Leaderboard

Popular Content

Showing content with the highest reputation on 11/08/22 in all areas

-

3 points

-

My guess would be that maybe some historical localised water ingress or leak has caused an area of rot and water staining. The 'rot' looks long gone and if everything is dry now, as above, patch it up and don't worry!2 points

-

Could it be DHCP lease expiry? I'll swear some of my stuff loses it's IP address every so often and takes a while to renegotiate. Similar experience to yours of stuff being unable to connect over the LAN while WAN unaffected. I seem to recall I could ping them on their IP address though which doesn't make sense.2 points

-

Definitely take some time to peruse supplier websites. Heck, get them to do a design for you that you can then reverse-engineer to understand the process...2 points

-

Part of that is the way future generations emissions are counted. Say you and a partner have two kids, and we each use 1 unit of energy. It is assumed that you inherit half the children's emissions and half their child's emissions. So that will be 3.5 units. But bonkers as it assumes nothing will change in 2 generations. But if you take yourself out the equation, you only save 1 unit. But your descendants are, under the current counting scheme, responsible for 2.5 units. So killing children is a better thing to do, not yourself.2 points

-

Cold ran down from Manifold, under the floor, then up at the point where the sink was going to be. Photos of stop cock and cold manifold. Plant room is in an upstairs loft section, so main water goes there also. Other photo you can see various white pipes coming up at the outside walls. Hot pipes are in the ceiling and drop down. Walls were all battened to form service gap the plasterboarded2 points

-

This, I think may be at the bottom of a lot of issues. I've had weird, bordering on hostile, reactions to fitting a heat pump. People convinced that I'll be freezing in winter and ripping it out next year, kind of like some reactions to Greggs doing vegan food the other year. On the other hand I've had an ASHP installer telling me that it will be roasting warm in the house and there's no way I should be even thinking about a things like a wood burner. Turns out both are talking shite.2 points

-

Your steel has a Web thickness of 8.9mm and at 90mm a HSS hole saw will do this easily. As @markc said, get a Starret one and use at low speed. Do not push too hard or you risk damaging the teeth and keep it straight. Get a can of aerosol cutting oil to make life easy. I reckon 5 mins per hole max.2 points

-

Not wanting to do your project for you, but point you in directions where you can research. You need to build an index of topics you need to cover to justify MVHR, steps to design, choices for the design and implementation, costs 'v' cost savings etc. You will need to know each circuit pressure drop, what noise suppression you need and MVHR unit size you would select, what features the unit will incorporate and if boost will be automated or manual, reasons why any cost and/or user implications. If automated on humidity, what downsides there are in a UK climate and high summer time humidity and how to overcome. If manual what is a user never boosts what impacts on the building fabric. Also look at the UK implications of low internal humidity resulting from MVHR in the winter. Is this an issue in the UK or is it more a cold climate thing. Look at the Passivhaus Institute, building regulations, for the country where your house is sited. There is also plenty of information on this site. You should also demonstrate how your flow rates compare to house volume and overall air changes per hour. Comparing building regs with something like Passivhaus guidelines. Advantage/diadvantages of various system configurations dMVHR, MVHR and hybrids between the two such as Fresh-R. Again look at costs, ease of implementation of new build and retrofit.2 points

-

Because its old, ie 9 inch walls, no dpc etc, under that is a geocell/foamed glass bed. The chaps doing the limecrete that went over it put it there. Part of their system. I then laid the water pipes before they came back and laid the floor. Compared to most of what goes on here, its a thermal catastrophe, but options were limited given the construction and the possibility of flooding.1 point

-

Yes there may have been a water leak from the old kitchen, that said it doesn't look like it has impacted on the floor joists structurally. With my SE hat on I need to say that screeds are heavy so you should check this out in terms of the main floor joists being able to carry the extra load from the screed. Have put this caveat in as have seen some floors that run off level by 75mm say on old tenement flats.. thus a 75mm thick levelling screed is going to add a fair weight! In terms of moving forward (SE view accepted) I would also put some noggings (dwangs) in under the weak spots in the floor boards with D4 expanding Pu glue to make sure you don't get a squeeky floor later on. What you are aiming to do is to just support the edges of the floor boards where they could rub together later on. Fifteen minutes work and less than a tenner to avoid that annoying squeek.1 point

-

1 point

-

If the floors not spongy don’t worry about it and get that ceiling repaired before he turns up 😇1 point

-

No because voltage drop would be 10v (assuming no other loads) and RGBW compact would only get 14v. This is why Loxone do the tree cable, but there would still be limit on how much lighting you could put on a single run of this. Yes, but this is close so you could almost certainly use 5-core 0.75mm for this, maybes less.1 point

-

1 point

-

Our electrician did all LED strips (some of them 5m+ long) back to the plant room in 0.75mm2 to start with! Only when I showed them my voltage drop caclulations did they agree to run 230v/DALI feeds to various locations to have the drivers more localized. So it is worth understanding the basics and checking whatever they do makes sense.1 point

-

Whats happened to youtube, I had to watch a 20 second ad to watch a 13 second video! Crazy!!1 point

-

I agree with you, I’ve had people trying to shame me for living in a fairly draughty old railway property, but compared to many I use very little gas or electricity because I’m usually at work.1 point

-

We don't have any children, have not been on an aeroplane for years and don't commute. We could probably heat the house by burning pandas and have less impact on the environment than someone who has kids. That's not to say I'm not going to do my best to reduce my impact further but I'm not going to beat myself up if I'm not knitting my own tofu.1 point

-

You could do what they show or staple. Use Pert-al-pert pipe as it is easy to form, straightens easily and bends well by hand.1 point

-

Well using gas directly is using 100% gas and using the electricity grid means using only 40% gas. And that will decline over the lifetime of the heat pump so you can call it maybe 25% gas. So that's 4x better. However, heat pumps use electricity 4x more efficiently (350% efficient) that burning gas directly (80-90% efficient). So 4x and 4x again and we're at 16x better. But we still need to factor in efficiency losses to generate the electricity so it's not really 16x better. But clearly a lot better.1 point

-

Used these too. Got them and tool from TLC https://www.tlc-direct.co.uk/Products/GPJC2C.html. Mostly 2-way, but did use 3-way in a few places for some reason.1 point

-

Where did your pipes run from manifold John, in floor or through ceiling?1 point

-

I'm no plumber, but I think your rising main is best coming up into the plant room, then run everything else internally in the ceiling, dropping down the wall to sinks etc as required.1 point

-

I know, I was being slightly facetious because as per usual the elephant in the room is being avoided - it's all about consumption. Yes and yes. I'm still completely bemused by the continued circular rhetoric. The problem isn't technology, it's the political, cultural, economic, social and behavioural systems we've constructed and they seem to have more inertia than anything else we've come across. I agree. I also knew a farmer who harvested a lot of heat by burying pipework within the mounds of manure - used to get a reliable 60C all year round coming out of those pipes.1 point

-

Siberian larch treated with Sioo-X sprayed and brushed in. There's a couple of details I'd do differently if doing it again. I've used lead flashing over the top of the windows, lapped up onder the cladding; a proper aluminium pressing would be better, like the ones you linked to. I did the cladding a couple of years before I got round to fitting cills, so fitted the cills between the cladding reveals. I should really have taken the reveals off and fitted over the top of the cill.1 point

-

Or how about starting with a refurbishment before going the whole hog? You will gain a lot of DIY skills whilst living in the house which you could use on your self build later if you get the bug?1 point

-

Yes say the average UK boiler is 75% efficient, using 16k kWh pa gas to supply 12k kWh pa heat. A modern ASHP will use 3k kWh pa, which takes around 4kWh pa of gas at the generating station. Currently the UK grid is using less than 50% gas so only 2k kWh pa on average. I grant you the overall grid demand will increase massively but there are plans (haha!) to increase that through installation of renewables and nuclear, and reduce fossil fuel still further.1 point

-

On my jobs, we retain a hard cold for human consumption at the kitchen sink, and another to use as the filling point for the heating system.1 point

-

What about this? https://www.pvccladding.com/aluminium-drip-profile-3mtr-anthracite-grey-p-XT-DWFP-AG/1 point

-

Given the height of the wall I would be wary of freestyling it. Better to get a structural engineers input IMO.1 point

-

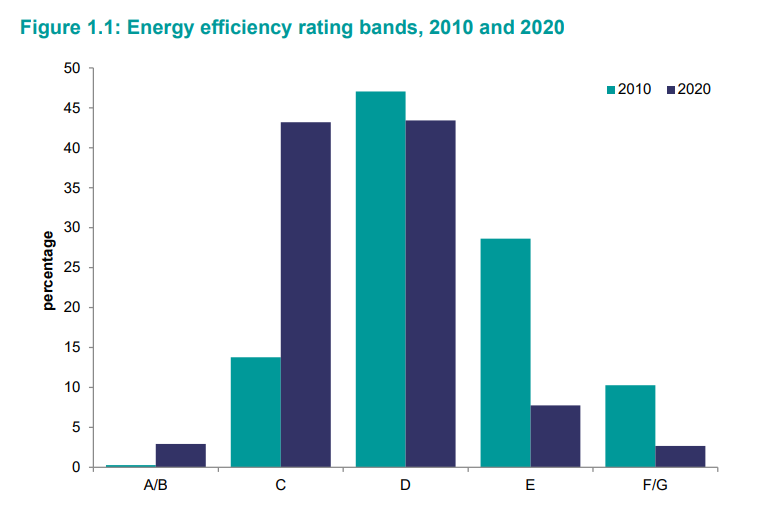

I think those claims are somewhat overegging it, and perhaps overstating the potential. But I think it depends what you are talking about reducing - presumably the heating cost on a totally uninsulated house? You won't achieve that when the traditional model for a trad house (eg as used by Energy Saving Trust) has 25% of heat losses via air leakage, and some more (10%?) via doors and windows which can't be insulated. If working on overall society-wide numbers we also need to remember that the average EPC number is already up at around 68, so we already have a big chunk of the low hanging fruit. This is the shift from 2010 to 2020. It becomes more difficult and far less cost-effective once your trad house gets to a C, and we will need to rely more on decarbonised energy supplies there. F1 point

-

HI. I installed my own GSHP and love it. Very cheap to run and reliable. Re trenches..... Yes best if pump is on the high side to prevent trapped air as pump runs slow. I went on a course provided by the supplier. Pretty basic but did give a few extra hints. I dug 4 x 50m trenches 1m wide. I was told the pipes must be 1m deep, no more as sun heat wont always get there and no less in case deep frost. I used 'as dug' sand below and above for protection. Half the price of building sand. The wetter the ground the better. Clay is good, chalk or sandy too dry. Gives better conductivity to replace lost heat. Used a 2 ton digger with driver. Took 4 days to dig, lay slinkys and refill. I have no extra heating such as log burners and house is warm enough even in deep winter. Avoid trenches near trees as they will cause shade from sun. Been running 6 years now. AS JohnMo suggested, I have a 200l buffer tank between pump and ufh and rads. Allows the pump to run longer but less frequently. My house a new build, well insulated 300m2+.1 point

-

I would recommend getting an engineer's advice. The overall wall height is 2.4m and is holding up your neighbour's land. The construction of the new wall has the potential to undermine the existing retaining wall so consideration of temporary works or staged construction will be needed. There's not enough detail on your plan but the reinforcement design will also need thought as there is the potential for some surcharge loading from the existing wall. Plus dealing hydrostatic pressure. Oh also, party wall agreement may be needed.1 point

-

Oh I was commenting on the above post. Vibro-stone columns are what he probably had. Both VSCs and CMCs are displacement piles so they improve the ground - so yes this would avoid the thermal bridging as once the ground is improved, you could build up treating the soil as a competent strata. Definitely worth getting that looked at as an option and may have come about in value engineering anyway. The thermal bridge itself was probably pretty minor. Or you could have switched to a structural raft with insulation laid on top (this would be my preference in poor ground - even with VSCs, put down a structural slab then insulate on top). A decent thick screed would make up a lot of the thermal mass otherwise lost.1 point

-

1 point

-

1 point

-

I built another shed for that as well. That was well used and I only had to train one individual on what a bog brush was and how it worked and it was all good from there.1 point

-

Vibro-stone columns? Often a good choice. CMCs are another option but fewer companies here have the rigs.1 point

-

Thanks looks like a creative solution. So the piles don't tie in directly with the concrete - just support it from below? Did you use a local contractor for the job? Or was it an MBC job? (Sorry haven't had a chance to dig through your blog etc yet).1 point

-

Did this exercise over a decade ago. I have virtually no parasitic loads now. Rather than look to power it renewably, is there anything that can be properly switched off i.e. printer. How about a bit of electronics that senses one half of a co dependant bit of equipment that turns on the other bit i.e TV and satellite box or sound system. As nice as it is to have everything instantaneously available all the time, a few seconds wait is not a killer. Was only 45 years ago we had to warm up the TV.1 point

-

No the biggest reduction would be remove yourself from the planet. But nobody talks about population growth.1 point

-

No the biggest reduction would be better insulated houses. Including your own. Also in your calculations you use the cost of a boiler as £2300, I paid £1000 for mine. Looking at Screwfix the prices vary from £500, upto about £2500, so you have chosen top end to suit your calculations. If you are looking to retrofit a HP the comparison is do nothing and keep gas (then only gas consumption is included), or replace like with like then a similar gas boiler would be chosen. Or replace gas with a HP, life style choice, most in this country cannot afford.1 point

-

I think the term you’re looking for here is greenwashing as those statements are neither linked nor relevant. A boiler also has all these things… and therefore this can be discounted. You ignore end of life recycling in this instance though, and I would also be concerned about the question and quotes on leakage from transmission systems as they are random statements. If you want to make comparisons then they need to be whole life and not just bits you have the data for to illustrate a particular view.1 point

-

It is just a shame that a heat pumps running costs are so much higher than an efficient gas boiler It would also be nice if the power run a HP was greener1 point

-

Don’t underestimate the cost We settled on an arts and crafts design for the roof While they do look nice and will st your build apart from others Our trusses and loose rafters will cost around 12k Another thousand on lead 13 K on slates Laboure would cost a fortune I’ve been on it two weeks and I’m no where near finished I spent two days cutting birds mouths into the trusses prior to the crane arriving1 point

-

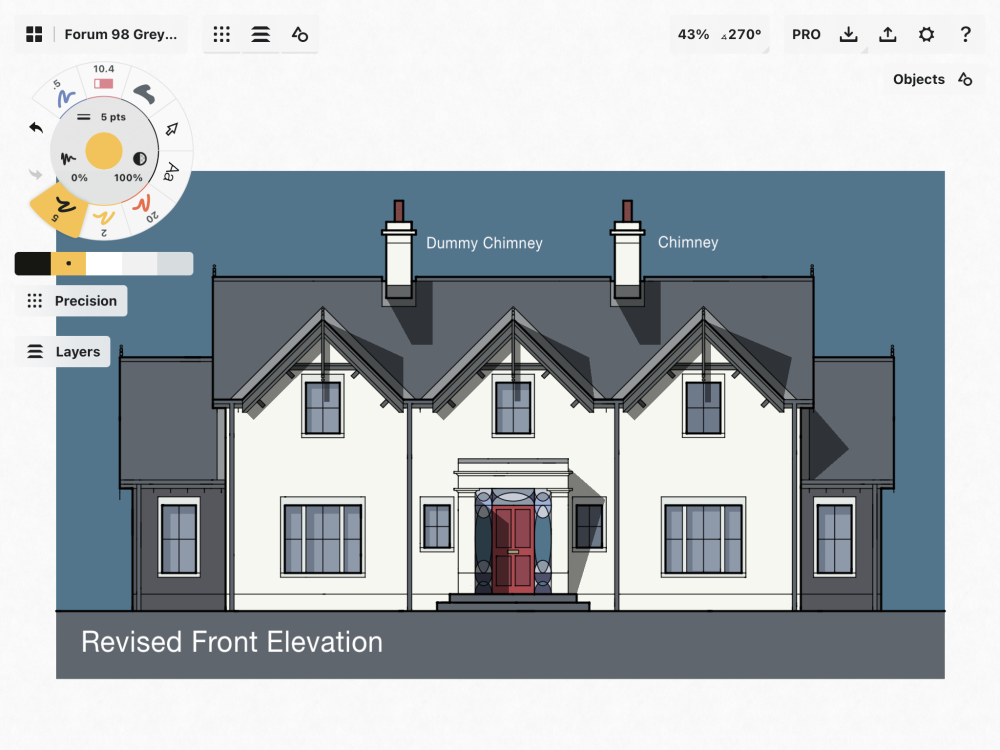

My first thought is do you really want a house that big? Not only is it big, but has some awkward shapes and is not "optimum" design in terms of build cost per square metre. If the planners want 1.5 storey / room in roof, then there is not much choice other than dormers, but I do much prefer dormers like the house you pictured above where the dormer roof slopes down to the main roof without those horrible vertical side cheeks that most people fit to dormers that are awkward to build and hard to detail insulation properly. Or what we opted for was big "gable end" dormers like above the garage on your picture above. Detail that with a roof hung from a big ridge beam, and you can pretty much get the whole of the upstairs space unencumbered by trusses etc and make good use of the space and have vaulted ceilings right up to the ridge.1 point

-

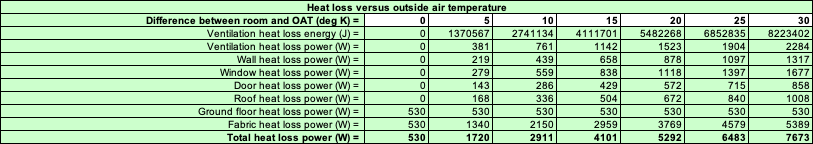

this is an interesting thread for me as we're finalising our ASHP size and have a few options! I'll start with a bit of background. we have a basement, ground and 3 bedrooms on the first floor. at the moment the plan is to only heat the ground floor using wet UFH. the FF will have electric UFH and towel radiators in the en-suites and we have decided to use split/ducted AC units for cooling on the FF so can use that for supplementary heating if required. our M&E guys have worked out that we should have a 11kW ASHP but that is based on all 3 floors having heating requirements. here's my output from @Jeremy Harris's spreadsheet: that is based on 1 ACH which is the most I'm hoping for so, fingers crossed, the actual figures will be less. So I can see from that output that 6kW ASHP is too little and an 8.5kW ASHP might be pushing it a bit in the coldest days and I can understand why they suggested a 11kW unit. But, after further discussions with them and with the fact that only the GF will be wet UFH they have said that my heating requirements for the GF is only 3.6kW and so we could potentially only require a 6kW unit. Although, as we've no idea how the house will actually perform and we may need heating in the basement I'm a bit concerned that the 6kW unit doesn't give us any potential expansion if we need it in the future. As such, I am thinking of simply going for the 8.5kW Ecodan unit. seems to be the sweet spot and will easily cope with our initial demands but also gives us a 'buffer' should our heating requirements change over the years. From a cost perspective there's approx £500 difference between each unit. What are other's thoughts on our situation and which heat pump size would you recommend?1 point

-

So my saga of a search for the right toilet frame and flush plate has almost come to a close. I'm most likely going to go for: Grohe Rapid SL frames bought here in the UK and order flush plates from Europe (as was suggested by @Temp on this thread) One that that surprised me though is that the same product appears to have drastically different warranty period depending on where bought from. The 1.13m SL Rapid frame and cistern comes with a 12 month warranty, or a 5 year warranty, or a 10 year warranty. Contrast this builderdepot product listing versus this victorianplumbing one. Can anyone explain this? Is the customer really being asked to choose to spend more to get the 10 year warranty, or is this just a mistake on the builderdepot site?1 point