Leaderboard

Popular Content

Showing content with the highest reputation on 07/17/19 in all areas

-

I have this hankering to start a standalone blog, and maybe write an e-book. It needs thinking time. Back in a month or so, though I will keep an eye on messages.3 points

-

Thanks to @JSHarris @PeterWand all the rest of you for the kind wishes. Everyone is safe. The almighty @Russell griffiths came to my rescue with his mate. Chopped up the tree in no time with their magic chainsaw skills : Now I am just left with a whole in the wall: and a few logs from my chainsaw massacre Wiltshire edition I m off now for a cold one and will update blog maybe later. Russel has a great photo of how I butchered the trunk with my 1st try felling a tree. I have some time-lapse which I might post later on once I found some time to edit it. Might take a few days.3 points

-

Scaffold down and windows in...big dose of euphoria....feels like a real milestone. We can now get a sense of the completed project. With the scaffold removed the house now looks far more suited to the plot and we hope our neighbours will be as relieved as we are. The window install went well. Our windows are Velfac and we opted to use an approved installer as it extended the warrantee to six years. It cost a bit more but the standard of install was good with great care being taken. A few grubby hand prints on the render but nothing we could not clean of with soapy water. One aspect of doing your own build that we had not considered, is the fact you start out with something perfect and new. It will slowly age and degrade. It’s akin to the feeling of the first mark on a new car. Pat and I have restored a couple of cars in the past and avoided going the whole hog of a concourse restore as it can spoil your willingness to use and enjoy the car. We just need to keep the same mind set with the build. With a house we can lock, our intention is to let the dust settle. We’ll come back to the project with fresh enthusiasm in October.2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

I know you must all think I'm on some commission deal (I'm not), but SageGlass really is (imho) the most elegant and least intrusive option if your budget will stretch to it.2 points

-

Hi all. So lots and lots of dramas with windows, I don’t do drama, I’m like James Bond never fazed ?? it looks like most of the dramas are caused by the fitters and not really the windows can anybody shed some light on what was wrong, what did the fitters not do, what did the fitters do wrong, how would you put this right next time. I intend fitting my own so would would like to know some of the pitfalls before I start. Having seen a lot of window fitters on site they don’t look a lot different than the scaffolders so I’m not surprised people have dramas.1 point

-

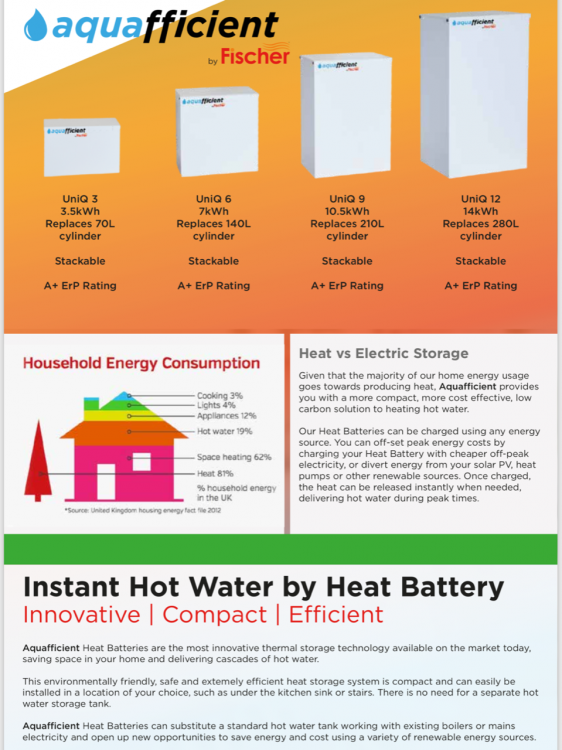

Depending on the electrical and wet connections being all complete, commissioning ( eg switching it on ) is down to flicking a switch. The unit will have to have been ordered according to the intended application, ergo the control unit will come pre-selected to the correct 'setting', so it's very much plug and play. Sizing, and selecting the correct 'model' is where the attention needs to be, as many have fallen foul of licking their finger and waving it in the air in the days ( now gone, thankfully ) where Sunamp would sell direct to the public........ 20 minutes is actually more like an hour, per size increment, where you'd need to stay with the unit until it heated fully for the first time. eg a size 6 unit would require babysitting for the first 2 or so hours ( 3kW required for ~2 hours = 6kW input = fully charged from 'empty' ) so you know it runs the heating cycle and 'knocks off' as it should. Plumbing connections should be checked after the unit has fully heated up, as sometimes weeps start after the pipes heat up and expand a little. There are 2 heat exchangers in each UniQ heat battery, so 2x pairs of 22mm connections. If you are using an UniQ for hot water only, you need to parallel the heat exchangers so water flows through both. This not only maintains the 2 HeX's in a wet environment ( copper would corrode a lot faster if left dry as it would suffer from condensation if open to atmosphere, and it would also ebb heat away wastefully ) but then, if paralleled, you'd benefit from a far greater flow rate for DHW too.1 point

-

It’s all reclaimed York stone off the site. Lovely stuff, weighs a tonne and a bit of a fiend to lay... if your local I have fair amount left in stock.... local places are selling it at £100 per square meter.1 point

-

You might find that borrowing on the existing house is far cheaper than a self build mortgage1 point

-

You might be better not viewing by area but by build type, what method do you want to use no point looking at an icf build that’s 10 mins down the road if your going timberframe.1 point

-

My conveyancer seemed to think this was not that straightforward. Apparently because you are splitting/selling to yourself, even if to your own ltd company then it throws up issues. I can't remember the ins and outs without looking into it but would be interested to hear how you get on OP and whether mine was just being defeatist. Having said that it wasn't impossible, just easier to build the new one first, then split title when you are ready to sell old one. If that is the case then probably to best to raise a mortgage on existing whole property, build new then settle mortgage when selling old. Be the cheapest finance surely?1 point

-

See this thread.. https://forums.moneysavingexpert.com/showthread.php?t=5797650 Google found what looks like form AP1 here.. https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/744253/AP1__2018-05-25_.pdf You should get a solicitor to help fill it in and will need plans of the site. I'm not sure if you can give yourself an easement? That's another possible issue. I would also speak to a mortgage broker. You might find remortgaging your current property is cheaper then a specialist self build mortgage. Make sure to check out all the fees, including for early redemption. When we purchased a buy to let in the 1980s it was cheaper to increase our mortgage on the house we lived in than take out a new one on the buy to let. Finally a reminder to make sure to get your self build CIL exemption paperwork done before you start any building work on site.1 point

-

1 point

-

1 point

-

Thanks very much for starting this thread. Made me think: my hands are only going to get worse (Dupuytren's Contracture) , the images - and the links - you posted are very useful Thanks.1 point

-

And, it seems, immortal : https://en.wikipedia.org/wiki/Electrocution The next thing you know a new religion will have sprung up about you. Might last a few thousand years, if the last reported person to rise from the dead is anything to go by...1 point

-

As far as I know the only way to "split" the title is to transfer part of the land. This may be possible if, say, the land is currently in joint names and you transfer to sole name or vice versa. You could also transfer part to a ltd company owned by you. You can do the transfer for nil consideration, so no CGT, but check with lawyer and accountant first.1 point

-

and may i add i have only broken 3 ribs on a tree stump and electrocuted myself 4 times over the years so i am uber safe. Oh and smashed my nose once, and broke a finger... No dont listen to me1 point

-

You may find it useful to chat to the mortgage company. They would take a charge over the land (including your current house), then you can build your new house, sell the current house and repay the mortgage company from the proceeds. When you sell you will transfer that part of the land with the current house plus the outside space that will go with it and it will be registered under a new title at land reg. Your new build will be the same title as current but with the old house removed.1 point

-

TBH I wouldn’t go with a domestic installer. This is an aircon unit at its core, find a local aircon engineer and get their opinion on what is best and what they are comfortable with. Most of the domestic installers are one trick ponies who have installation in mind and when it goes wrong are nowhere to be seen ...1 point

-

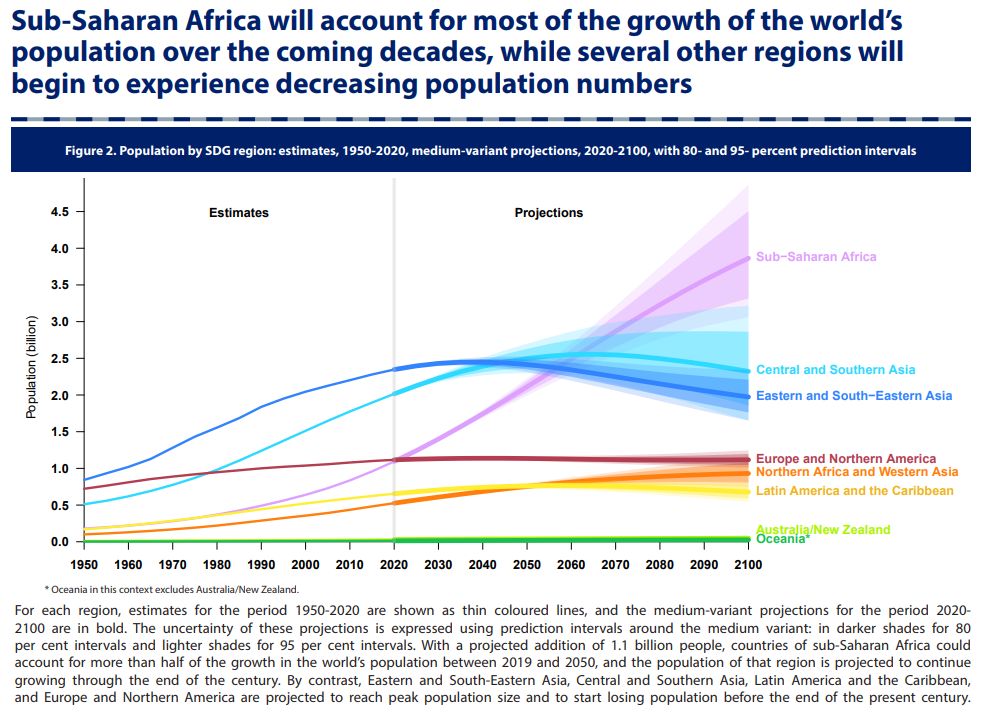

The UN estimates that 26m people a year have been displaced due to weather and climate related events between 2008 and 2015. They estimate 200m people will be displaced by 2050, less than 10m a year. 10m a year is a number the world could quite comfortably cope with, it already is. Europe, China and Japan are all heading towards flat or declining populations, and even growth is slowing in the US, so this can offset it. It actually may be less disruptive than it has been as immigration has been into already growing economies historically. Offsetting this many countries will see development which means better living conditions and job opportunities. They may be able to internally offset the climate issues or they may offer a more attractive economy to stay in. Within 75 years all regions of the world except Africa will see flat to falling population and i suspect that almost certainly people will move to falling population as the new crisis. I also seriously doubt that the fertility rate in Africa will stay as high as forecast, as other areas have got richer fertility rates have fallen much faster than expected. UN predictions below.1 point

-

I looked into building to passive standard with single skin and EWI thinking it would be cheaper and simpler. But I changed my mind and went for a 300mm full fill cavity instead. EWI to passive thickness was a bit pricey and quite a fiddle to install, also needs more specialist trades when compared to a cavity build which is far more common. I also felt that external block and render was more durable than the thin coat EWI render systems, and far easier to fix things to, like downpipes or overhead cables.1 point

-

Previously I never understood the requirement for things like wifi controls or being able to control your heating from your phone. However, I'm now wondering if it's more about an app that simplifies the controls rather than controlling it when your away from home.1 point

-

We backfill with EPS and weak mortar below DPC and use a step DPC with weeps above to close this cavity off. Only downside about bringing your trenchfill up to the top is you have to make sure that you have enough space over the top of the founds to get any drainage or other services out through the wall as you will be very high up. Alternative is you sleeve the pipework and reinforce appropriately.1 point

-

They will need plating, and a bolt schedule producing for the column to beam and beam to beam join. Sitting a 203 on top of a 250 clearly creates a point load, has that been factored into the design...? Out of interest, how much are you paying for this SEng service and where in the UK are you...?1 point

-

1 point

-

1 point

-

For Glass, it’s pretty much down to a couple of values and it will be supplied from the usual suspects. I personally look to supply 48mm glass unit, 18mm space between the panes, psi value of .040 or below and argon gas filling. That’s the optimum unit in my view for a 0.5Ug. You can play around with the coatings to vary that Ug. Frame and style wise, it’s down to performance of the system, look/style and functionality. Which is a personal choice.1 point

-

I'm getting some advice in. Won't strip the crown further. Will assess now and keep you updated. Cheers1 point

-

Thank God someone - anyone - questions the primacy of the Teuton. My experience of German products is not uniformly good within Germany . But for export - different matter. One of the principal factors for me is my knowledge and understanding of the German QA system (TUV). The system is (was when I had experience of it - VW emissions ?) rigourous. I am not in a position to be able to compare one company's offering against another in any sophisticated way: we chose mostly - boringly - on country of manufacture. Stupidly really because German manufacturers never miss the opportunity to mention that their product is made in Germany. We spent about a year looking at several manufacturers: Velfac, Gaulhofer, Internorm. We fitted Gaulhofer (Austrian) windows. I'm fiddling about with the window reveals at the moment, and therefore looking closely at how they are built. The hinges: solid, well designed. Smooth as silk. High quality steel (well it looks high quality) . The ability to adjust individual door hinges - in and out, up and down - all I need is two screw drivers and a bit of muscle. Little things like clearly explained instructions on use, beautifully grained wood - straight, excellent finish. A huge 4 meter window which glides across the runner - one finger pushes a tonne (?) along the track. The track wheels have brushes which sweep the track : I have got down on hand and knees to check how well it does so because nobody other than me cares about keeping the track clean. Treble seals - I have no experience of why treble seals are better - I just assumed that three is better than two. Glass doors that have that VW clunk: they 'feel' solid. The locking system looks as if the TUV (QA) inspectors had eaten gravel for breakfast. I am well aware that my detailed experience of German products is perhaps out of date. I am glad that you have the gumption to poke at the halo that surrounds some German products: German manufacturers badly need to rebuild their reputation.1 point

-

Stop stripping the crown !! The weight in that is counter balancing the rest of the tree. It will also stop it rolling anywhere. What kit have you got available ..?? Scaffold is preferable to ladder here - I take it you’ve got decent PPE such as trousers or at least chaps ..?? What size saw, how many and what type of chains ..??1 point

-

We are hopefully over our window issues (fingers crossed) but only last week we had Internorm out to re-seal two windows where the glazed unit meets the frame. Internorm are blaming the window fitter's but when I asked him why do they not just have a seal/gasket between the frame and glass unit he said they have had problems long term and sealing with their product will last years. My reply was that this sealant had not lasted long since the windows have only been in 12 months to which he just raised his eyebrows. He also said it had been finished off incorrectly, the original installation team had squared of the sealant to the glass and he said they should have put a slight radius on it to allow the water to run off, my reply to this was who is training these guys. When you receive Internorm windows the small windows usually arrive pre-glazed (factory finish) and these windows have sealant that is square to the glass so the mind boggles. My reason for replying is that although you think you are buying the dogs b------- of windows it soon becomes clear that there are so many factors to take into account I am not sure you get what you pay for. When you place your order go over it with a fine tooth comb as our dealer tried to apportion blame to us when the wrong thickness of window arrived and it was only the installation manager sided with us that we managed to get a replacement. When the Internorm chap turned up last week and I asked him to look at a roof terrace door because it has a tendency to leak in really driving rain, he took one look at the door and told me it was the wrong type of door to have in that location. I was absolutely gobsmacked and said how the hell was I suppose to know that when placing the order and he just shrugged, told me he would order a rain deflector for the bottom as they have come across this issue before. Buyer beware I suppose. Happy window searching by the way!!1 point

-

There are oodles of windows to choose from, I chose Internorm over cheaper alts such as Ideal Combi, Velfac, Rationel etc as I have a very exposed location and wanted the best I could afford as I knew they would get a battering from the weather........ also some of the others could not do the bigger panes of glass and good sight lines etc...Internorm offered me the most on my wish list but I do regret not having the solar coating (was told I wouldn't need it) or factoring in external blinds (ditto on being told not necessary). The film we have fitted is a big help but can never be as good as a factory finish and overheating is something to be aware of when speccing your windows. Whichever windows you choose.....and you need to go and look at some, take a tour to some members houses to see different brands in situ perhaps......make sure you have good fitters. My lovely (and expensive) windows totally messed up by suppliers rubbish fitting team.1 point

-

Top marks for posting this thread. Takes a bit of guts to post an error of judgement this size....... You are young, fit keen and have loads of energy. By the time you finish sorting everything out, you'll be older, wiser, more cautious and knackered. Just like most of the commenters on this this thread. May I suggest you use a sharpened chain saw blade?1 point

-

Has it still got the crown on it ...?? How tall was it...?? That will stop it rolling, the weight needs to come off back as far as the pivot point so you will need access and I’d suggest a tower, section off the base first ... but it a pro would be safer1 point

-

That looks pretty dire for just 13 months use. Makes me wish I'd taken our old Sunamp PV heating element out after three years to see what it looked like. Harvey softeners are pretty slim and look fairly neat. We have one and it seems to work very well. They are sold under a few different names, as I think Harvey has licenced the core technology. We have this model: https://www.uk-water-softeners.co.uk/product/dimensions/1 point

-

Russell >plonker Well @Patrick Rodney ? We are all pleased you are in one piece. I think you potentially have different safety issues than cutting it down. One issue is how it moves unexpectedly when you cut bits off. Breaking a leg is dead easy with a coupe of tons wobbling around. Others can probably advise better, but to hold it in place it has to e done from different directions or have a self-retensioning apparatus for when it moves. Are you actually sure it is 7 tons? Might it be less? No particular benefit, just a smaller elephant to eat with chopsticks. I would listen to @PeterW on this. He has worked as a tree man. We had a 90 footer blow down and just miss next doors’ bungalow roof years ago at the previous house (they have a sprinkling of different coloured tiles now). On that occasion a local chap said he would do it for the firewood. So we snapped his hand off, and left him to it. 4 days later... Best of luck. Ferdinand1 point

-

You plonker. And you met me the other day. Did you not know what I used to do for a living. Would happily have done it for you for a bit of exchange labour. Nothing else for it but get in and cut it up bit by bit.1 point

-

So it took a few weeks for the planners to accept the planning permission (I didn’t realise the starting date was not the date they received it). Original decision day was over 2 weeks ago. We agreed to an extension as they were swamped. We agreed to another extension last week on the condition that they would talk to us if there were any issues - that deadline was Monday. Yesterday we get a call saying they are about to reject it due to the increase in floor area - the agent checks again that our previous (still valid) planning permission has a greater floor area than the plans were are submitting (and these plans have balconies which while they are included in the floor area, obviously have less impact if it was a building. Our roof height is lower as well. Hopefully it will be sorted today but the stress of this combined with trying to complete the timetable before tomorrow so that teachers can see what they are teaching and when they are teaching it before they go off on their holidays on Friday is getting to me.1 point

-

NHBC say 225mm cavity below dpc. Can be reduced to 150mm if there are weep holes.. http://nhbccampaigns.co.uk/landingpages/techzone/previous_versions/2011/Part5/section1/sitework.htm1 point

-

Cost of fixing system will start to outweigh your thicker insulation costs. Also consider final finish on the insulation and how you will manage windows and doors. 215 on flat will be 50% more expensive on blocks and mortar too.1 point

-

1 point

-

plastic tie them to the metal web so they run at mid-depth in the joist. easiest solution1 point

-

Thought I would post a few photographs of the finished room. We love it and the OH made a brilliant light/mirror after seeing what we could get for £140. luckily it was broken so we sent it back and he made his own. it has a sensor at the top, LED lights around the sides and the toothbrush holder is on the right. The shower itself is great. Aqualisa with a control as you enter so no more cold wet arms. Its is brilliant. And it didnt even take that long to do - a few months........1 point