Leaderboard

Popular Content

Showing content with the highest reputation since 01/10/25 in Posts

-

I'm so pleased with the way this turned out. It is a covered way through the whole width of the wing with the main glazed entrance behind the photographer. The floor is entirely of harvested glacier cobbles. These were formed when the glaciers had streams running beneath them, rolling stones along and forming these shapes. The cobbles are in bands in the sand , and were recovered when digging foundations and drains. They were carefully selected from a huge pile, one by one, for size and being flattish on one face. Most are rounder than these. The right hand wall and the arch are original, repointed in lime mortar. To the left, off camera, is an original timber clad stud wall, including a door, retained for heritage and interest, but there is a new wall behind it. There are pencil writings on the wood cladding, concerning numbers of sheep etc. Everything done by my daughter and SIL. 'except the straw bales' as they put it.28 points

-

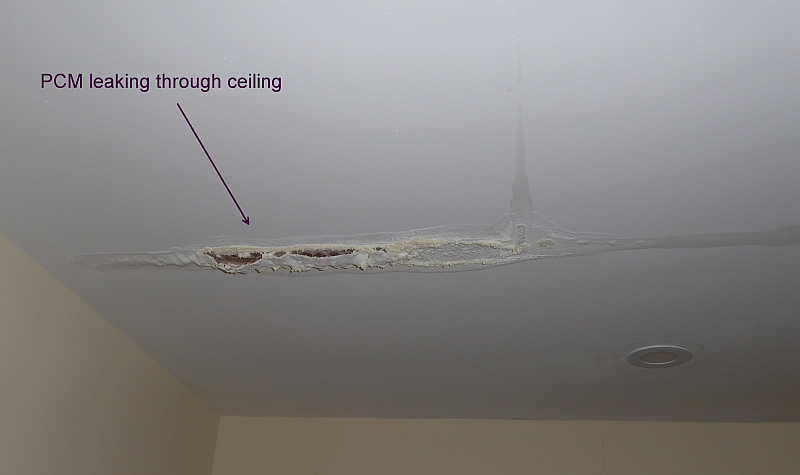

First of all, my apologies for being silent for so long. TBH, having finally settled here in our new home I needed a break from self-build. Not for any particular reason at all, just that I'd been living and breathing it for so many years that I needed some time out, a bit of breathing space if you like. Old age seems to do this, creep up on us almost unnoticed (and I'm now in my 70's). Also I was spending way too much time here, to the exclusion of other things I should have been doing. Anyway, thought I'd post here to hopefully shed some light on how things have gone with our Sunamp adventure, and give a bit of a gentle warning. Those who've been here, and on Ebuild before this place, may remember that we bought a Sunamp PV right back in the early days, before this place existed. We ran that for well over a year, with a few minor teething problems, but it was enough to convince me to swap it for a larger Sunamp UniQ eHW 9, which I did in September 2018. That also had a few teething problems, but Sunamp sorted them out quickly and without fuss. Since then I've been more than happy with the Sunamp. It's provided reliable hot water, mostly heated by excess solar generation, in fact far more hot water than we have ever needed as it turned out to be a bit over-sized. The first time we went away on holiday I turned everything off and was amazed to find that when we got home a week later there was still piping hot water available. I cannot complain at all about its performance, it has been significantly more efficient than a hot water cylinder, which was the reason for me being so enthusiastic about it back in 2016. Sadly, our Sunamp died on Saturday morning, and ejected its phase change material all over the floor, down through the ceiling in the kitchen below: A check upstairs in the services room confirmed that it's death had been spectacular, with PCM all over the floor and a long icicle of sodium acetate crystals down the back of the unit, from the burst casing inside: To it's credit, despite this it had delivered two showers that morning before we spotted the problem. Sadly this was to be its dying endeavour. I contacted Sunamp, not because of any warranty claim (there was no warranty anyway) but to ask them to put me in contact with a local installer for a replacement. I spent the weekend looking at the specs of the newer Thermino models and, given that the 9kWh (11kWh) UniQ was overkill for just two showers a day I decided its replacement would be the smaller Thermino ePlus 150, with the PV02 key to better match it for PV heating via the Eddi (when summer comes back). I found a couple of online suppliers, price, including VAT looked to be around £1,800 or so, plus delivery, which sort of seemed OK. I'm not up to getting the old unit downstairs and the new one up stairs, so I contacted a few local plumbers. All said they wouldn't touch this job. No idea why, it's a pretty straightforward swap, as the PRV, TMV etc is all there, just a matter of re-jigging two 22mm pipes. Seems the technology just scared them off, or, perhaps, it might have something to do with dealing with Sunamp? After a lot of delay, Sunamp customer services came back to me, asked for photos, then went silent. I got on to them again and they gave me contact details for a couple of installers. I contacted them, first one got back to me saying it would be around £6k to swap out our failed unit for a new one. I questioned this. He said it was about a day's work. Now, I'm all in favour of paying a fair rate for a job, but I know how long this job is going to take and I know the cost of all the materials. I am not going to pay a bloke £800 plus per hour, no matter how damned good he is! So, looks like I have to fall back to hiring a stair climber and doing it myself. PITA, as I'd have happily paid someone a few hundred quid to do this (over and above the cost of the bits) but I point blank refuse to stuff over £4k in someone's pocket for a job that is so straightforward, especially when there are installers advertising prices of around £4k to replace an existing hot water system and cylinder for a Sunamp, a job that is a heck of a lot more work. Sorry for the rant, thought it was worth posting here as a warning to others thinking of going down the Sunamp route. I can't fault the performance, but if the cost of repair and maintenance by a Sunamp approved company is so crazy then it may give some pause for thought. I've half a mind to bin the Sunamp and just get a high efficiency 150 litre cylinder installed. No idea what that might cost, but I doubt it would be over £6k. PS: Seems I have hundreds of PMs that have accrued in my time away. Sorry, but I doubt that I have a hope in hell of answering them all!20 points

-

Dear forum members, Our house is complete and we have been resident for three months. I thought to post some pictures and I offer to answer any questions people might have. I don't put ourselves on a pedestal as being any better than other projects, only to say that we have done it. Our primary decisions: We chose a RIBA architect given the importance of the initial concept The layout is somewhat novel, having an H footprint with a single storey 'extension' to reduce the mass of the main house for planning purposes and to help project the rear of the house beyond the shade of the ridge line We chose timber frame (we have built with timber frame, brick and block and ICF in the past) because of speed of construction, and thermal performance We selected MBC from a shortlist of three TF suppliers, and chose MBC's insulated slab We are very pleased to have chosen a large solar array (9KW) and Tesla battery. We have used no grid electricity since commissioning. We have a Valliant ASHP with UFH but haven't had need to heat the house yet We have MVHR which works very well with our air tightness of 0.89 We have no fireplace or chimney We project managed ourselves, and were onsite every day and I did a lot of carpentry / general work alongside the proper trades Project timing: groundwork prep Dec 24, slab Jan 25, frame erection February, windows March, resident 4th July, finished end of August.15 points

-

I should probably start a blog for this sort of thing, but I just wanted to let y'all know that we finally got planning permission - 4.5 years after buying the site, after one application with a committee hearing, and the latest application that took nine months to determine. Thanks to everyone on here for their help, advice, and nudges on expectation alignment!15 points

-

I am currently waiting for Structural Engineer to share a report. But Pasquill gave me quite a comprehensive email but in summary: They have confirmed that the main issue on my site is that the steel valley beams have been set in the wrong position and at the wrong angle, they should not go through the internal corner as built and need offsetting a little this means the pitch is out by one degree. This has also caused the problems with the fascia and soffit lines. Pasquill say the Posi rafters already fitted may still usable if the beams are moved to the correct positions, though if any hidden cuts are worse than visible they may need replacing. If I do decide to replace the 12 rafters sitting on the valley, Pasquill have offered to supply new ones at a very reasonable price for me ( Which I have said yes to ). The next step is to fully dismiss the builder, take ownership of site. I have found a good joiner to come sort the posis, and will just await the SE to give me a plan of action for these steels.13 points

-

Major news!!! Guess what? Sunamp have just emailed me to say that they are going to replace our unit as it is covered by the 10 year warranty on the core! They emailed me as I was typing the reply above.13 points

-

So a few months in to our build and I have to agree that self-build is hard work! It's also an amazing experience in which every day brings something new. It's difficult to say whether this is physically the hardest thing we have ever done because I think age plays its part, we are late 60's or so and even though we are both fit people building at this age cant be compared to the house renovations that we have done in our 30's, 40's and 50's. What I can say is that we wouldn't swap it for anything, we have promised ourselves that we would self-build for years and to be actually doing so is an amazing experience. Onwards & Upwards!12 points

-

TL:DR just a bit of fun - Mods feel free to move if not OK in the section. So my first timber framed house completed, I had some must have criteria for the design. - Open plan - double height ceilings - EDPM roof - OSB walls with wood cladding - no high spec windows - main access will remain open at all times Background For every DIY project you end up with leftover materials - you carefully store them in the hope that they are useful one day I had too much in my storage area…… Why did I choose self build? (Always a common question right?) At the back end of winter I had to replace the last section of original fencing (43 years old so it s done well) so I had some featherboard offcuts. In redoing the fence I discovered a hedgehog hibernating in the leaf litter (at that time of the year I wasn‘t sure if it was alive or dead but apparently if they are in a tight ball it s a good sign) We’ve always had a lot of hedgehogs coming thro the garden they like bamboo leaf litter and we created several entrances and exits that we keep clear so they frequently come thro the garden using it as a short cut to other gardens Anyway with the little critter in my way under foot I had to work carefully round it (gender neutral at this stage) so took me a little longer than normal About a month ago I was glad to see the hibernating hedgehog woke up and I was really happy to see it snuffling round the garden (eating slugs) So last year I rebuilt and re-roofed my shed so had some EDPM off cuts and a fewoff cuts of OSB board from the roof and shed walls So rather than throw it all in the tip I thought I d build a better shelter as a open air pile of leaf litter isn t exactly a great shelter. So here is an almost finished hog house (needs a coat of preservative and I m thinking 70 s flock wallpaper for the interior maybe orange) Anyway enough background here s the pictures I also have so 75mm celotex left over but figured if the little bugger can survive under a pile of bamboo leaf litter it doesn t need an insulated house11 points

-

Rick - would strongly advise against this position and sending a letter like this. At this stage your builder is possibly preparing themselves for legal proceedings. In this instance you are absolutely advised to commit as little as possible to written (or even verbal form). I would advise that you don’t continue with this contractor under any circumstances - and get yourself in a headspace where you’ve accepted you need to find someone else. reading your contract you can’t unilaterally terminate the contract as there is the provision for remediation. My first course would be to request a without prejudice conversation with your builder. Within this conversation (have a third party present such as your SE, architect or a friend) set out that from your point of view the trust and relationship has degraded to a point of no return and you do not under any circumstances want the builder to continue. Explain that if that isn’t agreeable you will exercise clause 37 and at the builders Cost they will be required to replace all posi rafters and fit them to the satisfaction of your SE. State that Pasquill have advised they are likely not recoverable. This is an expensive exercise for the builder. Others may suggest you try and get them to cover the cost of doing the job right. Personally I wouldn’t trust them anywhere near my site. I would seek a negotiated exit and write off getting any money back. Alternatively, if the builder doesn’t agree I would advise you exercise clause 37 immediately. I doubt that they will remediate within 14 days but if you don’t follow the provisions of your contract your builder can pursue you. I would advise a letter that is entirely factual, unemotional and succinct if you need to serve a breach notice. I can help draft one if you need. Accept your relationship with your builder is over.11 points

-

Morning all. I don’t drop in here very often these days but just happened to browse on my way back from an extended trip to the USA. Lo and behold I see a post from @Jeremy Harris talking about Sunamp so thought I stick my head above the parapet and say hi. I’ve just looked at when I last posted here. It was June 2020! Where in hells name does time go? So here’s a quick summary of what I’ve been up to in that time (possibly not in chronological order): Fully retired (two years ago). Finished my build which is well documented here and there on this forum. Then sold it in 2021 and bought a “project” which I gutted (nothing left but 4 external walls, the roof and a worrying array of steel and acroprops). Then spent all lockdown rebuilding it. Finished the house but am still working on the landscaping. Spend vast amounts of time faffing about on my small holding (came with the house). Have I learnt anything? Yes, a fair bit: Stop buying houses on the national park, planning is a PIA (but the views are exceptional). When you retire you can’t work out how you ever had time to work! I can’t sit still. Wish I could (I’ve always known this really). Renovating an existing property is way more difficult than a new build. Building during lockdown was a complete nightmare. The window supplier/installer is more important than the window! Actually had a great experience with this renovation which is a world apart from the pain I experienced with EcoHaus SW and Internorm. Just stay WAY clear of “bleeding edge” technology. Exhibit A: SUNAMP (I might comment on the thread which started this resurrection off). Land is a time sync, the level of maintenance is mind blowing BUT it gives you an excuse to buy a digger, tractor and trailer. Plus a myriad of attachments Well that’s it for now. I can’t promise I’ll return to being a regular contributor. I simply spend much less time time in front of technology these days. I much prefer being outside. P.S. I think I’ve got one more build in me before I fully reach my target of eccentricity and too many animals.11 points

-

Thanks for all your help. We were last in the list of applications, but our worry was short lived. My wife read a short and personal speech regarding this being our dream for a long time. No questions from the committee to my wife or I and none either from the committee to the planning officers. Approved unanimously. Really chuffed and a bit dumbfounded it's finally over. The not knowing what the outcome is stressful. You put your life on hold.9 points

-

MVHR doesn't have anything like the airflow needed to provide serious cooling. Design in air conditioning (completely separate from the MVHR), and throw on some PV so you can run it for free on hot days. MVHR will help keep the heat outside.8 points

-

We’re rebuilding a Victorian bay window with a focus on thermal efficiency and restoring some period detail. To achieve this, we designed and cast our own bespoke window cills using GFRC, 3D printing, and innovative materials like glass bubbles to reduce weight and improve insulation. This post shares our design process, casting experiments, lessons learned, and the final results. Design I used SketchUp to produce the design for the side and centre cills. The bay has external wall insulation so the cill was designed deep to accommodate 10mm aerogel, 50mm PIR, render and the offset from wall. The 10mm aerogel was something I wanted to try out, and doesn’t add much compared to just using 60mm PIR. For some reason the grey versions of aerogel with a 0.015 thermal conductivity are not easy to find, so settled with the 0.019 grey blankets. We are targeting below 0.15 U value. The EWI gets us to 0.16 with additional internal insulation needed to be below target. The cills themselves are a thermal bridge 210mm deep then 100mm of structural insulation for a 0.34 U value, I haven’t yet decided on the further internal insulation to get below 0.15. I am trying new things out with this and will try VIPs. I have a budget for trying out new insulation. 3D printing The first concept of the design was printed out in a 3D model, including a wall return, stools for the jambs and mullion and underside drip. And later its mold to test the casting process. Structural insulation The plan was to install the cills on the exterior half of the wall, then given the deep cills a section of structural insulation was fixed into the wall to provide some support for the cill in case they were used as a step. Here this is fixed to the top of the wall and replaces the 50mm of PIR which otherwise would have been used. Casting Once the cill designs were done, I made a mold of the cills for casting with concrete and sand. The mold was 3d printed and via some experimentation manage to find a way to get a stone effect for the face coat. The idea of casting my own cills started while looking at GRFC concrete countertops, so my mix included glass fibres. The hope is that they prevent cracking, but the cills are already substantial so they probably don’t need them, but I kept with my original mix design. I don’t think the glass fibres added much to the process, except additional complication. If its reduces cracking then that’s helpful. Glass Bubbles I later tried an experiment using glass bubbles. Half the sand was substituted for glass bubbles to improve the thermal efficiency of the cills, (only a little) but its main advantage was in reducing the weight so it was possible to move the cills around with some ease. It also helped reduce deliveries of the sand. I was using a white sand which was an annoying bulky delivery. The glass bubbles tended to rise to the top of the mix, here the top is the bottom of the cill which was problematic for creating a flat surface. I later experimented with covering this to produce a flat surface but I manage to instead amend the mold design to be fill from its back. The advantage of this was that the slightly uneven surface was in an area where it didn’t matter and also the glass bubbles would be situated more evenly towards the back of the cills thus helping with the thermal efficiency of the cills on their internal side. Test casts I had about eight different cills cast before being totally happy with the design and the casting process. I experimented with using cast stone dust, but with a bad result (probably from my poor face coat application) so I moved away from a “bath stone” look to a white to be further finished. Completed Cills Once the cills were done, I was able to see how to progress upwards for the rest of the bay window. At the start we were happy to accept the bay would be a thermal bridge requiring lots of internal insulation. The benefit with this design is that much of the insulation is now external saving on the floor space. It took some time, which I have and I am happy with the result. Since I installed the jambs and mullions and making the header/lintels copying the original design in the area. Plus the cost is much reduced. The original plan was to spend 30k on the bay window build, as a standard build, that cost without windows relying upon insulation being done separately afterwards. Instead we have managed to spend 5k on tools and materials, including £500 for a 3d printer but lots of my time.8 points

-

Ufh pipes will cost a grand to buy, if you don’t put them in you need a serious word with yourself. I don’t understand the figures like some on here, but I know I’m sitting in the most comfortable house I’ve been in for a long time, just a gentle warmth in the tiles emits to every point of the house. it’s just an absolute pleasure.7 points

-

7 points

-

It's done!! Just wanted to say a big thank you to everyone with the advice on this one. After the advice I changed plans and in the end got a sand cement screed laid by a professional company who did an amazing job and finish. Time to move on to the next stage (I'm sure I will gleaming you wisdom again) Thanks again, few pictures before7 points

-

After the advice of pretty much everyone, for once I am going to admit defeat and have some professionals in for this job. We have found a couple of options we are happy with and will readjust the budget a little to accommodate but its not something we can afford to go wrong. I will take some pictures and update you in a couple of weeks when it's done but thank you so for your advice and help and I now know what to watch for when it's poured and what to prepare7 points

-

Came across this forum recently whilst searching for information about BNG, after delving deeper I wish we’d found you all about 2 1/2 years ago. My wife and I are just finishing our build, hopefully by the end of this month. Maybe 6 months later than projected, so probably not too bad. Our struggles along the way have been for the most part due to our main contractor going into liquidation in December 24. In some respects this may have been a blessing, in others not so. We realise now that not all of the headaches end with the completion of the build; reverting to LA building control after the liquidation is challenging, we still have outstanding land transfer issues and obtaining planning permission for a ground mounted PV array is laughable. Our build is a new build replacement of an old tractor barn, close to the ridgeway in Oxfordshire. It seems the forum likes photos so I will attach a couple.7 points

-

Cheers for the help everyone... got people lined up. Joiners are on site now fixing up / measuring. Brickies and welders coming next week. Should have things fixed up in no time hopefully.7 points

-

By way of background, I am the very aged IT geek that has done all of the SysAdmin since we first set up BuildHub about 9 years ago. I am no longer involved in Forum Management or politics; I just in keep the forum up and smoothly running, pro bono. i have also administered and run a number of community forums and wikis over the last few decades, mostly using open source forum packages such as phpBB and MediaWiki. However when the founding members set this forum up, we decided to use a commercial Forum package (there was a one-time purchase, plus an annual maintenance fee), because this customer funded business model offers us a better feature set and continuous through life improvement. We chose the forum app from the company now called Invision Community. This a PHP application that runs on a LAMP stack on a hosted Virtual Private Server (VPS). The VPS has grown in cores / RAM / storage over the years as the size of the forum and its user population have also grown. Three years ago, I moved the LAMP stack into a Docker Compose project, and the VPS runs this single dedicated Docker Project which is on open Github. If you want to know more then read the README at Github: TerryE/docker-buildhub which explains the setup. Our Hosting Provider is currently doing an infrastructure refresh so we have to migrate to a new VPS and at the same time I am retiring the use of Docker and switching to the open-source equivalent, podman. See this issue, if you want to know more: A Gemini Conversation about Migrating VPs and switching to podman. Warning: it's a bit long (17 pages) and technical, but it lays out the issues and context. This topic is just to keep interested members informed. Any technical discussion / comment is welcomed. I have opened a companion topic in Forum News and Site Issues: Rehosting the Forum Virtual Server to discuss the more general / policy aspect to allow this thread to focus on the nerdy stuff. 🙂 Can I ask you all to keep to the technical discussions here and use the companion topic for general / policy stuff. @TerryE is my user account but I also have the Godlike @Admin account to hide / delete off-topic posts if the mods don't move them to the general topic. 🤣😱7 points

-

I DIY installed my Vaillant Arotherm via an umbrella scheme and it was cost neutral once I received the £7.5k BUS grant. Headline figures were £4k for 7kW heat pump (250 m2 property) , £1k for 250l Vaillant cylinder and £1.6k for umbrella side of things. I did all of the plumbing and electrics and it took me 3 or 4 days off and on, it was fairly simple as already had the underfloor side of things installed, I did take the opportunity to remove the mixer and pump from manifold, also removed all of the actuators. System has been running great with COP in high 4's I used : https://www.air2heat.co.uk/mcs-umbrella-scheme Paul was great, he does a site visit, does the heat loss calcs, all of the BUS application etc. He is also flexible as to what manufacturer you go with and as far as I am aware supports Vaillant, Panasonic, Daiken, Mitsubishi & Samsung. I had already set my heart on the Vaillant but I remember Paul being a huge advocate of the Panasonics. I also understand he supports most of the country but may be wrong. A really nice chap so well worth a call.7 points

-

Brief update on this one just so the thread and any other troubled onlookers are aware. I've now gone through and inspected the eaves detail for everywhere I can for this extension. Found some horrifying things and insulated it the best I can. Those steps being:- :- Remove all poorly seated wool covering wall plates. :- Seal all gaps between ceiling PIR and wall plate with wool / foam/ tape. :- Reinstate PIR insulation where there was none :- Form Wedge to force wall PIR to be uptight against block :- Seal all gaps between Wall PIR and block with wool / foam / tape. :- Reseat wool covering wall plate and all sealed areas. I'm very pleased to report that this has made a huge difference. I have not had chance to put my thermal cam back on, but you can feel it in the room. It's actually retaining heat through the day now, heating on in the morning for a few hours and you could still feel the residual heat in there by midnight. Perhaps i'd got used to having essentially balls-all insulation in there so im hypersensitive, but very promising so far. and that's without any form of curtain / blinds etc. All the glazing (of which there's lots) is still entirely bare. Not to say im going to stop there, I will be still removing all the roof to fully seal it and add more insulation. But atleast now my horrifying suspicion that I may need to add interior insulation in an already finished room... has been quelled. I'd REALLY hoped I wouldn't have to do that and it looks now that i wont have to, so im very glad for that atleast. Id rather spend the time and money on further improving the roof, glazing and adding exterior wall insulation to the walls if I need to. Anyhow, some more images of fixes for future ref for anyone.7 points

-

Good morning. Been quite some time. I doubt anybody will remember me, but I used to enjoy participating on the forum. Only reason I disappeared a couple of years ago was, wife got ill, and to be honest, I found myself getting depressed. I don't think I even realised the depression, until I came out the other side.....I have missed giving Pocster a hard time for his solweld skills though. I hope all of your projects are going well. I must say, I'm looking forward to being back. The skill and knowledge level on the site has always been fantastic. Together with the willingness to share that knowledge, and the pitfalls, and good times. The only thing that would be useful to me at the present time would be if anybody has any recommendations for a really good planning consultant in the Hertfordshire area. Anyway, I look forward to participating again in this excellent forum. Best of luck to all. Regards Jim7 points

-

As above. All the best for another year of staring at one tiny problem for waaaaaaaaaaaaaaaaaaaaaaaaaaaaay too long. And then realising it didn't REALLY matter that much after all. Adios 2025, here we go for 2026. Get your house built asap, or it'll be 2027 and I'll be telling you off again6 points

-

6 points

-

We hear sentiments like this a lot and unfortunately they are based on a misunderstanding of the respources we have. This line is promoted by certain sections of the media (who unfortunately no longer have the journalistic integrity to check their sources), and politicians on the make, and is 'encouraged' by the oil companies who source oil outside the UK but know that promoting 'British Oil' will actually lead to more sales of non-British oil in the UK! I'm by no means an expert, but I used to work for a solar company (way back, the first solar installer in the country) that was founded by a man who came from the oil industry and had first hand knowledge to impart. Without going into the weeds (which I'm in no way knowledgeable enough to do - I'm dragging this from the back of my mind from conversation 25 years ago...) you need to understand some basics of the oil industry as it has existed for the last 100 years. And a little Geology. Where to start? Oli is not what you think it is. Most oil in the world (and unfortunately the oil available off our coast) is not the black stuff you see shooting out of the ground in the Beverly Hillbillies. It is a multi coloured sludge made up of a vast array of chemicals that need careful and expensive processing to become useful - and that usefullness may not be as an energy source. Most crude oil - like that available in the UK - is only suitable for chemical productions (fertilisers, medecines, etc), not high grade energy use. Setting up oil refineries is increadibly expensive and to maximise economies of scale, a single type of process tends to be dominant in any region. Essentily, individual countries have specialised in different processes, using particular types of oil that is shipped around the world. I believe we ship 'our' sludge to South America for processing into a usable product, and vice versa). TLDR, The Geology of the North Sea does not produce the type of oil that UK refineries are specialised in, and the cost (and time frame) of converting our refineries to handle UK-sourced oil and the percieved benefits (and profits) are vastly outweighed by and dwindling resources of existing drill sites. In a heating world, WE MUST NOT drill any new fields and even if we did, the product would not power our country. Promoting th use of British Oil is a wheeze by foriegn oil producers (in bed with corrupt politicians and journalists happy to trouser a commission) which keeps the UK dependant upon their products. 'Gas lighting' in the literal sense... Another important lesson regarding 'Energy Security' has been learned from the war in Ukrain. A distributed power production that is not dependant upon a single source of energy is better able to withstand interferance from bad actors. It is very hard to cpmpletely destroy a wind or solar farm in a bombing raid, and even if you succeed, it will only be part small part of overall production. A distributed power generation will keep the lights on. But if you blow up a gas powered station - or the North Sea drilling rigs that supply your gas - it is much harder to get back up and running. To achieve a renewables based distributed grid is going to require huge investment of our aging infrastructure. But the long-term result will be lower bills, which should boost the economy as it will make manufacturing costs cheaper. Espescially if, as weve discussed before, industry is encouraged to move up North to be near the wind generation sources. We were perhaps disadvantaged compared to our European friends in the last 80 years, in that the last 'bad actor' was so very inefficiant at destroying our victorian infrastructure that we didn't have to rebuild earlier. Ironically, we probably gave Germany a boost by levelling the country and forcing a better grid to be built...6 points

-

Update: I bought the Zehnder attenuated manifold a few weeks ago and fitted it, with great difficulty. An absolute pig. I was even less happy when I turned it on and it had made absolutely zero difference. A few hundred quid and half a day down the drain unfortunately. However, there is a happy ending eventually, as today I fitted 2 of the flexible silencers @Jolo suggested, near to the terminal in the main bedroom. I used 80mm as they fitted fairly well directly over the 75mm ducting I have. It appears @Jolo has 90mm ducting? Result, I can't hear any noise whatsoever from main bedroom terminal even with my ear to it! A dramatic improvement. Tested the airflow and it hasn't reduced whatsoever. Thank you @Jolo. The only baffling thing is why the semi rigid ducting itself has caused this effect on both our systems. Mine is fixed well every 600mm, no sharp bends. I have 75mm, Jolo has 90mm. I have Quiet Vent ducting, he has Ubbink. I'm surprised more people don't have this problem? Or maybe they just put up with it?6 points

-

Zombie thread, but in case it's of interest to anyone- this was the building fix. The neighbourliness part was almost the hardest part. Our neighbours weren't aware of this issue. After raising it several times as a non-urgent but upcoming issue, we then raised it when we were going through formal party wall notice for other things like chimney removal and our loft conversion. We have a deed saying we owe them enclosure costs for the wall built on the boundary if we build on it- they suggested they would waive that. We pointed out that when we built the extension we had planning permission for, or even if we built a direct copy of theirs, there would be a pooling issue from the water directed backwards. So there needed to be a fix. We calculated the enclosure costs based on 1/2 of what it would cost us to build that same wall now (using our builder's quote). They had a quote from their own trusted builder (who built their extension) to infill the gap in the wall and redirect the gutter- seemed somewhat high but it's a small firm doing quality jobs. We offered the use of a skip bag already on our property to save on skip hire and gave them bricks from my collection as pragmatic. We then insisted on paying the enclosure costs but insisted that the fix was done. Conveniently the enclosure costs were just above half the remaining builders quote. Our neighbour (retired solicitor) drafted a memorandum of understanding, enshrining that we were explicitly paying owed enclosure costs and they were funding the remedial works to their extension, with the accompanying contract, warranty, responsibility etc being completely theirs (although the wall remains a party structure). So a blend of goodwill and pragmatism plus sticking to the agreements, but all dressed up as down-the-line obligations. All done with tea and cake in their garden. Very grateful for all advice- needed a robust understanding of where we stood (which this forum enabled) as a foundation for that amicable outcome.6 points

-

Hello all, Whilst I've been on the site a while, I thought I would introduce myself and the new exciting (to me) project that we are at the very early stages of. After the fun and games of the purchase process, we are now the proud owners of a barn in Cornwall and today, we have also received our class Q notice. The barn now has permission to convert, a secondary class Q and we are in the midst of a redesign to go back for full planning permission under betterment. As you can see from the photos, a fair bit of work is needed.. But we feel very lucky to be in this position. Current status is that the previous tenants (Rams) have been evicted and we are moving on to getting utilities to the site! I will probably start a blog if I find the time! May the fun begin!6 points

-

Been a while and I was just randomly passing through when I noticed a few recent posts on this thread. Current update is we gained our Completion Cert in July (almost exactly 10 years to the day since buying the land), and the interior is nearing completion with just the kitchen to finish. Fully offgrid, we haven't paid a utility bill in 9 years. Living our dream and still pinching myself, tbh.6 points

-

6 points

-

Aero barrier have been and gone. initial air changes per hours was 1.7 builders did an excellent job and AB guys were impressed. after their magic mist was finished, they got it down to 0.2.6 points

-

6 points

-

6 points

-

Best thing is take your time. Get your plans right first. Even if you need to go back to planning to make changes. Step back, write down what you want and what you don't. Look at the following aspects Foundation level how are you going to do it Walls many different ways to build so get that sorted in your head before you go too far. Roof are you having vaulted ceiling, this changes how the roof is built. Insulation and airtightness, this then helps you decide on ventilation and heating system. Layout of house, it's very easy to make a massive house, if you are not careful. Use you current house, what is good and bad, what are room sizes like, ok, too big or small etc. how does the layout work or not? Write stuff down, revisit what you write down, is it still true. Once you know what you are doing don't change.6 points

-

Just as a, "don't give up hope". Six months and Three days after my planning application was validated. I got my planning application passed. What might be of use to some other people, is that i'm in Greenbelt. I have managed to turn a small bungalow, and a posh shed. which total about 850 square foot. Into Two, Two story houses of about 1700 square foot each. This is despite local objections from Parish Councillors, District Councillors, and Neighbours. I did this by using several people, who worked on my behalf. A local "Face" managed to convince the Parish council to offer a, No comment, to the application. Another local "Face" to convince the district councillor, to not call the application in. Finally, a planning consultant, to respond to the 27 page objection put forward by the neighbour. However, i think what helped more than anything was the Governments, Grey Belt introductiion. This allowed the planning officer to conclude that both houses together, would cause very little additional harm to the Greenbelt. There is obviously a lot more to the whole situatioin with regards my various applications, over the years, But i wanted to bring to the attention of anybody looking to develope within the Greenbelt that "Greybelt" may well turn out to be your friend, when it comes to your application. Best of luck to all, and thanks again for all the help offered by people on this site, over the years. Regards Jim. P.S. I have also retained full permitted developments rights for both houses when built.6 points

-

It’s taken a little while to get an exact figure With some moneys and bills still to go out and £1500 off the vat reclaim off a supplier Which we’ve now done We ended up with £42800 back off the vat Most of which went on the landscaping and gates So I’ve knocked that out of the total spent Carpet curtains blinds wood burner I’ve left in as part of the spend fees surveys buying costs Architects BC fees All in Land purchase omitted from the spend tax All complete 420m2 £3860006 points

-

The advice from SBMS above is excellent. And to the point. Having previously terminated two main contractors, I can confirm he's hit all the key points. Do this right and you will be able to cut the builder and protect yourself against any comeback. In fact, if done right, they'll be delighted to be able to walk away with a negotiated settlement that means you can't come after them for damages. If you don't have personal experience in commercial negotiation, maybe think about who you can trust to help you with this meeting (whether a friend or professional). And you want a third party there regardless.6 points

-

That’s awful welding. You need to get an independent assessment of the whole build to this point while it’s still fixable. And I really doubt your builder is actually capable of fixing this without someone standing over him checking everything he does.6 points

-

I lit our alcove at the back to wash the light down the large format tile that formed the back of the alcove so I’d say it depends on what you want to highlight. It’s also on a dimmer circuit this it it fully bright. I used very narrow LED strips, the narrowest they did and it’s mounted inside a track. The other thing to consider is make sure you have easy access to the driver. In my case there’s a walk in cupboard to the left behind that wall so all the wiring is inside a wall box.6 points

-

6 points

-

my 2 cents..... 1. external blinds are a must. plan them now so they can be built hidden in to the fabric of the house. we use ours to shade from the sun but also as curtains at night so don't have internal curtains for privacy. 2. just install AC when i was researching i read a lot on here about fan coils and underfloor cooling etc and, in the end, it was just too complicated for me. not being able to heat water and cool the house at the same time just seemed a pain. so we planned for and installed ducted AC in the bedrooms and wall mounted units downstairs in a few rooms that we thought would need it. it is fabulous. the external blinds help and we have them automated to shade and follow the sun around but sometimes you just want to open them up fully and enjoy the view! so the AC takes care of the overheating and it's powered by the sun via our solar pv so i don't worry about running costs at all. our south facing bedroom has been a steady 21°C since April regardless of the outside weather. keep it simple, install AC.6 points

-

Update on this one, we said we'd take the roof off and do everything we can to improve the insulation off. Well we did half of the extension, it took ages due to just how many problems I found. There were literally parts with zero insulation. Or other parts where the gaps between the kingspan were so large you could get your hand through em! So really positive news that we found so many issues. Work included, all tiles off, felt and battens off too..... then foaming and taping every joint, then adding another 50mm kingspan ontop (ensuring we left a 25mm air gap between felt and board)... then foaming all the joints on that too... It took a full day, but really pleased to say the difference is HUUUUUUUUGE. Room is massively retaining heat compared to previous. And we've not done the more problematic half of the roof yet (based on the thermal images) so excited to see what we find on that side. Likely cracking on with that half on june 9th. So will update then too... But in the mean time, here's the before and afters. Very pleased we did this, despite the cost!6 points

-

I agree with this. I hadn't been prepared for how lonely self building is as you spend day after day on your own facing stressful decisions that friends and family have not experience on but usually a trivialised solution. Even very close friends have a lot of sympathy, but not real understanding and the truest empathy comes from a shared experience. That's why BuildHub is so valuable to me, but with the caveat that @ToughButterCup adds that everything can look perfect. When the chips are down, there is a lot of kindness here though and that's invaluable. You'll get there!6 points

-

Folks, We are on our self-build journey, we selected timber frame then short listed 4 suppliers and in the end chose MBC. They erect our medium complexity house in 8 working days - very impressive. I think MBC's strength is their experience which shows in the detail / thought in the design office and the efficiency of their erection teams. Our site is constrained so working out the order to deliver materials, how things are stacked, the order that things are lifted by the crane is complex. The team didn't seem to make any mistakes and just kept working, rain or shine. [To confirm I'm just a paying customer and have no other association with MBC]6 points

-

6 points

-

Thought I would just update this thread with a few photos. It was a bit of a journey for me compared to the main build as the detail is exacting down to how sharp is that 2H. Starts from the original measurements (used a laser measure), drawings in SketchUp, produce cut list for https://sydenhamsplywood.co.uk previously Avon Plywood. Spec was 22mm Birch "artisan" grade. Then the invisible fixings which I used, for the first time, a Peanut 2 Mini jig and a few pocket hole fixings. I did use Ikea Pax frames and drawers inside the plywood surrounds and fronts. I learnt a lot, did the other bedroom and now have plywood floor to ceiling pantry, coat and boot and utility cupboards! Also window surround. Very fortunate to have the time and space and do appreciate the skill and cost of the professionals. Total cost £4.6K in materials. Curtains / blinds, window cushion to follow which I will not be making.6 points

-

Welcome back @Jeremy Harris, nothing useful to add to this thread but I wanted to say I have learned a heck of a lot from your posts on the forum (and still getting my head round some of the more technically inclined ones). Thanks for all your input over the years.6 points

-

Pretty much as I expected. It is pointless to engage with Climate Change deniers and Covid conspiracists, who never provide peer-reviewed sources and do not engage with reasoned debate backed up by evidence, but cite the Great Barrington Declaration as if it was a statement of fact. As an essential worker, visiting clients daily throughout the lockdown, I experienced more than enough of the horror of the pandemic's effects. I can tell you that the true Co-morbidity cost to my customers was traumatic enough that I still find it hard to discuss. 46 of our clients died in the first week of the lockdown alone, and I stopped counting after that. Is that 'normal for the flu season'? Those who stayed safe at home, fomenting conspiracies, can never understand how truly insulting it is to hear such utter rubbish repeated, let alone as part of a general discussion on a building forum. I'm thankful that I wasn't working in a hospital where I'd have actually had to watch them die, but I can tell you that there are many thousands of bereaved family members, traumatised medical staff, carers, and other essential workers who will never forget the lockdown and will never forgive conspiracy theorists who make light of their cost. Many lessons should be learned from the lockdown, and there may be alternatives to the various forms of lockdown and vaccination schemes used around the world. But all of these should be attempted with the best of intentions - to save lives, rather than prevent inconvenience. This is something for suitably qualified and evidenced discussion between experts - not a shouting match between DIY builders...5 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)

.thumb.jpeg.b28cd0cbc0f4f6cb4c86bc6d7270cc5f.jpeg)

.jpg.6d82280948da1ced357e791676969673.jpg)

.jpg.f5ad4d134bf18cc792740d393cdb1432.jpg)