Leaderboard

Popular Content

Showing content with the highest reputation on 09/15/21 in all areas

-

This has been a long time coming for my build. Yesterday me and a helper moved 450 blocks (over 6 tons) into position between my beams. There are still block cuts to do, drainage, and the brickie to come back this week to do the mortar the edges / vents and grout..... but it feels great to have a solid floor after 5 months of commencement, it's been slow going due the complex basement phasing but hoping things can accelerate now.3 points

-

If it doesnt say anything in your deeds then I suspect you don't have to give any notice. I would tell them something like.. "At some point over the next 10 (?) weeks you will need to exercise your right to run services over their driveway in accordance with the terms of your deeds. You anticipate this will require trenches to be dug and may take y days to complete the work. Unfortunately you do not yet know when the work will be carried out as you are at the mercy of abc utility company. However you will endevour to keep them informed and give them as much notice as possible".2 points

-

Here's an idea: Talk to the builder about your concerns. As you do so, casually lean against one of the columns. Wear a hard hat. If the column doesn't move, and the builder doesn't flinch, maybe they're stronger than they look. However, I reckon the column will fall, and when it does the builder will leg it. Two tasks completed at once.2 points

-

@Lorenz I've been working in the oak framing industry for the last 15years. 11year with a leading company in this sector. The majority of oak frames now are wrapped in a encapsulation envelope. But they still do the traditional builds which are alot more work but look the nuts and as you said above what you see inside you can also see outside. Obviously the traditional build comes with alot more problems with water ingress etc. The other way people do it is to have the oak frame built, encapsulate it and rather than clad it, have a screen of traditional looking oak on the outet face of the encapsulation panels. This way you get the best of both and piece of mind that if the water gets in it will fall into a "cavity". Obviously Two major factors with this way...1.You need deep pockets and 2.The frame you see inside is different to what you'd see on the outside! All the best ?1 point

-

The FFX ones say fixing thickness 6 - 25mm. The RS data sheet says 10mm for them. On that basis go with the FFX ones. (Resin is so much easier! Sure you'll waste a bit and go thru a few mixing nozzles until you get the hang. If you were nearer and I didn't have the dreaded Covid lurgi you could have borrowed my gun, brush, puffer etc).1 point

-

TBH I would just thicken the edges to 200mm deep and 200mm wide, chuck a couple of sheets of A142 mesh and then cast the lot.1 point

-

Ideally fill until a whole number of brick/block courses below DPC. Normally for "fully filled" I think that's 3 brick courses (or 1 block). Otherwise 6 brick (2 blocks). I think the minimum depth of concrete is 450mm but best check.1 point

-

Ours are spec'd 900mm to 1000mm 600mm wide with concrete poured to 600mm1 point

-

1 point

-

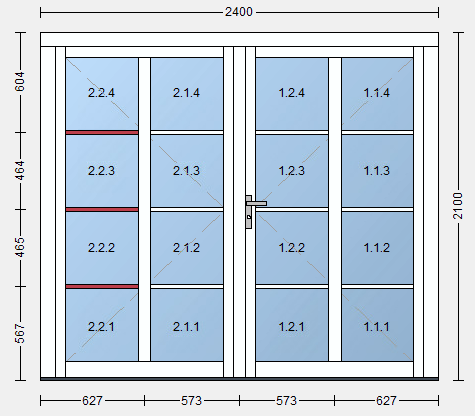

errr @craig is a manufacturer .. ? I like that option, and I would really look at that in future as I’ve always preferred French doors not hung on intermediate frames.1 point

-

1 point

-

My advice is to nail down the spec with the Mrs before you begin or asap. I build spec houses all the time and it is fine - my house has been a total nightmare. I have double power points installed which are going to be behind larder units in the utility (endless changes there ffs!), don't know what vanities and sinks we are getting (tiling starts tomorrow) - the list is endless. Perhaps I should just stfu and not ask? I can see why builders penalise variations - they are horrible. It has made me hate the place tbh. Either that or I just need a break (now booked thankfully).1 point

-

It’s great to tile on But I’ve seen a couple go wrong Ideally the insulation needs fixing to the floor with four knock-ins per sheet1 point

-

I would go with option 'B' because I care more about functionality than aesthetics and if the sashes are opening then they should let in air. IMHO option 'A' makes me wonder why they are opening sashes and not fixed. Just the way I am.1 point

-

1 point

-

I've been with Octopus for 18 months now - not through choice; my previous company was taken over by them. I've not seen any signs of trouble with them, however they've just emailed me to say that prices are going up for the second time since May (I'm on a variable tariff). As an aside, I submit my meter readings every month (gas and electric), and in return, I get a free spin of their "wheel of fortune". It's just a graphic that you click on. The wheel is divided into 12 sectors - 5 win nothing, 5 win £1, and 2 win 50 and 100 quid, so I get 7 out of 12 chances of winning something twice a month. After 13 months I had won nothing, so I wrote to them to point out that this makes me the unluckiest man who has ever lived (the chances of losing 26 consecutive times at those odds is less than 1 for every person that has ever lived - by a considerable margin). I don't trouble with it any more. They replied that it was meant to make meter reading 'fun' (Jeeezz..!), and assured me that people do actually win on it. I still think that it should actually behave as it appears it should.1 point

-

Does anyone know the new "post increase" rates for the GO tariff?1 point

-

Octopus did raise their variable rate prices yesterday sadly. Mostly on the night rate of my E7 tariff. now getting 20.6p/14.7p ? Standing chaarge up 1.8p too...1 point

-

Believe nothing from any sales rep unless they have the data to back it up.1 point

-

1 point

-

I agree with @Declan52, it really just sounds like a sales pitch. but I am a cynical b*****d.1 point

-

You need much greater depth compared to PIR insulation to achieve the same u value. If whoever is putting down sheets of insulation wrong then you have hired the wrong guy. There is little to no skill required for this job. Going by there info you would have a concrete subfloor then this flow screed then another finishing screed in top. That's a lot of concrete to buy. I would price up PIR insulation and compare it cost wise myself rather than believing a sales man.1 point

-

https://www.current-news.co.uk/news/octopus-energy-sees-160-jump-in-revenue-but-still-records-loss-due-to-relentless-investment No sign of over expansion and ambition is there. And the Kraken Technologies seems to be a cloud database with basic AI (which is anything but intelligent at the moment).1 point

-

Octopus don't do the silly unsustainable low prices so are more likely to survive. They have a good reputation for customer service and I like the way you can manage your account yourself so that is why I stay with them.1 point

-

I don't know where in the country you are but I guess between £2,500 and £3,500 per metre plus VAT.1 point

-

1 point

-

1 point

-

1 point

-

Check with BC to see if they have approved the drawings and specification. I’d go with blocks and mortar. A timber frame will need an engineer or specialist to design the frame and BC will more than likely require a structural certificate for the design and possibly the as-built frame and perhaps the roof trusses. They will more than likely need you to submit additional detail in relation to the timber frame. Check with them. I don’t see the problem moving the boiler. You’ll need a Gas Safe engineer to move it for you and you’ll need a CO alarm and somewhere to drain the condensate.1 point

-

I've used loads of stainless in various widths and it is very malleable. If you wanted, ping me a pm with your address and I'll pop a few meters of offcuts, probably 75 or 100mm width, in the post for you to see how it works. If it's too wide you can actually cut it with scissors. I use Robinson wire cloth, better prices than the Amazon link. https://www.robinsonwirecloth.co.uk/online-shop/Soffit-insect-mesh-stainless-steel-30m-roll-p496120771 point

-

Just a heads up BG have decided to increase there Metal Frame prices Others will follow I whopping 22% in the 1st of next month So anyone looking to buy Now is The time We leave stacks of it outside uncovered So very easy to store1 point

-

Timber could be an issue too if we start using it en-masse and have to grow it really quickly. A forest planted from new takes around 30 years to become carbon neutral, so before it starts actually taking anything out the atmosphere.1 point

-

Plastic bags is one thing - pretty much everything that arrives on my site is swaddled in layers of polythene. I bet my little site of 3 has got through 30 acres+ of plastic sheeting just on shite being delivered.1 point

-

Portland cement concrete. Too much CO2. Steel and concrete and petrochemicals to be displaced by organic materials, timber woodfiber, hemp etc . Buildings have excellent potential as long term carbon stores. Light polluting and noise polluting electrical devices. Every bloody appliance in our new house insists on beeping once it's finished and some even keep going until you've attended them. I'm looking at you zanussi dryer grrrrrr The quantity of 24/7 LEDs on smoke alarms, washing machines, TVs stereos, dishwashers, ovens, fridges form a mini consultation worthy of a skychart. Wet trades will gradually diminish as the skill base dries up (pun not intended!). It's generally heavy dirty work and hard on bodies. It's also difficult to dismantle for recycling.1 point

-

Some weed killers have come close to being banned.1 point

-

I'm finding it's the commercial sector that's pushing the sustainability and improvement of products for fitout anyway. If you've a large multinational company taking over a floor of an office building they have all these LEED, BREAM and other requirements they want to meet to present this green sustainable image to their staff and customers. They're looking to use low VOC products (trying to avoid that new car smell which are the chemicals coming out of the materials). Things like carpet tiles, paints, fabrics and foams in furniture, ceiling tiles, etc. Another thing they're looking for is that these are recyclable which is good as offices can get refurbished very often with layouts changing, partitions coming down and going up regularly. Carpet tiles are ripped up, ceiling tiles removed and they can now be recycled. In a domestic situation these products eg floor finishes are usually designed to last a lot longer so the requirement or desire of recycling them at their end of life isn't as great. I think this will change as more recycling options become available and move into the domestic sector. The thing is these companies usually rent the buildings so the push to have these as sustainable or recyclable isn't as great. Personally I think gas boilers will go but it will take time. I'm working on a third level university who's looking to replace all their current gas boilers with heat pumps. These are industrial scale heat pumps with a district heating system that will take place over the next 15-20 year plan to convert all the buildings. Some of the buildings are 1960's which require extensive thermal upgrading. In time carbon tax will deter gas boilers and force people to use other sustainable models. Gas boilers won't be banned but they'll become uneconomical.1 point

-

1 point

-

I think that biodegradable plastics will make a lot of progress for packaging. Plus house construction will work more heavily on dismantle-ability.1 point

-

With the knowledge we have regarding the damage plastics is doing I cannot believe we still have plastic bags! Was it not Ireland that banned them and re introduced paper bags? What a sensible move. Yes supermarkets are charging more fir plastic bags and call them bags fir life but I still see loads of them thrown away. This move away from plastic needs to move up a notch, and similar with all things polluting.1 point

-

Totally agree with this, and i think that goes even further than just the building trade, think electric cars, all those batteries! No consideration is given to end of life for products, its all about making a quick profit and moving on. For me i think a lot will change in the coming years with regards to plastic based chemicals, I was reading this article the other day... https://www.theguardian.com/society/2021/aug/31/pfas-toxic-forever-chemicals-air-breathing Sounds like the manufacturers witheld information to make the chemicals look fine, when in actual fact they aren't, and now cover alsorts in the modern home. Another thing we fail to understand is how chemicals interact with each other, and this also goes into the wider world, farming etc, the chemicals get tested in isolation, but never together which is how they are used in the real world.1 point

-

Sheets of polyurethane insulation. Disgusting stuff to cut. I wore a full suit of armour, had dust extraction on full power and it still got in my throat, eyes , ears , knickers . Ughhhh.1 point

-

Our understanding of materials and chemicals and their impacts on environment / biology are leagues above where they were even a couple decades ago. I'd be surprised if there was anything we currently use that would turn out to be as nasty as asbestos in a few decades. One thing that I do think needs to change is recycling. What happens at then end of the life of a building? He do we deal with all the plastic mixed in with the concrete and wood? E.g. plastic fibres in concrete, or ICF. There's no consideration for end of life logistics in modern building.1 point

-

Your unlikely to come across asbestos in modern buildings Post 90s Gas boilers will be around long after all of us are gone1 point

-

This banner is here as part of the Keyfob offer, supporting young enterprise and the forum. You can find out more about HERE. BuildHub is a non-profit, self-funding forum, run by volunteers. We've grown steadily over the years to become the UK's largest (and certainly best!) self-building and renovation forum. While the unpaid contributions of our volunteer managers, administrators and moderators help reduce our running costs, we still have unavoidable direct expenses, such as software and hosting. Unusually for a forum of our size - we recently registered our 14,000th member - BuildHub does not accept sponsorship or run ads as a way of covering our outgoings. We therefore occasionally turn to you, BuildHub's wonderful members, to ask for donations. If you are able to make a financial contribution at this time, it would be very much appreciated. There is no minimum or suggested donation amount, and even a small donation will have a positive impact. Donations via PayPal can be made to the following email address. Please remember to select 'gift' / Friends & Family or Paypal will charge fees. fundtheforum@buildhub.org.uk You can also request the forums bank details, please PM @newhome for those details and let her know of your donation. We'll post again once we've received sufficient donations to cover expenses due in the foreseeable future. BuildHub's Treasurer, @newhome, manages our funding account. Could anyone wishing to make a donation please send her a PM with your email, username, and the amount that you have pledged so she can confirm receipt of the funds and log your donation accordingly? All donations will be treated as confidential. If you can offer any skills that may assist with the support of the forum, please contact either Herb (@HerbJ) or Mike (@MikeSharp01) for details about how you can help. Accountancy and Technical skills, such as Linux or forum software administration, experience would be particularly valued or if you would just like to help more generally please feel free to get in contact. Thank you, as always, for your ongoing support.1 point

-

Worst case they'll f**k up and spin in the hole. Then, drill out to 14mm, clean the hole...and use resin! ? Edit: If you can get the spinning anchors out of course.0 points

-

Not so ! My solvent weld is spot on now . Get back to your gang bang shed you pansy !0 points

-

No expert of course . But , if I can do better then it must be real shit . As others have said stop all work getting BC to look . You sure I didn’t do it ? - can’t remember….0 points

-

0 points

-

0 points

-

Dig a deep hole and bury your first attempt of building a house in it. Then build a new one on top.0 points