-existent maximum peaks that were causing low battery voltage shut downs. I have 3 people staying next week which will be a much better test of the batteries. [Note for readers new to this thread: battery bank is 48V lead acid, original capacity 10kWh (at max 50% discharge) now about 1-2kWh]

-

From the clever folk (I have no connection with them) who created the embodied carbon database for the Royal Institute of Chartered Surveyors. Worth a look if you care about your carbon emissions/footprint when you buy the cheapest PV. Good summary at the bottom of the page. https://circularecology.com/solar-pv-embodied-carbon.html

-

Minor update: The pump IS after all running up to almost full power consumption 1.1kW, not just up to 600W as I posted earlier, which was what I recorded in response to a short toilet flush. However, it does so for a much much shorter time and starts slowing down towards a stop once the demand ends, far sooner than before. So quite a bit less power is being consumed per litre pumped than previously.