Leaderboard

Popular Content

Showing content with the highest reputation on 10/15/19 in all areas

-

Zoot, you don’t fully contradict yourself, but what you say in one post does not marry up to what you state in another. A builder you cannot speak to, or instruct, for fear of them packing up and walking off site is an asshole. Simple. You sugar coat the situation, even though I’m not sure you realise you’re doing so, ( and that’s not picking fault btw I’m genuinely concerned for you here ), and the relationship is hugely unhealthy from my simple interpretation. To be clear, there is no pack mentality here, just individual members posting their thoughts / observations You started this thread to get help / feedback / relief / confidence etc and therefore you must accept what had been written as CONSTRUCTIVE, as that’s exactly what it is ok ? Fyi if I spoke to / behaved around my customers like these bullies do then I’d be out of work and rightly so. They’re not the best builders at all, and I think you’d get better builders with ease. You’re clearly a little intimidated and apprehensive to cause ripples, but you haven’t got out of the ground yet and you’ve had your third litter of kittens already! Fantastic / amazing builders wouldn’t have f.ucked up the foundation level, end of. You're being given no opportunities to discuss / interject / guide and that is fatal. Were here to help so stop biting, also the advice you’re being given is free and impartial, so take a deep breath and look at this glass as half full not half empty please. Right now this feels like taking a horse to water but no drinky-drinky. Explain that you will NOT be paying anything for the founds to be made up to the height that you indicated before work commenced. Simple, and end of ? Their fcuk up, their problem to sort. If they walk off when you state that, good bloody riddance and hello new day and new builders. Either what you’re saying isn’t the full story, or you simply cannot see you’re being bullied. Have that chat, stem the anxiety of speaking with them, and set a standard for how things are to roll forward. Have a cup of tea and a digestive biscuit before replying. ?4 points

-

EVERYONE IS TRYING TO HELP! (with the possible exception of Onoff that is clearly just winding you up but I'm sure he did try in the beginning) I have read most of this thread and I really don't understand what's going on. If the empty footings were passed by the BCO then I'm sure they will be fine. I assume it's the top of your footings that you think is the wrong height? If so I still wouldn't worry as this can be corrected by laying more courses to bring it back to the height you were expecting. Same with the oversite (the area inside the footings) this can easily be altered by adding more or less hardcore. To help accurately we need either photos of whats worrying you or accurate diagrams. I'm not fussed if your builder is happy with what you provided. To try and help from the other side of a different country I need more details, preferably all referring back to a fixed datum. (existing FFL is usually a good one) and it would be even better to have a photo of the whole area so we can see if things in the surrounding area may be affecting it. The bit about not being able to have a conversation with the builders really does worry me. Although you don't want to hear it. You need to get things pinned down now. In writing or preferably on a drawing. If needs be it will be cheaper and easier for you to get another builder to carryon the work from this stage than it will be later on in the build.3 points

-

3 points

-

Respectfully, this contradicts everything you've said to date. The main guy is apparently a fantastic, highly regarded local builder, but you expect him to walk off the job if you point out that an error has been made by his guy? I find those positions difficult to reconcile. I just can't comprehend why you won't have a conversation with the builder. It doesn't need to be nasty or provocative. You just need to say that you want to be sure that what's being built is what's on the plans, and that you can't understand how what's currently there will give you that result. Tell him that you know you don't know what you're talking about and just need a bit of help from him to understand. If he's half the builder you say he is, he should be happy to explain. If he won't, then that's a screaming red flag in my opinion, whatever other stories you may have heard about him. Again, why are you compromising if they've made an error? Keeping the builder happy isn't your job as a client. Your responsibility is paying them for doing the agreed work - that's it. More generally, errors happen ALL THE TIME in building. I doubt there's a self-builder on here who didn't have to deal with an error at some point along the way. We had loads in our build. In my case, all but one of the contractors who made errors put them right at their expense. The other was unwilling to admit his team's error (poor workmanship, really), so they were asked to leave the site. It was very stressful firing them, but not as stressful as it would have been watching them continuing to do crap work. In short, if errors are being made about things as basic as finished floor level and they won't talk to you about it, you really want to ask yourself whether these are the right people to be doing the work. Put it this way: you keep saying how stressed all of this is making you. If you actually DO something about what's causing you stress, the problem will be resolved one way or the other. Plus a large part of the pain in stressful situations is the feeling of helplessness. Taking some control of stressful situations is a guaranteed way of reducing the total amount of stress you'll suffer. Finally, the reason people are posting things that are upsetting you is that you keep asking for advice, but you don't seem willing to listen to any of it. Ignoring competent people who freely share their experience and time to give advice is a sure fire way to rub people up the wrong way - and that includes people who are just reading the thread without contributing. I haven't given advice in this thread because I don't have any knowledge or experience in this area. But reading it makes me very frustrated about the way you're behaving - partly because you're sabotaging yourself and partly because you aren't listening to people, but also because it's frustrating watching someone allow others to walk all over them. As someone else suggested recently, why don't you go back and read this thread from the start, and see whether what people said would happen has actually happened. Perhaps that might give you some confidence to trust some of the advice you're getting.3 points

-

Keep up the moaning and dramas you will be ignored on here. All the best for the rest of the build.3 points

-

Not always IMHO. BH is VERY supportive and if you have a challenge/problem, people will go out of there way to help and solve it.2 points

-

A tactic I used with some trades was to say 'Help me to understand' vs 'I'm not happy'. At the end of that conversation you then have the right to say 'I'm not happy with that' or 'That's not what we agreed'. If they can't explain why the floor level is off without loosing their temper or walking off site then you can't deal with them. Maybe they're used to rougher treatment and that gets their respect, who knows.It's not how I operate and does not sound like your comfort zone either. Ultimately you control them by virtue of ££. If you pay for work that you're not happy with (or accept overage cost that's not your fault) because you don't want them to go away or be abusive, then that is extortion in my opinion.2 points

-

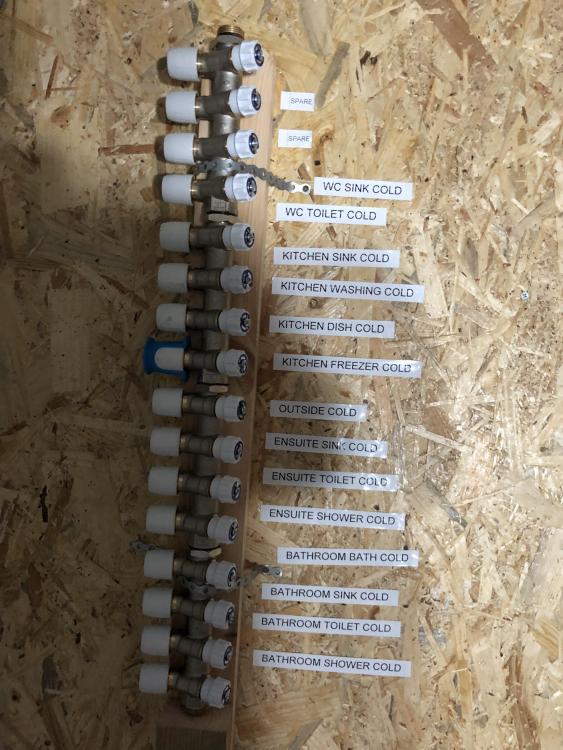

Don't do it! As good as those HEP manifolds are they tend to hammer terribly if you restrict them.2 points

-

2 points

-

Deep breath now ..... Fault allocation - on line or on the ground - is irrelevant. Its damned hard work stepping back from the whirlwind of stuff going tits-up. Forums can never be the best or only place in which to ask for and write about advice. On line, most people do their best to support others - but with the best will in the world, its a less than perfect place to deal with high stakes stuff like this. We are up to seven pages of responses - hard to read and interpret accurately. How about breaking your issues down into single chunks. Start a thread about each. And, where relvant, hyperlink them? And can I suggest that the more irritated you feel by any one response, the longer it should take for you (or anyone else for that matter) to reply. Yes, I dont consistently apply my own advice .?2 points

-

I found the lighthouse episode to be quite a downer. Very divorced from reality in many areas; the scale of the house, financing, foundations, staging of works etc... Just all seemed excessively naive. Sad overall really, losing such a wonderful spot when they could just have settled on the smaller house. Agree with @LA3222, the architect was likely a cause, overselling his vision without thought on budget. Shame the builder didn't get more sound advise elsewhere.1 point

-

I spent an hour or so in the architectural museum at Bath last week. I got chatting to one of the volunteer staff there, who pointed out that at the time that the grand Regency buildings in Bath were being built, architects were joiners and masons who had gone on to study design, after many years of working "on the tools". The thought that went through my head was that it's a pity this no longer seems to happen, as I doubt that anyone with a solid background in hands-on construction would likely to come up with designs that their clients would be unable to afford.1 point

-

Sorry, but it's not safe to run the Sunamp heating element from a 13 A FCU. That fuse is going to run damned hot, as it's always likely to be overloaded. Personally I'd never, ever, wire either a Sunamp heater supply or an immersion with a 13 A FCU. Mine is wired to a 20 A DP isolator, with an illuminated switch, and that is wired to a radial in the CU with a 20 A RCBO. The same radial has an FCU fitted with a 3 A fuse for the controller supply. The calculations that matter here are the average and worst case estimate of the supply current. 3 kW at a nominal 230 VAC gives a current of 13.04 A. The heater resistance will be approximately 17.64 ohms. If the voltage were to rise to 240 VAC, the current would rise to ~ 13.6 A, and if the supply voltage was to rise to the maximum allowable, of 253 VAC, then the current would increase to ~ 14.34 A. This may not be enough to blow the fuse, but it will make the fuse run very hot, and it is an inherently unsafe installation.1 point

-

Building control will normally want to see a proper design based on a percolation test from which you can work out the area of land you need for the soakaway system.1 point

-

Well the Chinesium bits did their thing. Make that Chinesium BIT as in I only used one. Forty two 25mm holes in 5mm 304 stainless plate aided by the odd squirt of finest Machine Mart cutting fluid from a Lucozade bottle. It's still SHARP FFS! Bench cleaned up and the plates all degreased in the kitchen sink when SWMBO wasn't looking: Pity I should have drilled 44...1 point

-

Both.... you have to plan for both of those, and tbh your issue is when the water reaches the top of the gutter it will find the shortest route to the ground and that could be via your cavity wall.1 point

-

Aye, the primary factor was the eventual weight of the water as @PeterW explained. If we didn't have an outlet, we'd accumulate 1.5tonnes per gutter across 10m. It might have held, but was an unacceptable risk to our Building control officer, so he applied balcony regs to get an overflow installed since we couldn't go over the edge.1 point

-

From the very beginning of this thread I was concerned about the lack of detail in the drawings and even more so with the lack of a written down fixed price properly broken down to show what was and what was not included in that price. It’s a very small and simple job in regards to detailed cost brake downs and transparency of what is and what is not included in the contract. I used to undertake contracts worth hundreds of thousands of dollars on a regular basis for very complicated works, it was clear down to the dollar what I was included and what was not, if the client asked me to change something or alter the quantity in any way it was a sit down to talk it through and get it all written down and a signature from us both to approve the changes. i have not giving you technical advice but I have provided you with warnings about how the contract is being run and my concerns about how it could so easily go horribly wrong. I stand by those warnings and still have hold my concerns, it’s a public forum and I am allowed to voice my concerns !!! If you don’t want to take people’s concerns seriously then that’s also up to you but then it becomes harder and harder for people to help as it’s like feeding a forest fire rather than fighting it. From far away it looks and sounds like this contract is destined to go Pete Tong and the longer you ignore people’s warnings and offers of advise the more us mere mortals find ourselves holding our hands in front of our eyes and peaking out between fingers when reading the saga unfold...... I wish you all the best of luck and will let the technical helpers continue to provide you with GREAT information and advise, should I be able to offer some technical advise I will.1 point

-

yes fill in an application fo0rm and get a written quote . bob: you been messing around with this for months now just get some forms and make real applications and get real quotes no point in doing anything and that includes you keep asking same questions on here until you have them and you know your services costs no one can give you any real answers on here -just guesses1 point

-

1 point

-

In the good old days, there used to be a C4 category, compliant with an earlier version of the regs. When that was removed, a lot of those now end up as C3's. Nothing to worry about, it's only C2's and especially C1's that need to bother you.1 point

-

1 point

-

For the pre-app stage and visualisation of the site, i used Sketchup and QGIS.1 point

-

I used Autocad, as I have been using it for decades and had a copy. I'd not recommend it for simple drawings, though, as it's expensive and the learning curve is very steep. I believe that Sketch Up is fairly easy to use, and has been used by some. It's probably overkill though, as all that's normally needed is a 2D drawing package. There used to be a free version of TurboCad available, and having used that a bit many years ago it might be an option. Not sure if Draftsight is still available free, but that's another package that I think some here have used in the past.1 point

-

Depends on what you want to do. If it's for just planning and visualisation, then any of the free online apps would do. If you are talking about actual design drawings for building control, engineering or construction.... Then that's a different ball game. Most professionals would use autocad or the architecture version of it. It's great, once you've spent a year or two learning how to use it!1 point

-

Welcome. TBH, it would be hard to do an EICR on any house that's more than a few years old and not have one or two C3s on it. All it means is "Improvement is recommended" and can often be down to the judgement of the person doing the EICR. Last one I did I noted a C3 for a cooker switch that was slightly too close to a hob, another C3 for a (metal) consumer unit that didn't have any RCD protection (wasn't required for the date of the installation) and another C3 because the meter tails were only 16mm², again fine for the date of the installation, but they need to be 25mm² to comply with current regs. If you list the C3s here one of us can tell you whether there's anything you need to do about them. The fact that they are C3, and not C2, or even C1, means they aren't very serious issues. One problem is that the old C4 classification has now been removed, as that was very useful for older installations, as it just indicated that the item was compliant with the regulations in force at the date of installation.1 point

-

Noise. Ball valves sheer the flow of water and create a horrible 'rushing' noise, whereas fitting one of these at the outlet connection is near silent by comparison 2 different definitions; Flow regulator / attenuator Isolation valve ( rotary / screw / lever )1 point

-

1 point

-

Nope. On or off, isolators NOT attenuators Flow restriction always at the outlet.1 point

-

They become quite noisy if you do that. If you're going to strangle the flow then fit a restrictor in the outlet. Beware reducing the flow to WC's as they'll take forever to fill and get on your nerves when you flush the loo at night. edit : restrictor ( not reducer )1 point

-

A thing of beauty. How come the outside tap is coming off that? The O/S tap should come off either directly after, or even better, before the stopcock to the house. Tee-ing off there would be a huge drain on flow for the showers, but if it's not used much don't panic.1 point

-

Solar panels only work well when you don't need heating, and don't need much lighting. Generation from them pretty much falls off a cliff in October, with very little being generated over the winter months, and doesn't pick up again until the Spring. As most people use more energy in the winter than they do in summer, this leaves a gap of several months of the year where there will be an energy shortfall, which means using something else if off-grid, like a generator, wind power or hydro power.1 point

-

My comment was neither criticism nor an attack. I'm genuinely concerned that you could interpret it that way.1 point

-

1 point

-

Quite seriously we were taught to rub a pair of nylon knickers up and down plastic conduit like you're spanking the monkey to generate heat and aid bending. So you've a head start there! ?1 point

-

Have you tried a pipe bending spring (as long as the bend isn't meters into the pipe)? Also try warming the pipe slightly with a bit of friction and this may help it be less likely to kink1 point

-

Yep I checked this as it was an option for me . Vertical or horizontal no issue .1 point

-

What do you want it for? That is the Bosch domestic range, I wouldn't expect great things from it or perhaps the longest life if you put it to any sort of real use. I personally won't buy DIY grade power tools - but when your building and using them like a pro then it pays to have good tools - I also love tools - I would quite happily go onto Screwfix right now and just buy a saw or drill or something that took my fancy! Keep an eye out on Screwfix and Power Tool World - some professional grade tools for not really much more money. https://www.powertoolworld.co.uk/tools/drills/cordless-combi-hammer As @AnonymousBosch says they need fed, pick a manufacturer and go for it - I use Makita and Bosch tools, which lets me limit my batteries to those two types. Makita batteries are expensive but once you have a set of them you can pickup bare tools for really reasonable prices. Sometimes I will also buy a whole drill kit on a deal just to get say 2 x 5.0Ah batteries. I bought a drill for £119 on a deal that came with 2 x 4.0Ah batteries, that was back when the batteries were about £60 each! No brainer and I got another charger. There is also always the scope to sell the bare drill or case or charger on eBay.1 point

-

@Hecateh, think about more than the drill. It needs feeding. With power. And that means charging. So you might want to think about any other power tools you want to use. When you buy one brand, it almost inevitably leads to buying other items from that '' family '' because you save money on the charger. Teuton (I can't stand the real name) do a light-weight range of power tools (link to a search for that type : Bosch 12 volt range). I use those because they suit my mangled hands, and are much easier to handle. Just as powerful - if not more so - than the one you are interested in.1 point

-

1 point

-

All you really need from the EPC for the RHI calculator is the expected annual heating and DHW load for the property, you must have some reasonable idea of these already to have designed the heating and decided on a 14kW ashp? It's fairly easy to work through the RHI calculator with a few scenarios to at least get a range. You can do a worst case scenario of 15kWh per m2 of floor area (i.e passive house) and see what the RHI would be on that, in reality an independent EPC would never estimate it that low so that will give a minimum level of compensation. FWIW my quote is £9k for ashp install including high spec 300L UVC with 100mm of insulation and quite a bit of plumbing, and it says between £7k and £3.5k in RHI depending where exactly the final EPC falls. As it's a retrofit I'm also pushed towards MSC anyway to get the low rating on VAT, and besides if I'm paying for an install I'd rather not be someone's first attempt (the market for reputable, experienced installers in our area is thin enough without adding a non-MSC constraint)1 point

-

Well BPC only supplied me with one silencer, so hope that is sufficient! I have no option but to fit mine horizontally.1 point

-

Silencers work in any orientation, so horizontal is fine. Based on my experience, I'd definitely silence both extract and supply. Our noisiest terminal before I fitted silencers was the extract in the utility room. It's a short duct run, and the fan and compressor noise from the MVHR was very prominent until I fitted the silencers.1 point

-

I really don’t think it will make any difference at all, but will wait to see what others say.1 point

-

If you post a picture during wall removal and after the steel is in place it would be of interest to lots of members.1 point

-

1 point

-

Just a quick update for those interested in following the project. We have now installed the Izodom 2000 insulated raft foundation ready for our ISOTEX walls. We have a few details in the roof structure to finalise but we hope to be onsite with the blocks in mid to late September. Anyone who is interested in looking at the insulated slab let me know. Tom1 point

-

Ok, confusion reigns... Water flowing at full wallop all the way down the pipe, from the manifold to the outlet, then meets the restrictor and you can gauge the end flow rate pretty well. If you put the restriction at the source, eg the manifold, then you have a restricted flow at source and then it suffers further losses caused by the resistance of the pipe ( hydraulic dynamics iirc @PeterW ) and the number of twists and turns downstream, and that’s what I’m referring to as possibly problematic. Can be done at the manifold, but possibly a higher rated restrictor would he needed there vs one at the outlet in order to achieve the same result Now can I finish my steak?0 points

-

? You could introduce it at the manifold if you are happy to fit an inline coupler. Would be experimental though as it would be pre pipe resistance.0 points

-

I think you should have the posts CNC Lathe turned from composite, and then have 3D metal deposition brackets made whilst setting it onto a series of hand welded double helical piles ... The roof should be cedar shingles - they take about 15 years to grow, so if you sow them this autumn you should be able to harvest by the time you’re ready to get the roof on ....0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)