Leaderboard

Popular Content

Showing content with the highest reputation since 01/09/25 in all areas

-

I'm so pleased with the way this turned out. It is a covered way through the whole width of the wing with the main glazed entrance behind the photographer. The floor is entirely of harvested glacier cobbles. These were formed when the glaciers had streams running beneath them, rolling stones along and forming these shapes. The cobbles are in bands in the sand , and were recovered when digging foundations and drains. They were carefully selected from a huge pile, one by one, for size and being flattish on one face. Most are rounder than these. The right hand wall and the arch are original, repointed in lime mortar. To the left, off camera, is an original timber clad stud wall, including a door, retained for heritage and interest, but there is a new wall behind it. There are pencil writings on the wood cladding, concerning numbers of sheep etc. Everything done by my daughter and SIL. 'except the straw bales' as they put it.28 points

-

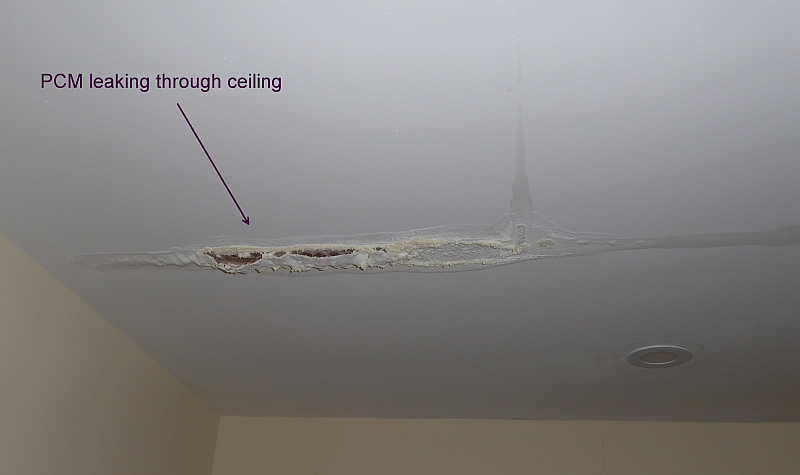

First of all, my apologies for being silent for so long. TBH, having finally settled here in our new home I needed a break from self-build. Not for any particular reason at all, just that I'd been living and breathing it for so many years that I needed some time out, a bit of breathing space if you like. Old age seems to do this, creep up on us almost unnoticed (and I'm now in my 70's). Also I was spending way too much time here, to the exclusion of other things I should have been doing. Anyway, thought I'd post here to hopefully shed some light on how things have gone with our Sunamp adventure, and give a bit of a gentle warning. Those who've been here, and on Ebuild before this place, may remember that we bought a Sunamp PV right back in the early days, before this place existed. We ran that for well over a year, with a few minor teething problems, but it was enough to convince me to swap it for a larger Sunamp UniQ eHW 9, which I did in September 2018. That also had a few teething problems, but Sunamp sorted them out quickly and without fuss. Since then I've been more than happy with the Sunamp. It's provided reliable hot water, mostly heated by excess solar generation, in fact far more hot water than we have ever needed as it turned out to be a bit over-sized. The first time we went away on holiday I turned everything off and was amazed to find that when we got home a week later there was still piping hot water available. I cannot complain at all about its performance, it has been significantly more efficient than a hot water cylinder, which was the reason for me being so enthusiastic about it back in 2016. Sadly, our Sunamp died on Saturday morning, and ejected its phase change material all over the floor, down through the ceiling in the kitchen below: A check upstairs in the services room confirmed that it's death had been spectacular, with PCM all over the floor and a long icicle of sodium acetate crystals down the back of the unit, from the burst casing inside: To it's credit, despite this it had delivered two showers that morning before we spotted the problem. Sadly this was to be its dying endeavour. I contacted Sunamp, not because of any warranty claim (there was no warranty anyway) but to ask them to put me in contact with a local installer for a replacement. I spent the weekend looking at the specs of the newer Thermino models and, given that the 9kWh (11kWh) UniQ was overkill for just two showers a day I decided its replacement would be the smaller Thermino ePlus 150, with the PV02 key to better match it for PV heating via the Eddi (when summer comes back). I found a couple of online suppliers, price, including VAT looked to be around £1,800 or so, plus delivery, which sort of seemed OK. I'm not up to getting the old unit downstairs and the new one up stairs, so I contacted a few local plumbers. All said they wouldn't touch this job. No idea why, it's a pretty straightforward swap, as the PRV, TMV etc is all there, just a matter of re-jigging two 22mm pipes. Seems the technology just scared them off, or, perhaps, it might have something to do with dealing with Sunamp? After a lot of delay, Sunamp customer services came back to me, asked for photos, then went silent. I got on to them again and they gave me contact details for a couple of installers. I contacted them, first one got back to me saying it would be around £6k to swap out our failed unit for a new one. I questioned this. He said it was about a day's work. Now, I'm all in favour of paying a fair rate for a job, but I know how long this job is going to take and I know the cost of all the materials. I am not going to pay a bloke £800 plus per hour, no matter how damned good he is! So, looks like I have to fall back to hiring a stair climber and doing it myself. PITA, as I'd have happily paid someone a few hundred quid to do this (over and above the cost of the bits) but I point blank refuse to stuff over £4k in someone's pocket for a job that is so straightforward, especially when there are installers advertising prices of around £4k to replace an existing hot water system and cylinder for a Sunamp, a job that is a heck of a lot more work. Sorry for the rant, thought it was worth posting here as a warning to others thinking of going down the Sunamp route. I can't fault the performance, but if the cost of repair and maintenance by a Sunamp approved company is so crazy then it may give some pause for thought. I've half a mind to bin the Sunamp and just get a high efficiency 150 litre cylinder installed. No idea what that might cost, but I doubt it would be over £6k. PS: Seems I have hundreds of PMs that have accrued in my time away. Sorry, but I doubt that I have a hope in hell of answering them all!20 points

-

Last week our timber frame structure shot up. This week was supposed to be the second week of a two-week frame installation but the team finished on Tuesday, having worked through the weekend. And off they went, but not before I persuaded them to stand still for 30 seconds for a snap for posterity. So here they are: Brandon, Jake and Callum - Great work guys! Their early finish allowed our chippie Alan to press on with the 18mm ply required over the roof for the zinc roofing. 60+ sheets of 18mm class-3 exterior ply were put up amazingly quickly by Alan with a bit of assistance from his pals on a couple of days. The only lifting gear on site at present is a Genie lift we bought, guessing it would come in useful, and Alan made great use of it to create a novel “Ply Sheet Lift 'n' Slide Sledge”. I pointed out to him that I’ll be patenting that idea, since all intellectual property rights obviously sit with us as site owners. He seemed unbothered. Next week Alan is away on hols (not in my plan, are you sure Alan?!). Thus we were going to have a quiet week which I labelled ‘contingency’ to make it sound more important. But Brian from Wessex Metal Roofing phoned me today (yep, Sunday) and asked if they can start the zinc roof a week early... “Oh, go on then.” So off we go again - more fridge-stocking required! Timber frame details Last week I promised to say some more about the frame structure, so at the risk of boring those not wrestling with the same choices we faced,t here’s some more detail (skip to the 'And finally...' section if you’re not interested): We decided early on that we wanted a factory-built SIPS or insulated Timber Frame structure. We’d used SIPS on our previous house with positive results. I contacted a dozen or so companies and received quotes from eight companies for supply and installation of the insulated structure: four SIPS companies and four Timber Frame. The price range was surprising: the most expensive was 240% the price of the cheapest. Of course each quote had a slightly different scope but factoring in the work we’d need to do to get them all to the same level of insulation and airtightness, the price range was still over 200%. In the end, shortlisted Turner Timber Frames, whose price was near the lower end but leaving us with a fair bit to do once the structure was up, and MBC who unsurprisingly were at the top end for an impressive approach and structure. After talking it through with Geoff our architect, he agreed with us that the price difference was so big it was hard to justify the MBC approach. Therefore we opted for Turners… And they have been really great to work with throughout. Matt, their Timber Frame Manager, has been very helpful and responsive. Their price has not gone up at all as we moved from initial quote through to signed-off design (in fact they came in below their initial estimates for steels and crane hire). They kept to the agreed timescales. Their sub-contracted installation team were really good, as previously noted. The quality of the frame appears very good to my untrained eye… and Alan our chippie seems impressed as well. The structure we bought is Turner’s Super Advanced timber frame: 140 × 38mm studs at 600mm centres with 9mm OSB sheathing and a breather membrane on the outside. The pre-fitted insulation is 120mm PIR and it fits really precisely everywhere. We opted for an additional 50mm PIR inside to give us a wall u-value of 0.13, recognising that in so doing that we had to fit the VCL, 50mm PIR, and 25mm service cavity battens ourselves (though all are supplied by Turners as part of the package). Some other frame or SIPS suppliers do all that for you, but at a cost. What you see in the pictures is the frame before we fit the VCL and additional insulation - I think you can see how tight that pre-fitted insulation is - it’s really very snug all round. I was worried we might have gaps to fill but there are none. The roof is open-web 254mm Easi-joist rafters with 11mm OSB, which we paid Turners an agreed addition to have their installation team cover with breather membrane and vertical 50mm battens to create the ventilation space we need for our zinc roof. Turner’s approach means we have no unsightly purlins to interfere with our vaulted ceilings. But the roof does present a challenge for insulation. We decided to opt for blown cellulose within the roof space which should fill the open web joists, plus 100mm PIR below the ceiling, to get to a u=-value of 0.09. It meant we had to find someone to fit the VCL below rafters and make it airtight (see below). We also have to fill in all the roof perimeter gaps to stop the cellulose blowing out, and we have volunteered Alan for that. He’s delighted (I assume). We always knew the blown cellulose was going to cost a fair bit. J W Insulation from Halstead in Essex came in with a good price and are lined up to do the work w/c 4th August. Before that we need the VCL membrane fixed the roof. In the end we decided that a specialist company would be best for fitting the ceiling VCL, the airtight wall membranes, and additional internal insulation. We have South West Insulating from Redruth coming along from 28th July to do that work. So we have a busy few weeks ahead - I am hoping all that activity meshes together and the various teams don’t get in each other’s way (and the drinks fridge is big enough!). And finally (for this week)… Frustratingly, despite the frame being up for a week now, as a wheelchair user with a 300mm high perimeter foundation wall to get over I have not been able to see inside. Until today… Although I promised Mrs P. that this build would involve no heavy lifting or lugging on our (i.e. her) part, today she has been heroically moving pallets, ply sheets, and 4m scaffold boards into place, which we have screwed together make a wheelchair ramp! So today for the first time we could both enjoy the shape of our new house from inside. And we love it! It's impossible to capture in photos but we are both really pleased with how it feels, the room sizes, the vaulted ceilings, the overall layout… everything. Which is just as well really as it’s a bit late to change the design now 🙂18 points

-

Dear forum members, Our house is complete and we have been resident for three months. I thought to post some pictures and I offer to answer any questions people might have. I don't put ourselves on a pedestal as being any better than other projects, only to say that we have done it. Our primary decisions: We chose a RIBA architect given the importance of the initial concept The layout is somewhat novel, having an H footprint with a single storey 'extension' to reduce the mass of the main house for planning purposes and to help project the rear of the house beyond the shade of the ridge line We chose timber frame (we have built with timber frame, brick and block and ICF in the past) because of speed of construction, and thermal performance We selected MBC from a shortlist of three TF suppliers, and chose MBC's insulated slab We are very pleased to have chosen a large solar array (9KW) and Tesla battery. We have used no grid electricity since commissioning. We have a Valliant ASHP with UFH but haven't had need to heat the house yet We have MVHR which works very well with our air tightness of 0.89 We have no fireplace or chimney We project managed ourselves, and were onsite every day and I did a lot of carpentry / general work alongside the proper trades Project timing: groundwork prep Dec 24, slab Jan 25, frame erection February, windows March, resident 4th July, finished end of August.15 points

-

I should probably start a blog for this sort of thing, but I just wanted to let y'all know that we finally got planning permission - 4.5 years after buying the site, after one application with a committee hearing, and the latest application that took nine months to determine. Thanks to everyone on here for their help, advice, and nudges on expectation alignment!15 points

-

I am currently waiting for Structural Engineer to share a report. But Pasquill gave me quite a comprehensive email but in summary: They have confirmed that the main issue on my site is that the steel valley beams have been set in the wrong position and at the wrong angle, they should not go through the internal corner as built and need offsetting a little this means the pitch is out by one degree. This has also caused the problems with the fascia and soffit lines. Pasquill say the Posi rafters already fitted may still usable if the beams are moved to the correct positions, though if any hidden cuts are worse than visible they may need replacing. If I do decide to replace the 12 rafters sitting on the valley, Pasquill have offered to supply new ones at a very reasonable price for me ( Which I have said yes to ). The next step is to fully dismiss the builder, take ownership of site. I have found a good joiner to come sort the posis, and will just await the SE to give me a plan of action for these steels.13 points

-

Major news!!! Guess what? Sunamp have just emailed me to say that they are going to replace our unit as it is covered by the 10 year warranty on the core! They emailed me as I was typing the reply above.13 points

-

Blogging: an activity where the perpetrator converts trivia into prose and in doing so reorganises their own otherwise disordered mind. Possible side effects: perpetrator enhancing feelings of self importance; boredom amongst those reading; history being rewritten. I find it interesting to contemplate why I don’t have quite such a burning need to blog at the mo. I’ve always enjoyed working with wood and metal and power tools. And that’s what I’ve been playing at for the last three weeks. I’m not really at home with concrete and soil and masonry - they’re from another planet. On top of that I’m working closely with Rolly the chippy, and he is knowledgeable and experienced, which translates into me having great confidence in him, and additionally he is calm, and has a very powerful calming influence on me. So my head isn’t quite so haywire most evenings now, certainly less than it was during both demolition and groundworks. My head is also full of diagrams and schedules. Both the project and the timber frame kit are constantly changing puzzles which I do kinda understand and can usefully sit and think through - and having puzzles to occupy me keeps both anxiety and random diversionary thoughts at bay. Which is a v long winded way of saying that I’m happy with how it’s going right now. Since the last entry the house has shot up. We’ve had roughly a metric ton of steels popped on to the top of the downstairs panels. Two steelworkers, me, and a genie lift, watched by J and Steve the injured builder. It’s fascinating how banter volume is inversely proportional to difficulties being encountered. It’s also fascinating how distracting, frustrating and irritating little side comments can be from the audience. I’d never cope with stand up - even the gentlest heckling would completely derail me. Jerry and Paul however are made of more hardy stuff. Most of the steels they got up in no time, but then we got to the bogey - the longest, heaviest beam. It would have been massively easier had it been wheeled into the house the other way round, and in hindsight we’d have finished quicker had we put it back on the trolley, wheeled it out into the road, smiled sweetly at the scowling motorists who appear to turn purple if delayed by more than 2,345 microseconds, spun the beam round and wheeled it back in. In fact that was even suggested, but no, perhaps because it would mean admitting defeat, we soldiered on regardless. Regardless and in near silence. Even the audience cottoned on and were uncharacteristically quiet. Then suddenly, we got the beam to spin round above the head binders, dropped it into place, bolted it up and the only thing drowning out the huge sigh of relief was the loud resumption of banter. Banter and tea appear to run our build, both as a glue and a lubricant. Feelings do run high at times and managing feelings, both my own and others, is far more important than I ever imagined. An essential part of that is that the peeps working with us seem to care about our progress, take pride in helping us. We make no secret of our inexperience and our reliance on others and so far that has been met with both kindness and determination to help us. We’ve been stupidly fortunate. Anyway, we’ve also put up the rest of the downstairs panels, including the monster 11’ wide one which was the heaviest of the whole build. Leaving that till we’d done the rest of the downstairs turned out to be a very smart move. We probably found it easier than any of the panels we put up in the first week of frame erection, despite the weight of it and the fact that it was awkward. Part of that is Rolly and I settling in to work with each other. There is now a lot less verbal communication than there was to start with. We’ve also honed panel handling so there’s less pure physical grunt needed. And of course, as time goes on with each panel fitted we’ve more room to work, and that’s also significant. With such a cramped site we are constantly tripping over stuff, moving stuff repeatedly, trying to get stuff delivered at the last minute, etc. But much as I might try to plan, at times there’s no choice but to work with way too little space. A good example is the joists. They were delivered before we’d finished putting up the downstairs panels and there’s an awful lot of them. Ideally I’d have put the delivery back a couple of days but that wasn’t an option. I had no idea how much time the limited space would cost us. Ho humm. Talking of joists that was the next job. Rolly and I deposited nearly another metric ton onto the downstairs panels by hand, (just how much does this ‘lightweight’ timber frame structure support?). I say by hand, but shoulders, knees, and just about every other available body part was deployed. I don’t know what lifting capacity each of us have but somehow when working together we exceed more than the sum of our two capabilities. It’s probably simultaneously driving progress and pushing us a teensy bit too far towards injury risk but it’s just what one does. Joists up Rolly set to making us a temporary staircase while I attacked flooring boards. The temp staircase really has helped reduce fatigue and made getting things upstairs safer and easier. Good idea Rolly. Anybody would think he’d done this house building stuff before. We’ve so many joists we almost don’t need flooring boards, but they’re on the design. Yet another metric ton of them. Plus several kilograms of this funny polyurethane glue stuff. That’s really odd to work with. The first day I came home with black gloves on, only non removable ones. I’m sure my fingerprints must have been obliterated (I certainly couldn’t unlock my iPad) so that would have been the time to do a bank job. But there was no time for niceties as the following day the upstairs panels were due and the telehandler was booked, so I had to get enough decking down to allow the piles to be dropped upstairs and sorted/distributed so the other two piles could follow. Rolly was given the day off for the delivery - he’s not supposed to be full time anyway and his skills are reserved for the clever woodworky bits. So Andy the Boss supplied a telehandler driver who was also a power lifter and another equally capable bod to help me sort the panels. When the downstairs panels were delivered they were dumped in the piles they were transported in and Rolly and I had to reshuffle them, which took lots of time and energy. This time I got the long suffering timber frame company to send me pics of the piles so I could work out which pile to do first and how to sort them into sensible piles. For once the theory worked in practice and despite the complaints about how near the edge of the deck I kept walking that day ended with three piles in a near sensible assembly order. I was pleased with myself but I had a nagging doubt - would it speed erection? As I was pondering this very question Dean the neighbour (two doors down) wandered onto site to offer his help with future deliveries. “Why wait for a delivery?” I asked, there’s tons to do and I’m certainly not too proud to accept help. Next day Rolly and I attended to the odd bits and finished the decking whilst the first lift of scaffold was put up. I’m not sure I did anything but look for discarded cups, (sort of) wash them, boil a kettle and make tea, repeat. Rolly has a near infinite tea consumption capacity but the scaffolders beat him hands down whilst managing, like Rolly, to work hard and get lots done at the same time. The song definitely has it wrong, nothing stops for tea but it gets drunk anyway. Tea is useful though. Rolly arrives way before we are allowed to start work so tea helps him cope with rising agitation as the clocks edges glacially towards 08:00. Tea (and biscuits) helps me get Rolly to stop work long enough to help me plan too. And as we drank our tea and discussed the upstairs panels Dean the neighbour arrived. “I can help for a few hours” he said. Now Dean is in his mid eighties so the average site age rose to 73 that day. Hence my initial caution. I started getting Dean to help me organise and stack lightweight stuff, but it became clear that as he tuned in to the way Rolly and I worked (it’s a kind of grunt and nod based language previously unknown to science) that more ambitious stuff was in order. Panels! The three of us got the first two corner panels up, rather effectively. Whilst Rolly was checking and bracing and securing those panels Dean and I got ready for the next panel, only we didn’t, we put it up ready for Rolly to do his check/brace/secure thing. Fast forward, and I do mean fast, and five hours later almost the whole of upstairs was up. Staggering. And very satisfying for all concerned. Perhaps the speed was helped by my sorting after all. The next day Dean pitched up we lifted the gable panels from the ground floor - there was no room on the deck to use the telehandler to get them up previously - we used ropes, crabs, ladders and way too much giggling but up they went so another keep me awake job was dashed off. Don’t underestimate the capability of us wrinklies. Not so easy was the cement board fitting next day. It’s a bitch of a material to work with and slower than I’d have predicted. But we need it done before we fit the roof trusses - finishing these and getting breather membrane on will be the first job next week. On Friday we were ready in good time for the roof trusses, all 19 of them. Two powerlifters from Andy the boss arrived just as the lorry backed onto site. It’s almost like it was planned. They took one look at the job, shook their heads and took up positions. It worked like this (after a couple of false starts): Driver on lorry pushes ends of truss to edge of lorry. Shortest guy on site grabs end furthest from house and has the job of stabilising the truss. It’s at this point I realise why I need platform steel toecapped boots. Short tempered power lifter grabs end of truss nearest the house. Truss is run towards house like a pole vaulter on speed. At last second short tempered power lifter pushes his end of truss skyward. Shortest guy at back of truss grunts and struggles to keep truss upright whilst swearing, profusely. Truss end is caught by other power lifter (the smiley one) just before it lands on the upstairs floor. Smiley power lifter drags truss upwards as shortest guy is dragged along the ground with it still trying to keep truss upright. Rolly and smiley place truss neatly on rapidly growing pile. In total there was 31 minutes between lorry arriving and the truss pile being completed - if my pics weren’t time stamped I’d not now believe it. That made even the short tempered power lifter grin. To finish the week while I continued fitting cement boards Rolly prepped the first truss for a test fitting. Getting the first truss up felt good, really good. That made me grin. I’m loving this part of the build. Yes, progress is visible, and that helps, but it’s more than that. Even when I’m doing things I’ve never done I’m in my comfort zone, and the muscle and joint aches diminish overnight, and I’m not generally laying awake worrying. OK, that probably means I’ve missed some thing or things that are really important, but I’m feeling good. Long may it continue.12 points

-

After many years of searching, we finally have a plot! Our offer on this plot was accepted in March 2024 and we've only just now completed. But we're excited that it's finally done and we can move forward. Next steps: We have an architect already and a set of draft plans. We'll be working to finalise these plans and take them to planning. The site has detailed planning permission already, so we'll just be looking to vary the design -- and not significantly so fingers crossed it goes okay.12 points

-

So a few months in to our build and I have to agree that self-build is hard work! It's also an amazing experience in which every day brings something new. It's difficult to say whether this is physically the hardest thing we have ever done because I think age plays its part, we are late 60's or so and even though we are both fit people building at this age cant be compared to the house renovations that we have done in our 30's, 40's and 50's. What I can say is that we wouldn't swap it for anything, we have promised ourselves that we would self-build for years and to be actually doing so is an amazing experience. Onwards & Upwards!12 points

-

After what feels like forever we finally started real works. We’ve done lots to the plot, tree clearance, root removal, digging out beds, planting, etc. but little to da bungalow itself. We held off stripping out ‘til we were sure the project was viable, which was über cautious but that’s us. Selection of timber frame supplier wasn’t straightforward. It came down to a local-ish company (ETE) who supply a panelised frame for manual erection on site or stick built on site under the supervision of an SE. Most frame companies require crane assembly, which we can’t have due to overhead wires. But once we felt we were in the right place, planning, party wall agreements, demolition survey, site insurance, timber frame supplier, the main peeps to help us build, etc. then we got down to it. That initially meant selling/giving away the kitchen, a fireplace, the conservatory, the UPVC windows and door, an electric fire and even a garage. I had intended to do more stripping out before the cavalry arrived, but there was always a more important task: digging test holes for the structural engineer (needed for the foundation design, so vital); getting the gas meter removed/capped off and the pipe cut of at the verge annoyingly costing £1,700 (not safe to have gas on site in the way, so vital); replacing fence panels including digging out big roots (to keep the neighbours on side, so vital); erecting a shed, with of course a base (to keep those working on site happy, so vital); moving the water supply (to avoid it being trashed by the groundworks, so vital); digging in (by hand) the 10m of electric duct, casting a concrete base for and installing a huge, but apparently necessary, meter kiosk to comply with the DNO requirements, enabling them to charge us £9,500 - ouch - so vital); dismantling the garage (which was in the way and we wanted it to be reused, so vital); and finally, dismantling the conservatory (which was also in the way and we wanted it reused, so, you guessed it, vital). Turns out breaking up concrete by hand is exhausting, but oddly therapeutic, even if you do bend your ancient trusty steel spade. I wonder, have I got so used to digging foundation test holes and digging soakaway test pits and digging out roots and digging in pipes and ducts that I’m actually going to miss digging? Scarily possible! Who needs a mechanical digger when you’ve a mattock from Amazon and a new steel spade from Toolstation? But then the real works start. 34 years ago we built our current house helped massively by Steve the builder, who was a bit older than us. This time round it’s a repeat, as the same Steve is helping us and given that I’m nicely in my 60s and oddly, Steve is still older, it means that none of us are in the first flush of youth. So my theory was that Steve was the brains and I would be the brawn. Wrong. Steve is both it turns out. Monday saw us stripping off roof tiles and after a day on the battens I was wiped. Tuesday saw me on the battens again for half a day stripping the rest of the tiles and then, just to vary things, I then spent some time on the battens stripping off the felt on one face so we could get the chimney down and kick down some ceilings (overboarded lathe and plaster). Whilst we were out on the tiles UK Power Networks, our DNO, dug up the road and put in our underground electric feed. And a quick bit of begging over the phone got the meter moved that afternoon, so we had site power again. Bliss in a coffee cup. So by the end of Tuesday I was pleased with progress but exhausted. On Wednesday we started stripping out walls and we discovered that there was a lot more plasterboard than I first thought. Damn. Pronto plasterboard skip ordered, we estimated that we’d need a 4 yard skip, so to be safe a 6 yard skip was ordered. Which meant we needed easy barrow access so we removed a window and cut a new front door. Wednesday night I went home totally exhausted and less than pleased due to all the newly discovered plasterboard. That night I came to terms with my limitations, so I messaged Steve to suggest he do a 4 day week to give me time to tidy up and recover. He agreed and offered to buy me a pipe and some slippers. (Pic of new door) The skip arrived promptly arrived at 07:30 next morning. There then followed a rabid day of plasterboard removal. Incredible how effective a spade can be indoors when instructions are given to the novice. By the end of the day we’d nearly filled the skip and had just a hallway ceiling left covered in the dreaded plasterboard. I could hardly raise my arms. One of Steve’s endearing features is his sense of humour. One of his most irritating features is his sense of humour. So as I’m on a step up, gritting my teeth and willing my arms up again and again yet another joke prompts the giggles. That was it, hopeless. My giggling got him giggling and progress paused. Priceless. But determination sustained and the skip was filled. Thank goodness for over-ordering. I went home a zombie, but with less energy. Friday and Saturday were tip runs and tidying up, and now on Sunday I sit quietly reflecting on a week that was unbelievably productive, thanks to Steve’s experience. But oh my, it starts again tomorrow. I have no idea if anyone will find these ramblings of interest, but they are, much like digging, remarkably therapeutic too!12 points

-

TL:DR just a bit of fun - Mods feel free to move if not OK in the section. So my first timber framed house completed, I had some must have criteria for the design. - Open plan - double height ceilings - EDPM roof - OSB walls with wood cladding - no high spec windows - main access will remain open at all times Background For every DIY project you end up with leftover materials - you carefully store them in the hope that they are useful one day I had too much in my storage area…… Why did I choose self build? (Always a common question right?) At the back end of winter I had to replace the last section of original fencing (43 years old so it s done well) so I had some featherboard offcuts. In redoing the fence I discovered a hedgehog hibernating in the leaf litter (at that time of the year I wasn‘t sure if it was alive or dead but apparently if they are in a tight ball it s a good sign) We’ve always had a lot of hedgehogs coming thro the garden they like bamboo leaf litter and we created several entrances and exits that we keep clear so they frequently come thro the garden using it as a short cut to other gardens Anyway with the little critter in my way under foot I had to work carefully round it (gender neutral at this stage) so took me a little longer than normal About a month ago I was glad to see the hibernating hedgehog woke up and I was really happy to see it snuffling round the garden (eating slugs) So last year I rebuilt and re-roofed my shed so had some EDPM off cuts and a fewoff cuts of OSB board from the roof and shed walls So rather than throw it all in the tip I thought I d build a better shelter as a open air pile of leaf litter isn t exactly a great shelter. So here is an almost finished hog house (needs a coat of preservative and I m thinking 70 s flock wallpaper for the interior maybe orange) Anyway enough background here s the pictures I also have so 75mm celotex left over but figured if the little bugger can survive under a pile of bamboo leaf litter it doesn t need an insulated house11 points

-

Rick - would strongly advise against this position and sending a letter like this. At this stage your builder is possibly preparing themselves for legal proceedings. In this instance you are absolutely advised to commit as little as possible to written (or even verbal form). I would advise that you don’t continue with this contractor under any circumstances - and get yourself in a headspace where you’ve accepted you need to find someone else. reading your contract you can’t unilaterally terminate the contract as there is the provision for remediation. My first course would be to request a without prejudice conversation with your builder. Within this conversation (have a third party present such as your SE, architect or a friend) set out that from your point of view the trust and relationship has degraded to a point of no return and you do not under any circumstances want the builder to continue. Explain that if that isn’t agreeable you will exercise clause 37 and at the builders Cost they will be required to replace all posi rafters and fit them to the satisfaction of your SE. State that Pasquill have advised they are likely not recoverable. This is an expensive exercise for the builder. Others may suggest you try and get them to cover the cost of doing the job right. Personally I wouldn’t trust them anywhere near my site. I would seek a negotiated exit and write off getting any money back. Alternatively, if the builder doesn’t agree I would advise you exercise clause 37 immediately. I doubt that they will remediate within 14 days but if you don’t follow the provisions of your contract your builder can pursue you. I would advise a letter that is entirely factual, unemotional and succinct if you need to serve a breach notice. I can help draft one if you need. Accept your relationship with your builder is over.11 points

-

Da bungalow that is, not us mortals. We carry on sweating in our hi vis. We were pleased with how the timing worked out - planning to demolish during cooler months so all the neighbours will be wrapped up warm indoors away from the dust, plus it’s hard work so cooler temperatures help comfort. So much for that plan with our mini heat wave! Steve took pity on me by leaving me recovery time on Monday and Tuesday. Good news from a site clearing and tidying point of view. It gave me time to kick down the last of the ceilings, mostly while the windows were still in, and then for J to pick out all the lathes for safety and for disposal at our nearby recycling centre (I’m old fashioned, I still call it the tip!). Trevor the trailer was bought for £200 just over a year ago to help clear the mountains of brash from clearing the massive overgrown conifers. Skooby the Skoda was bought as a building vehicle for £700. We now realise that they have paid for themselves many times over in saving in skip costs. If I’d known how much we would be saving we might have bought a car with a working heater, but hindsight is a wonderful thing. Monday afternoon was window removal time! Ben arrived bang on time and had agreed to help us remove the windows, though he’d never done it before either. I was relying on Steve’s knowledge. Shame he wasn’t there. So da bungalow now has a series of holes where windows were. Each neater than the previous one. If you look at them in chronological order you can see evidence of two keen but clueless numpties first hacking out a huge hole, taking forever, graduating in stages to the last one which was beautifully neatly and quickly and efficiently removed. Yet another example of experience being the thing that one acquires just after needing it. So by Tuesday evening we had a clear site, which is incredibly important on such a tight, narrow plot. And then next morning, Steve returned to the job, so progress exploded again. We stripped the felt and battens off, with muggins of course being the idiot hopping round on the battens for two thirds of the day, with the last third being careful removal of some of the roof timbers. Rather disappointingly, we found woodworm everywhere. So my plan to build my hideaway at the bottom of the garden from reclaimed roof timbers has gone. Some of the timbers came away scarily easily. But those that didn’t put up a hell of a fight - they used huge nails in the 1920s it turns out - and this wasn’t ideal as force had to be used in moderation in case of unseen weakness leading to accident or collapse. We were probably overly careful but better safe than sorry. The next two days are a blur of heaving and bracing and sledgehammering and chainsawing. Thank goodness for a decent twin battery Makita saw - saved us no end of time - and my little one handed chainsaw - AKA Lightsaber - was slower but brilliant in places too. It’s oddly satisfying knocking off the little bits of wood that hold up the soffits and facias and rainwear - sending the whole assembly crashing down in a plume of dust. Even more satisfying to push over the block gable - the thump when it hit the ground was like felling a big tree, primevally enjoyable. We did take a break for a site visit from the ground worker. He asked all the right questions which does give confidence, including asking me to gain permission from our neighbours for him to hand dig one shared corner of our frontage to carefully identify where our neighbours services are. He might even have a use for the roof timber mountain we now have! More skip cost saving. All this is punctuated with other strands of the project. They are vital but hard to find the will to divert onto when mid hammering. In that way J and I are working together fantastically. I haven’t the bandwidth to think - I run to keep up with Steve when he’s there - I run to tidy up when he’s not there to get ready for when he will be - I go home a bit too late each day and after a coffee and a discussion about the day I then bath and by the time we’ve eaten it’s bedtime. Buildhub, apart from my weekly therapy session (oh ok, blog writing) is a distant memory. So J does the thinking, I do the grunting. That’s a little bit of an overstatement as in my head, when I stop to access it, is a 3D model of everything and every junction and material and supplier and missing quote and little red flag of issue that might become critical path and hence needs sorting before it does. I can and do flick into ‘principal designer’ mode when needed. But the day to day scheduling and remembering is falling to J. J has given me a little exercise book and my own grown up ball point pen to keep my to do list in. It’s a bit year 5 but it turns out very effective, as long as J remembers to remind me to look at it. Between us we are working incredibly effectively. Long may it continue.11 points

-

Morning all. I don’t drop in here very often these days but just happened to browse on my way back from an extended trip to the USA. Lo and behold I see a post from @Jeremy Harris talking about Sunamp so thought I stick my head above the parapet and say hi. I’ve just looked at when I last posted here. It was June 2020! Where in hells name does time go? So here’s a quick summary of what I’ve been up to in that time (possibly not in chronological order): Fully retired (two years ago). Finished my build which is well documented here and there on this forum. Then sold it in 2021 and bought a “project” which I gutted (nothing left but 4 external walls, the roof and a worrying array of steel and acroprops). Then spent all lockdown rebuilding it. Finished the house but am still working on the landscaping. Spend vast amounts of time faffing about on my small holding (came with the house). Have I learnt anything? Yes, a fair bit: Stop buying houses on the national park, planning is a PIA (but the views are exceptional). When you retire you can’t work out how you ever had time to work! I can’t sit still. Wish I could (I’ve always known this really). Renovating an existing property is way more difficult than a new build. Building during lockdown was a complete nightmare. The window supplier/installer is more important than the window! Actually had a great experience with this renovation which is a world apart from the pain I experienced with EcoHaus SW and Internorm. Just stay WAY clear of “bleeding edge” technology. Exhibit A: SUNAMP (I might comment on the thread which started this resurrection off). Land is a time sync, the level of maintenance is mind blowing BUT it gives you an excuse to buy a digger, tractor and trailer. Plus a myriad of attachments Well that’s it for now. I can’t promise I’ll return to being a regular contributor. I simply spend much less time time in front of technology these days. I much prefer being outside. P.S. I think I’ve got one more build in me before I fully reach my target of eccentricity and too many animals.11 points

-

Last night was my first night sleeping in my new house, finally! Got 1 bedroom mostly finished. Ikea wardrobes, painted, blind and floor installed. Just enough to call it a home! Lots more to do but it saves rent and commuting time. I plan to take it easy for the next fortnight as the last two years have been creeping up on me. Small projects for the short term. Getting internal doors installed (by someone else!) currently. Put some acoustic insulation around the linings and cut it back. I like the look of the wood/oak veneer. Been chasing documentation for the BER (SAP) assessor. It adds up to quite a lot. Doors, Windows, Heating systems, section plans, U value calcs. Think I have all of it now - hopefully they'll issue a BER Cert soon! My airtightness commission went sideways, lots of leaks. So one of my snags is to put air tightness tape around all the ducts to the MVHR unit and outdoors and also between it and the manifolds. The testing unit is very sensitive (even dropping it puts it out of commission for two weeks!) so I've a bit of work to do before I call them back. The Renson Endura Delta 330 has a few levels of ventilation and they upped the minimums from 50m3/hr to 127. Will see with single occupancy if I adjust this down a bit. I can monitor the unit with an app only, there's no display. I noticed when I ran the supersayer gas heater for a few hours to warm the house (as the gas bottles had been unused for the last two years) the CO2 levels hit the roof and it went to max flow rate to clear it out. Anyway, I plan to use the Air to air system more going forward and that won't cause the same issue. Had two floods to deal with. I've a japanese bath I was trying out. We'd filled the bath with a little water to check for leaks a few weeks ago and it drained fine. The bath is on a platform to allow for a trap to be installed below it. The drain for the bath just fits into a grill so it's open and can potentially overflow which is what happened after I fully filled it, used it and two days later pulled the plug! Luckily I put the plug back in and used towels to keep the water in the bathroom as it's tanked / is a wetroom so no damage was caused to the rest of the house. There is a seat in the bath so I was trying to get the most comfortable position and removed the seat. I'll probably put it back as it's a short bath and my back didn't like the sitting position on the floor of that bath all scrunched up. The seat means you only get heat around your hips so will have to have a think about it more at some stage. Or get a bigger bath! The second incident was with the washing machine last night. The discharge pipe isn't big enough for the tumble dryer, air to air condensate and the washing machine so I got an adapter that taps into the side of the pipe with a spigot for the washing machine discharge. This didn't seal/hold so it spilled everywhere. I think I'll go back to basics, replace that section of pipe and glue on a y bend to create two parallel discharge pipes and this way I can get everything connected at once and no risk of floods! My car charger won't reach the car as it's about a meter short but that's due to a big hole I've to backfill with MOT. The dust is everywhere but at least with the internal doors I can mitigate this a bit going forward! So not finished yet but I have a doorbell, hot water, heating and an amazing house to walk around in and rest a bit before finishing the final list of projects and call it a day!10 points

-

This day has been on my mind for months. We really struggled to find a company that would visit the site and confirm whether we could get a static down the lane. In the end we took an educated guess and purchased a 2023 37x13 unit from a private seller. So at 1100hrs today, the wife of the driver (Greg Caravan Haulage) appeared in the driveway telling me I needed to go and cut some low hanging branches. We got the static on site relatively easy, but then it got bogged down twice whilst reversing it over the type 3 MOT. We had to Jack it up and then finally decided that sheets of 18mm shuttering ply under the wheels might be the way forward. In a nutshell , if we’d done that from the start we’d have got it done much quicker. It’s in position and I just need to get it levelled and on blocks now. A bit too stressful for my liking, but relieved. I’ve been more concerned about getting the static on site, than building the house.10 points

-

Once upon a time a deluded wrinkly, his much less wrinkly wife and their noisy little dog left their almost fairy tale rural retreat to live in a freezing rented bungalow while they buggered about trying to build a new semi-urban retreat nearby. (How clever am I avoiding the word suburban!). Everything would have gone swimmingly but for the fact that the head of the wrinkly was just too full. It sort of still is I think. In the four months since the last post (stop thinking of a bugler at sunset even though some days that feels appropriate) much has been done: We’ve built a garage and the front of site is much less of a moonscape. All our blockwork is in, much of it rendered. We’ve now got one flat roof and two slated rooves, one with loads of solar panels. All our windows and some of our doors are in. We’ve got 240mm of underfloor insulation and a circa 100mm sand and cement screed with lots of buried pipes, of both the heating and soil varieties. The screed alone changed things to more house than warehouse - fabulous. Almost all the internal wall skeletons are back up - so now we get a much better feel for the layout which is a very good thing. (We built some downstairs walls earlier but took them down to make the DPM and insulation easier.) Most of the frame insulation is in. There’s even loft insulation in the loft - ok it’s still in its rolls ready to be fitted but it’s still there, patiently waiting. And there’s some VCL in place and we’ve made a start on the inner skin - some battens and yet more mineral wool to form what is really an insulated service void to give us a half decent wall U value. The man cave has its insulated metal panel roof and is usefully storing tons of stuff. All the service pipes and wires are buried in a trench ready for connection to said man cave which meant yet more depressing hours on a digger, and now the back garden is a moonscape. A humongous insulated twin pipe monster conger eel of a thing is buried, surfacing at the concrete plinth for the heat pump at one end and in the under stairs cupboard at the other. We have surface water drainage pipes installed at the back. Phew. No wonder we are worn out. And I’ve probably left lots of things out too - when you are on site every day it’s so easy to forget what has been done and focus instead on the rather elongated to do list that keeps me awake at night. Not every night mind, some nights are a lot better than others and I am getting a vaguely sensible amount of sleep more nights than not now, thanks to constantly talking stuff through with J. But there is an essential difference in the build. Before we sold Bramble we knew we were running out of money so we weren’t going at full hurtle. I had a twenty minute drive to and fro and a soak in the bath, all of which helped me keep my head in the game. It felt like there was time to think. Now I have a twenty second walk (if I dawdle) to and from site. Despite the ice box (aka rented bungalow) having a really powerful gas combi boiler it has a low power electric shower that dribbles just enough water to get clean but not get warm. And we’ve the money we need to complete, so it’s warp factor 8 Mr Sulu. Now if I was doing this on my own I’d have no choice but to slow right down, and try and get my head together, and feel in control again. Thankfully we are totally in this together, so we aren’t slowing down. Not that it’s without tensions. J and I talk everything through and she keeps track of tons of things that I can’t (hopefully everything that I can’t, which is an unfair burden but that’s how it is). We identify short term priorities and I focus on them, with me tacitly accepting that I am not personally in control of everything as for me to be so would mean a lot slower progress: neither of us want to stay in the ice box a day longer than strictly necessary. So the tightrope act is to balance keeping the pedal down as hard as possible without us actually losing control or allowing any major cock ups to occur. Simples. It gets harder when there is anyone else on site but ourselves and Rolly, our chippy. Peeps are incredibly (and I believe unconsciously) attention hungry especially when their needs are coupled with my need to monitor all work and limit disturbance to the neighbourhood. It’s so frustrating that when a contractor is on site my own productivity declines enormously. And then there’s the gargantuan mess, especially in one particular case - the thoughtless dumping of spare stuff; the treading of material up and down the road without a care for the frozen moron still sweeping and hosing down the road in the dark hours after they’ve finished their second pint; the drifting flocks of discarded paper bags mixed in with fast food packaging. Sigh. At least everyone we’ve had on site so far has done excellent work, so that does compensate. The feeling of a lack of control is not helped by the fact that I’m completely useless at estimating the time needed for tasks - though as J frequently mentions we’ve not done lots of this stuff before so we should accept that we can’t know. The DPM and underfloor insulation took me many, many times what I imagined and I’ve a black belt in beating myself up. I enjoyed doing the lower polystyrene layer, so nice to work with, but hated the PIR layer. The polystyrene has spring in it and one can cut pieces a little oversize, lever them in and get a really nice, tight fit. It’s messy in that little baubles of white stuff get everywhere but they don’t get down your throat. PIR however is sooooo different. The dust it creates is truly horrible, it lingers in the throat many hours later even if a mask is worn, which it mostly was. It almost appears to shrink away from it’s neighbours - when cut to precise size and shape, wrestled into place shooting showers of nasty dust up as the air trapped underneath is expelled through the tiny gaps at the side - it still sits there showing a small but definite gap between the sheets. Not at all satisfying. Thank heavens we ignored the architect and chose not to put PIR in the walls. So it turns out that there is a job worse than moving tons and tons of crush. But thats now done, thank heavens. As an aside I’d planned just polystyrene, but the reinforced slab came up a bit more than planned so I switched to part PIR to get the insulation level I’d targetted. Note to self: get quotes for different thicknesses of stuff before deciding. Buying stuff that local suppliers have on hand saves tons, which accidentally benefitted us on the underfloor insulation - had things gone to plan it would have cost us rather more for the same insulation performance due to me designing in theoretically available sizes. Odd world, innit. The need to book contractors is a real source of pressure. An example: We have been recommended a plasterer who everyone says is brill and so is v busy and we don’t want to lose him, but that means guessing a timescale and thence sticking to it. I’m an ex-project manager. I know that to manage the project requires knowledge of the timescales for each task in the train, and as above - I really don’t have a scooby. Well, I do, but Skooby the Skoda probably doesn’t count in that regard. So, in summary we’ve got tons done, but tons still to do. Xmas has annoyingly punctuated the project but that’s probably a mental godsend - at least I’ve a popped ballon to enjoy putting in my empty honey jar. We’re working really well and closely together as a couple and I will get used to the feeling of panic just below the surface that not feeling personally in control causes; the foreboding that I cannot be confident that I haven’t missed something important; the relying on J that will deliver much faster progress. You never know, my next post might even be a bit about the build…9 points

-

On your marks: Get set : Wait! Day 1 of panel erecting was rained off. Humph. I tried to pretend to be human again by popping into town with J for a spot of bargain hunting (for stuff we don’t need, natch) but inside I’m still a self build automaton. My recovery won’t really start till we move in methinks. Next day we start the day by admiring my new paddling pools. The previous week I carefully swathed the piles of panels with tarps before it rained oodles. Good theory. But without me noticing the panels with doors or windows happened to be uppermost so they filled with gallons of water - pulling the tarps into the hole with them, so parts of the panels got a bit wet as I wasted time bailing and lifting tarps to get rid of the water. Eventually we started fitting sole plates. Happily the blockwork was very close to mm perfect so there was little in the way of adjusting needed. Next job was to fix trimmers to the outsides of the windframe which stabilises the rear of the house, and was, we felt, the safest place to start fitting panels. Cue Hilti gun. I was dead clever at this point. Instead of wasting money hiring I bought a cheap ex-hire one. After a false start requiring the gun to be swapped I tried to use it to fix a trimmer to the windframe. Nil pois. The flange was 12mm and there was no way a Hilti nail was getting through. So I’d ended up wasting more money than hiring. Damn. Will try and resell. The self drilling screws I’d bought as a backup didn’t work either, they just snap. So the cavalry, in the form of J, raced to Grip Fixings for some FB self drilling screws which, after some experimentation we did get to work. Once the sole plates were down and the trimmers were on it was time to play musical panels (without music, we are a no radio site). The panels were stacked for most effective transportation, not in installation order. But that doesn’t matter as each panel has easily removable lifting straps so it’s dead easy for the crane to pull them off from the top, drop them into position, apply a temporary prop and go on to the next one till they are all up and can be stapled together. If you have a crane that is. Our site is oversailed by next doors telephone and mains cable, and the front of the site has both kinds of wire strung across it too. That’s why almost all of the timber frame companies I talked to at the self build show wouldn’t quote. Just one SIPs company would but they gave every impression of not caring about minor details like feasibility, perhaps because with the prices they charge they could hire a Chinook. The company we are using typically supply builders who instal themselves, which suited us a treat as tins of spinach aren’t that expensive, and otherwise it would be stick built on site which was a bridge too far. We’ve benefitted greatly from the experience and engineering knowledge of the panel company so in hindsight right now it feels like a really good plan. But on the ground, when the panel that logically should be installed next is at the bottom of the biggest pile with the biggest, heaviest panels sitting on top of it, one questions previous decisions. Many times I called time out to consider if we needed more muscle on the team. I have excess bloody minded JFDI determination but compared to Rolly the Chippy I’m a snowflake. I’m not sure he understands the word can’t, which makes ensuring on site safety requires both strength of character and a big gob. And firmly resisting the temptation to ‘just go for it’. To start with it really did resemble one of the old sliding tile puzzles I used to do as a kid. Only with tiles that don’t slide and are up to 8’ x 11’ and weigh up to 135kg. It started getting better when I took some time one evening to ship as much possible down to the man cave slab at the bottom of the garden. With each panel it got easier and we steadily accelerated. Happy days. Not so happy when it rained though, but we erected the little camping shelter I had in reserve which gave us somewhere to sit and plan in the dry and it gave us the chance to deploy my table saw, which is useful. On the Friday the joist delivery and subsequent stacking took me most of the day. The delivery driver was about 4 decades younger than me, a foot taller, looked strong and was brilliantly helpful. At first, us moving 6.3m 47kg posijoists from the lorry to our slab saw me running to keep up. After the first few he slowed down to match my speed, or so I thought. A few more and I found myself wondering why we were going so slow. I’d worn him out. By the time we’d finished he was visibly wilted, but we’d done it. I separated the flat roof stuff out and shipped that down the garden too, which used up the last of my day. Thankfully nothing stops Rolly the Chippy so he’d carried on doing useful stuff. By the end of the week we’d got the two sides mostly done. I stood in the back garden and looked back at the pics of the site when it was first cleared. We’ve come a long way. It was a needed boost. The next Monday our big glulam arrived, easily transported on my super useful little trolley. I’ve been laughed at and teased about my trolley, but it’s moved an awful lot both on the slab and up and down the garden. Rolly’s little board with casters is better for moving panels on the flat slab but my DeWalt trolley is the bee’s knees otherwise. By the end of Tuesday we had all load bearing panes (external and internal) up, with header plates in place so we were ready for the metal men to come and instal about 800kg of steel atop the panels. So Thursday Rolly and I rechecked everything was still plumb (small adjustments needed) after the weight of the steels had landed and then it was time to focus on getting ready for joist hanging. Friday saw the arrival of the same team of brickies who saved our plant based bacon equivalent two weeks previously. They are a team of celebrity look alikes: Pete Townshend; Paul Weller and Charles Branson. Despite this they are a whirlwind. It hadn’t occurred to me that hitherto I’ve only worked with builders, not brickies. They are brilliant at what they do, but they only do brick and blockwork. So I needed to ensure that all was done/planned ready for them. That meant sorting all the breather membrane on Friday late afternoon ready for the brickies’ Saturday shift. J and I worked late to do enough to be ready for them and whilst we managed it, with only a modicum of tetchiness, I now realise, that looking back, I really needed to stop and carefully think through how the brickies would work in with the project. They are a force of nature. Light the blue touch paper and dive for cover, but in a good way. Sort of. Once they start things happen so fast that there s no time for me to think, and frankly I wasn’t ready. I think we’ve just avoided cocking up but only by overusing J and my combined brainpower and if I’d been on my own the project would now be in trouble. It isn’t helped by the fact that they’d offered to do two days to sort the plinth bricks. That bit I was ready for. But then they announced that they could stay till the house blockwork was all finished, so things I thought were a good few days away were suddenly NOW! I’m loving working with Rolly on the frame, he’s precise, informative, patient with my constant stream of dumb questions, and he makes us productive. But I need to do my part of project management too. And it turns out I find it too easy to get lost in the woodshavings. J and I are project managing between us and that is working well. At least I think it is, if you’ve seen Arthur Christmas we’re a bit like his parents, Dad, like me, wears bright clothes, smiles a lot and peeps think he is leading, but in reality Mum, like J, is keeping track and thinking and usually quietly steering. I must try harder next week or we won’t be ready for the upstairs panel delivery next Friday! And like Rolly the Chippy, I can’t let the word can’t onto site.9 points

-

…well, the shell of a house at least. What a crazy week. We chose the factory-built timber frame route because we like the idea that the shell goes up within a few weeks. But the pace of progress this week has been startling. The frame erection team of 3 arrived at 7:30am on Monday. A big yellow crane arrived at 8:00, with the frame arriving on an artic by 9:15. First off: a careful check shows that the frame fits the footings. Hurray! In fact the footings were within 3mm all the way round, which is credit to the groundworkers. From then on it was flat out and 7 days later the structure of the house is pretty much complete. Those guys do work very hard though - long days under a blistering sun, and straight through the weekend. They are aiming to finish the tidying up by Tuesday, get Turners to sign-off the frame, and head off home to Essex. A great crew - real grafters. We’ve also been very lucky with the weather of course, though the erection team certainly wished it had been cooler each day (we’ve had highs of between 28C and 32C for the last 5 days). We kept them supplied with cold drinks and ice-creams as best we could and we’ve installed a fridge in the workshop which has been popular. The frame itself looks very good - it all appears to fit together tightly from what we can see. No gaps around the insulation, or between the panels. I’ll say more about the frame structure next week but for now here are some pictures of daily progress, plus some at the end showing some of the detail: This time last week: Monday: Tuesday: Wednesday: Thursday: Friday: Saturday: Today - Sunday: And a few of the details, some taken earlier in the week: And finally, for both of you who made it this far, one of those oak posts I cut and chamfered last week (the softwood beams will be hidden in the soffit:9 points

-

We start the week with the latest quandary: how to show the warranty surveyor enough trenches so he can confirm he’s seen 50% of them. He saw some last week and if we dug the rest of them then that would add up to enough. However, if we did that we’d have a massive issue with spoil and we would not get the concrete lorry on to pour, so it would be barrows. Apparently pumping is an option, but we’d need to close the road which is a lot of cost and a great deal of time wasted. So, my Monday morning starts with red eyes from pointless endless ‘loop’ worrying instead of sleep, and the morning on site starts with a replan. The only way to do it appears to be to dig about two thirds of what remains, piling the spoil on the already done foundations, then let the surveyor see the newly dug trenches, then fill that and then next day (yes, this plan extends everything by at least a day) we pull the rest and pour on the final day. This involves lots of wasted time shunting piles of soil around - we can’t have a grab lorry on the road due to low wires, but we can have one on site once we’ve filled the trenches and they are thus stable. All the grab lorries are reserved for Kev the Dig’s last day. Now the issue with this is it mucks up our warranty inspections, (but not our BCO inspections as that one is in the bag already). So it’s on the phone to the warranty provider to seek guidance. Their response to my barely suppressed panic was reassuring and sensible: I’m to take more pics than David Bailey and show the surveyor as much as we can. I resumed normal breathing. But then - “Oh, and by the way, the surveyors report mentions removing roots round the trenches.” Yep, he mentioned that and I have done that I happily said. “And remove the shuttering too.” Another Roy Schneider moment. This is becoming a habit. Apparently this report was written before the surveyor went on holiday, i.e. before we poured any concrete. When, if it had been mentioned in the ‘roots’ phone call, we would still have had time to do that. Panic factor 8 Mr Sulu. Again, a reassuring and sensible response helped me calm down, for which I am grateful. We agreed all shuttering would be removed from the rest of the foundations, and advice would be sought but something low risk like that will be fine, the nice, calm voice assured me. I need to get lots of pics sent in to complete that bit, but it sounds like it’s ok. Phew. So then we finally got on with the dig. Lots of spoil shunting, a few little bits of soft ground to be dug past. A stern lecture (not needed, but kindly meant) from Kev the Dig about not going down a 1.4m deep trench as the sides were just too crumbly, and we were ready for our inspection. The surveyor arrived on time, and was happy and relaxed. Stayed a good few minutes this time (we were his only call that day as it was supposed to be a first day back and in the office day), talked through what we were doing. In response to the shuttering we left in he commented “oh that’s ok”. All that angst. Sigh. He appeared happy with all that he could see, noted that I was talking to the warranty provider peeps, so him being happy is the main thing. So we got on with pour #3 and removing the shuttering. The forces involved in pulling out a piece of 4’ by 8’ ply, even when less than half of it is in the concrete, is staggering. Kev used his digger to pull them out by the rope loops we had attached, but even then it was a struggle and only achieved by wiggling his bucket. Next day, we dug out the rest of the foundations, dumping the soil on the previous day’s pour and then lunchtime we poured #4. Bit of a moment when the digger severed the temporary site water pipe that some idiot had dug in and forgotten. Fortunately when I did that I had used the stopcock at the water meter so I knew it worked and the flow was quickly stemmed. Interestingly, after all my panicking this was the first instance where Steve and Kev showed significant concern and were moved to move rapidly. I guess water mixing with sand makes good castles but poor trenches. I simply don’t know enough to panic about the right things. That overcome the rest of the day went to plan, so we finished the foundations. Four tranches of trenches. Finally, a full set. Thursday was spent moving spoil to the front of site for 5 loads of a 16 ton grab lorry to be removed, and that still left some. Including the previous loads well over 100 tons of material gone by grab, all for a little three bed detached on a diddy site. Staggering. Next week we will hopefully get the invoices and we’ll find out if day rate did save us money. Fingers crossed. Next job is below damp blockwork and we’d planned ahead a delivery (meaning Steve had told me to book one days before) for Friday morning, first thing, so I could bump out and be ready for Steve to start blockwork Tuesday. At one point it had looked like we wouldn’t be ready for it so out of courtesy I warned the builders merchant and agreed I’d confirm by 17:00 the day before. Big mistake. Huge. Waited all day and despite reassurances over the phone no delivery. They finally admitted it would be there mid morning Tuesday. Visit to builders merchants for a ‘robust and direct’ discussion, which at the time felt pointless, as the rogue agent had absented himself, so there was a danger I might be shouting (I didn’t shout, but you know what I mean) at peeps who were already on my side. So instead I shared, in a measured way, both my feelings and the knock on effect on the project. Ten minutes after leaving there I got a call to learn that miraculously they had found a way to deliver Saturday morning, which they did. We aren’t allowed to work Saturday afternoons, Sundays or bank holidays so only a small proportion has been bumped out ready, but it’s a start. But the lesson is be careful with courtesy. In the everything at the last minute, think only seconds ahead building world giving someone a heads up that a delay might happen then sets that delay in stone. Won’t be doing that again. Far better to cancel at the last possible second and try not to feel bad about mucking peeps around. It appears that some won’t worry about how much they muck me around. Overall, in the end, despite my gripes it’s been a good fortnight. We aren’t completely out of the ground yet as we still don’t finally know how deep we need to dig down to ensure our solid floors are indeed solid, but the worst is definitely under us. Might even get some sleep now.9 points

-

Thanks for all your help. We were last in the list of applications, but our worry was short lived. My wife read a short and personal speech regarding this being our dream for a long time. No questions from the committee to my wife or I and none either from the committee to the planning officers. Approved unanimously. Really chuffed and a bit dumbfounded it's finally over. The not knowing what the outcome is stressful. You put your life on hold.9 points

-

After what seems like an age (but is not compared to others on here) we have at last are formal planning approval! We had quite journey, some of which is detailed here. We were told by our planning consultant just before Christmas that it would be approved by the 10th but of course until it actually states "Application Approved" on the portal then of course nothing is guaranteed. We were on site today cutting the overgrown boundary to the rear when I got the call to say that it had been approved. So, just a bit to do over the next year or so! Onwards and Upwards.9 points

-

After a full on week of getting the following jobs done. We’ve finally moved in. Given we have to hand the keys back to the rental on Monday, it’s been cutting it fine. 1) caravan foul drainage connected to the sewage treatment plant 2) water supply to shed for washing machine 3) installing Starlink. This was very easy 4). Fitting a skirt to the static from salvaged 18mm shuttering ply 5). Making some steps. So glad I never burnt the pallets. They are perfect. I won’t miss the hours drive each way and my commute to London is now 45 mins instead of 90 mins, plus our daughter is moving into her first home shortly and she’ll be 7 minutes away. A new chapter has begun 😃 ps - site currently resembles the Somme8 points

-