Leaderboard

Popular Content

Showing content with the highest reputation on 02/08/18 in all areas

-

I have to say the idea of using low grade plastic waste to make a product like this does seem to be a very good idea. Low grade plastic waste is hard to do anything with at the moment, as it contains a mix of different types of plastic. I know of one process that breaks all these mixed polymers back down to monomers, like ethylene, and these monomers can then be re-processed back into high grade polymers (plastics). It's a new process though, and expensive, so something simple like just making large, non-structural, plastic "logs" seems a good idea. The only downside I can think of is UV stability. Many plastics break down under UV exposure, and fade or crack. As these are made from a mix of plastics, some of which may be UV stable, some of which may not, there may be the possibility of degradation after a few years in the sun.2 points

-

Fair point @richi and well said. (should probably have skipped the bit in brackets). Thanks @JSHarris I have not read that. I will do so with interest, appreciated. I agree that Cochrane surveys are the gold standard. Jeremy, more generally I am impressed by your breadth of knowledge and that of many on this forum. I am learning a lot by following threads on a great range of diverse subjects (even the splendid sparring with @Fredd).2 points

-

Thanks heavens its not just me. Worse thing is I dropped mine off the tower 3m up. Then picked it up and it wouldn't drive screws. Convinced I'd ruined several hundred pounds worth of tool porn. 20 minutes later, took it out of reverse2 points

-

Well since you pointed it out. let me tell you the story, I had to take out a foot or so of topsoil, then put in 64 piles, bring in 400 tonnes of MoT1 for the piling mat , then there was the cage to put in, the wiring team had to come from Ghana, were all drunkards, so I sacked them : the NHBC got involved, but they were useless, so I asked a self builder. He did it on his own for half the price quoted by Wimpeys. Lovely bloke2 points

-

There's a point of view, widely held, that you shouldn't drink softened water. Supposedly because of the extra sodium ions in the water, causing high blood pressure. I call shenanigans, for two reasons: A properly adjusted, metered softener shouldn't add excess sodium The "science" behind the theory that dietary sodium increases blood pressure is, frankly, bunkum. It's believed that more people suffer from poor health from not getting enough salt than from the tiny, tiny effect that salt has on blood pressure -- as a direct result of the public-health advice to cut down on salt. (At this point, @Coopers is muttering "don't get him started.")2 points

-

2 points

-

Mornin' Fredd. I'll get the tea on. Mind if Rollo does a shift today? Been up all night makin' that sodding spoon, so I'm off back to bed.2 points

-

2 points

-

This is literally the only bloody thing I understood from this whole thread.....!!!!!! Can I borrow that spoon to slap my eyeballs out?2 points

-

1 point

-

Knowing the warranty companies well, I would turn that back on them. They will have had a set of plans and will have been given the opportunity to specify any amendments or terms. Ours will not cover the wine cellar for example as it’s a pre-existing structure that could not be fully inspected. If they required a certain standard then they need to state up front, not make an unreasonable demand at point of inspection ...1 point

-

My friends and I use these all the time. They are now used on real railways as well as the miniature and narrow gauge stuff I get up to. The oldest ones are now well over 10 years and although the colour has faded they take everything thrown at them by way of weather but are a disaster if you drop burning coals on them as they burn wonderfully.1 point

-

1 point

-

Brickie and renderer will want full runs - they set corners and work inwards. Your minimum run will be the largest length of the building in that case.1 point

-

Now for the tools ? obviously as I have no idea to stand half a chance I NEED all the gear. First job is coring out for the boss adaptor. I already own some hole saws and arbours but not the right size so I have treated myself to a nice new 14 piece quick change Bosch hole saw set (£88) now it would be far too easy if the kit had the only size I actually need so I had to buy a 60mm one separately but I didn’t find that out until the kit turned up ? next job job is to cut some 2” pipe. I already own a hacksaw and grinder but who uses that rubbish anymore. All 3 sizes of plastic pipe slices (£50) and they work a treat. now you you might think surely that is enough to get on with the job but you would be wrong. Even with the fantastic pipe slices I was ever so worried about nasty burrs on my pipe so I bought a nice debarred for (£8) so now I have all the gear and a forum. What could possibly go wrong ?1 point

-

To be honest @Fredd sounds like a right merchant banker. And shows why 75%of new house buyers are unhappy with the houses being supplied by developers.1 point

-

Have you looked at the data available from PVGIS? It tends to be very accurate, certainly within about 5% or so, in my experience. The site is here: http://re.jrc.ec.europa.eu/pvgis/apps4/pvest.php#1 point

-

They are produced by a process using foamed plastic extrusion, where about 30% is virgin PVC and the rest is a mix of thermosetting and thermoplastic re-grind. The new plastic forms the “glue” around them. We discussed this a while back but that’s about blocks I believe...? Nothing wrong with them per se but they can be variable in quality and consistency based on the type of regrind used.1 point

-

1 point

-

1 point

-

It makes it a lot softer than ours. According to the hardness table 60 - 120ppm is moderately hard and over 180ppm is very hard. Sorry I posted before realising you had already found the answer.1 point

-

@lizzie If your washer and drier are side by side can you squeeze an end support panel between them?. This would then support the worktop.1 point

-

I'm not sure that Fredd is a builder at all. I reckon he's a carpenter because he seems to be chippy as hell with some sort of deep set grudge against those who want a home built to a better standard than those he has a hand in. Well balanced, though, with one chip on each shoulder. What's the point of banging on about first time buyers and what they can afford on a self build forum? It really isn't relevant to much of what is discussed or has questions asked about here. Has a self builder down the pub taken the *^ss out of him so he now feels the need to troll a self build forum in retribution? Either way, this isn't a good place for him to try and inflate his ego or shrink his inferiority complex. Time to move on, bored with pointless contributions now.1 point

-

Solid laminate at 10/12mm will be OK but anything with a chipboard core I am not sure can be left unsupported over 60cm Neither of these are cheap (in comparison to 38mm laminate tops) so you may as well ask at your local granite yard. They will very likely have a 3m offcut of something 20mm that they can let you have if you are prepared to provide the template and fit it yourself.1 point

-

I run a kitchen design and installation business and we deal with a brand of German kitchen who also supply the said worktops through us.1 point

-

@Fredd I am not sure if you are just winding us up, like the Irish electrician tried to a while back, and the Architect that tried to convince people that t was illegal to be an Architect unless you were in some organisation or other, and had insurance and ... But I shall give you the benefit of the doubt unless you keep acting like a nob. That is a bit of a simplistic statement. My Mother wants and easy to drive car that is reliable and economical. She does not need to know how the engine works, or how the ZF gearbox automatically selects the gears. A house buyer is relying on the honesty and integrity of the building professional.1 point

-

Yes if you are using it to seal big gaps - normally caused by poor dot and dab - but there are foams that are designed to bond plasterboard to block walls. They deliver a more solid feel tbh and are quicker but the blockwork needs to be near perfect as you can’t sort the problems like you can with D&D adhesive.1 point

-

Loving the faux concern for buyers. someone is trying to look after sellers’ interests and nothing else. Lol, lol and thrice lol.1 point

-

If the trades do there job properly you shouldn’t need to use foam When I start plastering mine in a few weeks I’ll put some pictures on Showing that there is no need for foam1 point

-

Mason mitre jigs have stops on the waste side. Obviously it can be done by jigging up right but makes it even more pita. I allow a cutter per kitchen job done1 point

-

Respectfully, that sounds like argumentum ad verecundiam. The only bodies I know that disagree with the data are those that stand to look stupid for their previous recommendations (notably, the AHA). I'm happy to learn of any truly independent bodies that still believe the evidence is strong, of course. @JSHarris's point about Cochrane is right on. As with its previous reviews, its latest shows inconclusive evidence (but the reviewers stop short of recommending a reversal of the conventional advice). To be clear: the data show a moderate benefit of salt reduction among the hypertensive sub-population, but actually a dis-benefit for those with typical blood pressure. IMHO, Lewis Dahl is to dietary sodium as Ancel Keys is to dietary fat. Both unscientifically shouted from the rooftops about their data and their data alone. Self-aggrandisement is not the same as science. Despite the data being poor, their shouting caused the U.S. government to "do something" (because, hey, something must be done!) Important: I am not your doctor (I am nobody's doctor). So talk to yours. And read the science to decide for yourself. Here are some pointers (this is an inexhaustive list):1 point

-

Yup lol. Been stood there screaming at it for 5 mins and then realise im trying to send the screws in anti-clockwise1 point

-

Agreed. I put in a Combimate a few months ago (plumbed for the whole house, not just the boiler). It makes it much easier to clean taps, etc. You don't get the soapy benefits of soft water, but you also don't need to find space for a hulking great machine that uses additional water, electricity and needs refilling with salt. Phosphate-dosed water is believed safe to drink (many USA municipal water companies dose at source).1 point

-

On a serious point (accepting that this thread is only a wind-up), when we were looking around for a main contractor we did go and look at a small development of 5 houses being built by a company that, on the face of it, seemed to be worth asking to quote. The first house on site was the most complete and whilst we were being shown around there was a chap busy applying airtightness tape. The boss was called away to the site office and we were left chatting to the chap doing the taping. His first words to us were something like "This one's already failed the air test twice, I'm wasting my time doing all this just to get it passed. I'm not faffing around like this with the other four". As only one house in the development needed to be air tested, then it's pretty clear that the other four weren't going to comply with Part L1A. From what I've seen since, walking around doing thermal surveys, this sort of practice seems pretty commonplace.1 point

-

Personally I think that might be the best idea. Starting threads that are only intended to troll the forum isn't on, in my view.1 point

-

Chin up! At my last job we had a talk from one of the leading sports psychologists in the UK who works for national rugby teams etc. His advice to top athletes was quite simple - concentrate on the things you can change (i.e. your own performance variables) and ignore the things you cant (weather, other team etc...). While a surprisingly simple approach, it does help as it removes focus on extraneous issues. You can't control your neighbours attitude but you can ensure that your deliveries are as professional as possible and that things are left as they were before.1 point

-

Hello, welcome from all of us. It'll be very interesting to hear from you about the differences between self-building now and then, especially in relation to the differences in technology. We look forward to hearing from you Ian1 point

-

1 point

-

morning you air tight eco builders! my point here is not to let your architect set your DPC height he wont be the one digging out the muck and paying for it to be hauled off. Let him set the ridge height (if needed) and you work it down from there. Too much ££££ at stake. You do not want to dig a big hole and put your house in it. This is my normal process now: 1. scrape off all the green crap 100-200mm. 2. laser to see what levels are like. 3. Hammer a spike into a corner, measure ridge height to adjoining and where DPC needs to be on the build, mark it on the spike. I use a leica D8 for this. cheap and brilliant little tool can even work out pitch. 4. Now if that mark is above ground, all well and good. if its the mark is minus more than 100mm then roof pitch it changed to accommodate. worst I've had is 550mm which we jiggered down to 220. Still a lot of wasted cash though. The 40k example wasnt just muck away cost (15k) we had to get an adopted sewer moved as the footings were so deep and too close. If we were 200mm higher then the sewer move would not have been needed. YOu drawn a diagonal line from your footing out into the build depending on depth and if it intersects sewer. ching ching. Oh yes the sewer company subs out the job, it gets costed by the subbie and you cough up. No other quotes obtained. Legalised scammery.1 point

-

1 point

-

Sorry, I disagree. Everyone's jumped on two bricks and £40k muckaway, but he talked about groundworks, muckaway, altered ridge heights and changes to ceiling heights in the initial post, and a "5 figure" saving for 1-2 bricks. My point is that I think that rather than submitting any more arguments trying to prove him wrong, it'd be interesting to have @Fredd explain the figures. I absolutely agree that the proposed savings seem very high, and certainly that Fredd's initial post could have included more actual information.1 point

-

A very interesting and thought provoking thread. I think a lot of it comes down to a business culture in the UK that is not prepared to invest in training and are unwilling to move on from legacy methods. It is I guess one of the reasons why the UK companies have some of the longest working hours but lowest productivity. Where we are competing internationally, British owned companies end up becoming niche players with the car industry being a case in point. The house-building industry is however dominated by domestic companies, so they just carry on doing what they have always done. A good quality home seems to be as much about good design and attention to detail and I feel sure that if the volume house-builders put the same effort in these areas as they do in marketing, they could make significant improvements in quality and use their scale to minimise any additional costs.1 point

-

Depends what's the contract states..... It should be something that is expressly agreed. One of my contractors tried to make me responsible for a telehandler to offload materials and I simply pointed to the contract which was silent on offloading - so supply and install had to be interpreted to include everything necessary to achieve the installation, including the offloading and placing the materials in place for installation1 point

-

We too live in a very hard water area. Wve had a Twintec water softener for about 10 years (removed it from our previous home and refitted in the new one last year). Not cheap to buy/install but pretty much pays for itself after that in so much that the cost of the block salt is paid for by the saving in soap, shampoo, washing powder, cleaning products, etc. And of course, it takes less time and elbow grease too. For Mrs NSS, who has eczema, it's also a lot better for her skin.1 point

-

Depends what the items are Most places will try it on and ask you to have a telehandler handy1 point

-

you have hit the nail bang on the head here stoner. ive yet to do a build where there havent been compaints/hassle. it just goes with the territory. Crack on and be helpful where you can, delivery lorries are rarely there more than 20 mins. I only give notice where i will be preventing someone getting out when say concrete pump will be there for a couple hours. or a crane. if they kick off then (and ive had many) I just tell them to call the police. Not yet had the police turn up, have had council on phone though. explained the issue. notice given. no other way to do it. complainer being deliberately awkward and no wont move until its done which will be a matter of hours.1 point

-

Fair enough hounding them after a couple of days, but nothing at all unreasonable following up after a couple of weeks. Bear in mind that once you have quotes, you would look to negotiate and compare against other suppliers. Our windows and doors were initially quoted at just under £13K. I paid £8.5K in the end. There was a fair bit of back and forth but in the end, they wanted to secure a sale...1 point

-

My God, I'm overwhelmed with the Feedback and the high caliber of it!! Why didn't I come here last year....damn Thank you everyone. ok, Here is the two staircases, After talking with my wife who was only 'going along' with the spiral because I liked it so much, we've decided that the straigher type would be better. Something MORE like this: Lovely Curved Staircase - Stainless Nod: when you say impractical, what was the biggest issue you had with a Spiral staircase (bring a clothes basket down, or furniture up?)..baring in mind, this stairs was going to be a helical style one, about 0.5M inner diameter, 2M on the outside dia. AliG: My wife wants to 'hide' the entrance door to the Utility room, so that it blends in with the other cabinets. but that is a good point, there is no reason the blended door can't be the last 'cabinet' in that run. That is an interesting Idea about moving the Cinema room forward and putting the toilet in there (I need to talk some more with the Wife about that) Dudda: Well spotted: the kitchen light is something I am worried about, The height over the Kitchen at the moment is 2.7M. I see what you mean about making a vaulted ceiling all the way up...That would be HUGE We were thinking, of having a ceiling box, with recessed led lighting, which would be on almost permanently, lighting that area. something like this? or maybe this is needed ;p And the opposite idea is what we were thinking of in the sitting room, a recessed box, with recessed lighting, but maybe like you said, the Full height affect might be better Here was the only Full height area we had planned before coming here ;p ProDave: Yes, the west wing, was a result of planning unfortunaltey, the origninal house occupied slightly less then half the garden space, and the planners rejected it, and one of the main reasons were, that it left room for another house in this tight urban area They have too many requests for kids building houses in their parents driveways.. Extending the front face of the house was one way to placate them. The Garage is a workshop and will never have a car inside it ;p. JamesP: Natural light is not always on option unfortunately, we are hoping to compensate with a little artifically stuff. You are right about that shadow, but it's about 3pm before the shadown starts to affect the dining room, I'll make up a shadown simulation if you really want it. Nickfromwales: That Cinema room, is supposed to double as somewhere to kick the teenagers, when they reach the age in about 10 years. so not just for films. No chance of rotating that house in the plot The Front faces onto the main road (See Page 3 on the 'approved file in the first post) AliG: That's a big post ;p That's a good structural point you make there, yes the plan was to have two steel beams like you say, meeting at right angles, not only did we want more room in the sitting room, we wanted double hanging doors, that slide into the false walls, so that the sitting room can be fully opened to the kitchen/dining area. The stepdown you noticed, was the differene between, the poured concrete ICF floor of the bedrooms, and the proposed rafters (no floor was put in) over the Garage/Utility area. That's a pure genius idea, I didn't think of lowering the floor area over the Garage Utility to help out with the rooms upstairs, but if I leave the floor like original giving 2.7M of height over the kitchen, there would be a transitiion for the HRV ducts..might be manageable though. I hear you on the low ceiling heights, 2.4M is a minimum for the bedrooms, and downstairs, it's 2.7M everywhere we'd normally be living, but the Utility and Garage are up for adjustment I'll play with that now, using your standard "2m of head height at the front edge of the sofa" Would raised bedroom ceilings, not make the house less energy effcient? because of the extra space needed? We are using a warm roof, with 225mm thick slabs and hopefully an airtight finish. you don't think roughly 12M2 is enough for a kids room? If the upstairs toilet stays where it is(need to discuss the major idea of moving it to the cinema room with my wife), we'll move the window to the south for sure, so this means an AMENDMENT to the planning...so I better get any other ideas fixed as soon as possible.1 point

-

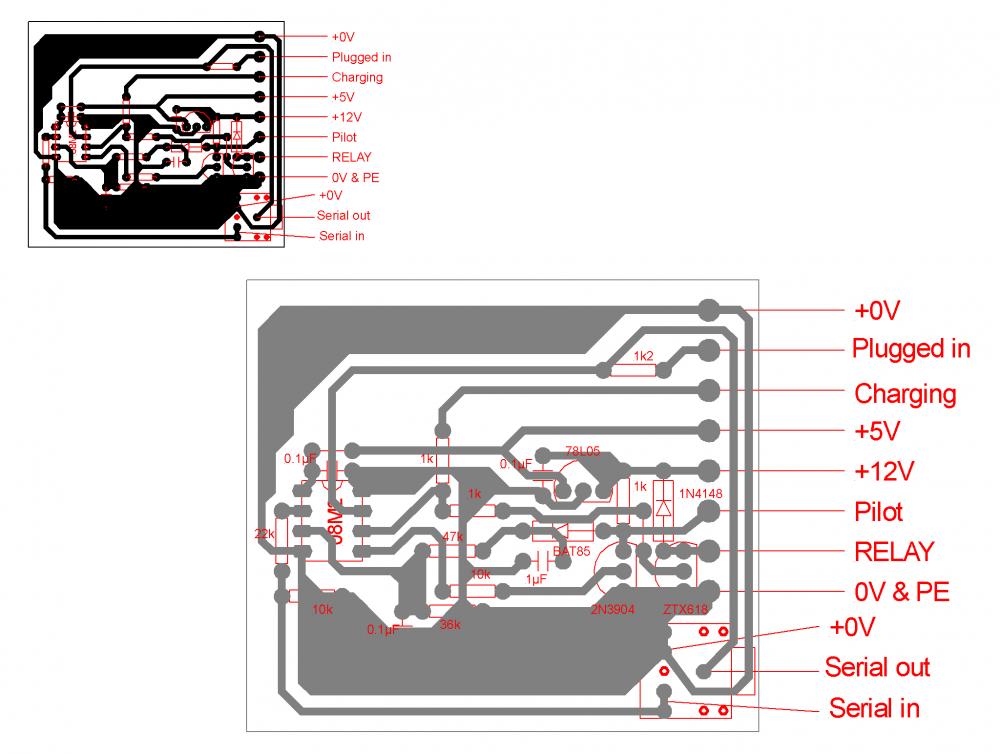

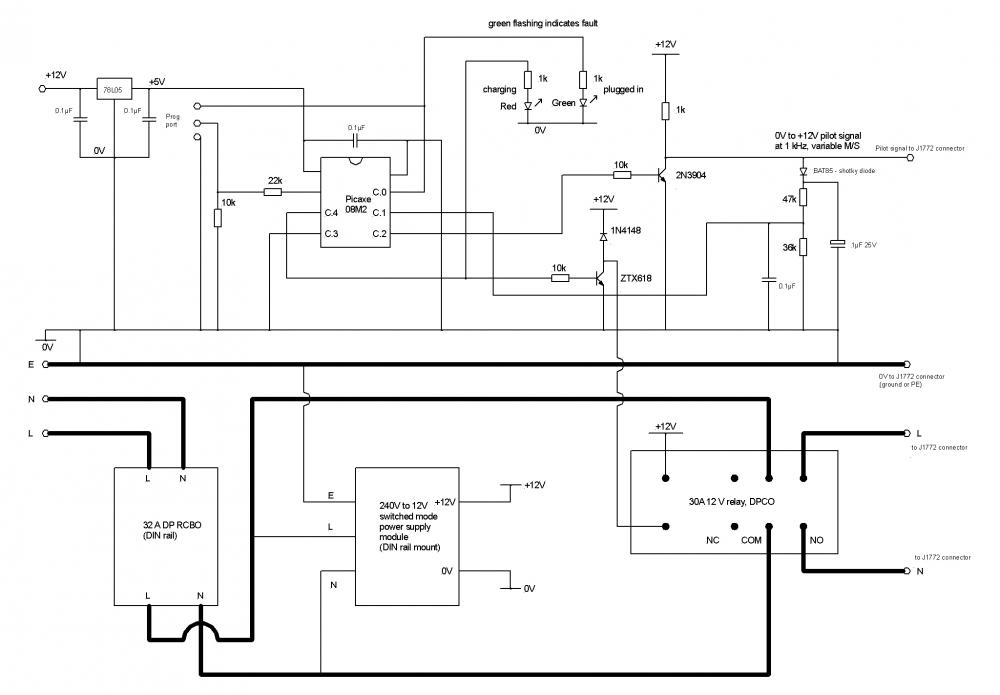

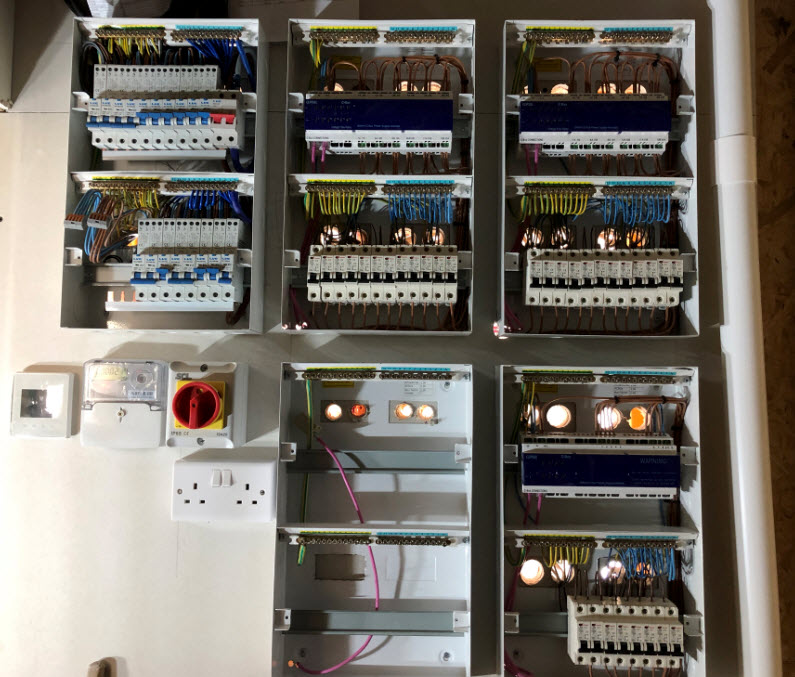

Here’s some more info on EVSEs, a schematic and generic parts list for my basic 15A/30A version (max current can be changed in firmware – the components are all rated for 30 A). First you need a 32 A capable Type 1 plug: https://evconnectors.com/electric-vehicle-chargers-and-accessories/j1772-32-amp-plug-and-cable-ds1-ev32p-nc, unless you are only looking to install a 15 A EVSE, in which case you could look at getting a 16 A plug: https://evconnectors.com/electric-vehicle-chargers-and-accessories/j1772-16-amp-plug-and-cable-ds1-ev16p-nc You can opt to buy the plug and a special 5 core cable, from the same links, but the cable is a bit expensive and you only actually need 4 cores (I’ve never understood why they run both pilots up the cable, as one is either unused or cut off and terminated at the EVSE plug end, if you go for a cable with a plug on both ends). It’s worth making a decision now as to whether you wish to use public charge points, as you can save some money buy making your home charge cable fir both your home EVSE and a public charge point. This costs more for connectors, but there is an overall saving. A 5m cable will be fine for all public charge points that use an IEC62196-2 socket. I’ll assume for the moment that you just want a 15 A or 30 A home EVSE with a tethered lead. If you want to make up your own lead and connector, then 4 core H07RN-F cable is ideal, as it’s very tough and remains flexible in very cold weather. For a 15 A EVSE you can use 4 core 2.5mm², for a 30 A EVSE you need to go up to 4mm² cable. As a guide, this link shows prices from Quickbit, who are generally fairly competitive: https://quickbit.co.uk/cable/cable-h07rn-f-cable/h07rn-f-cable-4-core Terminating the cable inside the Type 1 connector ideally needs the proper crimp tool, but it is possible to solder the cables to the buckets in the pins with care, and there’s plenty of strain relief, so solder doesn’t present a reliability issue. If you don’t have a big soldering iron (the pins are around 6mm in diameter and do need a powerful iron), or a crimping tool, then it may well be better to just bite the bullet and buy a Type 1 plug with a cable already attached. You will need a waterproof consumer unit type box to fit everything into. I use Italian made boxes that have room for the circuitry, and space to take an IEC62196-2 socket on the front, if you want to go down that option. These are on Ebay: http://www.ebay.co.uk/itm/IP65-MCB-RCD-Enclosure-Caravan-Hook-Up-Distributiobn-enclosure-adaptable-box-/251948088117?hash=item3aa946bb35:g:NpAAAOSwd4tUCdfa from 247 Supply, and have enough room to take a 12V power supply, a 32 A DP RCBO, and the circuitry. The relay is mounted next to the PCB in the blank area of the box at the bottom. You can either fit a cable gland at the base of the box to take the trailing lead, or you can just fit an IEC62196-2 socket on the front if you wish to make an EVSE that works like a public charge point, with no tethered lead. There a pros and cons for each option, and I’ve built one of each, at opposite ends of the drive. 99% of the time I use the one with the tethered lead, as it’s quicker to uncoil and plug in. Rapid electronics can supply all the components. The relays I used were Finder 66.82.012.0000 that are rated at 30 A at 240 V, with a 12 V coil. They are easy to fix down with screws. I used an alloy plate cut to fit the back of the box and mounted the relay and circuit board on that. The power supply I used was a Meanwell 12V DIN rail mount one, that has some spare capacity (one on mine also runs a wireless CCTV camera). The model is their DR-15-12, which has the stepped top needed to fit inside a consumer unit type box. The LEDs can be fitted in holes drilled in the spare spacers to the side of the RCBO and power supply, so they can be seen under the clear cover. The code for the microcontroller needs to be programmed in via the serial port connector at the lower right of the board, and is tweaked depending on whether you want a 15 A or 30 A EVSE. The same basic circuit is used for the variable supply unit, but I feed in serial data from a radio link to the unused input port, C.3, so the PCB is slightly different, with that pin broken out, along with +5V and 0V for the serial data radio module. The firmware is also a lot different, as it constantly polls the receiver to get the current state of excess PV generation (if there is any) and adjusts the mark-space ratio accordingly. I can post the code for the basic EVSE later if you feel up to making one, and can easily make a PCB for you and programme the chip. If not, then there are some good kits around at not far off the same price, that don’t need so much DIY. This is one option: http://evbitz.uk/EVBitz.uk/EVSE_Kit_-_Type_1.html that uses the Viridian EVSE module, that has all the control stuff and contactor already built in. These kits will fit into the enclosure I used, and you can choose to just buy the Viridian EVSE controller (http://evbitz.uk/EVBitz.uk/Viridian_EPC.html) and the Type 1 plug and buy your own cable and box. This is the schematic: And this is the PCB layout:1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)