Leaderboard

Popular Content

Showing content with the highest reputation on 11/18/23 in all areas

-

I've never met an automatic air valve that didn't eventually leak In a sealed system they are only needed initially when the system is filled and for the first few cycles when any dissolved gasses come out of solution. So I either fit a manual valve and just bleed it a few times over the "break in" period. Or I fit an automatic valve and then screw the cap closed after the break in period.3 points

-

I'm about 95% happy and not one for sweating the small stuff too much. Unlike the general experience I was by and large very happy with the work done by trades but most we used were either pals/folk I knew (and had confirmed by others their work was good) or recommendations, which will help reduce the risk of having a cowboy on site. The only exception I'd make is for groundworkers, and I also wouldn't let anyone near airtightness or insulation - do that yourself as there's no understanding at all among trades and not enough care for the things you won't see.3 points

-

The problem is that those who have the respect to be listen to in terms of solutions are respected scientists. Scientists do not get respected by theorising untested solutions based upon data sets that are incomplete, with wild variations in possible outcomes due to it being such a complicated modelling. We end up sound bites from politicians with an agenda, or celebrity driven scientists who quote opinions not science. All reasonable people agree that we need to do something, but it will come at a huge sacrifice to those who have the power to do it. There will be a few dead canarys before things change.2 points

-

Taken a few readings using an IR non contact thermometer, not much wind today. the fixed frame showed an improvement of between 0.3 and 0.5C between the ‘improved’ and original frame. the opener showed between 0.0 and 0.1C improvement. on a day which is quite still I’d say this makes sense, so the opener has drainage holes but they drain into the main window profile which then drains externally, so any air movement would have a longer more complex route. can’t comment on sound insulation as both of the treated areas are at the back of the property away from road side. I have ordered another 50m of rod to complete the other windows, which all in moneywise will be around £20. will try and remember to take some acoustic readings on my phone before and after when I do a window at the front facing the road, and also take additional reading’s temperature wise when we are forecast some strong wind which I think is due this week.2 points

-

I'll give my reply and let the proper plumbers come in a minute to agree or disagree. It will work, BUT it is not right. The fitting your HEP adaptor is intended to connect to looks almost the same, but the edge of threaded pipe it fits to has a pretty square edge. Your fitting intended for a copper pipe with an olive has the end machined out to match the olive so presents just a very thin edge of pipe.2 points

-

I like a self leveling laser level to cast a line around the top of all the units. You find if you move a standard level around the top of the units it changes. With the Lazer you can average out the errors in the units, and it's so easy to level front to back at the same time .2 points

-

Sod the courses though Steamy, it's all about just giving a damn about your work2 points

-

Environment Analysis 14 November 2023 By Michael Le Page Will global warming continue even after we hit net-zero emissions? Understanding how the atmosphere responds to rising and falling carbon emissions is a complex business, and now researchers have found taking longer to reach net zero could see global warming continue afterward. When will global warming end? It is unclear The longer it takes to reach net zero, the greater the risk that global warming will continue for decades or millennia even after we have cut greenhouse gas emissions, according to an assessment by climate researchers. This means we may have to emit even less carbon dioxide than we thought if we want to limit warming to, say, 2°C, making carbon budgets even smaller than current estimates. “The timing at which we reach net zero is also key,” says Roland Séférian at the National Centre for Meteorological Research (CNRM) in France. Climate modellers once assumed that CO2 levels would remain roughly constant after emissions ceased. In such scenarios, the oceans would continue to warm for several decades, leading to further surface warming. But more than a decade ago, modellers realised that in fact the oceans will continue to soak up some of the extra CO2, leading to a gradual fall in atmospheric levels and less of the sun’s heat being retained. Recent climate models suggest that, by coincidence, this cooling effect balances out the ocean warming, meaning surface warming halts within a few years of emissions stopping. Not all climate models are the same, however. Standard climate models don’t include all feedbacks, such as how much carbon is taken up by plants on land. More comprehensive “Earth system” models suggest that if, say, emissions stop when the world is 2°C warmer than pre-industrial times, there is a 33 per cent chance that the planet would continue to warm past 2.3°C. Yet this is still not the full story. This is because even the Earth system models don’t include all feedbacks, such as the melting of the ice sheets on Greenland and Antarctica. He and his team have now done a comprehensive assessment of the uncertainties over timescales of decades, centuries and millennia. They looked at 26 factors that could lead to more warming or cooling, from the loss of forests and the melting of permafrost to shrinking ice sheets and changing ocean currents. For around a third of these factors, such as some cloud responses and the extent of sea ice loss, we have no firm knowledge and can only speculate, the researchers say. While some of the factors are expected to cause cooling, there is a general tendency towards additional warming, says team member Joeri Rogelj at Imperial College London. “Peak warming could be higher with additional impacts, damages and challenges,” he says. “It really means that reaching net zero becomes even more important as a milestone.” Additional warming doesn’t mean unstoppable warming, says Rogelj. It could be prevented by continued carbon removal after net zero, for instance. But in a comment accompanying the paper, Michael Mann at the University of Pennsylvania points out that carbon removal at the scale and speed required for halting warming might not be possible. “What is most urgently required is a rapid phaseout of human-induced activities that produce carbon pollution,” he writes. “I think this is an important paper that emphasises that our understanding of how much the world will warm or cool after we hit net zero is still uncertain,” says Zeke Hausfather of Berkeley Earth. “While our best estimate is that warming will stop when emissions stop, it’s also possible that the world might continue to modestly warm – or modestly cool – after net zero.” Journal reference Frontiers in Science DOI: 10.3389/fsci.2023.11707441 point

-

I think we are already at that stage. Using your analogy a few mines collapsing killing lots of people will be next. I think the first real pain will be the collapse of food security. The planets history of change also includes many extinct species not killed off by humans, and the planet adaptions have not always been human friendly!1 point

-

I actually think part of the solution might be accidentally presented to ourselves by nature and natural selection. Perhaps a large algae bloom in the oceans, or Mushroom forest that springs from the retreating permafrost. The planet has a history of change, and has adapted each time. Granted the current change is massively accelerated by humans, there should still be something out there that benefits and thrives from the excesses, that we could use to ease the symptoms1 point

-

Spot on that! That's just the size I'm looking for too! In the same ballpark as the abacus ones from rubberduck. I think that would fit snuggly in a 500mm wide hole!1 point

-

this is what we got for the kids bathrooms. https://www.qssupplies.co.uk/bathroom-furniture-shower-taps/168379.htm wanted recessed so as to give more a sense of space as they're not huge en-suites. not cheap though. here's a photo of the bathroom with the hole ready for the cabinet to be fitted once the room was tiled and painted.1 point

-

True but sadly the standard of those properties will not be tough enough for the harsher environment. Drainage designed for 100 year events will have to cope with these events every 10 years. Brickwork mortar strengths will need to be increased Roof covering designs will need to be upgraded against higher winds Basically exposed elements will wear quicker. The grade or wind zones will need upgrading from these: https://klober.co.uk/resource-centre/uk-wind-speed-map Let alone trying to finish your building in adverse weather conditions.... Yes "What is most urgently required is a rapid phaseout of human-induced activities that produce carbon pollution,” Let me know when this starts! Presently there are too many inconvenient changes to human behaviour required to achieve the rapid phaseout of human-induced activities that produce carbon pollution which are required to result in net-zero emissions. I think we can only rely on technical developments to offer alternatives that humans will find as acceptable behaviour changes at present. As humans are known for the "needs must" approach to global warming we will not react until the s**t has already hit the fan. Unfortunately there's no instant action giving rise to an instant result in this case. We're not talking about a hair dryer, a shower and a toaster. Elon Musk better get a move on before the weather patterns stop the launching of space rockets! Marvin1 point

-

So we have a plan to fix the planet, but even now, nobody knows if the plan we have will work, will it stop warming, will it cause the planet to cool, etc. So in spite of being certain it is man made CO2 that is causing the problem they don't have a scoobie if stopping all man made CO2 will make any difference or not. No wonder some people cannot take this seriously.1 point

-

Ha, no such thing exists. If there is a detailed drawing, I'll only show indicative lines only Get a plumber in and they'll give you the story in an hour or so.1 point

-

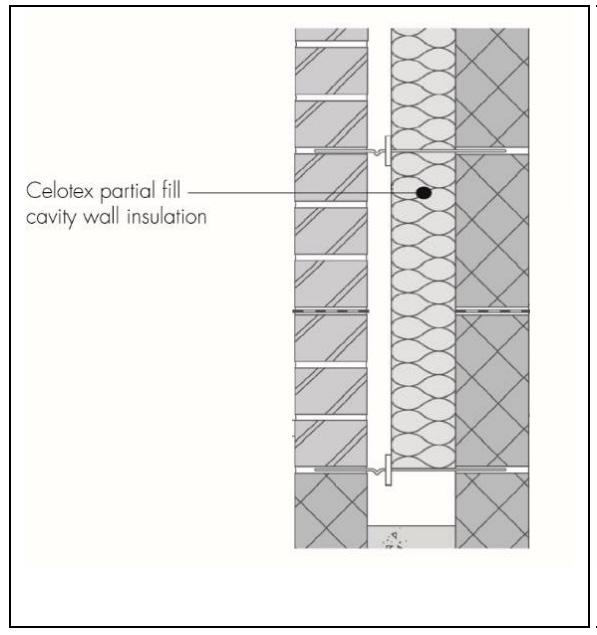

Due to site constraints we had to do the outer skin first, and will be now adding the insulation and building the inner skin from Celcon blocks. A few questions I have which I would appreciate any advice on ? How come in some images the insulation doesn't go to the bottom of the cavity? Wouldn't that reduce the wall's insulation properties? Is there anything wrong with going all the way to the bottom of the cavity? As I'll have to cut and place the insulation in the cavity before we lay each course of blocks against it, I was wondering whether it matters which side of the insulation I place tape on. As in, looking at the illustration below, from left to right, would this be ok at preventing airflow? bricks - 25mm void - 75mm PIR - tape - Celcon blocks. Or should I go to the effort of trying to tape on the side with the 25mm void? Any tips for making sure there is no gap between the PIR and Celcons when doing it in this order? Anything I should pay attention to when helping the brickie? I would have much rather had the Celcons up first and been able to place the PIR against them etc, but that wasn't possible. Thanks!1 point

-

1 point

-

We have recessed mirror cabinets (although yet to fit them). Not sure where they came from as the better half bought them. I’ll try and find out and let you know.1 point

-

Zero issues for me . It’s a big mirror but shallow ( which I needed ) . *just* squeezed it in a single stud wall . Has a shaver socket in it so plugged an Alexa flex in it . So I can shout and swear at it rather than SWMBO . Looks identical to when I installed it 👍1 point

-

My gut feeling is that we've already pushed the cart over the hill and there's pretty much no way of stopping an extreme future. Even if we hit net zero tomorrow, there's still so much we've already pumped into the world, that (to use an analogy this forum would understand) the slab has had a hundred years of underfloor heating pumped into it, and even if we find a way of using air con that doesn't make the situation worse, we'll have to have the windows open all year round for a long time to come to deal with it. Trouble is, that due to the increased sea temperatures, we'll be dealing with a lot more extreme weather events, not just the warmer seasons, but the strongest storms ever recorded and getting worse for decades. Saying all that, we won't hit net zero for a long time because of corrupt governments and a greedy fossil fuel industry.. So we're actually in it for a lot worse.. When things get bad, modern economics will collapse, the knock on from that will kill more people than the weather will. If you think energy and food are expensive now, you wait to global crop failures and blanket bans on shipping come in. Anyways, at least we've all got half finished houses to live in!1 point

-

Thread revival @Pocster, I'm looking to fit a recessed mirror/cabinet into my small downstairs shower. Not too many results on the old google. What did you fit? Have you been happy with it, has it stood the test of time?1 point

-

1 point

-

My carpet isn't the issue, it was just an example. No doesn't happen in practice. The real answer to the transfer process is not a simple one. So will work through what happens. Water flows through a pipe at temperature X. The temperature transfers to the screed or concrete in a uniform manner, up, down and sideways until it meets a thermal resistance. The resistance could be heat flow from other parts of the pipe, insulation or the floor surface. The further the heat has travelled away from the source (the pipe wall) the lower it's temperature as the heat energy spreads outwards from a small pipe. A water pipe section will interact with the other parts of the UFH array. So for well insulated modern house. 1. For a given flow temperature, say 30 degrees, with dT of 6, mean flow temp is 27 degrees. This is around 20W/m2 output to the floor. Floor will have a surface temperature between and 3 and 4 degrees warmer than the target room temperature. If you have insulation above the floor surface the heat transfer to the room is restricted. Move to point 2. 2. A heat pump will modulate it's output to keep return temperature stable, but also to manage a fixed dT and maximum preset flow temp. Once at maximum flow temperature the heat pump will modulate output to its lowest point for a given flow rate, then dT reduces between flow and return, over a period of time (minutes or hours) below its minimum preset point, the heat pump stops adding heat (it's compressor shutdown). Move to point 3. 3. For a given heat flow into the floor (product of flow rate and dT). The more restrictive the surface finish is, the more difficult the heat transfer mechanism. So instead of transferring the heat from the pipe, to the floor, to the room (heat flow is restricted by floor covering), the return flow temperature stays slightly warmer, decreasing dT quicker than normal and shutting down the heat compressor sooner. Less heat is actually transferred to room. To compensate you either increase flow temperature or you accept a cooler room, as in the case for our bedrooms. Add a 4 port buffer, you could easily be flowing 5 or more degrees hotter than you thought you needed. Also if you are running zones and on/off timings, these all add to a rubbish CoP.1 point

-

Insulated plasterboard inside the walls? No undoing or redoing work.1 point

-

1 point

-

Not only training and experience, though. Attitude is one of those hidden aspects of any domain which hides in plain sight. You can be trained and be experieced all you like : if - post training - your attitude accepts a bodge as good enough - because you can hide it , then unless theres extrinsic motivation (...I'm going to lose my licence to pratice ..) , you won't develop as a PERSON Think check-rides as a train driver / pilot / bus driver. Who check-rides a plumber? ( shaaaadup @Pocster )1 point

-

1 point

-

Or a short piece of copper pipe from the olive conn then hep20 !1 point

-

I have a strong feeling that the dire state of the housing sector plays a strong role in promoting poor work. Haven't we all talked to tradies who sneer at the building standards of the major providers? Who snigger at the Building Control regime. But the market will take care of that issue won't it? Building Control officers in Germany are really powerful. They can ( or could when I was there) recommend that builders (tradespeople) lose their licence to practice. And the trades' association vigorously police their members. A German mate once said to me - Why should I employ a chimney sweep who can't manage a large block of flats? - Cos someone else will do it cheaper...? ( I seem to remember it takes about 5 years to qualify over there) - Das ist Scheiße.... That translates as it sounds1 point

-

Outside observation Sounds like a pretty big ASHP you are looking to install, could your efforts be better spent making fabric improvements to the house so you could install a way smaller heat pump and get down to single fan unit? Also without very careful design your proposal could end making the noise worse, rather than better, and end up focussing the noise in a single direction. Choose make or model of heat pump also makes a real difference in noise production and how annoying it is to othes.1 point

-

I think @sharpenermay be referring to this thread about noise in another forum. https://renewableheatinghub.co.uk/forums/renewable-heating-air-source-heap-pumps-ashps/noise-planning-expert It does discuss some of the issues encountered in depth, based around the experience of someone apparently facing enforcement action under nuisance law. Unfortunately the individual in question is definitely in violation of planning regulations and the local authority are probably using this to conflate the two entirely separate branches of law in a way which is not entirely helpful. I will shortly be posting on the same thread the best statement I can get out if my eho on the criteria for noise nuisance. Its sort of helpful, and sort of useless.1 point

-

After some debate, Jan and I decided that we could press out the sag in the cells if I made a suitable jig, so I made up an H frame that is held against the side of the SunAmp by some tape strapping, and which could hold a pressing plate (a square of OSB3, and with two bars that allowed a set of folding wedges to apply the pressure. I then brought the SA to temperature and used the wedges to load up the pressing plate and push the cells back true. All that remains is to allow the cells to cool back to solid phase and then I can reassemble the SA. A bit Heath Robinson, but simple, very cheap and effective. Job done. Here is a pic (note that the wedges are pretty much at the end of their travel as the cells are back in shape and position :1 point

-

Welp, a week of big sighs. Got the two side sections of wallplate on and they demonstrated, rather clearly, that the walls weren't straight enough. Here's the SW corner: And the SE corner (fiddling a week later after sorting out the SW one): Fortunately, not fatal - I "just" have to take down bales, resize them, and restack until everything's within tolerance, which is about 5cm for quality load-bearing construction (at least, according to the Canadian building code. Might be able to get away with more than that, but I definitely can't get away with half the wallplate hanging in space). The usual way to keep this from happening is to put up some vertical timber braces at each corner and use them to guide you as you go up. Obviously, I didn't bother. Lesson learned 😅. I've sorted out the NW corner, at least in terms of how it kicked out W - it might still be too long, as the SE corner is, but I know it's not *as* bad, at least. Vaguely considering putting some of the strapping horizontally along the wall and compressing laterally, to see if that might straighten it all up, but that might be madness compared to just redoing it. Bleurgh. Chances of getting to the roof next week diminishing rapidly, anyway.1 point

-

Apprenticeships are very expensive. I just had a quick look at my local skills college and they do a Level 1, 1 year course in Carpentry, £1292. Electrical Installation Level 3 is £3345. Now level 1 is really for the functionally illiterate, and Level 3 is just a gnats above a GCSE. Now I know that 16 to 19 year olds get the education for free, except it is not really free, just comes out of general taxes. I am starting to think that a Science Degree is good value (no point commenting on an Arts or Humanities one as they are pretty poor value). Let us say that it cost, on average, £2k per course and you study for 3 years. My Hons Degree was 140 points, 120 ify them were actually needed. Each of the first two years was 7 subjects, so 14 in all, then the final year was 5 subjects and the project. So 20 in all If an apprentice does something similar but at a lower level, then £2k times 20 comes out at £40k. Similar price to a Science Degree. Except they are at a much lower academic level.1 point

-

Well just goes to show how really lucky I was with my builder, no problems at all and really nice to have around (no wonder he is booked up for about two years)1 point

-

I had plastic bags tacked to the walls throughout the house and they still chucked empty crisp packets etc on the floor. My other half collected it all up and put it in their van 😂 They never did it again.1 point

-

ive got a list as long as my arm (and leg) of the things the builder did that were p!55 poor, you get what you pay for. The only saving grace is that the external brick work is really nice so that was a bonus that cushioned the blow somewhat. Just daft things like they didnt tool off the silicone on the doors for example, and the setting out of rafters and joists is erratic as is their overly zealous use of a nail gun. Thats passable at best but i have found they used bits of knackered old fence i had behind the shed as parts of the roof in the porch. I mean thats just mental, the fence i took down as it was borderline falling down and it was only fit for burning, i had it stashed for fuel for the chimenea, not for a brand new porch. Too much hassle to pull them on it after they had left, i just wouldnt use them again or recommend them to anyone.1 point

-

I don’t think that’s a good idea, do you? 😱 Yes, I read some time ago that German companies mostly still run apprenticeships and are family run rather than big corp and university degree oriented. when I was building a garage at a former house my 10 year old son asked how I was making decisions on what to do, I told him certain things are dictated (building regs) but mostly it was common sense, his reply was “when I grow up I want to go to university and get a degree in common sense”. Bless him……1 point

-

We often have this discussion about skills - it runs something like ' We need more skilled people for for trade xyz' And I always suggest that skills are just the icing on the cake. We need to give tradesfolk parity of esteem with their non-trade colleagues. Until there is a rigorous and universally accepted Apprenticeship Scheme - one that engenders respect in the pub and the building site, then we'll continue to suck our teeth with irritation. The German model isn't perfect. But it's better than ours. And Apprenticeship depends on an excellent education system: one where those not going to University have the opportunity to get highly respected qualifications as trades people. And there's less than no chance of that.1 point

-

My wife was far more important to our build than I was. She ran the entire site. Most of the guys we had onsite were pretty good, but a few struggled with taking instructions from a woman.1 point

-

Alan.. what a brilliant post and thanks for the compliment. I posted based on what I know from the design / engineering side. You have just fleshed out the part of it in legal terms and more importantly the procedure you can follow.. big learning curve for me / stuff I didn't know about. You explain well how to execute an effective strategy... off to read your post again. Thanks again for spending time writing.1 point

-

Definitely not as 1). The likely design is that the pile is left high, then cut back with the reinforcement tying into the edge beam. Dpm would interfere with bonding. No dpm is necessary as the concrete is (make sure it is) very dense. Neither option shows any insulation. Anyway, under the slab and tucked into the wall seems right to me.1 point

-

My hunch is no. Especially if you expose the materials to the air of that room, before laying. I'd be more concerned with expansion but the same applies. Is the product laminated? So like plywood?1 point

-

Yes, you can definitely use breathable membrane as the 'hammock' and it arguably performs a 'belt-and-braces' function as an 'anti-wind-wash layer'. If you have nothing better to do for the next few hours read these. The BEIS Best practice document is interesting insofar as it is one of a series (IWI, solid floors, suspended floors and rooms-in-the-roof) which were published in (I think) 2022 but (as far as I am aware) barely publicised at all. I may not agree with absolutely everything in them but they have clearly used knowledgeable sources. Seach 'BEIS Best Practice' for the whole bunch. In terms of material it is an expensive option, and it drops bits on you, but in terms of (semi-) rigidity flexible wood-fibre is soooo good. No dropping-out or drooping. Cut 20-30mm oversize, squeeze like a concertina and pop it in. I do 'support' it, as I want a membrane, but I am certain it would stay more-or-less forever without additional support. Under-floor insulation guidance: https://www.gov.uk/government/publications/insulating-suspended-timber-floors-best-practice https://www.greenbuildingstore.co.uk/information-hub/insulating-suspended-timber-floors/ https://www.ecologicalbuildingsystems.com/post/best-practice-approach-insulating-suspended-timber-floors http://www.sofiepelsmakers.com/suspended-timber-ground-floors.html1 point

-

Have the loops all been fully purged with cold mains water at full wallop to blast them clear of all trapped air? If this has not been done properly you’ll never get proper flow. Running the manifold with the automatic air vent as a means to remove trapped air is no good whatsoever as the flow rates are extremely low and absolutely will not get the air locks out.1 point

-

Depends ..! Yes it should but it’s sometimes not. And it needs more than the 9mm poly crap some plumbers use. Joints should be taped too.1 point

-

Just the same principle that you apply to balancing radiators. Flow control valves on each duct battery and flow valves would help too. Could even use a 2 port UFH manifold but you would need to make sure you insulate the pipework well to stop condensation.1 point

-

We have an MVHR unit that includes an air-to-air heat pump, so can heat and cool. We never use it for heating, but as I'm sitting here typing this, with an outside air temperature of 25.6 deg C, the MVHR outlets are feeding nice cool air at around 12 deg C into the house. It isn't powerful enough to cool the house down if it has been allowed to get too hot, but is quite effective at maintaining a comfortable temperature. The most effective way of cooling the house is the under floor cooling system, run from the ASHP that can also heat the floor in winter. That's not running right now, as it's set to come on if the house gets above 22.5 deg C, but when it does, we find that cooling the floor is more powerful at reducing the house temperature than the MVHR. Summer bypass is not very effective during the day here, but does provide cooling at night, when the outside temperature drops below room temperature. However, we are in a sheltered location, with the house set in a cutting in a south-facing slope, and that does mean we have higher than average outside air temperatures. BTW, there is no problem with condensation in the ducts, as they will always be well above dew point. There is a lot of condensation in the MVHR unit when the cooling is on, with a constant trickle of condensate running out of the drain pipe.1 point

-

0 points

-

Have to agree with Jack on this one. The guy that we waited a year for - as he was so highly recommended by our neighbours - was an absolute sh*t show. Most of the work he did needed to be redone after I'd paid him almost 7k.0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)