Leaderboard

Popular Content

Showing content with the highest reputation on 04/07/24 in all areas

-

2 points

-

That started just as a ground mount PV, then I thought it would be madness not to enclose the sides. It is only as a rough storage shed in this case, firewood, bikes, and things like cement mixer etc. Just a load of pallets for the floor. If I was going to make it as a proper shed / hut I would make it a bit higher, and build the shed but a lot lot better.2 points

-

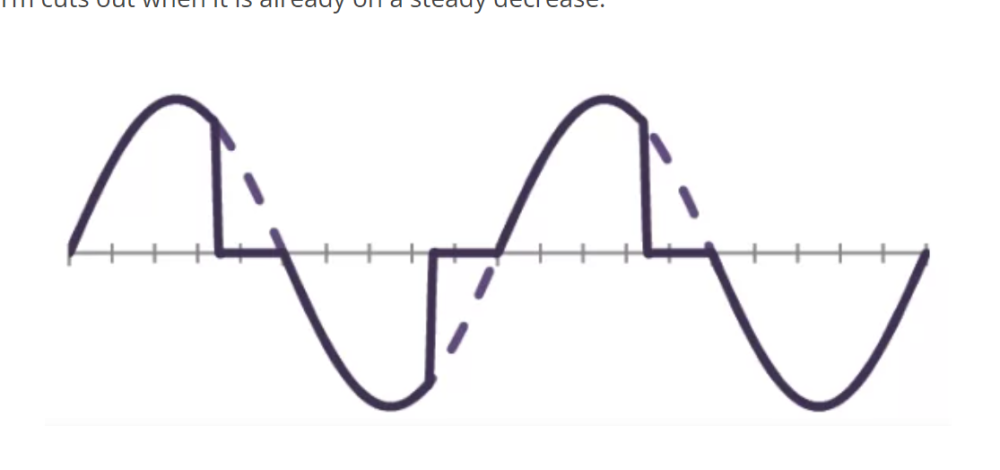

The challenge with mains dimming LEDs is the forward voltage of the LEDs themselves, the circuit configuration of the LEDs, the rise across the rectifier, the passive current limiting, and the dimming strategy used. In mains driven off the shelf LED bulbs the best we can expect it a floor in the dimming level for smooth operation. Each LED in the bulb will need a voltage across it, known as the forward voltage, before it will turn on and if they are wired, in the lamp, in series - which is the preferred choice because parallel needs very closely matched LEDs, then those voltages add up so you need at least that voltage to turn them on. Given that the forward voltage of an LED varies by colour - because the band gaps needed varies by colour and manufacturer so the turn on voltage varies. White LEDs have the highest forward voltage of most LEDs (UV LEDs are higher) at over 4.5V if driven hard (which you will when used in lighting) so if you have 16 of them all in series then you are going to need 72V to turn them on. (Image Source Wikipedia) When you rectify - turn it from AC to DC you get approximately 1.4 x the AC voltage out so 240V AC in becomes approximately 330V DC out (in a perfect world) - its a thing so don't worry about it. So we have 330V to play with, carefully, but we also have a lower limit of 72V if we want the LEDs on at all. So this gives us 72V as a percentage of 330V which is approximately 22% (Where I got my expectation of the 20% in the above post) but it is not as simple as that. Trailing edge dimmers, the ones most admired in this application, cut the AC cycle off to a varying degree so for most of the cycle the peak, although truncated, is still above that required to provide 72V after rectification but as it gets towards the end of the wave form the peak remaining is not enough to generate the 72V after the rectifier and the whole thing falls to bits. Image source: www.ledsupply.com/blog/dimming-leds-guide-how-to-tell-if-your-lights-are-dimmable/ The fact that the lamps get a bit jiggy when you approach this point is down to a combination of a heap of factors which I won't go into but include the fact that the forward voltage required to turn the led drops as the available current drops, as it must when the voltage drops across a fixed current limiting resistor and the ability of the smoothing capacitor to bridge across the tops of the spikes given the now very limited charge voltage and charge times.2 points

-

Here is a thing for all on BH to keep at the back of your mind when investigating say on old barn that you want to convert to a house. Below is some of the things we consider as SE's. Remember that the SE works for you and will try every avenue to show what you have will be ok (provided you pay them for their time) for you.. but also for the person you sell the house to.. that is just about how all SE's start out.. as Civil Enginners.. the clue is in the word Civil.. we primarily work in the the public interest.. it's just you that picks up the tab. You may want to reuse the existing barn concrete slab and build on top of it. It may well be that you have had farm machinery running over the top of it for years and you know in your heart it is ok.. but that is not enough for BC or an SE that is going to sign off to say it is going to last for another 50 years.. your mortgage lender may ask the same! The concrete ages.. suffers from sulphate / ammonia attack, concrete carbonises and offers less protection to any embedded steel, the rebar becomes prone to corrosion. I'm not saying it is all gloom and doom but if it is going to perform for the next 50 years you need to get your ducks in a row. Now I know that a lot of folk on BH are not a fan of Architects, SE's etc that can offer advice.. but if it all goes wrong what then? To recycle and old farm shed floor you need to know initially the thickness of the slab, how much the thickness varies, if there is any mesh in it, what that mesh is and how heavily it is corroded. You also need to know if the mesh has just been flung in or if someone took a bit of care when they cast the old slab. Now you could core one hole.. examine the sample and then say.. ok lets go to the design guidance.. which says.. sling your hook if you only have one sample. Minimum is three samples but from experienece the safety factors you need to then apply to only three samples often make a design unviable. I've investigated industrial / farm building slabs and found that the most economic balance is to take 5 no 100mm diameter cores and see if you want to send them for testing. It's a good balance as with 5 cores you can get a handle on how well the slab was laid.. if the cores look crap or too variable then no point in spending the money on testing! You know early on if the concrete / workmanship is rubbish and can see if the mesh (if any) is all over the place. If you get good looking cores then it is time to make hay! You get a feeling.. we have a good slab here .. lets take another two cores. Why you ask.. well the more cores we have the lower the probablity we have crap concrete and varying slab thickness etc.. it's to do with the maths / probabilty theory we use to assess the concrete slab strength..but the difference 5 and 7 cores could result in a 15- 20% increase in concrete strength.. which is a lot when we are in the no man's zone.. do we dig out or retain a massive floor? To test another two cores may cost £200! and that could have a major impact on the fundamental design decisions which can cost thousands... maybe more.2 points

-

Isovit e-cork is used as a mortar/adhesive for fixing cork insulation board to masonry. We've used it for sticking wood fibre boards (internally) and it worked very well1 point

-

Good Q. The inlet pipe is plumbed right to the bottom on these and there's only a small overflow hole toward the top of the sampling pot. We had an issue with the pump last year which had it out of action for a week or so. At no stage, running or not, have I ever seen any floating scum layer. I've been advised by the reps of two different distributors that even a couple of weeks without power won't affect the output quality of a mature plant noticeably1 point

-

1 point

-

You could sister the joist one or both sides of the rafter, or double up as you say.1 point

-

You guys are amazing, thank you. This has brought me so much more clarity over what to do next1 point

-

Not really, it's pretty sticky stuff. Glue top bit on first, then glue side bits so they help hold top bit up, and maybe stick a Broom/brush/curtain pole wedging the middle bit up.1 point

-

Try another SE Most will will do the BR submission cheaper than an Architect1 point

-

Thanks! I can put the Intello Plus behind all the insulation but it means extending the detailing provided by the timber frame builder and I'm not that confident yet with so many critical junctions in getting them all right. I plan to install 220mm insulation, then the Intello, and test air tightness before adding the extra layers inside this. Not going for the certification as can't afford the Architect any more but wanted to aim high and the fabric is where I'm not holding back cost wise. Thanks for the advice/insight!1 point

-

1 point

-

If the bco accepts it and it works, then that may conclude the process. It will probably never be tested by the authorities. I will try reading the instruction manual again, to see if I can work out how it works, and if it is a real or imagined advantage.1 point

-

Correct. It's an SBR- Sequencing Batch Reactor. It goes through a run of aeration and settling cycles before a final settle and pump out.1 point

-

1 point

-

I found that when heating setpoints were set to say 20c if any single radiator trv detected even a slight decrease from setpoint the boiler would fire and keep firing when any of the 11 TRV’s requested it. This is not an efficient way to heat a home IMO.1 point

-

Is it. At around £100/m3 delivered it must been one of the cheapest materials there is. You can buy standing timber, with the bark, at around £55/m3. Once planed to size and stacked in Travis Perkins, it becomes about £2300/m3. I am adding to this, as I am a bit bored this morning. The embodied energy in concrete is around 2500 MJ/m3 (700 kWh), timber is 5100 MJ/m3 (1420 kWh), the embodied carbon is 360 kg/m3 and timber is 280 kg/m3. Food for thought that is. https://theconstructor.org/sustainability/embodied-energy-building-materials/567108/1 point

-

Some of the most recent SDS(+, max) drills have an electronic clutch system that will detect when this happens and reduce torque. There are also some mechanical clutches around. https://support.dewalt.com/hc/en-us/articles/360012664938-What-is-the-DEWALT-E-Clutch-System https://support.dewalt.com/hc/en-us/articles/360012593237-What-is-the-difference-between-Brake-and-Kickback-Brake-on-the-60V-MAX-DCG4141 point

-

😄 thanks for your reply @Thorfun that spreadsheet looks very similar to mine!1 point

-

Current limit driving of the LEDs is, as @jack says, perhaps the best way forward as you can keep the voltage well above the forward voltage lower limit and just control how much current the LEDs receive and therefore drive them right down to off. Sadly it requires more infrastructure to manage it. Perhaps the best way is to get intelligent bulbs as they rectify the AC and then current control the LEDs so can go down to off but require communications, Wifi, Zigbee, Z-wave, Bluetooth ... to control the brightness, and often colour. Alternatively you could stick with mains dimming and: have fewer lamps on at all if you want lower light, get lower output bulbs so they are not bright at full power or live with the lower limit.1 point

-

@LnP We used Hallmark blinds -> https://www.hallmarkblinds.co.uk/ . There are other members that have used them as well. I think they are manufactured in eastern Europe, Poland? It's about 3 years ago now that we were looking, so things may have changed a bit but back then, there didn't seem to be many (UK) suppliers. External blinds are common on the continent but here, they seem to be only used on commercial premises. Some of the companies we identified had UK websites but didn't seem to have any suppliers. Our criteria were size, we've got some pretty big apertures we needed to cover and price. I don't think there's a great deal of difference between different makes when it comes down to the slats etc. They all seem to use Somfy for the controllers. Ours are all on sliding doors, so if you want to, you can open the door a bit to get some through breeze in the summer, although the downstairs overhangs on our build mean that in the summer, the sun doesn't shine into the rooms if we have the blinds up. Hope that helps Simon1 point

-

Yes, our Graf One2Clean has a built in sampling chamber and the treatment plant wasn’t too dear so simplified the install with no extra cost.1 point

-

1 point

-

I'd get up a camera recording the boundary, well out of reach, and inform builder of this. That'll sharpen attitudes a bit i think.1 point

-

For the edges I remember them laying a half brick down on the outside, then the block was supported by the beam on the inside and this half brick in the outside. Then again same done between the beams around the outside. I guess technically this means my inner cavity walls are sitting on the blocks, but these blocks are sitting on a half brick for the core of the strength. Sort of see them in this pic here.1 point

-

I have 230v Loxone dimmer configured for "trailing edge" driving some bollard lights on the front drive. They dim down to 8% before they turn off or start to behave weirdly. Don't know if it's the fittings that are good though, or the Loxone dimmer. Most of the LED drivers (downlights, low-level lighting and LED strips) support 0.1% dimming, others 1% and some track lights at 5% (which is a shame). Results at such low level of dimming with LED tape and been dissapointing though in my case https://forum.buildhub.org.uk/topic/33333-led-tape-varying-brightness-from-different-modules/.1 point

-

Seems quite high, and somewhat disappointing, I was hoping they would get down to about 20% - they won't fade to / from black with a trailing edge system as @jack says. I suppose it could be a function of the bulbs you are using - the circuitry won't be common to them all and perhaps some are better than others.1 point

-

1 point

-

FIT ended in 2019 and was replaced with SEG that for suppliers over a certain size must pay at a pittance of a rate-5-7p/unit. Both government backed and regulated schemes Octopus offer their own export tariff at 15p/unit, but that can end at anytime as its neither FIT or SEG so no government backing. Loss of that rate is worth considering when calculating battery payback.1 point

-

@MVHRDesigner thank you for sharing this information. One of the buildhub conventions is that people who work for companies that we might purchase goods or services from indicate their interest/affiliations, so that buildhubbers can take account of that when considering any position put forward. So I would just like to invite you to do that, if you will. Thanks ☺️1 point

-

@joth I figured it out! I have working blinds now. I found this post https://groups.google.com/g/loxone-english/c/jpVNFGtFwEA/m/UIjNxTd7AAAJ which led me to set the Value 2 correction so that a value of 1 = 100 and things are working now. need to time the full open/full closed so I can update those values and then I can see about automating them with the intelligent room controller.1 point

-

Here’s a quick update we moved in early January. Still got loads to finish off inside but we got all the EWI and render on before winter, fitted our kitchen and a bathroom and for two bedrooms done. Basement is done as well and still not leaking ! I’ll do a more detailed blog later but we are very happy with our self build / eco renovation / it’s just an extension isn’t it?! / (and the only other trade we used was my friend Pete the electrician)1 point

-

Mine just fits in 900mm, excluding the filling loop (though that could be repositioned), but doesn't have a plate heat exchanger like @TerryE1 point

-

My architect specified 90mm Kingspan K106 (at £44 per sq m) for a 100mm cavity. The specified tape is also extortionate at £68 per 50m roll My builders found this almost impossible to fit because it requires an absolutely flat internal face and then a "snot-free" finish without sufficient space to get tools or fingers in. This is a stupid specification and the Building Control guy agreed when he came to inspect. We're having K-Rend so he was not as concerned, but his recommendation was to use a 110mm cavity as a miniumum to avoid these problems. I assume that Kinspan use their specificiation because that is the only way that the models give the necessary u-value, architects and designers then take this as written without any regard to the installation practicalities Regards Tet1 point

-

I actually remember reading about a case similar to this not too long ago. I have managed to find an article which covered it: https://localgovernmentlawyer.co.uk/planning/318-planning-features/47278-incorrect-plans-a-strict-approach The application was granted on the condition that the development complied with the plans. As the article mentions, the plans showed the development property as having a lower ridge height than the neighbouring properties. But, if it were built to the approved dimensions, the development property would be higher than both, in one case substantially. In the judge's view the plans showing the relationship to the neighbouring properties were not simply illustrative; they were a material part of the planning decision. The plans should have been capable of implementation and they were not. As a result, the whole permission was not capable of being implemented.1 point

-

1 point

-

A smart TRV is just internet connected, a marketing ploy to make things sound better than they really are.0 points

-

0 points

-

Unbraced gables are quite vulnerable to collapse in high winds. Ask @ToughButterCup.0 points