Leaderboard

Popular Content

Showing content with the highest reputation on 01/06/22 in all areas

-

+1 on approaching an experienced mortgage broker - it's a fluid environment and lenders have different and changing criteria. Also +1 on talking to your current lender. Even if you choose not to, be very, very wary of doing anything 'clever' as if they find out (small but not zero likelihood) they can ask for immediate redemption of loan which will force you to sell. We naively took out a 5 year fixed rate residential mortgage on the property we purchased to demolish while living in it and in PP limbo. When we got PP and a buyer for our BTL house we realised that we should probably tell the mortgage provider that we planned to demo and rebuild. We considered maybe not telling them but we'd had a few strong objections from neighbours during planning and would not have put such mischief beyond them. After 16 weeks contemplation they said no, you need to redeem (plus the early repayment fee) if you want to build. So we made the allowable 10% overpayment to minimise the pain. Then then a week later they said, oh, maybe we can let you do it under strict conditions (i.e sole contractor etc). Then they said no, again. At that point we just asked for the redemption fee to be waived in lieu of the delay and changes of mind and they said ok, even though it was against policy etc etc. Remortaged with Ecology and was plain sailing from there on in.3 points

-

Thank you to Peter W for responding Very difficult when someone posts a picture and asks What wrong with this As you thought not a Plumbing issue Swapped the stats and actuators Nothing Left the actuators off the two effected zones Slowly stated to get some heat in the pipes Electrical then Put a tester on all the actuators The two effected had no power going out I took backplate off the two effected stats and found a live feed had snapped Half a day for me Half an hour for a good electrician Great feeling when those caps pop up on the actuators3 points

-

@Onoff why can’t you just build it in those cavities like they build walls (decades ago)?2 points

-

That won't bring much money in up front, and without PP in place and locked in (ie started) it will be very tricky. (Update: unless you find a dreamer. On another platform I was hearing of a long-term option purchase by a developer of a house with land when the lady died, and the pesky old lady lived into her 90s and he died first. Which is a bit like giving a tablet to a horse with a blow pipe. *) @harry_angel Can you cobble together various revenue streams and loans - tax-free lodgers etc. It will be a jigsaw to get to 150k, though. If you get to three lodgers, it is an HMO. But 2 could do towards 20k a year. F * The horse always blows first.2 points

-

The elephant in the room is for anything over 4kWp (actually 3.68kW limited by the inverter) you need prior permission from your DNO before you connect it, and there may be a fee to even apply, and there may be network upgrade costs to pay before you are allowed to connect that much. This is why 4kWp is such a common size, it is the largest you can connect by right, without having to seek prior approval and you only notify the DNO after is has been connected. If you have 3 phase, you can connect 4kWp per phase so up to 12kWp may be possible without prior approval. Don't for one moment think PV will do all your needs. It won't. In the summer it will generate loads more than you can use very often, in the winter when you need most energy it will not produce enough. We have a typical 4kWp system and manage to use almost all we generate and that is saving us about £300 per year, about 1/4 of our total electricity usage. Even if we had 4 times as much PV it would not do all our needs as in summer it would generate way more thay we could ever use or store, and in winter it would still be only generatig a tiny fraction of our needs.2 points

-

1 point

-

just dropping back in after a good while away, saw this post, i agree with @joe90, can't see them unless looking hard. i had my roof hooked on and it's great. takes longer to set out but you save time in the fitting. there is also less chance of breaking due to overnailing as per another post asking how tight to nail. the other plus point is with having to double nail, replacement is almost impossible, however, bend a hook, slide out slate and replace. one thing i have found is that when replacing one, sliding it in on top of a slate ripper makes it easier to place the head over the counter battens. i would also suggest you don't need to keep the required overlap as the tail can't lift so would save in the quantities required.1 point

-

1 point

-

1 point

-

Well if it is not as well established as the product you thought you were paying for, then this is really poor on your contractor's behalf and he should be rectifying it for free and apologising profusely. I really feel for you, as it seems your contractor has cut corners without your permission. Your remedy would be for him to, test the UFH pipes are okay, fix if not, make good the cracks and leave the screed in the condition you expected it in. What is your floor finish on top of the screed, as if all the cracks are going to be hidden, it should be quite straightforward for him to patch it up. Or are you concerned about the structure of the screed and the integrity of the UFH pipes? I think it's unlikely they will have been damaged but I'm no expert. If there is any problem with the pipes, then that is going to be harder to fix, but still fixable.1 point

-

1 point

-

1 point

-

Two BH members knocking lumps of one another: how about helping @CotswoldDoItUpper instead ?1 point

-

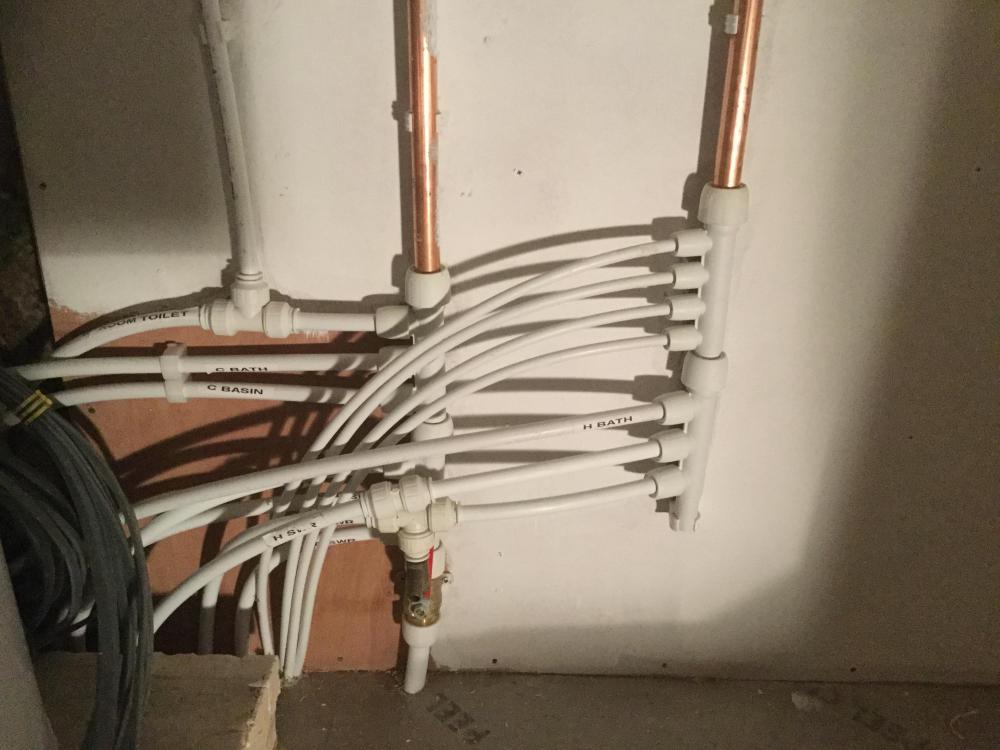

First things to check are the static and dynamic water pressure and the flow rate of the new supply. Then decide on your water heating strategy, and then design the hot and cold system around this. Manifolds won’t fix poor flow or pressure, so you need to start from the beginning.1 point

-

Curling you mentioned. That is a worry as to curl it has to bend up off the underlying surface, so will crack when it drops back to pace when loaded. The If I had done this bad job to my own house I would let it cure completely, then stamp or thump all over it to make it crack, then rub it flat with a stone (a brick even) and fill the cracks cosmetically. It wouldn't be right but I'd be living with a risk of my own creation. BUT I wouldn't accept that from a supposed specialist contractor. Discussion would start as 'break it all out and do it properly'. It would probably end up as 'no more money, just go' on the assumption that thy haven't been paid. As you have UFH pipes in there it is very much more complicated. I winder what stresses are occurring in the pipes as the screed shrinks and curls. The pipes are working as a sort of reinforcement so the cracks may have been much wider (and more numerous) without it. If they are your general builder and you want to keep them, then only you can decide.1 point

-

Better than ordinary "mastics": https://www.tlc-direct.co.uk/Products/WKONEGEL.html?1 point

-

If using PVC conduit (which is what I did) and as suggested by ProDave above, have it at a tiny slope or fall to outside. If doing as markocosic suggested above coming out at the floor be careful with outside ground level. If you've a level thresshold you run the risk of having moisture coming inside. Additionally bunching them together makes it a tiny bit harder to seal so extra care and attention is required. I find it's easier to seal and airtight individual cables than a bunch.1 point

-

Yep; if you are SE and have big debts no one wants to be your friend. I would use a recommended broker as there are ways to "work around this" - as a for example ;remortgage as a BTL . This may avoid some issues you are having but may indeed create others. It's all a bit of a game ...1 point

-

The nearest I know of (I've not researched extensivley) is SolarEdge SE3680H can be oversized to 5700kWp of panels, and supports a DC-coupled battery. Solax have a similar offering X1-HYBRID-3.7T https://midsummerwholesale.co.uk/buy/solax/solax-x1-hybrid-3.7-triplepower https://www.solaxpower.com/wp-content/uploads/2021/05/X1-hybrid-datasheet-1.pdf1 point

-

I wonder what the penalty is for having a non compliant system connected? It it was just being instructed to disconnect it immediately one might take a risk? If there was some more substantial penalty it might not be worth trying. Anyone care to look that up?1 point

-

That is just stupid DNO logic that an inverter designed for 3.68kW output could produce 10kW output. It might for a few seconds before going bang. Even a simple 16A circuit breaker in the output would trip if it exceeded 3.68kW by much. Funny how they accept circuit breakers to stop you drawing too much from the grid, but would not accept such a proven reliable device to stop you exporting too much. Something needs to change to allow more schemes like that to actually happen.1 point

-

Does someone make a system where you have a large, say 10kWp solar PV array, connected to batteries, then an inverter, with the inverter output limited to 3.68kW? That would allow the over sized array to charge the batteries during the day and discharge over a longer period at the maximum G98 rate, thus allowing a larger array to be (loosely) grid connected.1 point

-

No. I was using my previous experience of living on boats and being dependent on lead acid batteries. I hoped the later sentence, that you did not quote, highlighted the futility of running a home on battery power whens mains power is available. Long term liveaboard sailors are moving over to Lithium battery banks but these cost way more as you indicated. These sailors tend to cruise in tropical latitudes with PV arrays of 400w to 1000w. Their offgrid lives are sustainable with induction cooker hobs, washing machines, water makers and 12v lighting, however their daily energy consumption is much lower than a northern latitude house. Some of these sailors find PV+Lithium is enough and eventually ditch their onboard diesel genset but they always have the main yacht engine available to top up the battery bank on difficult days.1 point

-

Sunamp You will also need a special version specific to a heat pump; their standard Phase Change Material changes phase at too high a temperature to work with a heat pump.1 point

-

In the ceiling, it is far easier to cut a hole in a plasterboard ceiling to fix a problem then to dig up a floor.1 point

-

1 point

-

1 point

-

Yes, got the storages on, probably put 13.5 kWh into them this morning. I had just been cleaning the house, so I probably put in another 0.25 kWh.1 point

-

I've been following a flowscreed company on facebook, they regularly post pictures of work they do, nearly all of the pictures are new build and the screed is getting pumped in with the stud wall framework already in place.1 point

-

I will do a CAD (crayon assisted drawing) later, only a diverter valve from heating to DHW.1 point

-

Putting concrete tiles on in place of slate usually leads to roof sagging without extra support Theres probably no felt under the slates That why the roof leaks when you loose a slate I would strip the roof Membrane and Batton and reuse the slate I did this with my neighbors roof (Welsh slate) and had to buy about a 100 extra slates and simply re holed others1 point

-

Well done for confirming whose product it isn't. I looked up Longfloor and they state that shrinkage is Drying Shrinkage - <500µm/m pH - ≥10 If I have my figures right that is 1/2mm per m or 1:2000 If your room is 4m long then a crack would be 2mm. Cemfloor are the same, so their statement of No Cracking is incorrect. We are back to: it should have had a crack inducer/former across the doorway.1 point

-

1 point

-

@patp cheers for the response, but it's a bit far for us! Please do let me know if you hear of anything closer, it would be really appreciated.1 point

-

Pleasure! Forgot to mention the usual tip, angle the drill slightly downward on the way out and loop the wire downward on the outside, so if any weather does makes it way to it, it won't travel back along it into the timber frame.1 point

-

I would, architect error or install error. Very little thought on the warm line and is going to end up with moisture and possibly mould. Check the 1:5 section drawings for window position. Check if you signed these off, if not put it back onto the architect. If drawings show further inwards. Put this back to the supplier. In a SIPS kit I like to install halfway in the panel or on the outer edge of the panel.1 point

-

One day I hope to have enough free time to #£&@ about like this. Not jealous much …. Honest .1 point

-

I had the three bathrooms Venetian Plastered back in 2016 and I was charged £62/m2. The team that did it were excellent and the finish was superb.1 point

-

Looks like I got away with the dishwasher trick. Had it done, unloaded and restacked with dishes without her twigging. They came out rather impressively hot and in fact held their heat for a long time...(heat store project? ?) The next, new, rough plan goes like this then: I cut a board the size of the recess. Found another bit of mesh. I organised the flints how you'll see them face on like the reference photo. I then mirrored the photo. I've laid the flints face down on the board then tried to rearrange with reasonable gaps. The mesh gets laid on top and the mesh cut out where the high points are. Shouldn't matter if it doesn't sit quite flat. I'll clamp the mesh down onto the flints then blob Fischer or similar resin in each flint to hold it to the mesh... hopefully!1 point

-

My guy says £120 to £150 per m, he can recommend a chap in Scotland he did his training with and says he is very good, I can P.M. his details if you wish.1 point

-

Hmmm... Impetuous me decided to cut the cable ties off...one flint slipped straight away the other just fell off. Where the blobs are at say 3 or 4 points around the periphery of the flint it seems to be holding. Where they're at the top, in effect suspending the flint, not so good. Some like the 4 at the bottom seem to have held. The two at the very bottom were just Sticks Like Sh!t. So WTF sticks to flint? I'm now wondering if in fact Sticks Like Sh!t is in fact better adhesion wise than the white Ever Build stuff. Thus, with the intent of doing a basic "peel" test to see how the adhesion of each is: Lines of white Ever Build Multi Stick and clear Evo Sticks Like Sh!t on both the rough and smooth side of a flint. Left to dry atop the oil boiler.1 point

-

The Everbuild grab adhesive was marginally better than Sticks Like Sh!t but it still slipped a bit. Very like Sikaflex EBT: The lower ones were a pain. Then I had a brainwave, use cable ties to tie the flints to the mesh then blob in some adhesive. As I've said some flints are quite thin and have no tail. I like to think of myself as the Hengist Pod of flintwork! Craftsman and those easily offended, look away now! Going to let it set as is then finish off that top bit. The coach lantern going on the two projecting studs should hold everything in place if it all fails! ?1 point

-

How about remortgage through a new lender? If you go through a decent broker you may also get a better deal than you currently have. I have just arranged a deal fixed for 5 years at less than 1% and they will do 80% LTV. The broker should be able to steer you towards the right lender.1 point

-

Don't count your chickens yet - you know the old maxim that if you don't ask you don't get ? If you have such considerable equity and your history is impeccable, discussions with the underwriter, even through what appear to be intransigent lenders can pay off sometimes. I know, because I've negotiated mortgage lending for myself from a lender who wouldn't normally touch self-build with a barge-pole. Are you also dismissing the idea of exploring an equitable charge? I suspect the problem you might always come back to is point 2 of your OP as any mortgage based lending will need to pass those tests - ridiculous as many of them might be! I quite like @Ferdinand suggestion of getting PP in the garden ? (I'll run away now too!)1 point

-

If you spend a little time using this tool it will help you to understand a lot more about what results you will achieve from your system: https://re.jrc.ec.europa.eu/pvg_tools/en/tools.html First thing to do is to scroll on the map all the way down to your property. The results will then be based on the solar gain at your position on the planet. Play around with the options and you see what happens. For a 4kW system in December, where I am, will produce about 3kWh a day on average.1 point

-

It’s just shrinkage I normally put an expansion joint in all doorways Or at least cut a line across the opening with my trowel1 point

-

1 point

-

0 points

-

Generally seems to have dried ok. If the resin sticks to the flints like it does my hands I'll be well happy. The odd lighter coloured blob (though not all of them) is still wet, uncured DeWalt resin from the tail end of the tube, when it was just resin coming out with no hardener. Maybe as it was a bit out of date? I'll live with it as the tube was a freebie! Resin is horrible to use from a normal gun imho. Much prefer the Fischer, space shuttle esque resin tubes. My daughter couldn't squeeze the DeWalt stuff in the standard gun. With the Fischer gun it's a doddle. The "towers" are a concern as in where the distance from mesh to flint is such I've had to build up the resin in height to bridge the gap. Now to try and "hang" one without everything falling off! Edit: Must get laddo to print up some pads for the clamps so they sit over the "+" of the mesh and don't slip off.0 points

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)

.jpg.8c190979063ba43fe4ac51f7b323e311.jpg)