Leaderboard

Popular Content

Showing content with the highest reputation on 10/31/24 in all areas

-

Indeed you have. And deliberately, politely we ignored it. We have about 16 square meters of glass facing south west. And every single person who visits us comments on the large expanse of light, the views, the engagement with the colours and shapes in the garden, the easily visible bird life, the sudden but brief shaft of golden sunlight at the end of a depressingly grizzly, grey day. I'll pay a few extra quid for that. Houses are for living in.3 points

-

Should have paid attention to the windows more, we were set on an aluminium single large pane of glass..... But someone somewhere (expletive deleted)ed up the order and split the windows with one fixed pane and one opening pane, and a massive mullions down the middle of it. Was devastated when they turned up and we realised, builder replaced the kitchen ones back to large single pane but gentlemens agreement that asking him to replace all windows and take the £20k hit would come back to haunt all of us. Electric UFH mat in the bathrooms, for when the tiles are cold but the house is too warm for the proper UFH to come on. Electric towel rails, we have the ASHP powering the towel rails on a circuit and it never gets hot enough to do anything. We have a lot of of glass which makes the house feel chilly through science I don't understand... Not sure id change them to cancel this out though.3 points

-

Looking forward to tapping this brilliant resource for all its worth! I’ve posted a long summary of our position on another thread. All help gratefully recieved! sam2 points

-

Is that just for the looks? I have always persuaded clients to use profiled, screwed cladding. Why? 1/3 cheaper, and much less specialised. You should avoid any penetration through cladding but esp with ss. If there is damage through wind or branches, ss is horrible to repair of replace. In an urban situation, ss is mimicking zinc or lead roofing. In a rural situation that doesn't apply. Can suffer from 'oil canning'. FOR ss....no exposed screws. I reckon 1 per thousand has needed remedial work.2 points

-

2.5kW solar, even tracking, won’t do diddly-squat for heating, and if you need a 21kW heat pump you’ve got far better places to look at for practical energy/efficiency gains I assure you! Leave it all A/C, and keep it simple. Installers and repair/service agents will take one look at a Frankenstein setup, realise it’s completely illegal (ergo unsafe to work on), and walk away. It’s a “no” for this one I’m afraid, but also can you get more solar? That’s where I’d put any funds from “avoided tomfoolery” tbh.2 points

-

I'd delete the wunder, just have the UFH pipes clipped to the top of the insulation, then screed over it. Wunder is generally for retrofit type UFH solutions. https://www.google.com/search?client=firefox-b-m&sca_esv=ac906d086053e2fc&sxsrf=ADLYWILx105RMbvDOxf-zlkWoOuniAaNAQ:1730356982083&q=Ufh+clipped+to+insulation&udm=2&fbs=AEQNm0AAii1lAhsPaaai4wByEaaipRAHWexzqXOes0FJK1_cCNcUFPPaxlyqBmr552nx3oIdFmFVO-OYSmQ6Gk3927r7w-t_mEMV1VSh-D5CmUgrota0Y23Tc96ea72Hhr6ZrhTNSaUCtq6qMlLLaMfYA9ZnAE2wrP63LGwcadZMK3PIxxf-vkjdLvClApQAENmVQoy6Npx7KR9TQIsTi-SwMqWmvvx7SQ&sa=X&ved=2ahUKEwiypIGKgriJAxUOUUEAHWu1BIMQtKgLegQIFBAB&biw=248&bih=487&dpr=2.072 points

-

Having used seconds and co a couple of times, the stock i bought showed no discernable issues aside from the odd chipped corner. Id have no hestitation doing so for something like this. For both layers.2 points

-

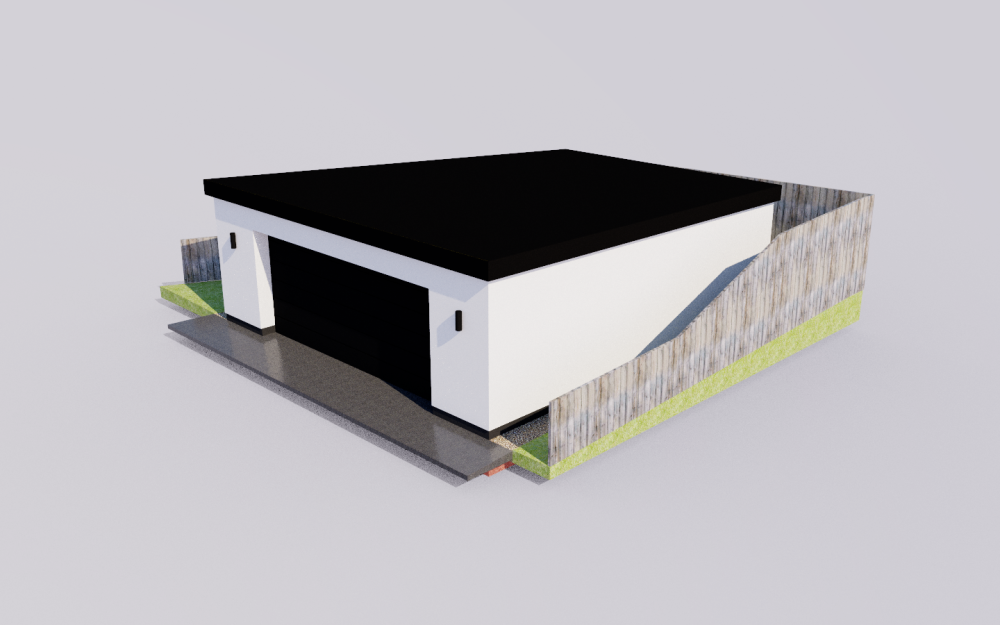

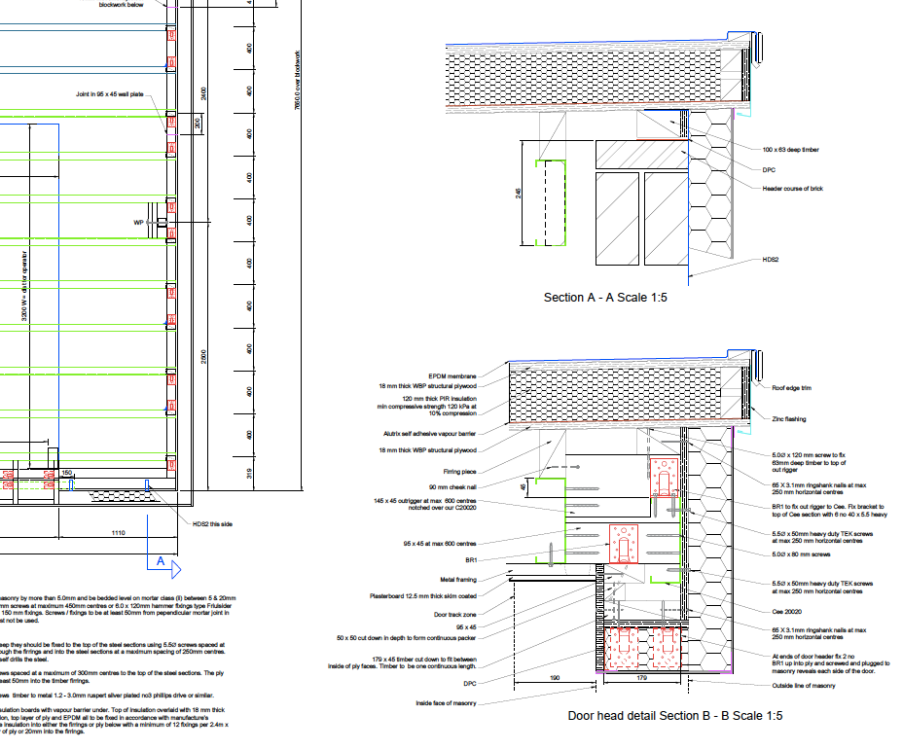

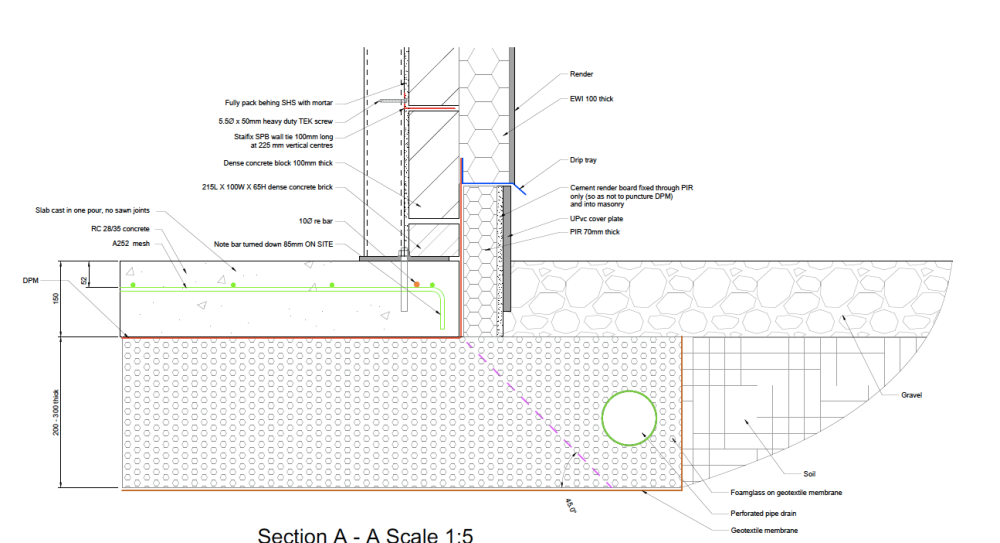

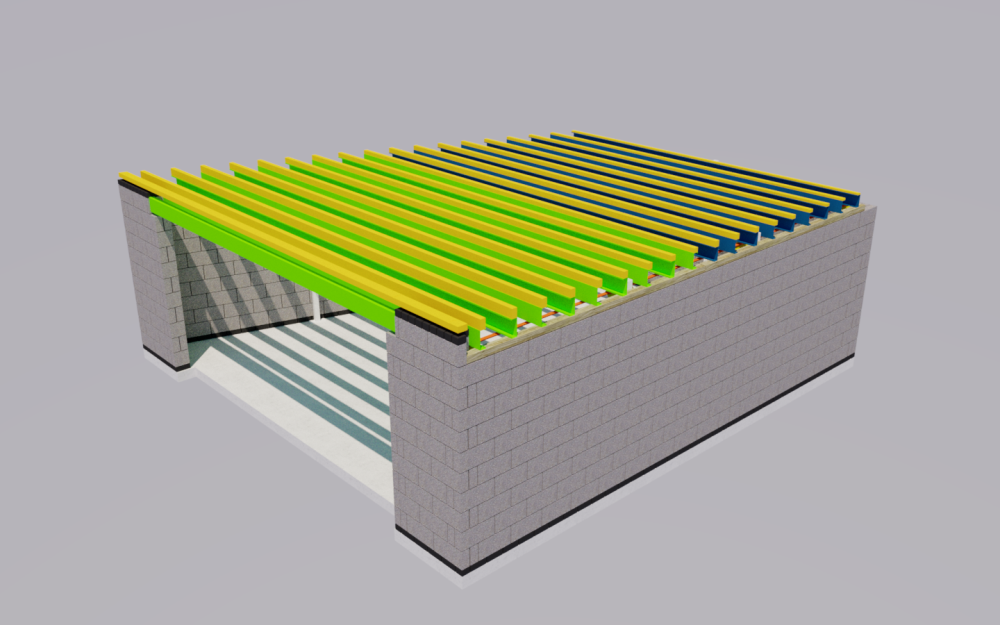

Designing my new build detached garage in SketchUp was easy. Finding someone to convert my fantasy garage into something that Building Control would be happy with was more difficult. I wanted the detached garage to be well insulated, and I may well have got a bit carried away. I wanted to use Geocell Foamglass for the foundation topped off with a concrete slab. I then wanted single skin blockwork clad with external insulation that married up with the Foamglass so that the slab and block work where inside the thermal envelope. I also wanted a warm flat roof. On top of this the garage was to be trapezoidal in plan to make the most of our odd shaped plot and big enough at the front to take a 5m garage door and finally I wanted a thermal break at the door between the slab and the outside world I contacted a local Structural Engineer who came round for a site visit. There more I spoke the more bewildered he looked. He'd never heard of Foamglass, not necessarily an issue but he didn't seem even vaguely interested in finding out more about it and its utilisation. I rapidly came to the conclusion that I couldn't work with him so I pondered my next move and decided to get in touch with a (well known on here) Structural Engineer/Architectural Designer who happens to live at the other end of the country. I wondered if he'd be able to help me out or steer me in the right direction. It turned out that he could. More than that, he took on board all the odd things I wanted to do and worked with me brilliantly. He's an absolute mine of information and had lots of great input with which to finesse my design and he clearly knew what he was talking about which is so reassuring. A site visit wasn't necessary, I provided a site survey and soil survey from the house build and then photos and Google Earth filled in any blanks. I probably drove him nuts, every drawing he sent I added to my SketchUp design because I really wanted (needed) to understand how it was going to go together and didn't want the standard "the builder will know what to do". There was a great deal of detail in the drawings: The upshot of this long story is that working with a Structural Engineer/House Designer who I'd never met and who never visited the site was a great experience and I'm glad I looked further afield than the local offerings and would recommend the same approach to anyone else looking for an SE/Architectural Designer. You’ll find him here:@Gus Potter and if you’re looking for a Structural Engineer/Architectural Designer I would heartily recommend you get in touch 👍🏻1 point

-

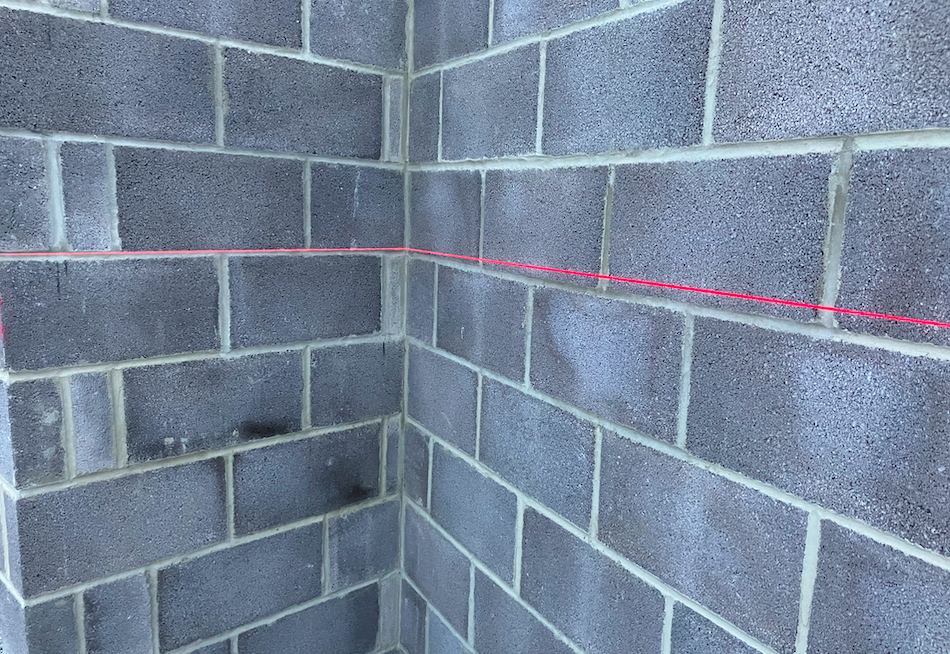

I wanted to build a garage/workshop that would be comfortable to work in year round and also keep the cars, bikes and tools that are stored in there in good condition so I decided I would insulate the slab and eventually settled on Geocell Foam Glass as it looked like it was going to be a pretty straightforward way of achieving an insulated foundation. We dug a hole and took the spoil to a local farmer on a Transit tipper, lined the hole with Geotextile Membrane and then bought the Foam Glass in. Access is a real problem for us so I had it delivered to a nearby builders merchant and then I trailered it in, two 2 ton bags at a time. We pushed the bags over into the hole and spread it about. Foam Glass doesn't really like being spread about, it has a coarse texture that grabs hold of everything, but it is very light and we got there in the end. Once filled to the required level I whacked it down. That was quite a difficult task as well as when I turned the whacker it would lift up the Foam Glass that I'd just whacked down. Again, I got there in the end though and covered the compacted Foam Glass with the membrane. It may actually have been easier to cover the Foam Glass with the membrane and then whacked it. Next time I'll try that (there won't be a next time!) I then built the formwork for the slab, lined it with DPM and set out the steel work following the very comprehensive plan provided by the SE. Concrete was poured and power floated as I was going for a painted floor finish (that changed...) The concrete was covered and left to cure following more comprehensive instructions provided by the SE and that worked well, not one crack has appeared in the circa 7m x 7m slab. The walls were going to be single skin blockwork so wind posts were required. I resin anchored those in place and then awaited the arrival of a highly recommended bricky. If the bricky had known how to use his laser level he would have been dynamite... Unbelievable really. I took the inaccuracies in the block work out with the wall plate so that I had a level starting point for the roof.1 point

-

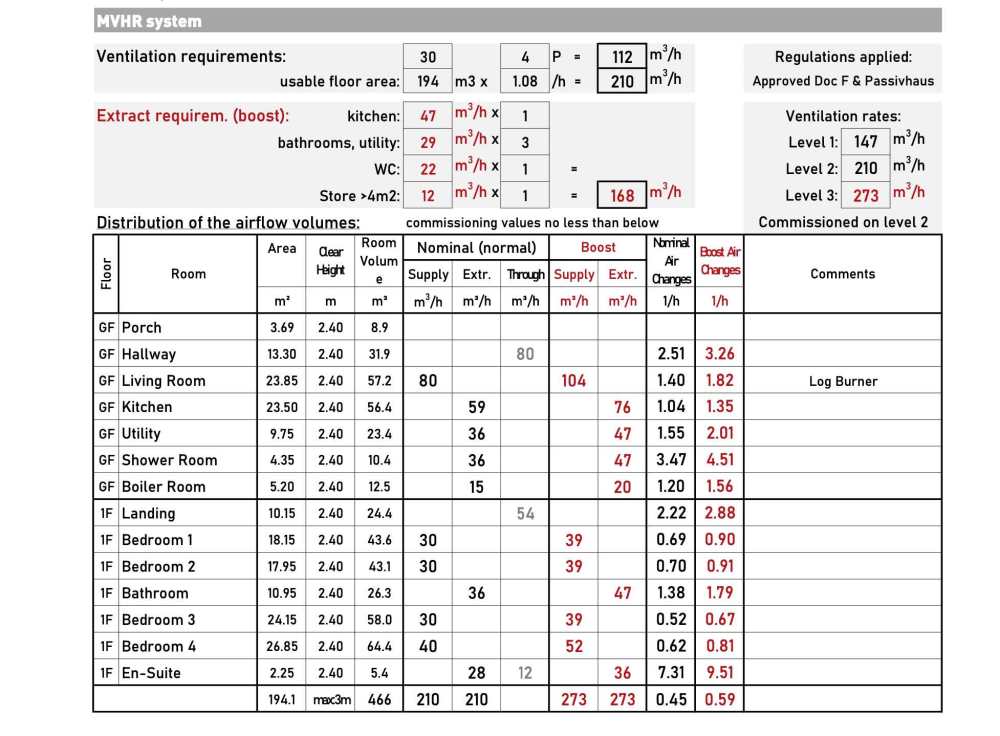

Out otf interest, wha construction was your build to achieve 1.5? I'm aware that the building airtightness and MVHR flow rates are separate things, and them flow rates also have to factor in around 90% of the ventilation will have the heat recovered from it. I've attached an MVHR pre design estimate from one company some time ago showing flow rates, it does have a mistake on it for at least one room. If it's so negligible, I'm happy to ignore that part. MVHR is excluded from the heat loss survey. But the airtightness of the building which won't be known until it's built and tested, will make a big difference in reducing the total heat loss if the correct ACH are input, rather than the softwares default ACH used which assumes the worst case air tightness result of 10. Sizing a heat pump should be based on an accurate heat loss survey otherwise you face short cycling issues in the shoulder months around 12 to 15C outdoors. The 5 KW heat pump can modulate down lower, Ive had mixed answers of 1.2 and 1.5Kw. 7Kw model is around 1.7Kw1 point

-

1 point

-

Yes, I made this mistake too - thought 4x2m would be plenty for plant+washing/util+cat feeding but it's way too small. Having 2 doors into there (access through to garage) doesn't help. Also I think I'd push a bit harder to get the laundry in the upstairs fam bathroom (or adjoining it). In addition, I regret going with plasterboard and 25mm service void in the plant/util room. It would have been much better with ply-lined walls, no service void, and have all services in surface trunking. I've tinkered with so much of the ASHP since install (3 years ago) this would all be much more robust without crumbling plasterboard. Finally, putting more effort into coordinating the layout of manifold/UVC/ashp pumps etc - The installers put the all in rather haphazardly again not making best use of the space. Other than that, the main thing I'd do differently next time is demolish and rebuild rather than deep renovate, perhaps doing something more ambitious with planning like upside down house, if the plot suited it. (Our current house really would work nicely like that, enclosed bedrooms on GF and nice views across road to the common on the FF). This is not so much a regret of the last project: on balance I'm far happier we cracked on when we did rather than drag out a couple more years on the design and PP for a rebuild, but if doing it again, a clean sheet rebuild would be the main motivator.1 point

-

Be careful what you wish for - we have black corrugated cladding and roofing on the 2 storey section of your build. Looks great and fits in with the rural location. But in the summer months as the sun comes up you can hear bumps (best word to describe it) as the metal catches the sun and begins to expand. I'm assuming this is the same for SS? Wouldn't change it for anything though, it's just one of those things you hadn't thought about and have to learn to appreciate. Feature, not fault... Simon1 point

-

Plant room size is an interesting debate. At the start I wished I’d gone a bit bigger as we made the hallway 400mm wider by stealing it from the plant room. However as necessity is mother of invention I made it all fit relatively neatly and the wider hallway is far nicer. Unless you’re going to also use the plant room for storage space with cupboards and shelving then it just needs to be big enough.1 point

-

@saveasteading The SS option I suppose was more of a longevity viewpoint. I have zero experience with SS. I know cladding with metal profile would have been exponentially quicker and cheaper. I was worried about it's lifespan being so close to the coast. Who knows I might be tempted to rip off the tiles and clad with metal profile if the tile lift keeps waking me up,might have to go back to work though😔 .1 point

-

Another post i will disagree with. Our plan had a large "plant room" but the realities when actually doung the work, was it made no sense. All that is in our "plant room" is the mvhr, a few electrical boxes related to the ASHP, a circulating pump and an expansion vessel. There really is not much indoor stuff for the average ASHP. Consumer unit was far better on the wall in the utility room. And hot water made much more sense in an airing cupboard formed from the corner of the spare bedroom putting the tank central to hot water points of use for quick hot water delivery. I summary our services are distributed each being where makes best sense.1 point

-

Hi all! I'm on a mission to create a fantastic family home in London, either through new construction or extending and renovating an existing property. Currently leaning more towards extending an existing proprety, since finding a suitable infill plot in a nice area of London is almost impossible. Seems doubly impossible since I'd like the end result to be > 150sqm and that makes planning very unhappy since it'll involve multiple storeys. Looking forward to sharing the journey here!1 point

-

@nod Please share it in the forum rather than DM. I imagine there's nothing confidential about the size of your plant room!1 point

-

Poor stud work, out of alignment so boards bending to compensate. wet studs drying out poor boarding, not cutting around doors just butting up. boards not falling on studs correctly not enough screws. the list goes on and on. I boarded mine, to the letter, it couldn’t have been done any better, I have minimal cracking. but I definitely have a few in places that i really thought wouldn’t have, it’s a bit of a bastard really. it just depends if you have a few or a lot.1 point

-

1 point

-

agree to this. Was totally seduced by "Grand Designs" and went for double set of doors meaning the entire back end of the house cant be used for furniture at all. If i could go back id do what you suggest there for sure. Saying that, in summer its the absolute dogs danglies but summer is "blink and you'll miss it" here in the North East.1 point

-

If you are staggering overlaps these don't make much difference as they become air pockets. And consider the proportion of area....negligible.1 point

-

As they’ve done quite a neat job so far, yes I would be around and be prepared to interfere - but I wonder whether they’re just going to insert some new posts without disturbing anything. Is that possible?1 point

-

You (tiler) can build that out with cementitious flexible tile adhesive, no problem at all. Just dub the low areas out in a few sets to get the wall spot on for a nice even finish, and a good consistent line across the bath edge (so you can’t see that the wall bellies basically). Do not use acrylic/ready mixed stuff there whatever you do!1 point

-

1 point

-

My parents have a BWT, seems to do the job well. https://www.bwtshop.co.uk/product-category/luxury-water-products/water-softeners/ I'm about to pull the trigger on a BWT Perla 20L Using BWT16 discount code, it comes in considerably cheaper.1 point

-

Update - I had paid PWC with a credit card, so I made a Section 75 claim against the credit card company .... and they have refunded my money, all £905!! Very happy😁.1 point

-

Every single time. They're like quartz watches. Superior products but people don't like them because they're cheaper. Agreed. Would do the same with our sliders and make them 500mm high window sill tilt and turn instead. They'd cost about 1/3 as much.1 point

-

Moved the house 5 metres back. We have a massive garden now, way too big, but hardly any turning circle at the front onto a main road. I was so focused on the interesting stuff that I overlooked the basics 🙄 I would have said no to full height windows. Terrible to get the thresholds thermally broken, leak lots of heat in winter, too much solar gain in summer, and don't increase light much. But architects love big windows. Be warned! No bay window type rooms poking out. Nightmare. I would have thought about room sizes and solar panels earlier. I thought I did but we should have made the rear return wider to accommodate more south facing panels. If doing it again I would do things simpler.1 point

-

I noticed you suggested secondsandco for the first layer of PIR which keeps the cost down, but I believe you can have variance in thickness, rumpled tape or crushed corners etc would you not do two layers from secondsandco because of this or was it just omitted?1 point

-

Whatever the final thickness you pick I'd prefer to see the boards in two layers with the joints staggered. It would also allow you to insert the DPM into the middle reducing the risk of puncturing.1 point

-

Or hardcore/stone (thickness dependant on ground) with sand blinding. 150mm PIR, 100mm concrete. Even less digging. Only negative if you can call it that is slower response time on heating. Worked fine for me in an old house with uninsulated walls. It just sat at a constant temp all winter. Without knowing the foundations situation less digging = better in my world.1 point

-

Oops. Sorry. 100mm will do it. Total 460 so still safer and cheaper than your 650. You don't add the 20 for ufh. It is in the screed , so 630. It may be possible to skimp more, but I'd need to know the circumstances.1 point

-

I think it's to cover a worst case scenario i.e. a fire in the flue generating abnormal temperatures.1 point

-

I agree with others.. 150-200 mm PIR and UFH in screed of 70-80mm Avoid Anhydride (spelling?) screed because it's hard to tile onto. Form expansion gaps at doorways don't screed right through as it will crack. The expansion gaps is just a deliberate gap so you ensure it's straight not curving into one room or the other. If carpeting go for special low TOG underlay and keep total TOG to 2.0 or less. Stone and tile is great with UFH.1 point

-

1 point

-

The pumps aren't DC in any real sense. They are variable frequency AC, created by an inverter chopping up DC. Chopping up DC created from rectifying AC is no major problem. 240v AC is a a useful "universal" form of power - you power wall will output it efficiently, and your HP will accept it readily. Your electrician will be able to work with it and components like breakers, monitors, switches etc are easily availble. I doubt the efficency gains (if any) would be worth the extra hassle of a non standard setup.1 point

-

UFH mats just under the bathrooms tiles/lino for a quick boost to toe temperature. Probably TF it. Timber is much nicer than concrete to work with. Avoid the design temptation to keep making everything bigger. 186m², 150m² would have been fine. PM it myself the next time with the knowledge of hindsight.1 point

-

I like EPS but for this instance I would be tempted to use say 200mm of PIR to avoid too much digging. 650mm is a lot of wheelbarrowing muck. Buying PIR in 100mm thicknesses is often cheaper than odd sizes too. Have you considered a pumped screed to avoid too much labour? How about this. Excavate 350mm. 100mm type 804 hardcore leveled and compacted. 100mm PIR from secondsandco DPM. 100mm PIR Slip membrane. UFH pipes spaced closely, say 100mm for quick response time. 50mm pumped screed. Floor finish. Should be a good bit cheaper than the one you proposed and with a higher heat loss house a quicker heating response time would be advantageous.1 point

-

1 point

-

Would have 100% been more demanding to the builder to do what I had on the plans. I ended up with a lot missed off, things slightly out of place that had massive knock-ons, and just generally it was a bit shit. At the end of the day I was paying them to do a job, and it went on for that long I just wanted them gone but it's cost me months (years?) to work around the issues I was left with or rectify them.1 point

-

The value of this thread is a legacy for future buildhubbers. I relied on previous such threads, and as a result we now have heating mats going under the bathroom tiles for nice cosy toes in the mornings, which was not in our original plan.1 point

-

A total of 19 'C' Section steel joists were used for the roof. We had two different sizes, the taller ones were for the larger span at the front of the garage and the smaller ones at the rear. The joist were mounted side to side and the 'fall' of the flat roof was to be front to back of the trapezoidal garage. To get the required fall I needed firring strips on top of each joist but with the fall being front to back and the firing going side to side each firring would be a different size. I couldn't get a saw mill to cut me 19 firings that were all completely different sizes so I did it with a skill saw. I also put a slight taper on top of each firring so that the roof boards would sit on the whole of the firring. That all seemed to work a treat and was less tedious than it sounds. The rest of the roof was standard warm roof build up: OSB - Vapour Barrier - 120mm PIR -OSB - EPDM. Getting 56m2 of EPDM up on the roof proved tricky. It arrived rolled up and I thought it might actually roll. Not a bit of it, it was reluctant to go anywhere. In the end we placed a couple of ladders against the roof and then used ratchet straps to hoist it up bit by bit. Once the EPDM was up on the roof the rest was a breeze, really easy to work with and stick down. For the external wall insulation, we started with a 300mm high band of XPS around the base, sat on top of the foam glass. Above that was Rockwool for the breathability and fire resistance. The XPS was finished in black render and the Rockwool in white render, we then filled the trench around the garage with gravel leaving 150mm of the rendered XPS as a plinth. I couldn't quite get my head around how the finished rendered rock wool would feel, it's quite amazing, solid as a, well, rock. You'd never guess it was rock wool under the render.1 point

-

@Nickfromwales@JohnMo sound advice and is what i've done previously, it'll be intersting to see the relvative cost difference between D/TG from the same supplier, that is where I'd be looking at the pricing in detail than purely going for a cheap set of windows. Interesting comments on bi-fold v sliding. My head was in the place that sliding would be more water/air-tight than bifold (fewer moving parts/less seals etc).. Your 'bifold over sliders every damn day' has got me thinking. Just to give you some context, we have 3 main large openings. Main bed = 5.5m, Kitchen/Dining/Lounge = 8.4m and Rear onto patio = 4.4m. Our SE has managed to design in a beam so the 8.4m opening can be clear span.1 point

-

Been on "abrasive wheels" training a few times with work. Strangely enough, it's exactly the same each time.1 point

-

1 point

-

Sometimes they have the opposite effect as miscreants on electric motorbikes can evade police cars by zigzagging through the barriers.1 point

-

Your first example looks like it's to protect anyone, esp children, coming from that path against running/riding straight into what is probably a road where the picture is taken from. I've plenty of sympathy for the issue of accessibility but please don't cut down something that's intended to prevent a serious accident.1 point

-

Thanks for this post and keeping it updated - I'm following closely as we're starting to look at this for our build (builder had just mentioned to us yesterday to ensure that rainwater drainage mustn't be directed to the waste water drainage field). We had been recommended the Klargester Biodisc, partly as being the quietest treatment plant on the market (we're in a very quiet location and weren't aware of the noisy created by air blower pumps until it was mentioned to us). Good luck with the build.1 point

-

Don't think of it as a "PV-ASHP system", but two entirely separate entities that do totally different things at different times. Then life will be simpler and happier.1 point