Leaderboard

Popular Content

Showing content with the highest reputation on 01/29/24 in all areas

-

2 points

-

Don’t discount EWI quickly as it solves a lot of problems, plus you can achieve pretty much any finish you want, so shouldn’t be a planning issue. I’ve used it on my bungalow (60s) to good effect. Take a look at my blog on here, I’ve posted a fair bit as I’ve been doing it. never used multifoil, though I do remember seeing the buildup spec many years ago suggesting that to achieve anywhere near a good u value it required supplementary PIR, whether that’s changed since I’m not sure.2 points

-

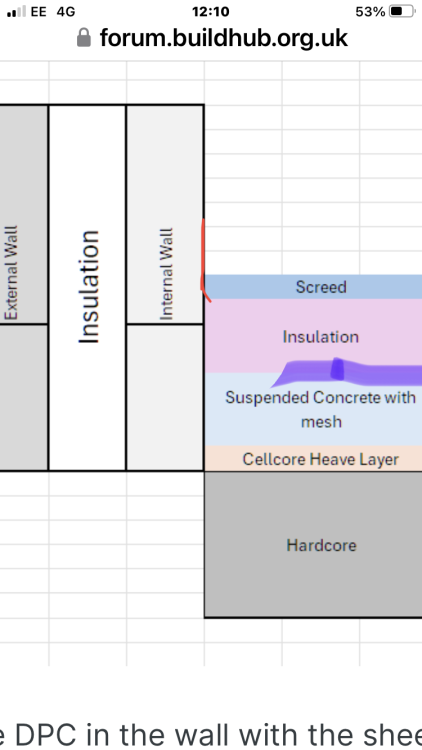

Bit more progress. We are now fully plastered and I’ve done about 60% of the painting. Heating has finished the floor drying mode which resulted in one relatively short minor crack in the floor. Worktop was installed today. It’s big a very white. Nice job by the fitters. We have a slight problem in that the sink is a little too deep (by mm) so it’s fouling the drawer beneath stopping it from fitting. I can check a bit out of it but the kitchen company has agreed to make up a new drawer carcass and I’ll swap the front over. Also a bit of a palaver fitting the extract duct for the hob.2 points

-

Will a 13 amp supply be enough to run what you need in the hut? Assume the temp power you have available is TT earth (rod) and 30mA RCD fitted? Whatever you do, don’t buy that SY cable extension lead. Totally unsuitable for the task. As much as air con guys like to use it outside, it perishes in UV light eventually. Some people seem to think it’s a substitute for SWA! It isn’t. I find it hard to see how they’ve effectively earthed the braiding too. It should be something like H07-RNF flex. It all depends on the likelihood of damage in the particular situation though. Probably best to get some advice off your electrician.1 point

-

SY cable is not really ‘armoured’ - it’s usually used in light industrial settings for yeah some protection but mostly noise screening. As sites are a risky-ish environment, so you probably should use your own judgement re physical protection (swa / conduit / risk of damage etc) but probably also a decent sparky re correct earthing (i.e. TT with measured impedance), correct rcds, testing the bonding etc.1 point

-

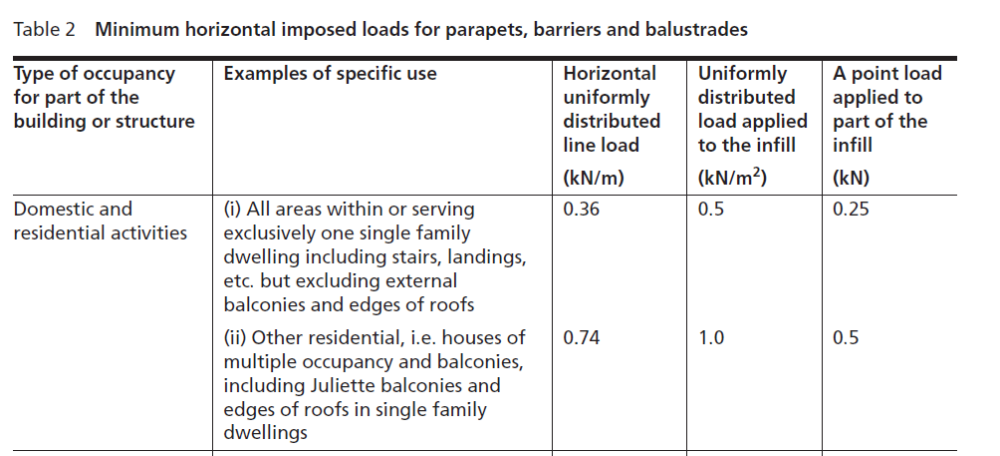

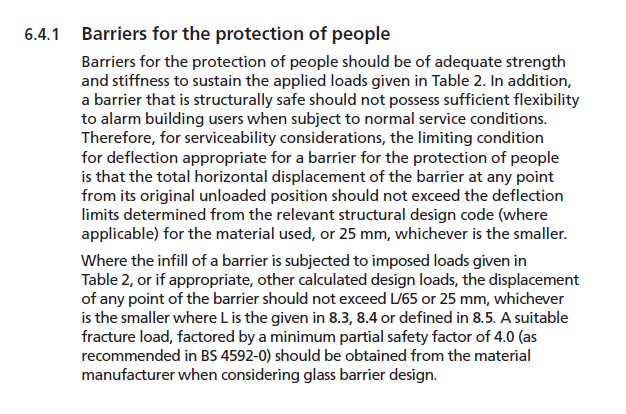

Well that's a good start! To keep you on the right side of things below are the design loadings from BS 6180 for domestic internal stairs, landings etc. Your on the top line. Often the governing load for the hand rail is the horizontally uniformly distributed load of 0.36 kN/m (~36 kg per metre run of hand rail) and this load usually get transferred to the top of the hand rail. An important point here is that these are unfactored loadings.. thus no factor of safety built in. The other important bit is the deflection of the overall asssembly, from the same code The 25mm deflection is a key requirement. If you want have a test of what you have. Take your hand rail length just say 3.0m and calculate the horizontal force at the top from the hand rail 3.0m x 0.36 kN/m / 2 = 0.54 kN (~54 kg) Get a spring scale ( for weighing fish or something) and apply that load to the top of the uni strut. See how much it deflects by < 25mm Next test for strength using the Eurocode factors of safety. Take the 0.54 kN load and and multipy by load factor of 1.5 = 0.54 x 1.5 = 0.81 kN ~ 80kg Also make an allowance for material defects that may manifest later. Apply a material factor of 1.3 thus 80kg x 1.3 = 104kg ~= 1.02 kN test load. Two things to remember. You are testing the newal post in isolation here and I'm not taking into account the potential bracing effect of the handrail running perpendicular to the newal post down the sloping part of the stair. Some may and rightly say.. it's always stiffer than that once you put things together. I say.. your often right but can you imagine how hard that is to prove? and also you can often shift the problem somewhere else if you shed load from the newal post. On the other hand 104 kg is about 16 stones.. there are plenty folk that are heavier than that.. and if you have a Rugby team partying, a couple of big lads could push the thing close to its design limits. Report back.. check the deflections first in case the strut fails early.1 point

-

I ordered Spanish tiles from Tile.Expert last year (Equipe and Mainzu). Everything was fine.1 point

-

we bought from Ultra Leds https://www.ultraleds.co.uk/plaster-in-standard-recessed-plaster-in-led-aluminium-channel-3-metre-length.html1 point

-

When I built my build I used Spanish slate and looks very similar to welsh slate and far cheaper.1 point

-

1 point

-

We've not bought our tiles yet but our architect says some of his other builds had floor tiles from Tile Expert and they were ok.1 point

-

1 point

-

Marazza are a good brand Rocia stock them and will bring them in direct order above 100m2 Usually about 3-4 weeks Expect to pay around 30 odd For ticket prices of 50 odd1 point

-

1 point

-

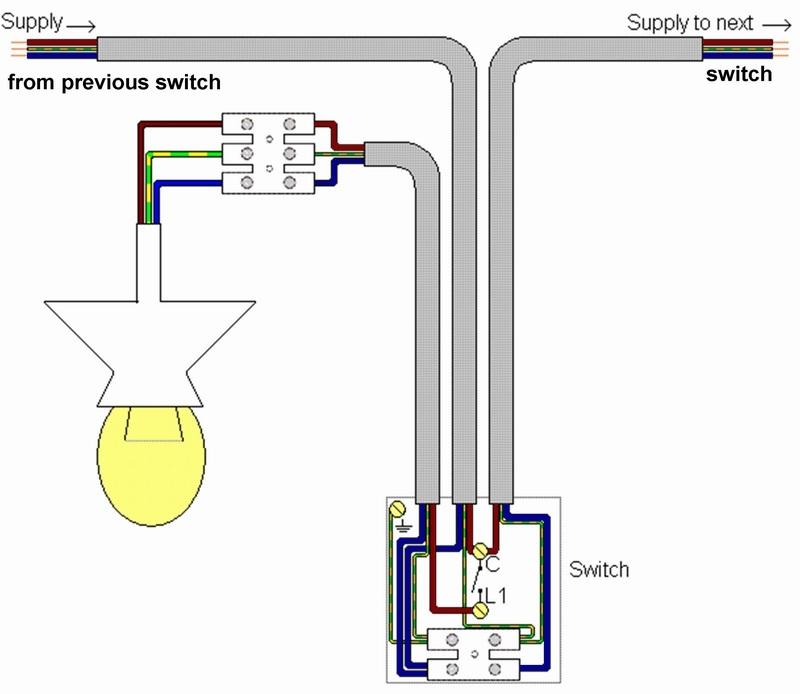

I had one of those, total sh1te, replaced it with a “real” switch. I agree but without testing where the wires go or knowing I could only guess. Anyway what could possibly go wrong? 🤯 get yourself a multimeter.1 point

-

Cross-posted with @markc. Yes, they can be very dirty, but I have been quite happy with 2nd hand slates; it's just all the sorting - not only into good and cr*p but also into thicknesses. I don't think I would have won my 'junior roofer of the year' award, but 'not too bad' would be a fair accolade!1 point

-

You can't ignore it. At the very least you must write and say that you are not happy and why. It sounds as if they have done what was required. The issue seems to be who is managing the process and who reports to who? If we could see the initial brief and instructions to and between all parties, then we could understand the situation. That is what your lawyer or claims surveyor would do, at some cost. . They will also assess how much you have lost through this process, which may be nil. Cheaper is for you or a friend to run openmindedly through the paperwork and summarise who said what. In particular look at the initial design...was it an overview or detailed?1 point

-

1 point

-

1 point

-

Going back to the switch, yes I recon the neutrals were linked in the box, not on the switch plate. .. they could have been used as lives but should have been taped accordingly if so. Put them in a wago or block on their own …. For now lol1 point

-

But why did it have to be redesigned in the first place1 point

-

1 point

-

1 point

-

1 point

-

I would guess that one cable is incoming (power supply) and the other feeds the actual light 🤷♂️, therefore one live into common and the other into either l1 or l2 (does not matter) and the two neutrals connected together in a separate cable connector.1 point

-

Bit of a winter, eh. Took the chance of a break in the weather this weekend to finish the roofplate and get (some of) a flat roof up there. Pics: Ended up working in the dark at the end, which was all sorts of fun. The OSB3 isn't glued&screwed properly yet, and I've got some wood of the structure left to do, but the tarping situation is much improved - two wrapped around, and one laid flat on top of the roof, since it's not quite watertight yet. Now there's space in the garage, I've placed an order for EPDM so should be able to finish the roof properly soon. The two wall-protecting tarps can stay like that until it's time to render, they're great. I've been a bit worried the whole time about how a square roof might look on top of the D-shape of the building, but it's coming across as quite cute in the end - to me, anyway. It's like a little guy with a big hat (and sleeves at the moment, too!) Managed to take a knock to the temple while building the roof though - screwing a short bit of wood below a joist to support another joist, holding it in place with my head to stop it from spinning round, I was getting frustrated and put the drill into reverse. So it spun around and clocked me one. No concussion, but a good reminder to slow down. More time, more people, maybe nails instead of screws for the final piece I need to get up in that way.1 point

-

It's not easy to compare the heating costs as they house has been extended and changed quite a lot. But as a reference today the heating oil is about 70p per litre which means about 7p per kwh equivalent energy. I am running Heatpump on Octopus Cosy tarrif which is 17p per kwh, assuming a COP of 3 I would get about 6p per kwh of heating energy. So like for like cost will be in similar range. One area though which I think could be improved is the duct insulation. Warm air ducts are quite big so big surface area and if they are in cold space then that would mean more heat loss. Wall mounted units have very thin coper pipes coming in which are easy to move to thermal envelope of house and less surface area so they have less heat loss. The warm air duct system is super quite compared to wall mounted Air to Air units which is big plus in bedrooms.1 point

-

What sort of system do you already have, vented, unvented, combi. If you had a pump, why not just replace it. I put a twin impellor pump on my hot water for the bath/shower, 16 years ago, not had to touch it since. It was the cheapest pump from Screwfix, about £100.1 point

-

I've used the same pump that's used on these, in a solar HW system. The pump is actually surprisingly powerful for the current involved.1 point

-

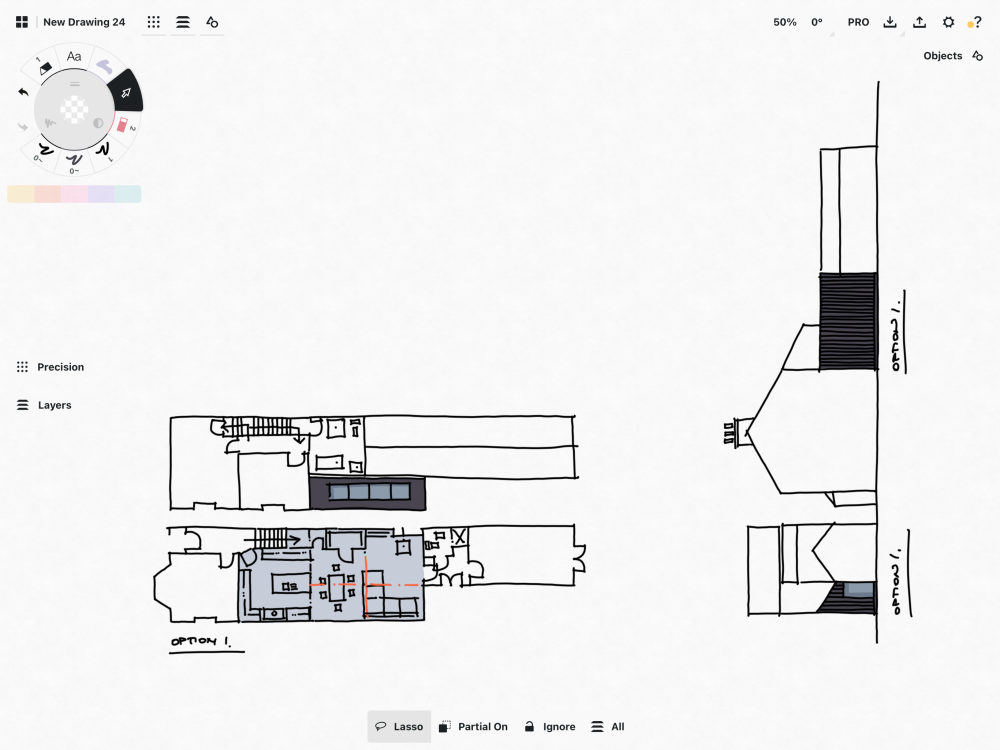

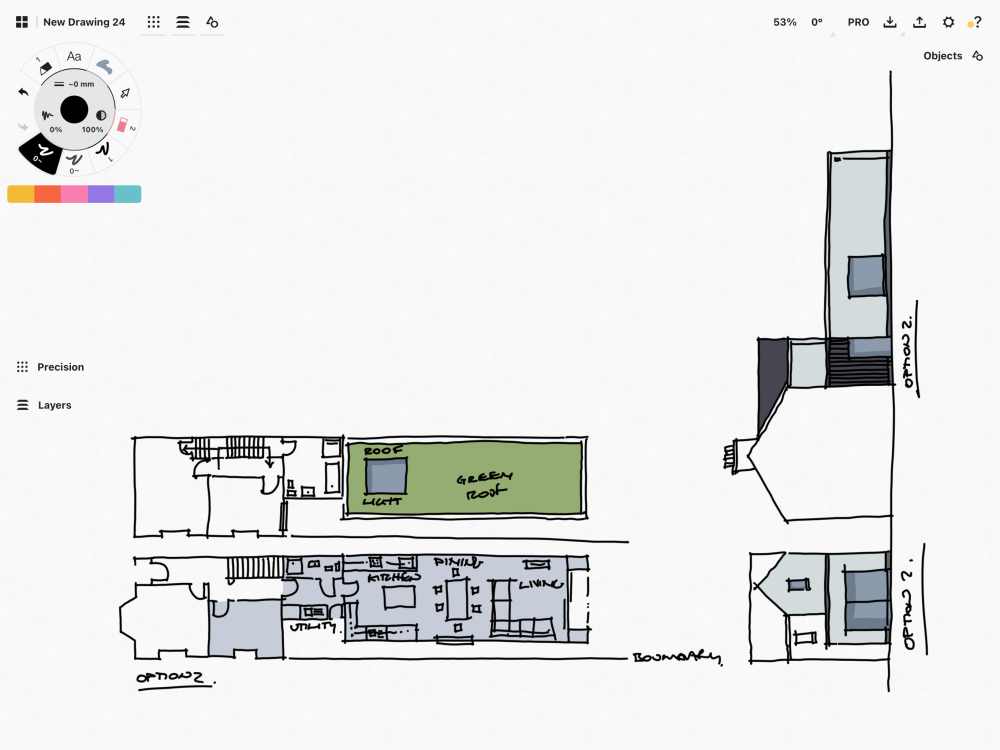

For opening up kitchen/diner @ETC's option 2 looks easier to build (less steels, all single storey), plus it keeps direct natural light into the rear reception room1 point

-

Would suggest you are overthinking something here. You system is what it is, low loss header no point, but you have one, unless really well designed specifically for your system they reduce efficiency. But you have what you have. If you are concerned with running out of hot water allow more time slots for heating. I heat once in the morning and again in the afternoon (but it will only add heat if needed by the thermostat), you could just as easily allow it to heat anytime based on thermostat thermostat. If you aren't consuming the thermostat will get to temperature and stop the heat cycle. Unless you are willing to pay a huge amount of money out, to get a plumber in and pull your house apart, just use your thermostat, the timer you have - done1 point

-

Well Imperial is a good university, so the product must be good It would be interesting to look at the original research and see the logic for the invention. It says it’s a 0.5bar boost, so maybe that’s enough pressure to go from hampster’s pee to … something else. One solution I know works is a Stuart Turner dual 3 bar pump. Expensive, but we’ve had the same one for 30 years, and apart from swapping out the little pressure vessel a few times, it’s been flawless. This is on a vented tank. You have unvented?1 point

-

Yeah I didn’t foam around the hep20 . I foamed around the 110mm pipe . The hep2o’s move freely through the pipe .1 point

-

Same here! BTW, remember to leave a bit of slack on all the wires. If they are just right, they can become tight when you put the cover on slotted trunking and end up pulling on the connectors. I had a redo a few of mine because of this.1 point

-

It depends perhaps whether this was general advice or detailed design. As @Moonshine this is perfectly feasible in block, but needs detailed design . I've done a basement and chose to use a proprietary block system into which went reinforcement and concrete, rather than standard blocks. But it needs very specialised and expensive waterproofing if it is to be an occupied space. On the other hand, a reinforced concrete wall, designed as if for a swimming pool, water tank or reservoir is feasible too, and may need less waterproofing measures. Cost difference? It depends on a lot of variables. Without seeing the detailed design and covering correspondence, and the client brief, and understanding of the contract and supervision responsibilities, we can't really comment on the design suitability, and I probably wouldn't choose to anyway.1 point

-

I used 6mm sand coated basalt from Orlimex UK Limited. they supplied in 2.5m lengths then just cut them to length and install an o ring in the middle as a drip. They costed out at 22p each.1 point

-

That was my original design bodge, when I realised my LG ASHP had no "correct" way to turn HW on and off from an external device.1 point

-

Snipping tool! That's the answer I wanted. Works great, even in turbocad model view. A great tool that I didn't even know I had! Thanks again Jack1 point

-

Building a habitable room under that roof without fully replacing it, is probably the silliest thing I’ve heard in a while. Any wind driven rain will just leak through onto the insulation, it will then track down the insulation until it finds a way out onto the plasterboard ceiling, you won’t be able to pinpoint the leak as it won’t appear where it originally came from.1 point

-

When roofers are removing the slates they will be scrap. If they take care to remove carefully it could be twice the labour, so twice the cost! The same with battens. If it is going to be a habitable room after the work is done then it is well worth doing it now for piece of mind, because a water damaged room is a lot more costly to repair than a water damaged loft1 point

-

Let me explain why it seems right to be focusing on payback period right now wrt wall U values. I have a choice to make .14 or for £6k more .11. Some of the remarks above, while obviously correct, do not help me decide. Let's just say I decide to go ahead with U .11, while my identical brother decides to build an identical house next door, but with just one exception, he uses .14. Some time later both houses are finished. ASHP, UFH, MVHR, air tightness, windows, all other insulation, .... all identical. We are both very pleased with our comfortable houses. How can we, or anyone else tell the difference? It seems to me that the only difference is that I am spending ca. £50 per annum less on electricity, and he paid £6K less on his build. Thus it seems perfectly reasonable to focus on payback in this instance as there is no other difference. Or am I missing something?1 point

-

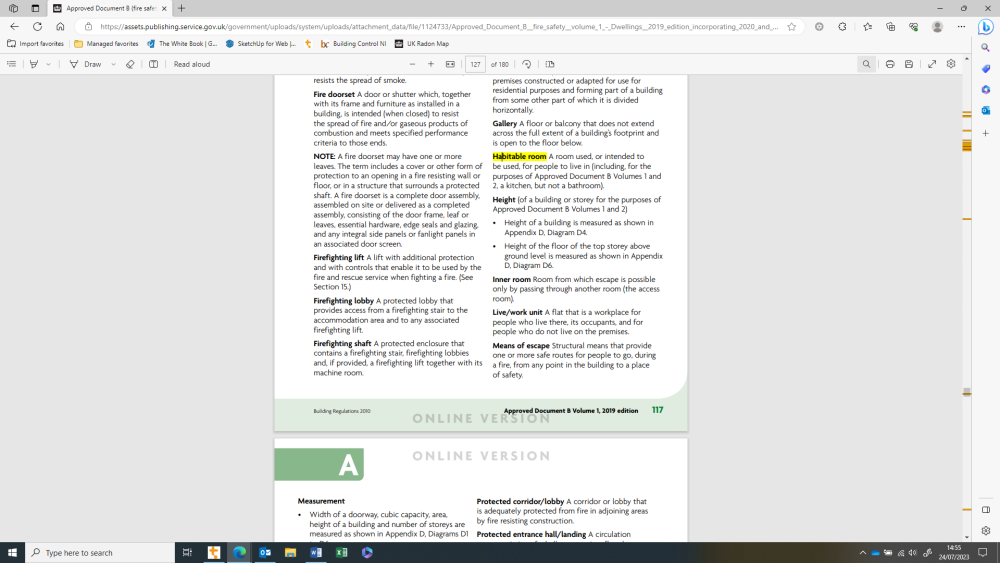

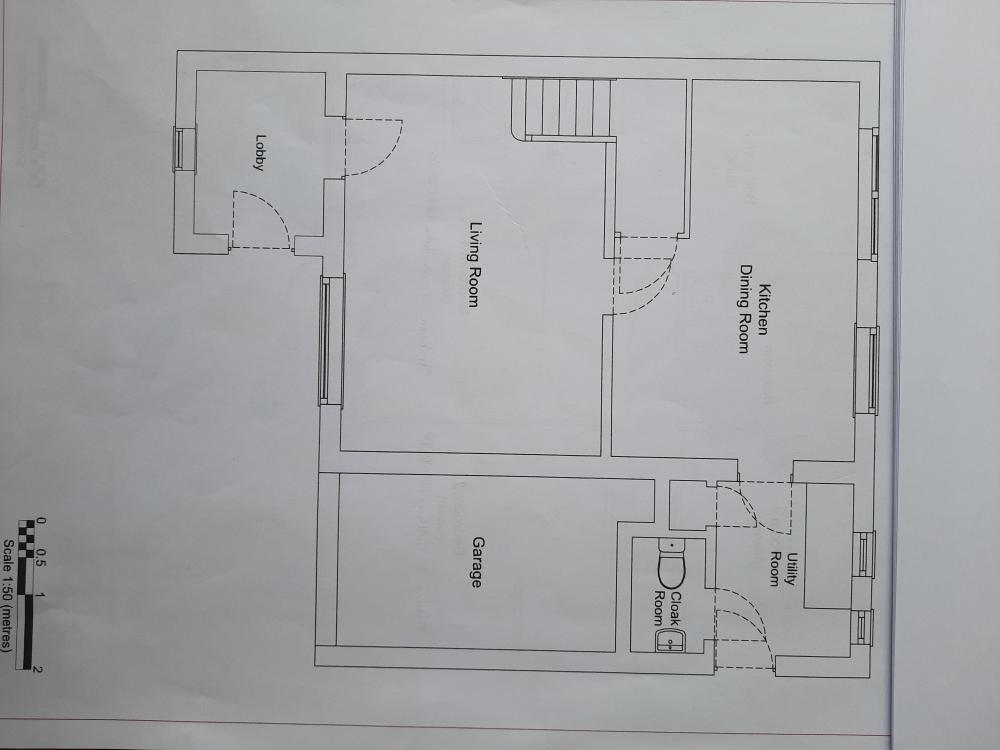

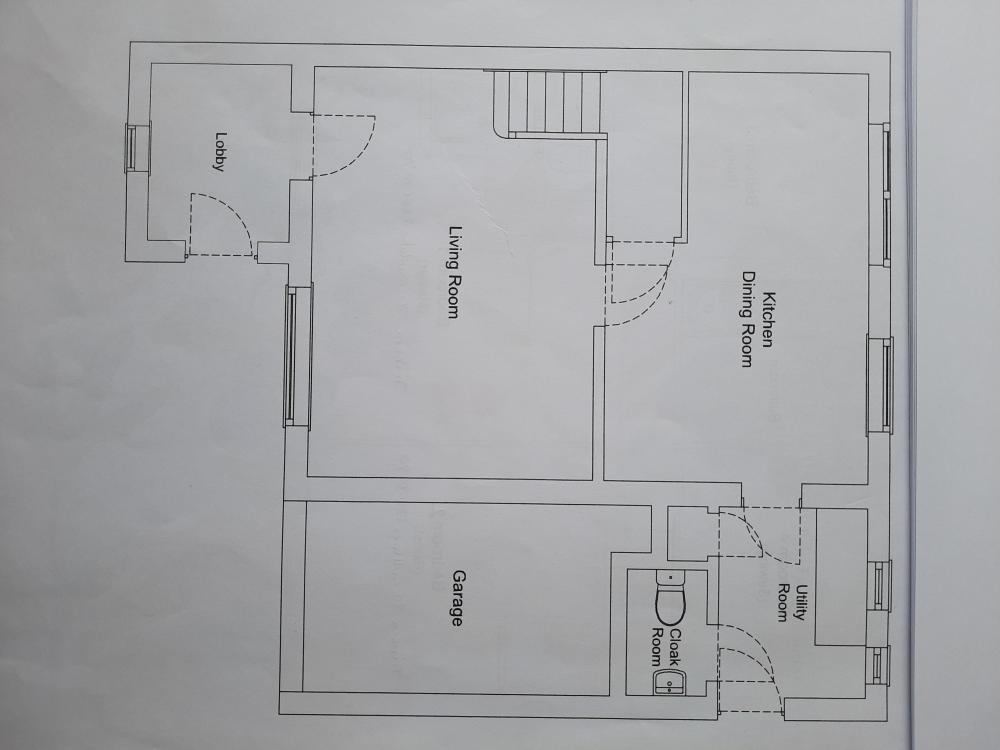

Rubbish. It's not a habitable room. Look at the definition in Approved Document B. In any case if this were the case every single room on the ground and first floors in all houses all over the country would need EEWs. Go back to him and ask him for a definition of a habitable room/space. EDIT: I have just looked at your floor plan. The Living Room is the inner room (to the first floor bedrooms which I am presuming if this is a new house all have EEs) - not the porch.1 point

-

1 point

-

Could always do this for monitoring (from https://www.loxone.com/enen/blog/ehome2-future-homes-standards/) 🙂 I was going to get some of the local bytes smart sockets (which are pre-flashed with TASMOTA), but there are some things that it is easier to monitor in the consumer unit or Loxone panel or that don't have sockets. Does the Emporia support three-phase and voltage sensing (I don't have any three phase appliances, rather single-phase split across three phases)?1 point

-

1 point

-

0 points

-

Is that all it takes, a smelly partner. Should have told my BiL that, would have saved my sister robbing him. I fitted my shower pump under the bath, it pumps to the bath mixer tap, and therefore the shower as well. Can you do something similar as a temporary measure.0 points

-

unfortunately not, the new system is going in the new part of the house, which doesn't exist yet. If I wait that long to get the shower working I'll be going through divorce #2 I think...0 points

-

No! Do not put neutrals in common, neutrals stay separate. Post a pic of what you have in the other box. simple switch is common and L1 or L20 points