Leaderboard

Popular Content

Showing content with the highest reputation on 10/24/19 in all areas

-

Good news is I think the contractor felt ashamed enough to apologise and rectify the work on one roof today. Turns out being a reference for half the other self builders in the development has some sway when they realise it! Taken today and tomorrow off from work to supervise onsite directly and ensure the rest gets fixed too. Thankfully I had spare material for the car port which can be cannibalised for this, and they'll be paying for replacements directly out of their fees.5 points

-

Yes, I installed a Paul Novus 450 in 2016 and it has been operating successfully and quietly since it was commissioned in October 2016. I routinely change the filters. It is installed in a reasonably Plant Room , which is accessed from the garage and is adjacent to the downstairs cloakroom and pantry/utility room. The MVHR unit is mounted on feet, directly to the floor (passive foundation) and not attached to the TF structure, so no vibration induced noise.. I ensured that good sound insulation was installed on walls and ceiling. When in the Plant Room, the MVHR unit is relative quiet in normal operation but the noise increases on boost, but not enough to be uncomfortable when working in the room ( cleaning golf clubs as I was on Monday). Outside the Plant Room, in the garage or house, it is completely silent, though if you have really good sensitive hearing you might just hear a very low noise on boost, when you are in the cloakroom. The MVHR unit has flexible silencers to connect to the steel ducting, which goes to the two plenums in the room above ( see plenum). I have also wrapped both the flexible silencers and the insulated extract duct (from the MVHR to the outside extract grill) with a layer of aluminium foil faced ductwrap insulation, which made a noticeable reduction to sound level on boost. The Plant Room is located immediately, below the Guest Bedroom and there has never been a noise problem. In fact, the inlet and extract plenums are installed in a service cupboard in the guest Bedroom and they are completely silent. The plenums are connected by steel ducting and a large silencer before the inlet plenum and a flexible silencer on the outlet from the extract silencer. All the inlet and extract vents in each room are reasonably silent except for a slight increase in noise on the extract in the Family Bathroom when on Boost.3 points

-

The LPA have now recatagorised these documents as sensitive, this means they can no longer been seen publicly through my neighbours application. I incorrectly assumed they had been uploaded by my neighbour to assist his appeal when in fact the planners had used the documents to determine the outcome of the application. I'm not certain whether the LPA made an administrative scanning error and that is why they appeared online. Or whether this is usual practice. Either way Im content they have now been removed and I am no longer associated with this application. I doubt any lasting damage has been done to my impeccable reputation!!2 points

-

Last week they had asked to delay works and when I said no due to kock on effects they just didn't turn up. So this week they rushed. They didn't plan or think about how to operate on site in a desperate attempt to get to the next job. I had half the garden setup for them to sort and cut the material on the ground, battening to make frames to carry the material, winch to pull it up, they ignored it all! It was heated indeed this morning. They defaulted back to excuses and them not having the right tools or equipment etc... Bad attitude really. Tried to blame me and other contractors. When I asked why those issues were never raised with me they said they were minor and they could work around it... A bit hypocritical. I reviewed what exactly they were doing and pointed out that at no point were they following the installation instructions I had demonstrated to them and had printed out in my hand. I pointed out that jig and recip saws should only be used for short stretches and curved cuts, not the full fecking length. The sheets should be upside down on a covered surface during cuts to protect the surface from scratches, they hadn't. I've given them today to show they can do it properly and fully rectify the installed sections. If not, I'll have to DIY as no other roofer around these parts is interested. Should have seen the red flags. Experience gained I guess.2 points

-

2 points

-

+1. If the tanking has been on long enough to get some surface dust on it, just clean it lightly with a damp sponge prior to laying on. I use a grout float to butter the tanking with the tile adhesive ( rubber edges trowel ) about 1M2 at a time and then you’re guaranteed a great bond. Do that for the 1st metre of the wall, and then you can fall back to just a wipe and laying by bedding the tile only ( depending upon how flat the walls are of course ). Do not EVER consider using acrylic ( ready made in a tub ) adhesive over tanking ( ask me how I know how that goes lol ). 3 days later, porcelain tile, acrylic adhesive ( bragged up by the Ultra area rep ) and over tanking, and when I removed the supports to cut the lowest course in all the tiles slid down the wall ?. Cementitious products ONLY over tanking, especially with porcelain ?2 points

-

2 points

-

Photos of mine: I used an old car cooling fan, with the motor replaced with a brushless DC one for better speed control. The motor and speed controller are standard model aircraft parts from China (Hobbyking, I think). The speed is adjusted using a model aircraft servo tester, fitted with a better knob. The thing runs from the DC power supply in the photo. It's massively too powerful for testing a passive house, but was fine for finding air leaks in our old, 1980's, house. The bit of MDF was cut to be a tight fit into an open bedroom window.2 points

-

Mostly I see the blue pipe just coming into the building, then a stop cock, then copper.2 points

-

There is a bit of a myth about using ASHPs (or any heat pump) in an old thermally leaky house. The thermal load, is the thermal load, a heat pump does not care why the load is what it is. What it really comes down to is sizing correctly. With a traditional boiler, gas, oil, electric, you work out your maximum load, add a small contingency, they go and buy the nearest size to it, knowing that it can run at full power when it is demanded. A heat pump, and especially an ASHP, does not work like that. As you get closer to the maximum output, there is a greater risk of them 'icing up'. This is because more, damp air is being forced though the unit, just as it is trying to get the biggest temperature difference. Then what happens is that either/or/and, an electrical resistance element is switched on to help the unit out, the heat pump can 'steal' some of the stored water to heat up the external radiator to defrost it, it can just switch off until it defrosts. It may e a combination of all of them. This is why ASHPs have to be oversized to reduce the chance of them running at maximum output and the resistance heater coming on and reducing the chance of frosting. And that is before the heat emitters have been considered.2 points

-

Looking at your revised list of C3's, I see the old chestnut of "plastic consumer unit" has cropped up. At least this guy has given it a C3, some try it on as a C2 to try and get a consumer upgrade done. The Wiring regs are not retrospective so there are few circumstances where you MUST upgrade it. As already noted if you were wanting lots of alterations on one of the circuits not rcd protected, then a CU upgrade might be worthwhile, but even then it could probably just be dealt with by fitting an rcbo Personally I would not do anything to address those C3's other than bear them in mind when planning future work.1 point

-

Okay. I am an electrician in the Highlands. I do new builds and other notifiable work. All that Building control require is an Electrical Installation Certificate (EIC) and you don't need to be a member of a competent persons scheme to produce and sign one of those. I do work in Highland, Invernessshire and Moray council areas and all have accepted my certificates. iirc Invernesshire phoned me when I submitted the first one to them to check my qualifications and were happy. If you are just doing alterations to an existing building then not very much is notifiable, the two that are most likely is a rewire of a flat or 3 storey building requires a building warrant. This £100 rebate thing, is the "Certificate Of Conformance" scheme. This was introduced in Scotland about 10 years ago. IF you CHOOSE to use an electrician who is a member of such a scheme then you will indeed get a small discount on the building warrant fee. When the scheme first came in, I attended a Highland council seminar about it and it was made clear the scheme was optional, so I have chosen not to sign up to it with the additional burdens it would place on me. I advise my customers not to tick that box.1 point

-

Nope that would look proper shite the velux ones are not that unattractive in the flesh.1 point

-

Yes, although 8 person capacity could apparently be achieved by increasing air flow rate.1 point

-

I expect so as it’s the same for a septic tank, treat it well and it can be years between emptying......1 point

-

On a simple roof like mine where there are no angled cuts it’s possible to not have any cuts showing full stop. However you order the length exactly for the roof length (cheeper to order all one length) you then need to cut down the short sections above and below the velux, this is just a straight cut across the sheet, not along its length. These cuts are then hidden below the flashings, there is a bit of jiggery pokery as you also need the turned down edge to fall into the velux gutter so you need to flip some sheets around to make this happen. Again no cuts required. You adjust the overlaps to make sure the tin that runs down the edge of the velux is a FULL length so NO CUTS. It’s usual to need to cut the tin at one end of the roof but again this is hidden under the eves flashing.... so in short YES it’s possible unless your a total tight git like me who had worked his sheets out to the very last one without and left overs..... and then realised that due to flipping the sheets around I had ended up with one cut edge that I could not hide...... buy a new sheet and plus pay £200 hauling fees.... I could live with it and put it low down hidden by the gutter !1 point

-

There you go, hopefully question answered. Could you let us know what the outcome is though, as that would be a useful conclusion to this thread.?1 point

-

1 point

-

@Visti you’ve got a good attitude mate and you have covered your bases with written instructions and gone above and beyond your duty to provide them with a work area etc. I really hope they come good, if not stand your ground and don’t give an inch.1 point

-

No immediate action needed for any of those items, IMHO. If you're ever having any major electrical work done, then just add a consumer unit change to the work list, and that will cover everything except the "cables in walls" point. Not sure what that is, could be just that it wasn't possible to inspect buried cables in walls (bit OTT, IMHO, but some do record such points). When a new consumer unit is fitted it will be fire resistant and include RCD protection, plus there will be (or should be) details of the installation left with you. A consumer unit change will be around £80 to £100 plus labour, should take less than a day to change, inspect and test. Labour rates vary, around here it would be around £200/day.1 point

-

1 point

-

As a tilling contractor I’ve not used bucket adhesive for many years As Nick says Bag mix is cement based and the only choice for porcelain and works out cheaper1 point

-

I thought that Part P didn't apply in Scotland? Unless things have changed, then I don't think there's any need for an electrician there to belong to any particular body in order to inspect, test and issue an EIC. @ProDave will know, as I'm pretty sure he's not a member of one of the cartels. For completeness, for those in England and Wales (not sure about NI) building control are supposed to be able to do the inspection, test and sign off under Part P, as a part of the rest of the building inspection system. However, I found that in practice some building control bodies are not able to do this, as they don't have anyone with the right ticket to do 3rd party inspections and test. I was going to do all the wiring in our place, and just get building control to sign it off, but was told they were very sorry, but couldn't do this, so I'd have to use a Part P registered electrician.1 point

-

Yes, that's right. It won't be calibrated so there's little you can say about the actual air change rate but it'll show up leaks and, depending on how you use it, may give you an idea of relative changes in leakage. Here's a thread on the subject from the other place. Sadly, the pictures seem to have disappeared: http://www.greenbuildingforum.co.uk/newforum/comments.php?DiscussionID=73961 point

-

Good news is UK gov (or the civil service that runs it) is aware of the increasing divergence of building regs ventilation requirements vs low energy best practices. See recommendation 10 (table 1) on pg 18 here. Timeline to address "2019" yeah.... Does someone have a guide to making this home made blower? Sounds a fun project. I'm assuming it's really just for diagnosing leaks not making an accurate measurement?1 point

-

I've done exactly the same, as the house was being over-ventilated at the building regs rates (and our BCO wasn't interested, either!). I turned the whole system down a bit for the background ventilation rate, and that seems to work very well. Mind you, there are only two of us in a 130m² house, so that's one reason why the building regs rates were a bit too high in practice, and the main snag with using area to determine ventilation requirements, IMHO.1 point

-

I initially set my MVHR rates to satisfy building regs. and SAP for the BCO, who incidentally wasn't interested. After the building was signed off I set the system to PH rates because I think it makes far more sense to base the set up on the volume and purpose of each room than overall rates.1 point

-

We have Enphase microinverters (per-panel DC-AC inverters, rather than DC-DC converters like SolarEdge), which offer similar advantages in shaded situations. Another advantage microinverters offer is better generation in low light. In a conventional inverter string, the string as a whole needs to generate a certain amount of voltage before the inverter starts working. With microinverters, each panel needs to generate a minimum voltage. In low light conditions - early morning and late afternoon, for example - a microinverter-based system will start generating earlier and continue generating later than a conventional string inverter. I don't know how much this adds over a year, say, but I seem to recall it was good a few percent. Worth looking into whether optimisers do something similar.1 point

-

Believe the MAFIA offer slightly expensive contract options for proving yourself right if that calculation does not work out. ? (Payment would be required in advance) You need to think about everything. You can also get and need to think about (you may have done this): - Potentially a saving on roof tiles etc if you go "in roof". - A partial insurance policy against rising electricity prices (and potentially against policy designed to drive out gas - potentially quite quickly if the rhetoric-over-reality lobby win). - Similar against potential supply issues. - Potentially the lecky car saving / ability to start using batteries for short term time shifting if required. But batteries are to a major degree probably dependent on having solar. - The price of tech may change by the time you build it. eg I would expect the price of solar to fall modestly over the next 2-5 years (I mean 10-20%) after a fall of 70% or so since 2010, but a greater fall in battery prices (maybe) due to tech and scale. - You could use secondhand panels if you need for some years, or tweak your install otherwise. - Those numbers will only get better if energy prices increase. Which depends on policy, whether offshore wind lasts, and whether they build any white elephant supply options. (See Tidal Ponds, or perhaps Nuclear). OTOH I can see oil prices falling depending on the level of demand - 25-30% of global oil goes into passenger transport and that will shrink by 95-99% in half a century if we consider ground transport. - As a temporary factor, it could be argues that current mortgage rates make the finance free or potentially below inflation if you have capacity. - The spec of your house may change (or not meet or exceed your aspirations). - It is virtually always possible to reduce the cash cost of anything by 20-40% depending how you do it. - Finally you may decide to invest for the environment. This was in some measure my motivation. Mine are currently probably on a 13-16 year payback, but I jumped before the subsidies were cut, and have a Plan to move half of them to a South Facing roof (2 strings, 19kWp install) when I get my car port / veranda past the management. I think my call would be to build a long term cost spreadsheet incorporating 200 years of bills to explore options, maybe increase the house spec somewhat, and at least provision for the possibility to do it effectively in future. Then play your best informed game of "spot the ball". And remember that there will be wrinkles in the process - this does not apply to you but it is a good example. Ferdinand1 point

-

These should be cheap :- cut with scissors! http://www.elastolith.nl/en/diy/diy-verwerking/1 point

-

If that Nicholson’s stuff is a bit pricey, even though it looks very good, you could probably get a support tray folded and add an insect mesh, then lay your lead over it.1 point

-

@willbish just spoken to a mate of mine who said give Nicholson’s a call. He reckoned you could use their Airtrak product to do what you want but may need to lift the ridge roll slightly to get the ridge to settle at the same angle as the roof. Think this is the stuff he’s referring to - see VR200 https://www.nicholsonsts.com/sites/default/files/files/standard/AIRTRAK Feb 2017 HR.pdf1 point

-

I would use this under the lead: https://www.roofingsuperstore.co.uk/product/flash-vent-boxed-in-3m-roll.html Not designed for this exact purpose but think it wold work.1 point

-

Pretty easy to use - there are a couple of different systems but they work much better on a tile backer board so consider that rather than plasterboard. Interior systems are easier than exterior as they don’t need to be waterproof. Range in price from £20-40 sqm for the tiles plus grout and adhesive.1 point

-

RHI was a massive incentive for me,during a refurb i have removed the storage heaters and the THTC and replaced it with a 7kw panasonic ASHP system wth radiators, coupled to the fact that i got a £10k interest free loan (im in scotland) and the projected payments of £300 per 1/4 or £8400 over the 7 years means that my heating system has cost me £1600, my house is far from passive but the system is well specced and manages to keep the house warm even in horrible weather like right now the wind is 34kt gusting to 46kt and its raining i am still curently waiting for progress on my RHI application, although that is mostly my fault as i have had to produce more documents that have taken me a while to sort out. The loan in my opinion is not a loan as you still have to have the funds to install the system then claim the money back, in my case i had to pay roughly half the total after first fix install and delivery of the heatpump/ DHW cylinder, fan rads etc i then had to complete plasterboarding, taping and filling/ painting before the second fix and commissioning could take place, only after the system was commissioned an MCS certificate was produced. I then had to have the EPC redone to reflect the changes. before submitting my loan claim form by which time i had paid the plumber the remainder of the balance. i don think it is reasonable to expect a tradesman to wait for payment for so long.1 point

-

The way the trade would fix this is with plastic tube washer and concrete screws, this gives a thermal break and a fairly easy application compared to using resin overhead which isn't great fun. 250mm version of this https://www.fixfast.com/products/fastener-systems/surefast-reg-flat-roofing-fastener-system/sf-75mm-tube-washers-for-insulation 100mm version of this https://www.fixfast.com/products/fastener-systems/surefast-reg-flat-roofing-fastener-system/sf-rs-6-1-fasteners-for-concrete-and-timber-decks Fixfast have an Irish branch if that is where you are from memory? If you are struggling from them there's other sellers online.1 point

-

the biggest problem that i can see is the fact that the glazing beads are completely wrong, there should not be a mitre in the bottom corners, that detail forces water into the corner and into the joints the bottom bead needs to also be wider and have a drip detail as currently all the water that hits the top window will run down the glass and straingt into the gap at the top of the bottom window1 point

-

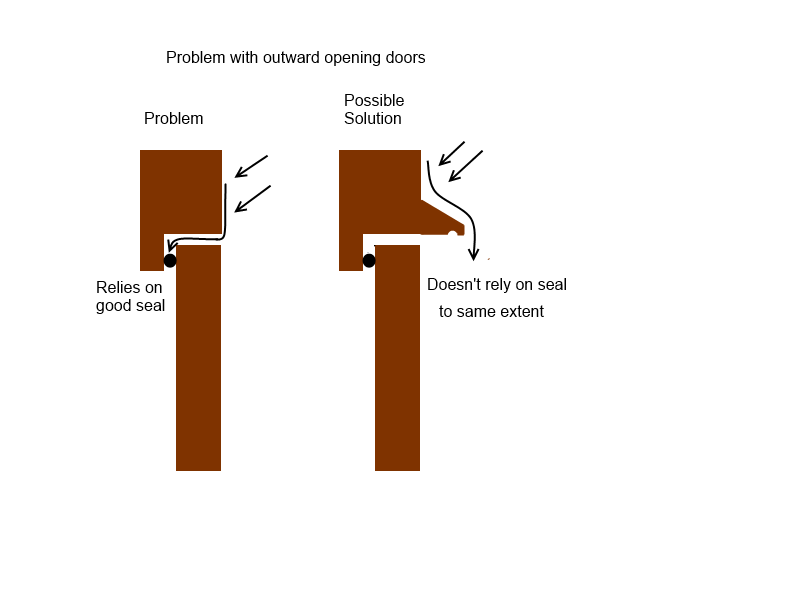

In the video there is water coming in the top of the door. That's somewhat unusual as normally the roof overhang or gutters shelter the very top of the door to some extent. Part of the problem is that the door opens outwards so the seal probably mates against the inside of the door or wipes against the top of the door. On inward opening doors the seal can mate against the outer face of the door. Check for any gap between door and seal at tge top and fix that by raising the door if its sagged a bit. In addition I recommend fitting a weather bar with drip groove above the door to divert any rain outboard and to shelter the gap at the top of the door. This should be the width of the opening in the wall eg wider than the door. Edit to add this sketch of what I think is happening..1 point

-

A tip I got from another forum from a passive house builder (who was nearly as tight as me ?) was to let the bath water sit there after a bath till it was at room temp, it helped heat the house, better than some fancy heat recovery system in the drains,!!!1 point

-

The attic trusses arrived today after making a three hour journey from Inverness to Skye. Offloading took place at our site entrance. Our joiner did a great job weaving between odd trees on our access. Trusses unloaded and ready to start being fitted over the next few days. Had a sneak peak on the top of the scaffolding to get a view from where the treble velux windows will be fitted.1 point

-

Some day for it. Today was one of those special days where suddenly years of work starts to come together in front of your eyes. No machinery here just elbow grease. It was all going so well until the building inspector turned up. A few internal load bearing walls to be finished and then on Monday we have the telehander coming to stay for a couple of weeks, followed by the delivery of the attic trusses on Tuesday.1 point

-

As @Nickfromwales says, there are several different Sikaflex compounds. Originally, Sikaflex was only a polyurethane, moisture curing, sealant/adhesive. This was the stuff that earned Sikaflex a good reputation as a sealant that would tick like sh*t to a blanket, on damned near anything. The two downsides with it were the slight smell and the fact that it was, if anything, too good an adhesive (damned near impossible to get off when cured). Since then, several manufacturers have come up with other formulations, from polysulphide sealants (excellent stuff for sealing up the joints inside aircraft wing fuel tanks, but smells awful and I'd avoid it like the plague) to a wide range of modified silicone polymers and polyurethanes. CT1, Evo Stik "Sticks like Sh*t" sealant and Unibond F|T101, are examples of MSP adhesive/sealants that are near-identical. Sikaflex EBT is a polyurethane that seems very similar to their old 223 industrial grade stuff, marketed as a building adhesive/sealant. In general, there's not much to choose between any of the MSP or polyurethane products. All are significantly better in just about every respect to standard moisture curing acetoxy silicone sealants, although some of the better neutral cure silicone sealants perform almost as well as the MSP stuff, but there's not a big enough price differential to make it worth using them, IMHO.1 point

-

0 points

-

A bog standard sliding chop has a fairly fast running motor and some decent tolerance but is designed to just do wood cutting. The Evo ones have a slightly slower running motor so they can run different types of blades for different materials, and usually from experience have tolerances that you can measure with a yardstick ..... You can probably tell, I’m not a fan ..0 points

-

0 points

-

It is well worth making your own blower if you can as when a house is tested, there is not enough time to find all the leaks. And the leaks are very obvious. No need to get hippy @joe90 with his josh sticks, but I will travel for 200 Marlboro and petrol money.0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)

.thumb.jpg.4dde1be80beacbb9600a4713832fae53.jpg)

.thumb.jpg.f6d3c0055e3fe83be928955fbfce0bd4.jpg)

.thumb.jpg.f55eea0200b578eddca755fbbbdfdd22.jpg)

.thumb.jpg.973e9b397323c482fd122cf44fb701dc.jpg)