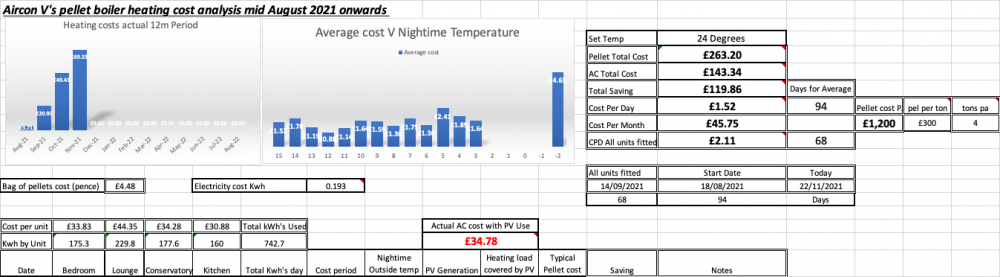

Leaderboard

Popular Content

Showing content with the highest reputation on 11/22/21 in all areas

-

That explanation avoids one key issue: everyone has a slightly different learning style or - better put - set of leaning styles . Thank God. One person's '... shorter, easier to say and more correct ... ' is White Noise to others. As is - to a non-chippy - a bird's mouth , or - to a non-plumber - a half inch iron, or MoT1 to anyone who hasn't had to bother laying a foundation. And as for Thermal Mass...... Science needs to learn to communicate its content better to the general public. Thank God some people realised that some time ago4 points

-

Haha, I seem to remember a pic with more bullet holes than a Die Hard movie3 points

-

I agree. Think of it as you have "reversed" the position of the hot bit and the cold bit, not reversed the physics that operates it, then it makes sense to most people. And most people understand you put the hot bit inside the house and the cold bit goes outside the house. Then it does heat the house.3 points

-

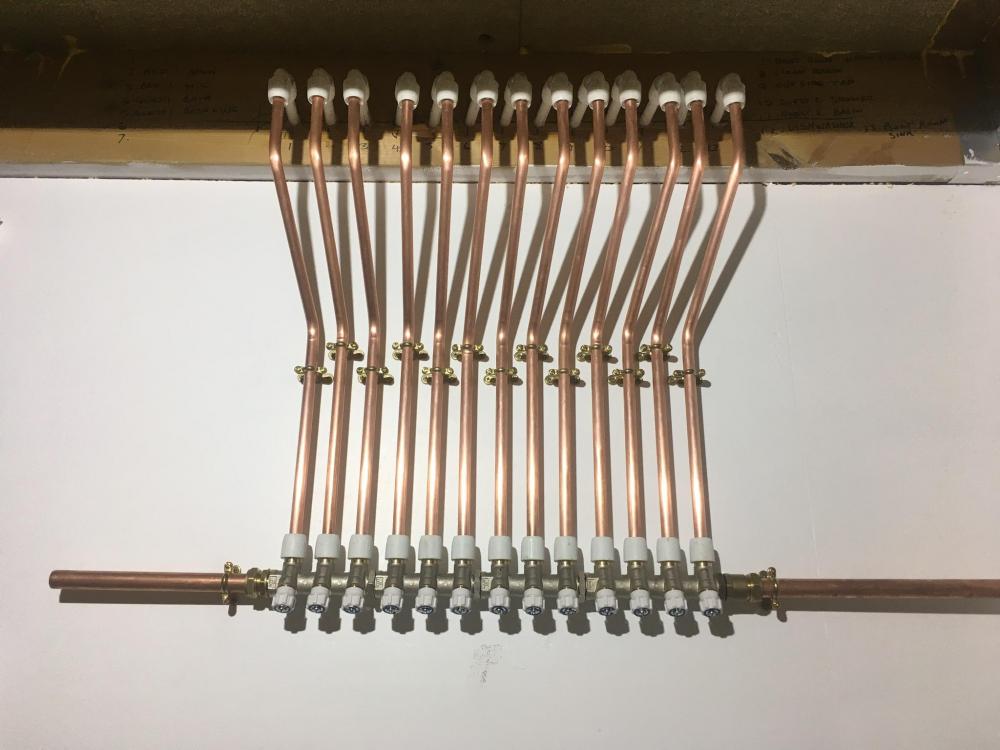

There are many benefits, and I never carry out an M&E project without manifolds for hot, cold, AND hot return. Sometimes the client only needs 2 outlets with HRC, but they still go on a dedicated HRC manifold regardless. Reason being is that the hot supply and the HRC both terminate immediately before the outlet, so to kill the individual hot to a particular ( HRC serviced ) outlet you need to be able to isolate both the hot feed, and the HRC loop to 100% shut off supply. As above, you can design out the need for an HRC, but those instances are usually based on an ideal layout / positioning of hot water device vs hot outlets, or with a caveat that a little delay to a couple of the furthest outlets is tolerated. Mitigated by correct pipe-sizing mostly, but still suffers if there is larger bore pipework before the distribution manifold, as there can be a much bigger dead leg there vs any of the terminal pipe runs. I often set up the hot manifold to have the HRC serviced outlets come from the far end of the hot manifold, eg opposite end to the hot water supply, so as to pre-heat the rest of the manifold and maximise the benefits created with shortened / correctly sized pipe runs. Current project will also feature occupancy switches ( PIR detectors ) to run the HRC only when a room is occupied, and only for a set 'on time'. @Adsibob I think with your hot return loop done with series plumbing, there are a good few disadvantages, and even without a manifold aka radial arrangement you should have had a better tactic for HRC deployment, particularly if you already knew the water would need to be recirculating for extended periods whilst you relaxed in the bath. Are all your hot runs very well insulated? I typically run the 15mm radial hot feed and its partnered 10mm HRC together, in a single wrap of 22mm dia x 25mm wall Climaflex pipe insulation, to massively reduce heat losses from that often lengthy pipe run. This also preserves the residual heat in the pipe(s) after the HRC pump has cycled and shut off, which reduces the amount of cold dead leg shunted back to the hot water device at each 'pump on' event. It would be minimum industry standard practice to install a suitable ballofix / other isolation valve immediately where the pipe run terminates at each outlet, so you do not have to shut down the entire wet system in the event of a single device failing / needing service. If you do not have these then it's a poor installation IMO. The manifold provides means of remotely and centrally mounting these isolation valves, so for eg shower mixers and bath fillers, often with nowhere to practically access such local isolation valves, can benefit from this also. This is the Achilles heel of series plumbing. Outlets have to share the flow dynamics of the pie run that feeds them all. That's usually mitigated with a very big pipe run at the hot water device, 22mm or even 28mm, then diminishing as it gets further away, usually down to no smaller than 15mm. If your hot supply is also the HRC loop then that can be more problematic, as it should arrive back at source via a non-return valve, so the return pipe side cannot 'back-feed' the outlet, ergo the furthest hot outlet will always be the worst performing / most affected outlet eg where other outlets are opened upstream whilst it is being used. A real PITA if that happens to be a shower. I converted to radial + manifold over 9 years ago and will never go back to series, unless its a flat with one bathroom / kitchen and they're all next to each other etc where it's then just not justifiable.3 points

-

Cheap yoga mat or camping mat cut to fit and stuck on with carpet glue2 points

-

Welcome. At a high level, you normally start by working with an architect to come up with some 'sketch' schemes for the plot with a view to what meets your needs, your budget and is likely to get planning. This normally focuses on external size, appearance, position on plot, access, parking etc etc. You may need to pay for a topological survey of the plot and street scene and also acquire map data on the surrounding area to build your plan upon. Once you have a good scheme the architect can work on the detailed design to get to the planning approval stage. You may or may not get planning immediately and if not be required to go around the loop again. Once you have an approved plan you can think about how to get it built. Some choose to stay with the architect who will then to take you through the next stage and use in structural engineers etc to create a set of detailed drawings that you can take to tender. Services (power, water, sewage, telecoms) also need to be considered if they do not currently exist on site - some of these can be very expensive (10s of thousands) so best to get early quotations on these as it may make or break your build. Many package builders can take your planning documents and create their own detailed design from those, using their in house SE etc. You may stick with the architect or part ways at this stage but there are still jobs like discharging planning details etc that are required. You may need to design the foundation system, separately (again, this is primarily a SE job but requires information on the ground conditions which can require a survey). Some frame companies will include this in their package. At this point you should have a good idea of the frame cost but that is only a fraction of the build - you will need to spec and cost up the rest of the build which may require a project manager or a quantity surveyor. Once you have all of that, you should have a budgetary cost and perhaps even trades identified to do the work. You then need to finalise your finances and then contract to get it done. These are the preliminaries ....2 points

-

Re the scientific explanation. It makes me cringe when someone tries to explain heat pumps by talking about compressing gasses and evaporation etc. While he is technically correct, as in the joke thread above, most people will simply not understand. Why can't they just say something like "it extracts some heat from the air by cooling the air a bit, and puts that heat into your house" Most people would understand that.2 points

-

the thing with blockwork is you can stop and gather more funds if you need to --TF once you start you must get it wind and water tight pretty quick blockwork can stand being wet for a long time1 point

-

1 point

-

The networking rule of thumb is that things that don't move (TVs, consoles, etc) should be wired and leave WiFi for the genuinely mobile things. Ethernet cat 6 is relatively cheap and while you're building, easy to put everywhere it could possibly be needed. There is no obligation to actually connect it up but even terminating each run to a simple patch panel is not expensive. You then get an ethernet switch with the necessary number of ports and patch all active circuits into that. Then you patch your router (likely one in the same as your DSL modem) into the switch and it will share your domestic internet service across all your active circuits. In my case, the home DSL / WiFi is in the study and a few devices plug straight into that. The spare port is connected to an ethernet wall plate which runs up to the switch (with all the others) and is patched in. I would not be too concerned about the health aspects of WiFi, you are exposes to lots of electromagnetic radiation sources with your mobile probably the most common but the power output is very low. If you were to stand in front of a high power microwave transmitter then yes, you would come to some harm but luckily they are generally not accessible to the general public. I would not bother automating blinds - we have electric Venetian style ones external to the house and just tweak them with a wall switch if we want to reduce glare or let more light in. They do the job of preventing overheating without any adjustment.1 point

-

https://catalog.mann-filter.com/EU/eng/dimensions This tool will allow you to input dimensions and find something close.1 point

-

Out Titon unit uses plastic framed filters that they sell direct for £12.75/pr: However they can be easily refilled with other filter media so I bought 1 sqm of 10mm G3 media for £8 which should do me for about 10 swaps. Not only will it save a lot of money but at 80p/service I figured it might make me less stingy about how often I do it too!1 point

-

Welcome. The main things to look at first are site access, services and if you can build on it. Just because there is already something there, it means nothing. Your local authority website should have lots of information about its planning and building strategy.1 point

-

Preliminaries: https://www.designingbuildings.co.uk/wiki/Preliminaries_in_construction1 point

-

welcome. I can highly recommend Mark Brinkley's Housebuilder's Bible as a great book to start with. he covers a lot of stuff from beginning to end and is a great reference to refer back to during the build. oh....and spend the next 3 months reading the forums on here! Although 3 months might not be enough. ?1 point

-

1 point

-

Did that with a load of clearance carbon pollen filters from a Ford Transit..! £2 each on eBay .. Some of these are counter productive as they can heat the air past the outgoing temperature and the heat exchanger can start to cool the incoming air rather than warm it.1 point

-

Yes. Tho I think we've enough for the current floors, but will need your box for the basement.1 point

-

Indeed, I'm actually using 25mm electrical conduit as it the OD works with the 28mm sds I'm using ?1 point

-

Its a mathematics thing! You don't learn it you can't use it! The two most important subjects to be learnt to a good level: Communication and mathematics. And the other one I recommend is Yard Sticks - the ability to stand back and view the probable outcome.1 point

-

Indeed it does, but But how often does @ToughButterCup go out and buy apopularr science book? seems to me to presume that science isn't messy, full of complexity, and shrouded in various scales of grey, particularly at the forefront of knowledge. That is because the liberal arts who run publishing and media insist 'on a narrative'. It has made the whole presentation messy and complicated. As I said earlier, most science uses pre-GCSE levels. Yup, a vast number of people really don't want to look at an equation as it usually means they also need to know what the components parts are of that equation - pandora's box. That is the fault of our education system that rewards the wrong things. Education has not been dumbed down, just that different things are assessed these days. Also, mathematics is not science. It is just the language used. So claiming that equations puts people off, should be liked to people disliking red wine and cheese 'because it can be French'. Richard Feynman was asked to explain, in 3 minutes, what was involved in him being awarded a Noble Prize. "If I could explain it is 3 minutes, it would not be worth a Noble" was his reply. Worth spending 1/718,812 of your life watching this.1 point

-

Or buy a can of this …. Much better and more reliable. https://www.toolstation.com/action-can-ld-90-gas-leak-detector/p65456 @Coops if you’re bending coated copper pipe then use a 50mm pipe fitting as a former and do it slowly. Also be very wary cutting the coating off the pipe, use a sharp Stanley knife and only cut in a radial manner, never slit the coating along its length. Best way is to cut the coating off in short sections and twist it off. Also buy a proper adjustable pipe cutter and only use that to cut the copper pipe. … and never use flexi pipe and jubilee clips on gas pipe inside a building !! EVER !!1 point

-

Even if they don't have a pressure gauge built in, the changeover regulator usually incorporates a test nipple onto which the gas engineer plugs his manometer with a hose to do the drop test.1 point

-

More screws needed Tell him you'll pay for them!! Good job otherwise.1 point

-

We have plastic covere copper pipe all way from regulator on the bottles to Britannia dual fuel cooker. Comes up through floor behind it. Think we have one joint outdoors underground. Wrapped in denzo tape.1 point

-

Yes, that's my understanding too, penetration will be sleeved with conduit and foamed1 point

-

Yes, this is precisely why I’m asking. Electrician is fitting the first fix for the floor sockets tomorrow. To avoid running a lead across the top of my floor and avoid that trip hazard, I need to fix the position of the desk (to within 60cm or so) now.1 point

-

But a fridge working in reverse would heat the inside and cool the outside ?. (It’s an explanation I use and people understand it ).1 point

-

I self installed in my new build and had a chap sign it off afterwards. Plastic gas pipe buried outside from cylinders to outside kitchen, convert to copper before entering the building (as no plastic pipe inside in case of fire melting it), bayonet fitting on wall fir flexible gas pipe to cooker. Tested and passed ?. Just make sure you test all joints with washing up liquid in water and a brush (like you would to find a puncture) when pressurised.1 point

-

1 point

-

1 point

-

Not nearly as neat as @Nickfromwales work but we're getting there. Plumber has already told me off for not going close enough to the bi-folds ?♂️ How important is it to insulate the flow pipes out of the manifold? And for how long? I've 4 flow and 4 return going through the one doorway and narrow route through the kitchen. We've only 40/50mm of liquid screed so I'm not sure we've the depth for insualtion. Flexible conduit?1 point

-

To put it into perspective, I have so far only exported 290kWh. If I was eligible to be paid the smart export at 5p per kWh, I would have received the grand total of £14.50 so far. But to be allowed to claim that small payment, I would have had to pay an MCS installer to have fitted and certified it. That low level of payment would never repay the MCS cost.1 point

-

You do have to notify the DNO under G98 that you have installed a system, but you don't need to be a member of any organisation to do that.1 point

-

It's the diplomacy of keeping the area tidy and whodunnit when it resembles a yard sale! !! For noise isolation I would scrap the sliding doors. build a proper separate room. Thermal bridging isn't rocket science. You just need a completely continuous layer of insulation. If you can draw with a pencil anywhere on the plans where you can go from inside without bumping into a good layer of insulation you'll have a thermal bridge. Concrete is bad, steel is terrible. Having a look at the plans I'm beginning to wonder about the wisdom of the non aligning front wall. It'll add a lot of steel to the design, a lot of cost and be very hard to get right thermally. I would propose something like this. You'll end up with the same floor space but much less hassle. I appreciate the aesthetic value to the front of the house as is, but a good architect should be able to overcome this pretty easily. Also while we're at it bin the PIR in your roof between the timbers. It's difficult to fit (rarely done right), shrinks, leading to thermal bypass, offers poor heat protection (decrement delay), is poor in fire, burns toxically, is expensive, and offers little noise protection. Blown cellulose, mineral wool batts or woodfiber will be much better in real life. Have a look back at @ProDaves roof or @Jeremy Harris for good examples.1 point

-

I'm self employed and recently needed to provide a SA302 which is proof of tax paid (therefore proof of income), normally available a few days after the tax return for the previous year is submitted. Bank were not interested in company accounts as what's important is your personal income. Now this was for a residential re-mortgage so may be different for a new build one (I used ecology for that).1 point

-

Well don't, because it is a misleading description. It works just like a fridge, except the cold part is 'the outside' and the warm part 'is the back'.1 point

-

Get a decent mortgage broker. Their fee is normally covered by the lender. Lenders like them because they understand what is acceptable and required and don't waste time with applications that will not comply.1 point

-

Our installation was delayed a bit but should be in this week. Will be interesting to see what happens in this upcoming cold weather... @Hanksy - how have your units been getting on?1 point

-

Agreed. This would be seen as reasonable in any future argument so the planners would be unwise to pursue it. You could make it even less combative by suggesting that you have the right to submit a formal planning application for the same matter, but you don't wish to be awkward and appreciate that it would not not help their workload.1 point

-

We got a formal response to our NMA a couple of weeks back from LPA. I submitted the request about a year ago. We did however get an email from the case officer saying he was ok with the proposal in little more than the set period, so I considered that approval in writing and proceeded with the build.1 point

-

I'm not an expert on English Planning as Scottish Based.. But in Scotland a domestic Planning application costs £202. What would happen if you just submitted a fresh application, take the punt and see what they do? Explain that you felt forced to submit a new application as you had no response and you felt that this was the only way to get a reasoned response to your non material amendment ( called a non material variation in Scotland). Never tried it though..just a thought. That would put them in a bind if you caveat it this way. Harry yes you can try and leveraged but if you have burnt your boats already by playing hard ball then frankly you are stuffed and need to suck it up. If you have spent a bit of time building relationships and engaged with the planners early on then it should be easy..1 point

-

“Can they try and inject an S106 into a Certificate of Lawfulness app?” No. “And does a change of use app from outbuilding to dwelling entail a fresh/full app or can that be done under S73 too?” A change of use will require a Full application.1 point

-

It may be useful if you could get a cheap (self adhesive?) 100mm grid layout mat. Maybe 1m wide rolls.1 point

-

Hi All and thanks so much Hanksy for keeping us updated with your figures. We've taken the plunge and bought 2 x 5kw Daiken ac units to heat our large kitchen diner. Having them installed this week - will let you know how things go...1 point

-

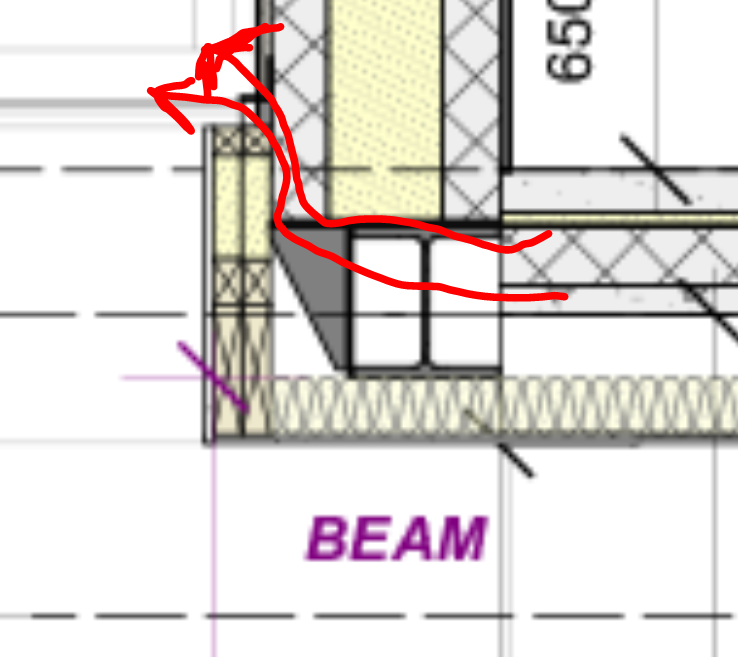

That is a different footing wall make up with aircrete blocks and for some reason the vents are position very low on the inside. The plastic vents are sized to slip through the 50mm gap under a floor block between two beams. Those heavy blocks around you perimeter are incredibly strong. Don't worry, just ensure the 40mm slips are fitted all around. @PeterWwill be along shortly to provide a definitive remote inspection.1 point

-

1 point

-

The Bristolian school of Pocsterism dictates one's computer monitor should not be visible to anyone entering the room.0 points

-

0 points

-

0 points

This leaderboard is set to London/GMT+01:00