Leaderboard

Popular Content

Showing content with the highest reputation on 12/29/22 in all areas

-

All painted up and plumbed in. Really pleased with the way the rounded corners turned out. You keep wanting to stroke them. I used two coats of Rust-oleum kitchen cabinet paint (which went on well with a brush) over Zinsser primer. Knobs off Amazon. Room still looks a bit bare but will get a mirror, towel rail, shaver socket etc after the shower is done.6 points

-

First go at assembling it. Not all glued up yet. It still needs taking apart, sanding, priming and painting before reassembly. This is the first thing I've made by trusting the CAD dimensions. Normally I would cut part A and then cut part B to fit part A. This time I pretty much cut everything to the dimensions extracted from the CAD and crossed my fingers. Working OK so far. Mostly water resistant MDF so will need sealing well and a good paint job. The rounded corners were made by cutting a 75mm Diameter Poplar cylinder/dowel into four bits lengthwise. The top drawer is fake. The lower doors have soft close Blum hinges. .3 points

-

https://www.theheatpumpwarehouse.co.uk/shop/heat-pumps/air-source-heat-pumps/5-kw-panasonic-aquarea-high-performance-mono‑bloc-j-generation-1-phase-r32-wh-mdc05j3e5/ Change of £2500 with a controller, weather-comp built in etc. Super quiet, and an all inclusive mono block. Cracking bit of kit for the money, I’m very impressed with the ones I’ve installed to date. I’d install this plus a HP UVC now, as you’ll defo regret it in 5-10 years eg after it’s too late to recover the spent ( ever rising in price ) electricity. I used to be a fan of an all electric ( non-HP ) PH, but after seeing how ( exceptionally ) well these units perform and the unarguable CoP values…..not any more. No ma’am. Add slab cooling as a residual ( free ) bonus, and it’s a zero brainer. Introduce an EV and attempt to charge that during daytime pockets of ‘excess’, and then you’ll be saying a very long “goodbye” to every ounce of excess previously earmarked for “other diversion”. That means either the majority of your DHW comes from the grid, or, you opt to charge the EV to near full overnight, and only use it to capture any excess during the day by tethering routinely and filling the remaining ‘gap’ you’ve purposefully left. Unless retired that’s a little impractical in honesty. PV into a HP as a multiplier is the logical path, giving up to 3x the revenue per kWp of roof space. Turns a 4kWp array into a 12kWp equivalent. Couple this with; both heating an oversized UVC and charging the slab from cheap rate EV tariff, and you’ll be sub 5p/kW for a huge chuck of the winter heating and DHW, where PV output will diminish to less than 25% of the net micro-generation. Measure twice, cut once 😉2 points

-

Hi, Thanks for looking. This is just a preamble to a barrage of questions regarding smart home electrics. Basically, I am trying to decide whether fully integrated smart home is for me. Here is my quick rundown of what I need, and how I see integration: - smoke alarms - this needs to be upgraded standalone system that is Grade C category LD1, so no way would it be integrated with anything smart. - CCTV - same as the above. I can't see it being part of the smart system. It will be just 4 external IP cams with POE and NVR recorder. Nothing fancy. Separate app controls, I would imagine. - TV - I initially thought HD Base T, but concluded that each of the TVs will just have Freeview, and a choice of a dongle(s) like Amazon Fire and Apple TV. We are not massive TV people, and this is all we need. - Sockets - nothing fancy obviously. and nothing else. - Internet - one router connected to OFNL + some hard wired wifi extenders around the house, hidden in ceilings, or storages. - AV Hub - there is only need for one. And that is in the Living Room. It will have a soundbar and a hardwired subwoofer. Or maybe some speakers in the furniture. Now, here is where my dilemmas start: - smart blinds - it would have been Somfy Tahoma with its own app. All set once and optionally shouted at via Alexa configured through IFTTT. If I choose Likes of Loxone, then I would need 11 x blinds motors @ around £200 + VAT each. I imagine I would need Relay extension. Can I control blinds up and down by a simple DC reverse, or would this be two channels per blind motor, and thus A LOOT of relay units? - smart heating - it could be Wunda Trade smart actuators, hub, and room stats. Or I could buy Loxone ones @ £79 + VAT each. I would need 14 ports. That is a lot of actuators, and equally even more relays and extensions... Am I right in saying the temperature control could be had by - MVHR - can I somehow integrate that? I have a Zehnder Q350 with ComfoPost12 coming. Can I send triggers from movement sensors in bathrooms via a relay in Loxone to switch on boost? Does Humidity sensor in the super expensive Loxone switches allow me to pick up a reading through DI / tree, and assign signal to a relay output if RHI goes above a certain figure? - around the house speakers - There would be 11 speakers around the house, and these could be seperate Sonos amps (I would buy used ones), or Loxone Miniserver + some stereo extensions, and of course speakers. - Lighting - The plan is to use non-smart lamps and spotlights, as well as 12/24V drivers for LED tapes. Loxone Tree switches (especially the Pure) look really sexy. But am I right in thinking that @ £234 + VAT I am essentially buying a single (1 gang) switch? What if I need a 3 gang? And slave units by the bed for his/ hers / spotlights / LED? That sounds like a lot of switches per room, right? And if I consider Faradite Tap-5, then that's 5 digital inputs per switch. Time that @ number of rooms, and I am starting to create a control room rather than DIN cupboard for all of the "hub" gubbins. Am I missing something here? Whilst I can swallow £3k for the blinds, £1500 for heating controls, and another £2k for audio, without even doing the proper maths I arrive at a whooping figure of about £10k for lighting alone, EXCLUDING light fittings. Am I being mad to even consider??? Help please? I am starting to arrive at a conclusion that perhaps individual "mini-smart" solutions are just as capable. Although, as clear from the above, I can't think of one solution that would be good for lighting and dimming. I guess I should have formed my subject question more to the tune of "is it worth spending sooo much money on this". I am not super intelligent when it comes to building electronics from scratch, but I can kind of see that I could almost write myself a list of algorithms that I would like certain things around the house to do automatically. No, I don't even know where to start with Raspberry PI... Thoughts please? 1st fix time as soon as mid Jan'23! Thanks! Bart1 point

-

Vauxhall vans are pretty rubbish Whilst i have a van Tipper trailer is more use on a self build1 point

-

But the exhaust vents to the outside and it is the exhaust that makes the most noise. I had an external oil boiler before I replaced it with a heat pump and my next-door neighbour still has one, although it's inside a little brick-built boiler house.1 point

-

You might be better off with a trailer. It would be cheaper and there's less risk of problems. I've been thinking about getting an 8ft twin axle one with a load capacity of about 2 t.1 point

-

Lots of fun and incredibly useful. I would get it professionally cleaned if I were you, never know what’s on those seats.1 point

-

They both look a reasonable choice. I bought a Transit Connect for £2K for the duration of the build. Turned out to be more like 3 years than the one year I envisaged, but ideal (if you're hands-on) for stuff you can't or don't want to put in a car. If I was buying again, roof bars and a tow bar would be on the wish list.1 point

-

... and learned. Someone 'freezing' when the soft and smelly hits the fan somehow is a very interesting reaction to observe. I've seen it described as 'Cognitive Overload' And seen family members 'freeze' when they were younger: arm through a window pane, seeing my thumb hanging on by a thread (passed out) .... seeing my first (of 6) ICF bursts ... By the third, I was totally prepared Preparing for 'normal' accidents to happen (as @Gus Potter above does) is a trick I've had to learn the hard way. It's the first one of the series of disasters that always gets me. Never fails.1 point

-

We live in a quiet road so the background is around 35dBA max. 10 dB below this is unachievable. Essentially the requirement as specified by the LPA is (I suspect unwittingly) a refusal dressed up as a consent. MCS (ie permitted development) is effectively (close to) 2-3dB below an assumed background of 40dB. The MCS standard is, unlike the condition specified by my LPA, both deterministic and achievable.1 point

-

If you google the code you gave above you might (after a couple of jumps) find the same number as me for that product: that is 7.35 kW. Max for a UK plug is about 3kW, and actually 3kW often doesn't work too well if either the plug or socket isn't high very quality - you can get arcing and heat. In principle you could do it and expect the 13A fuse in the plug to blow if you used more than one ring/zone. But I wouldn't. I'm sure a qualified electrician will be along in a jiffy, but the 'right way' of doing it would be a dedicated circuit to the consumer unit on say 20A or 32A wiring / breaker and out to a proper cooker-rated switched spur with the hob directly wired in. Or just buy yourself a single/double zone hob less than 3kW.1 point

-

Most induction hobs are 7.5kW / 32A, way over the rating of a 3 pin plug and normal circuits. It needs a dedicated supply off it’s own fuse/breaker.1 point

-

I have put in lots of these fans. The Icon 30 gives a stronger extract but needs a larger hole cut. I like the delayed start module so the fan does not come on for short visits. I bought 35 from someone on ebay https://www.ebay.co.uk/str/stc120pinner and contacted him directly for a price.1 point

-

1 point

-

There is a recognised construction of osb over the trusses, then vapour barrier, then battens then the metal. That is from Cladco, ready coloured 'slate grey', but there are many suppliers. Then yes, screwed to the battens. It will all be discussed on BH already, I'd think.1 point

-

Indeed, the fact it runs on 230v doesn’t say how much power it uses1 point

-

Probably not. Induction hobs are usually high power. Are there any other rating plates or other info, even a make and model number.1 point

-

So when you've finished with the basement captives is it straight into a bath of hydrofluoric acid?1 point

-

Change the cloakroom extractor for an icon fan https://www.airflow.com/products/icon-range That has a mechanical shutter that closes when not in use. With one source of draught closes that might be enough.1 point

-

Great minds ... Jan thinks I am mad, but tolerates this one. We use maybe 100ltr in a typical bath and maybe 120 lr in a full one, but let's stick with the 100 figure. We have our baths reasonable hot, let's say 45°C; our rising main is currently at 7°C and bathroom ambient at 21°C so the Δt riser -> bath is 38°C and ambient -> bath 14 °C. By letting the bath cool to ambient we lose roughly 37% heat to the drain and 63% to space heating. The specific heat of water is ~ 4.2 kJ/kg/K so cranking the numbers, we have 4.2×100×24/3600 kWh = 2.8 kWh going into space heating and 1.6 kWh going down the plug hole. In our case we have a low energy house with electric resistive heating and 2.8 kWh is a non-trivial % of the daily heating requirement so this is definitely worth doing. Incidentally: We have SunAmps heated overnight for storage so this bath costs about 80p on our tariff of which 50p is offset against space heating, so the effective cost is 30p (plus the 0.1m³ water). We have a double bath and use this feature (though usually serially these days 😉) so the cost per person is 15p. We have softened water, so bathing generates very little scum and the bath is easy to wipe clean, even if the water is at room temp.1 point

-

1 point

-

1 point

-

Top tip. When you have finished using the bath, don't empty it until the water until it has cooled to room temperature.1 point

-

Spraying 30mm of foam will defo help keep the bath warmer for a bit longer, and leave access for plumbing ( with some strategic foaming / cutting out ). Certainly won’t hurt that’s for sure!!1 point

-

1 point

-

1 point

-

That is where the VCL usually is. I don't actually think having a VCL in the right place, and then a final vapour proof covering attached will give any problems, as long as there are no leaks.1 point

-

Have you got someone that can do a drone survey for you?1 point

-

It keeps the water vapour that is generated/exists inside the house on the warm side of the insulation so as not to risk forming condensation on the cold inside face of the roof covering (and any other part of the roof construction that sits on the cold side).1 point

-

The term Vapour Control Later is a bit misleading. All it is, is a barrier to water vapour. So is imperious both ways. The concept is that the inside of the building (in UK) is warmer and has more water, by density, than the external air. By stopping the flow of this warmer, wetter, air from passing though to the colder, insulated cavity, there is less risk of dew forming. This reduces the chance of mould forming and causing problems. As you have a GRP roof covering, which is a good vapour barrier, in the outside, is there any ventilation space below?1 point

-

1 point

-

I stuffed a load of PIR off-cuts in the void under and around the bath before I boxed it in. No idea if it has any benefit though, other than saving a trip to the tip...1 point

-

Nope and no idea. You could experiment with a metal cooking dish. Fill with hot water and measure the temp every five minutes over an hour. Then do the same after adding a layer of foam to the bottom of it.1 point

-

S Plan or Y Plan setup .? Most likely the 3 pumps are back syphoning through the coil in the cylinder due to a valve letting by. Non return valve (flap type) would stop it in the flow to the cylinder.1 point

-

1 point

-

You mentioned regular visitors in you original post. Is that paid for guests if so are you claiming cost of electricity as a business expense. The pay back on a battery for us was calculated at 13 years so really not worth it, but we can use a lot of what we generate as we can send some to another business building, on the third phase. You might want to consider a 3 phase inverter that would allow the battery addition at a later date (add battery on solar side before inverter so as to limit losses) when they hopefully get cheaper. it also depends on your build time as the longer you take to finish the more you might be able to judge your usage and claim back the VAT of the battery just before sign off.1 point

-

im in central Scotland, rural area, the house is quite visible from the main road which was an issue in the previous application which was 2 storey and all white render, with lowering ridge height in this design and some stone cladding i was hoping to reduce the visual impact. Bad luck not getting to use the ubiquitous white. But this gives you more scope for individuality. i just googled barn conversions central Scotland.. plenty ideas there.1 point

-

Barn style isn’t more expensive, no. Stone is more expensive than brick obviously. You could mix. When I do a barn, I concentrate on the detailing. Open eves, half hipped roof, stone on the main with a cladding extension, a nice feature brick pattern to break up the elevation. Barn windows are usually one big one (that used to be the barn door), big vaulted spaces, maybe a fireplace with some feature beams. I love an open gallery so you can really appreciate your space. I probably could not give you an example without knowing your area’s style and site shape.1 point

-

Thanks, will contact them for a quote. It's my idea of a door... Long story short, I could have a solidoor for £3k. But this one is a loooovely pivot door from UrbanFront, made in black oak with irregular grooves to perfectly complement my charred timber cladding all around. Oh, it also comes with finger print thing which I might ditch, and a £2k handle (just for the bloody handle!). Funnily enough, survey or installation NOT included...1 point

-

1 point

-

I can't see anything wrong with your calcs. I did something similar to this calc a few months ago for an existing property i.e. I have some reasonable energy usage stats. I came to these tentative conclusions (some or all of which might be nonsense) : + until Ofgem make the feed-in a proper % of the standard rate, selling the surplus is not worth the bother. + a HW diverter is a fairly simple way of using a lot of the extra generation. + you can always add the battery later if the cost/benefit is good. + even if you have good projected usage and generation stats, the sizing calcs are a bit iffy - there are just too many assumptions. The key assumption, of course, is electricity prices going forward - hopefully things will normalise a bit once the Ukraine war is concluded. But that implies the payback will be longer + ideally you could add single panels at a time to your model - until the incremental payback of the extra panel was longer than you could be bothered with. In my case (12 panels/6.5kWp is the max that will fit on this roof) I came up with these calcs: + but overall I decided that the panels themselves are fairly cheap and you might just as well fill the roof while you're about it (even if you don't use/install an inverter/battery to cope with max. panel output). That is, the fixed cost of installation is high enough that you only want to do it (that is, the bit on the roof) once (except that you might start with a smaller inverter / battery etc. if funds are tight). That might mean asking for something a bit more custom than the usual packages that get sold. You can probably change the electrics inside without much bother/cost later if needed. At least I can - since there's an easy / substantial / flexible attic space to use and easy to access. As I said - these conclusions might be nonsense , and they might be too specific to my particular situation for anyone else to draw any conclusions from.1 point

-

...and if you don't knock it down... I would use rigid wood-fibre, and get a WUFI (or similar) dynamic condensation risk analysis done first to inform the 'safe' depth you can use. Some say only 60-80mm, some say 100 OK in some circumstances, but bear in mind that, depending on the exg fabric the resultant U value will be worse than 0.3W/m2K, probably. Some would say use plastic ins (PIR nearly twice as good for a given thickness as some rigid WF) and just get the vapour control right. It is this bit - getting the VC layer right - which, while hardly rocket science, can often be done badly. Difficult for you to control from abroad! My stance on wood-fibre is that if it is designed to operate without a VCL that's one VCL not to get messed up. I have used it a lot, internally and externally. Is the pointing done in lime, by the way?1 point

-

I would steer clear of spray foam insulation. Mortgage companies and insurers are risk averse and scare stories have frightened them off.1 point

-

A friend of mine has done this. Sloping site and I think they can access a reduced height space under the patio for storage. Your concrete retaining wall looks good.1 point

-

1 point

-

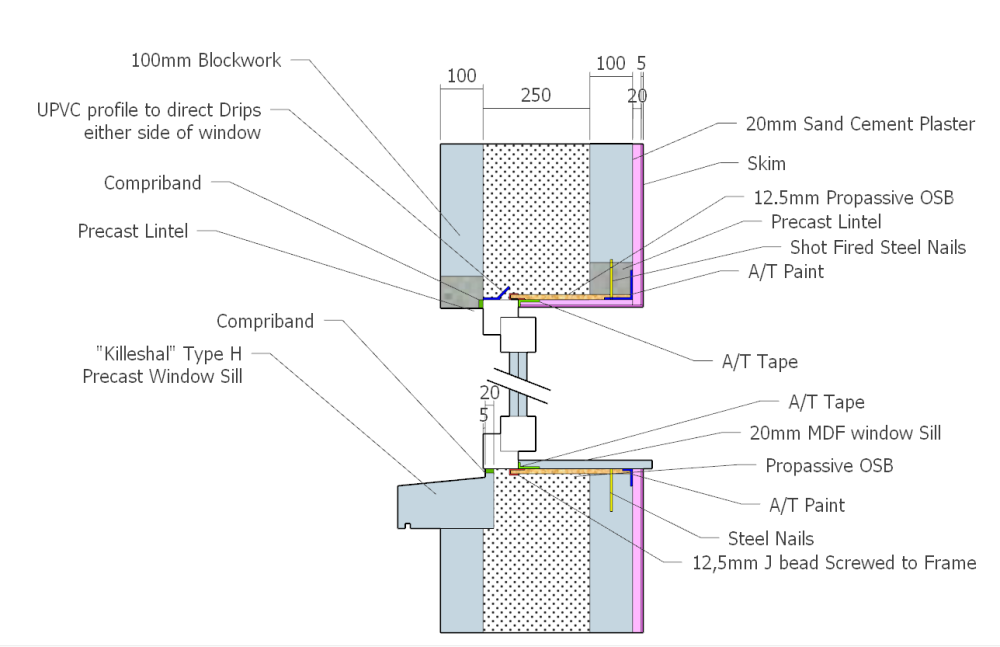

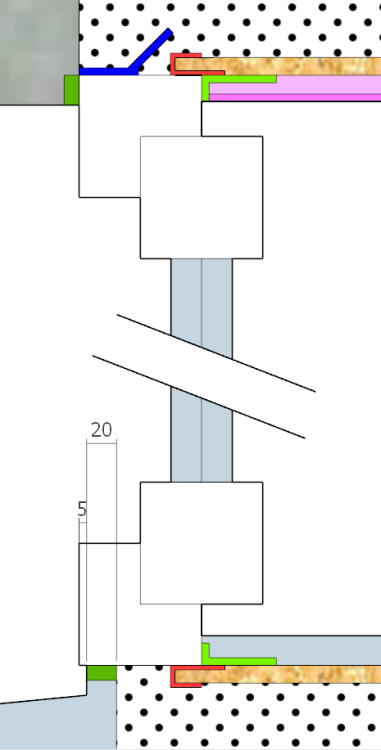

Improved UPVC window installation. I didn't bother drawing the horizontal section as most of the changes are the same. Points to Note 1. The useless cavity tray is gone. A small UPVC profile pre screwed to the frame will now direct any drips/condensation that run down the inside of the outer leaf sideways and harmlessly away. 2. Compriband is pre installed to the frames allowing tidy and quick expansion to seal the window to the outer blockwork at all sides. 3. 12.5mm J beads are screwed to all 4 sides of the window. This will allow an airtight 12.5mm OSB to be slotted in and then shot nailed to the inner leaf for speed. The block layer should leave the upper lintel maybe 30-50 mm higher than the outer one and packers can make up the difference. Similar story with the sill. 4. Pre install the A/T tape to the windows to all for very speedy taping later to the OSB. 5. The OSB to Block junction may be better dealt with with fleece A/T tape and plastered over. You would need a little time with the window frames before the fitters returned to pre install all the bits and bobs. Also cowboy window installers would be no good. The J beads should be screwed securely into the window frames, especially at the base. Some accuracy would be needed from the mason but not enormous. The windows would need to be accurately measured. No rocket science but everyone would need to understand. Its a no mess install, no expanding foam or A/T paint or silicone. Very quick to windtight and airtight. All materials readily available and pretty cheap. If only we could all build 100 houses. We'd get it right eventually! Next task, Incorporate external foam filled PVC electric roller shutters which I would very much like.1 point

-

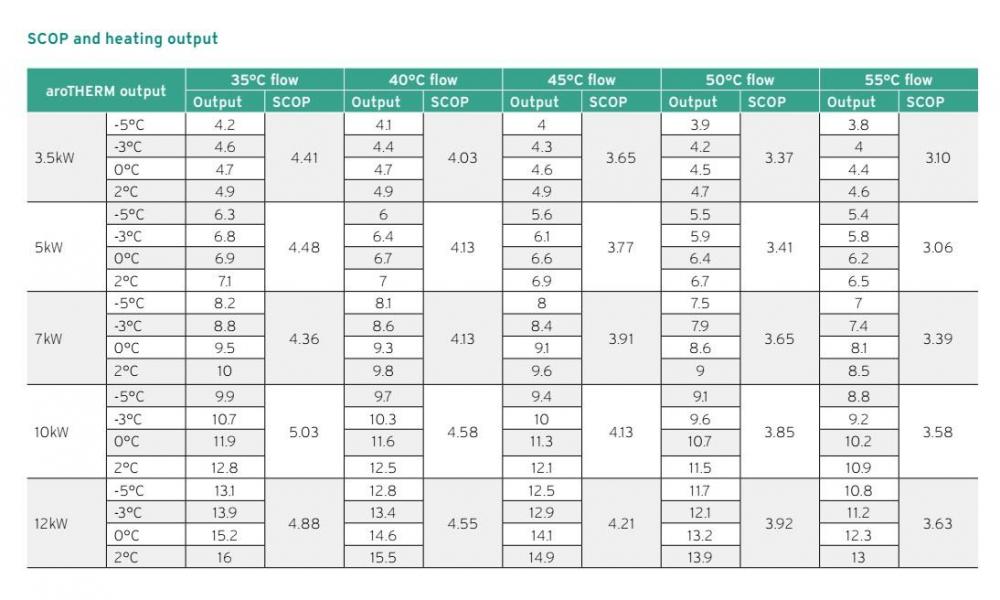

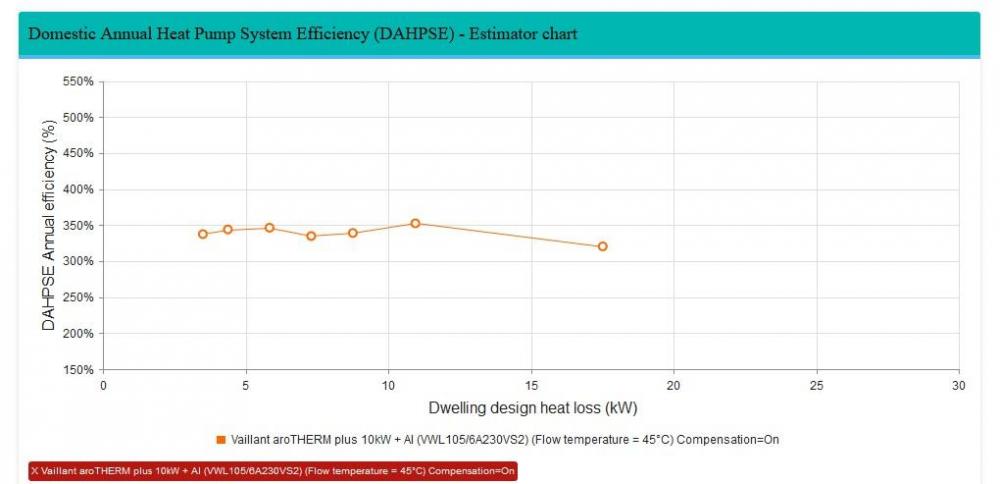

I would guess that you either choose the flow temperature for a constant temperature or there is an optional control system thaht uses either weather compensation or load measurement to adjust the flow temperature. I'd guess the F is for HW heating with a high flow temperature. If you scroll down on the page you linked to there is a more detailed spec to look at (although it's not detailed enough). There's an interesting BRE page which will estimate annual efficiency of a heat pump system. .https://www.bregroup.com/heatpumpefficiency/index.jsp It lets you select the heat pump, flow temp etc and shows a graph of the estimated COP.1 point

-

One key thing is to look carefully at the effect that getting wet has on any foam. For example, the thermal resistance of EPS is virtually unaffected by water absorption (it reduces by about 6% when wet), whereas the thermal resistance of XPS decreases a fair bit more (it reduces by about 45% or so when wet). I don't have the figures to hand for PIR or PUR foam, as I was only interested in seeing how EPS performed. The key thing seems to be to design the placement of the foam such that it isn't permanently sat in water, so that if the foam does get wet it can drain and dry out. XPS and PU foams seem to take much longer to dry out after getting wet than EPS. I believe that this may be because the interstitial spaces between the blown bubbles of EPS are inherently more porous than the very fine channels created when XPS is extruded. There's been a fair bit of testing done on various types of EPS, in order to establish how it performs long term when used underground, plus there's a few decades worth of practical knowledge gained from using the stuff to insulate basements for many years. Other products don't yet seem to have this level of collected knowledge, so it's hard to know how well they may perform in the longer term.1 point