Leaderboard

Popular Content

Showing content with the highest reputation on 10/23/23 in all areas

-

Buy the very cheapest pre made off the shelf softwood staircase from someone like Howdens, and regard it as temporary. Fit proper stairs later.3 points

-

+1 to the above, I had put a temp staircase in made from scaff planks and only put the oak/wrought iron one after plastering.2 points

-

I think your missing the point a bit, buy the howdens staircase, build a plywood box to fit under it to get your height, then put it on Facebook at the end and get £100 back for it. If you need winders just build them out of ply and chuck it on the bonfire in a years time.2 points

-

Good morning, im in central scotland and i have managed to get planning passed on 1 3/4 storey 5 bed house 180m2, and now have a guy working on doing the building warrant and engineers to come and look at the plot to dig test holes to asses foundation type/draw up drainage plans, im guessing all this could take around 4 months? being the first time of doing such a thing does anyone suggest what would be the correct order in which to proceed with next steps? should i start getting quotes on groundworks, timberframe etc or i presume i need to wait on all the detailed engineered drawings for this step aswell as a self build mortgage application? ive been thinking about water and elec connections and have a good idea now on how to proceed with these i may get some builders quotes to undertake the full job but i think the budget may only allow for me to personall organise seperately a groundworks team for founds a timberframe supplier to supply/erect frame a roofer plasterer stone masonary for exterior cladding which is natural sandstone windows/doors etc and a klargester bio disk electricians, plumbers and joiner any suggestions on next steps while i wait for building warrant would be helpful thanks1 point

-

Also have a look at Keylite windows, easy to fit, have a built in expanding thermal collar, the quality looks on par with Velux1 point

-

Rookie mistake. I forgot that the verticals needed to be plumb on two axis, and the right hand side panel was leaning into the room by a couple of mill. Jacked that up and Bob’s your uncle!1 point

-

I used HB2 kerbstones laid on their edge. They have a natural fall on them and I will set the doors to the top of this gradient. I finished the concrete to the inside edge of the kerbstone having turned the DPM vertically up the upstanding and cut it about 10 mm below the top of the concrete.1 point

-

1 point

-

with the government pushing hard to decarbonise house building, sorting the concrete would be a massive step. https://www.popularmechanics.com/science/green-tech/a40785162/microalgae-carbon-neutral-cement/1 point

-

Velux here. My understanding is they can’t fit flush and need a minimum upstand. If they were flush wouldn’t rain run down the roof and across the window? Ours are opening and fiited on a standing seam roof so it might be different for fixed rooflights on a different roof. Ours are fitted direct to the roof deck and the frame provides the upstand which is 90mm. There’s a flashing around it and another over this so the rain runs down and around the window.1 point

-

Why that much, isn't the financial risk basically the price of materials. If the supplier tries to insure is running costs as a risk, then they should not be in business, and they are probably already having trouble getting credit.1 point

-

Velux are the popular choice for a reason. They’re simple to fit and do the job! Just like Eclisse with pocket doors. Personally I wouldn’t use any other but I’m no expert and haven’t even finished my build yet. 😂1 point

-

No need for a union although why not have an organisation that represents self-builders? You just need a contract with clear stages, a contract administrator to sign off the stages and a lawyer to sit on the cash and to send it to the supplier when the stages have been signed off by the contract admin. I suspect that's what happens in grown-up construction projects anyway. The supplier may well book a proper sales increase (20% maybe?) by offering this facility and their competitors may lose out by the same amount. The customer can regard it as the insurance premium for guarding against the risk of the supplier going bust with their money. What's not to like? And, if you're a customer who likes to take risk, you can probably save yourself 3.5%, send all the money up-front to the supplier and keep your fingers crossed. Otherwise everything stays the same unless someone decides to dig their heels in or convinces a sales manager that escrow is in their self-interest. I estimated 3.5% (see below) when we all discussed this before.1 point

-

It will probably depend on if your neighbour complains. Will it be higher than their ground level and will it increase overlooking / loss of privacy?1 point

-

No. I have been reading up on it. It is a complicated process, both the roaring (4 stages) and the hydration a multi stage process depending on type. The typical makeup of Portland cement is. Cement Compound Weight Percentage Chemical Formula Tricalcium silicate 50 % Ca3SiO5 or 3CaO.SiO2 Dicalcium silicate 25 % Ca2SiO4 or 2CaO.SiO2 Tricalcium aluminate 10 % Ca3Al2O6 or 3CaO .Al2O3 Tetracalcium aluminoferrite 10 % Ca4Al2Fe2O10 or 4CaO.Al2O3.Fe2O3 Gypsum 5 % CaSO4.2H2O It is all about calcification and hydroxides which cause the crystallization. The curing is very interesting as time is important. Initially there is a rapid rise in temperature and the tricalcium silicate cures to give initial strength, then, over time, the dicalcium silicate comes into play and starts to cure, contributing to the final strength. While that is happening, some of the other compounds in it are reacting. As you know, concrete does not dry, it cures. The word drying should stopped being used in conjunction with cement products as it is misleading and causes misunderstanding of the processes (note plural). I grabbed the above from here, which is a long, but easy to follow description. http://matse1.matse.illinois.edu/concrete/prin.html You will see that energy units (kJ) appear often in the formula. That energy is what is doing the work of forcing molecules to bond. We often think that things getting hot is a nuisance, but in reality it is a vital part of the process. If you stop and think about it, a builder's labourer, who may have no experience in chemistry, should not really be allowed to mix up concrete, ever.1 point

-

Interesting but perhaps academic. 2 million acres of open ponds, in a warm climate. Thinks...that's...a lot of shallow, level, warm ground, and a lot of water. But if it takes that to cancel out the emissions, let's do double that and pile up the surplus lime. And hang on, my brain's not working properly and I'm sure I used to know this. Lime is roasted, using energy and forcing out CO2. When we hydrate it back to a hard lump, aren't we taking back carbon? Or is that just 50 years later when it is crushed and exposed to air? Anyway, my policy in design was always simple. Design well and use less stuff. Accept fly ash in the mix even if it isn't much cheaper. Don't overspecify the concrete mix. No waste allowed: have a ready use for excess concrete, offcuts etc. Half and faulty bricks collected and used. No skips on site...or they get filled with stuff you bought. In other words, what you would do if you were paying for it yourself , must be applied whatever the job size. If the whole construction industry did that..?1 point

-

Well apart from the edge losses, and radiation losses. Though they are generally quite small. You can calculate the dew point from the temperature, relative humidity and air pressure quite well. But for these purposes then this will do. https://www.calculator.net/dew-point-calculator.html I think it uses: Td = T - ((100 - RH)/5.) where Td is dew point temperature (in degrees Celsius), T is observed temperature (in degrees Celsius), and RH is relative humidity (in percent).1 point

-

Exactly, they seem to have a very good reputation from those I have spoken to. They are built to deal with the local environmental extremes!1 point

-

Hydrosplit is a made-up term for every monoblock that doesn't have a pump, just the heat exchanger and paired with an indoor unit that includes everything else, sometimes the nicely squared box DHW. But basically every monoblock with only the heat exchanger, it's a hydrosplit, as even if they don't sell a pairing indoor unit, you have to make it out of parts on the wall/cylinder. If you want the compressor inside, buy a water/water unit, and use any coils with water/glycol you find suitable(you can shape and put them where you want), with PVThermal as extra.1 point

-

It is an option if you can cut a straight enough slot. Where it meets the door or wall, you need mastic because the wind will blow water to the end.1 point

-

Yep it sits directly onto caberboard or screed. There is a lot of insulation between the floors but some noise does permeate down. Doesn't bother us as we have an unconventional layout.1 point

-

I would just foam them, think of all the energy you'll be saving! By the way whereabouts are you located? I lived on Lewis for about eight years so I know it fairly well.1 point

-

Burnt sand mastic is the traditional material for sealing around window and door frames into stonework.1 point

-

OK, here are my results based on my Dec-Oct actual OVO reading recorded by my Smart Meter: Dec was a funny month because of the Russian energy squeeze, a triple whammy: Russia; we were still on an old fixed tariff for the first few days, and the short term prices were in panic which OVO were better buffered from. We might get a similar pulse this year but we are on an OVO variable tariff and the markets are better prepared so I have decided to ignore this as a one-off glitch. (Note that the Oct figures are off since it is an extrapolation of the first 20 days, but the heating only started to come on on the 17th so this will rise slightly.) That aside, the Octopus Agile tariff gives overall lower monthly prices than OVO E7, but not hugely so. The main difference is during those May-Sep summer months where the usage profile is pretty flat and we get hit hard by the OVO peak rate. The Red bars are based on historic actuals as-is at the then Octopus Agile price. The Yellow ones are where I had a play with moving some of the time-shiftable load (CH, DHW, cold-fill washing) to cheaper time slots. This did seem to make a small but noticeable improvement, but not earth-shattering. My time shifting algo was just a first cut, and more work is needed here. So all in all, it looks like we'll be shifting to the Octopus Agile tariff in the expectation of modest savings.1 point

-

Frankly I would argue that Condition 2 fails at least two of the 6 tests that conditions have to satisfy to be valid, if used to control the gym. These tests are: Necessary, Relevant to planning, Relevant to the development to be permitted, Enforceable, Precise, and , Reasonable in all other respects. Is control of the use of the rooms within a dwelling "necessary" and is it "enforceable"? Why would it matter in planning terms if the gym space was used as an art room, a yoga space, a store room or a spare bedroom? Equally how would the planning authority find out what the space was used for and enforce the condition? Clearly the condition is unnecessary and unenforceable when used to control the internal use of rooms. For the planners to suggest they will not consider room uses because they have been "fixed" by the condition is stretching things just a bit too far... Furthermore, Section 55 of the Town and Country Planning Act makes it quite clear that works affecting the interior of a building do not constitute development for the purposes of the Act. That condition cannot be used to prevent future internal alterations especially if not relevant to the original approval. However, AliG sums up the situation for you in their last post. That gym window was always at risk being so close to the boundary and the upper rooms have double aspect windows. It may be a lost cause I'm afraid.1 point

-

Could have done with one of those , 10 yrs ago ……. 🙄🫤😂1 point

-

Cheap as chips and versatile https://www.ebay.co.uk/itm/404480199430?var=0&mkevt=1&mkcid=1&mkrid=710-53481-19255-0&campid=5338268676&toolid=10044&customid=EAIaIQobChMIv73AkYGMggMVDNntCh06BwMqEAQYCSABEgJViPD_BwE1 point

-

You will be surprised at how much more productive you will be with a staircase compared with a ladder. Tradespeople, if you are using them, will love you.1 point

-

Welp, storm babet has been and gone and it's all still standing.We got winds of ~50mph and plenty of rain, but it wasn't particularly noticeable in the garden - it really is sheltered. Got to four bales high on the bit I've been working on, drove those hazel spikes in, then got it all tarped up. Once the storm passed, I got the uprights for the window in, and (no pic of this) got the first bale down between them. Lots of notching. Managed to pick up an alligator saw cheaply, which is helping a lot with that part. Plan now is to get the rest of the walls up to four high and staked; get the windows in; then build the wallplate while the top of the wall is still fairly accessible. Ideally you do it while the floor plate is still accessible so you can use it as a template, but I was pretty tired of wood at that point ^^. I've got the dimensions written down somewhere. Once that's ready, I can haul up the bales for the final two courses; wallplate on; compress; build the roof; re-compress; build the floor. Then in spring, lime render inside and out. Pics - two before the storm, one after: The gap in the fourth course on the west side is *hopefully* going to turn into my bubble window, with a lot of shaping. I expect it'll be porthole-sized by the time I'm done.1 point

-

Agreed. Well worth it. Fix your own timber handrails to the sides and the open edge.1 point

-

In many cases it was once our money, being spent by corporations (banks, universities, public buildings) on a monument to themselves.1 point

-

1 point

-

I agree with you there. As a cheap work around, why don't designers project an image of their proposal onto a screen at the back of the plot. I know virtual reality is meant to do with, but it is still very artificial and depends on the accuracy of the initial plot survey.1 point

-

+1 - fit your lovely staircase as late as possible. In the US they often build a construction staircase that then gets covered with proper treads and risers etc. but don't seem to see that too often here. I built my construction staircases using plywood for stringers, osb offcuts for the risers and reclaimed timber for the treads. Cheap as chips. It has also been useful as we've been able to real world test the stair angle and riser/tread relationship to decide on a different angle slope for the proper staircase I'll be making shortly.1 point

-

Look at your current energy bills to see what kind of consumption you have. That’s a good starting point1 point

-

The best bit of buying your own digger is it is there, all the time. I had mine about 3 years, not only did it get used for all the digging tasks, foundations, drainage, treatment plant, landscaping, it was damned handy having it there to be used any time you wanted it. Often it would just get 5 minutes work to move something, you can't hire a digger in for that.1 point

-

So back to square one. Realised I am actually putting more electric into the garden room than the house, with direct heating. Garden room direct electric and house via heat pump. So have decided to sacrifice a little CoP and increase flow temp. To make this achievable, the house output needs to be reduced quite a bit, so flow rates have been set with a much bigger dT to compensate. Have programmed a different WC curve into ASHP and will monitor and adjust as required. Tonight we are getting down to zero degrees, so a decent test.1 point

-

Has nobody mentioned making a jig? You want to drill 2 holes in the shelf, and 2 holes in the wall, exactly the same distance apart and level. So take one bit of scrap wood, at least as long as the distance between the to holes plus a bit. Mark the holes on that bit of wood and drill a hole the size you want. Making sure the marking is accurate, and before starting to drill the hole make a centrepunch mark, ideally with a centrepunch failing that a nail, hold the point exactly on your pencil park then hit it gently with a hammer to make a dent to stop the drill wandering. Then use the jig to drill the holes in the shelf and the holes in the wall, getting an assistant to hold the jog dead level on the wall before drilling.1 point

-

There was a case of wire across the cycle path in Milton Keynes about a decade ago. Think there was a Sherlock Holmes story about it as well "The Ordinary Bicycle".1 point

-

Yup SketchUp, it's an old version on my PC. I would think a big coil is important but I'm not an expert. There is something to be said for buying as close to a standard product as possible future replacement etc.1 point

-

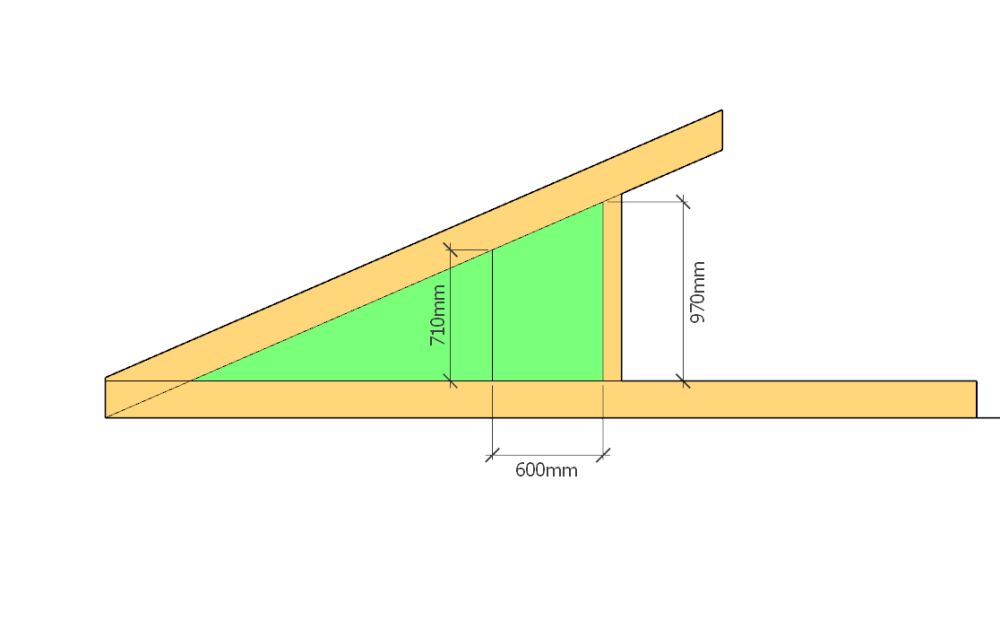

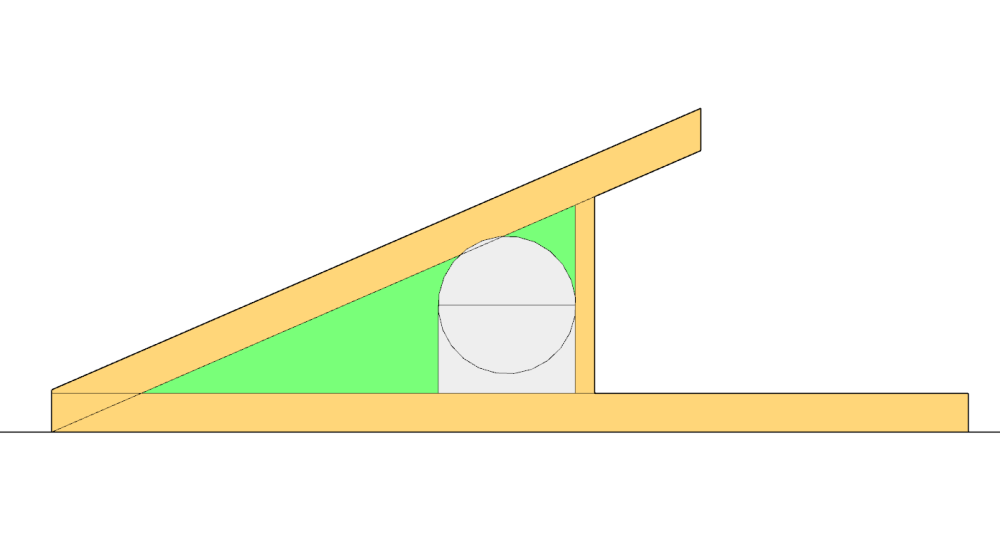

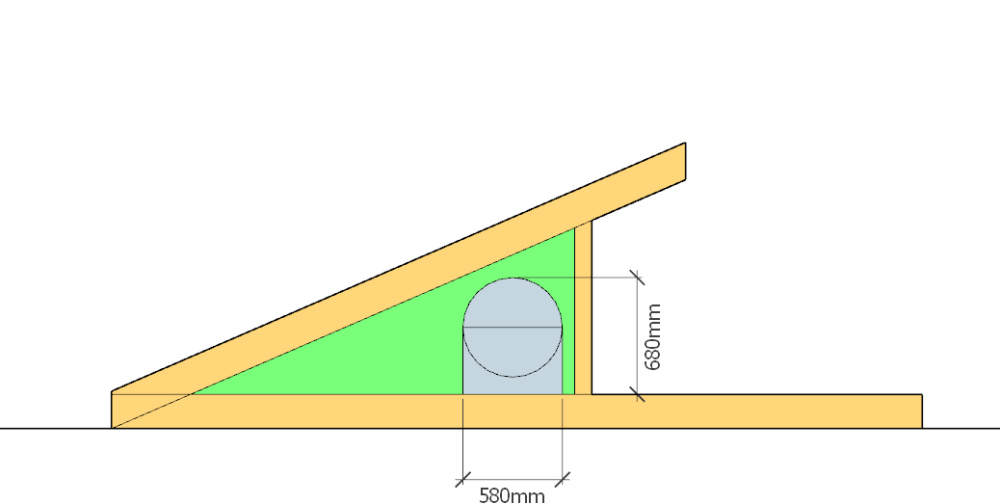

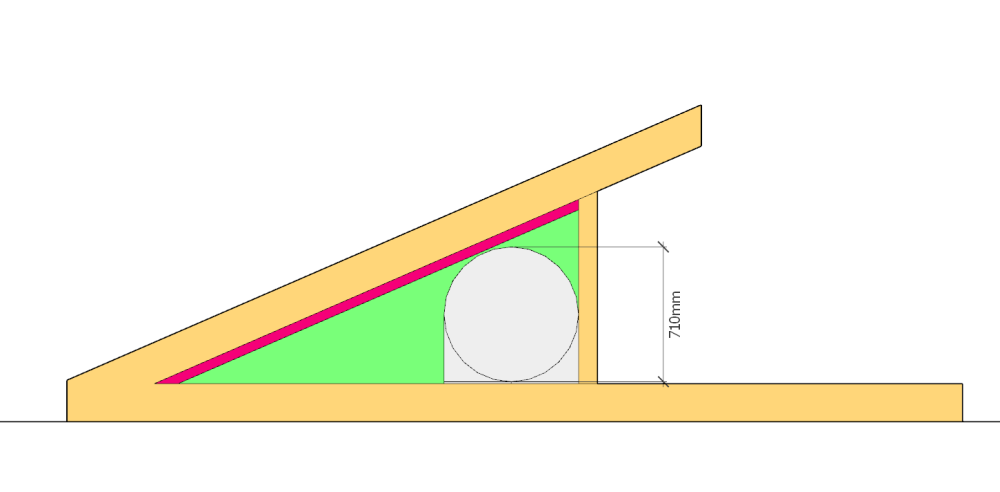

I think this is what you mean? Telfords Biggest Cylinder (400l/500l) doesn't fit The larger cylinder even with the lower cradle would be fantastically tight if you did want any insulation above it. Their Standard 300l and below will be fine, even with the PIR below the rafters. You may need the immersion relocated/lower cradle as it will be a pain to remove otherwise. No need to stop at 50mm insulation on the underside of the rafters then either.1 point

-

Take a look at Schiedel ICID system. The ‘distance from combustibles’, plinth, fireproof detailing through the roof and chimney height are important. Probably a BC / skilled installer thing and/or demonstrate you have ‘obeyed all the rules’.1 point

-

I had exactly this on my loft. Steels directly below purlin timber upright every x apart, boarded front and back with osb. When widening the distance between the uprights the timbers were to be doubled either side with a caveat of no opening to be larger than x times 2. As for insulating I did it the hard way; the void was formed using the triangulation timbers at the eaves as the back wall- just enough vertical after insulation to put a skirting on- Stapled breathable membrane on the timbers fully filled gaps with wool, encased in pb and plastered insides. It's awfully awfull to do Plastering laid on your side in a trangular coffin. If your going to do it this way, do the awkward work in the eaves before before you make the purlin wall up. If you want to leave the void as a Cold space then just insulate the walls and any doors and use a good seal on the opening edges.1 point

-

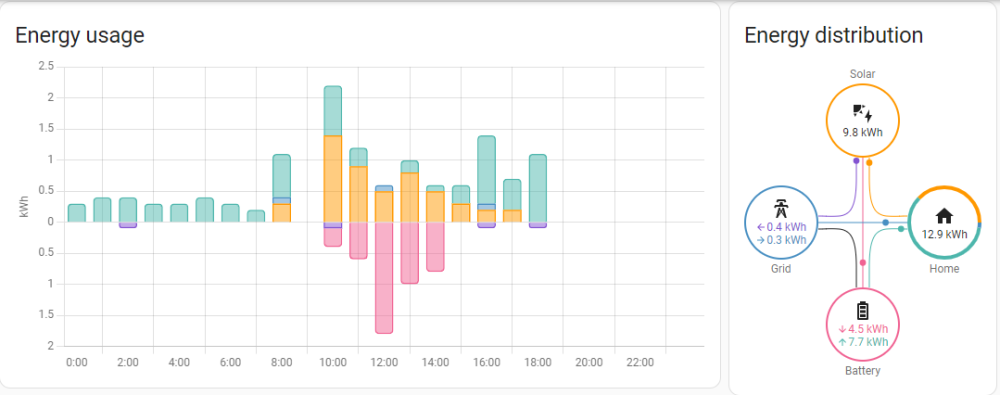

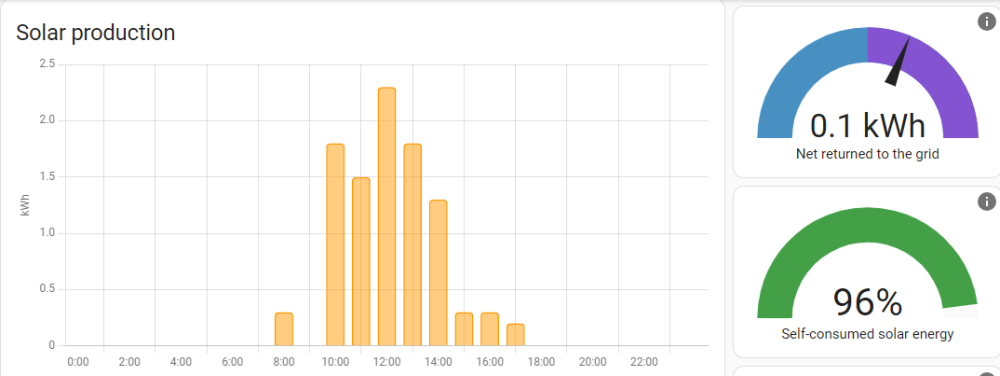

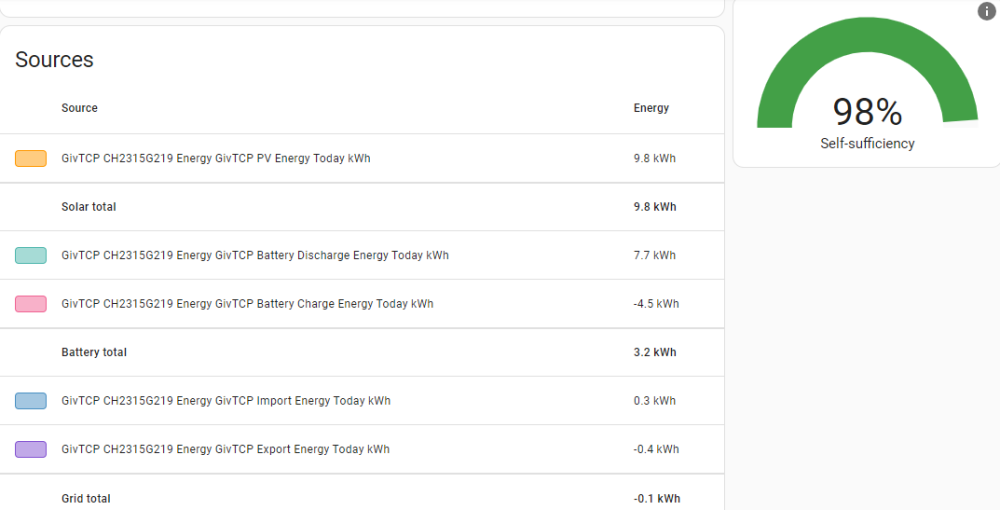

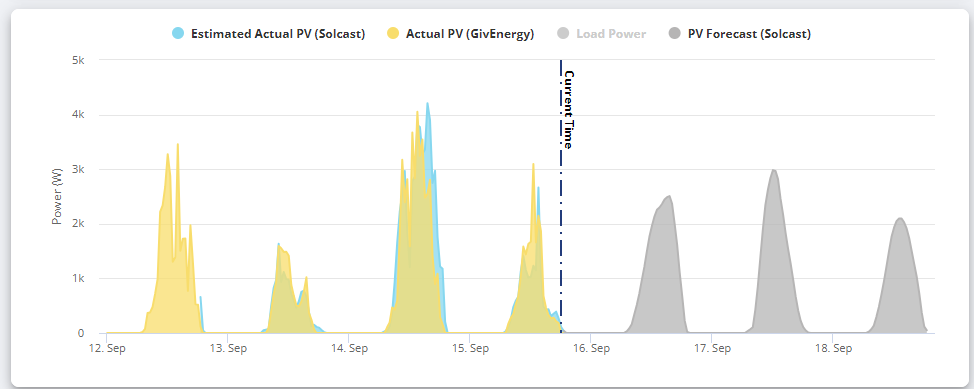

So a small update and stats Have now added the battery inverter to home assistant. The main reason that I got home assistant was to automate the charging on cheap rate, but only charge by the amount required, based on how much PV generation is likely the next day. GivTCP is the app running on Home Assistant, this connects to GivEnergy Inverter via an API, it also looks up the solar forecast from Solcast - another API. Dont get E7 for a couple of weeks, so running generated solar only. Have updated the Home assistant energy page, which looks like this, this is todays stats On the GivEnergy Cloud, there is the same data, but the forecast data is also represented. Fine tuning the Solcast page for my array you make small changes to angle and direction to fine tune the forecast compared to actual, but its not too bad from the looks of it.1 point

-

A wick, or capillary action to use the right term, will work regardless of orientation and does not care if it is inside a tube or on the outside of a filament. It is electrostatic forces at work.1 point

-

You are about as likely to get talked out of buying a digger here, as you are being talked out of self building a house.0 points

-

0 points

-

Possibly, as long as it does not clash with anything else in my busy schedule.0 points

.png.2b7580ae43f02800eee1529158aa7c20.png)