Leaderboard

Popular Content

Showing content with the highest reputation since 03/13/24 in Posts

-

I'm so pleased with the way this turned out. It is a covered way through the whole width of the wing with the main glazed entrance behind the photographer. The floor is entirely of harvested glacier cobbles. These were formed when the glaciers had streams running beneath them, rolling stones along and forming these shapes. The cobbles are in bands in the sand , and were recovered when digging foundations and drains. They were carefully selected from a huge pile, one by one, for size and being flattish on one face. Most are rounder than these. The right hand wall and the arch are original, repointed in lime mortar. To the left, off camera, is an original timber clad stud wall, including a door, retained for heritage and interest, but there is a new wall behind it. There are pencil writings on the wood cladding, concerning numbers of sheep etc. Everything done by my daughter and SIL. 'except the straw bales' as they put it.28 points

-

26 points

-

It’s been a long 12 yrs 🤣 I use to frequent ebuild ( I think that’s what it was called ) even before my build commenced . When that disappeared I did worry ! . But found the resurrection in buildhub . I knew I couldn’t do the build on my own . A non standard design with no help . I assumed ( incorrectly ) bco would be on my back with a self build and ‘help’ me … the opposite occurred . Everything in life I do on my own ( no rude jokes ) ; I can learn what I need to get the job done ( this does not make me an expert ! ) . Buildhub has been invaluable - I built a house via the internet . I think that’s (expletive deleted)ing amazing tbh ! So for all the noobs with no experience etc I do have advice ! You are either cash rich and time poor or the opposite. Cash rich you can pay others to accelerate your build . Time rich you do it yourself . As I am self employed and didn’t have the cash ( no (expletive deleted)er is going to give me a self build mortgage ) then time is my friend . Remove stress points . A self build mortgage will put you under massive pressure - to release the next payment . Don’t rent temporarily when you can buy . To partially fund our build we sold our house and bought a shitty flat . This took any rental issues off the table and equity appreciation allowed the crap flat to add to the finance of the build once sold . We then lived on site - a cash saving for sure at the expense of ‘normality ‘ . By not being tied to a loan nor tied to time I (expletive deleted)ed about for a decade and got it done . Stress existed - but it was rare . This is the way ! I still have a hundred bits to fanny around with . Remove pressure , remove stress . Appreciate everyone’s in a different situation . But don’t let the build destroy you . It’s a bitch and you are the master ( bit of bdsm there for my followers ) . Ask for help on the forum always . (expletive deleted) things up - so what ! . Waste 1000’s on a balls up - so what . Haven’t got a clue ? - so what . Plan a strategy!24 points

-

We had our first air tightness test today and achieved 0.25 ACH!! 🎉 Absolutely chuffed to bits with that. We have spent a lot of time taping every possible penetration, but I was still anxious in case we hadn’t quite been as scrupulous as needed.21 points

-

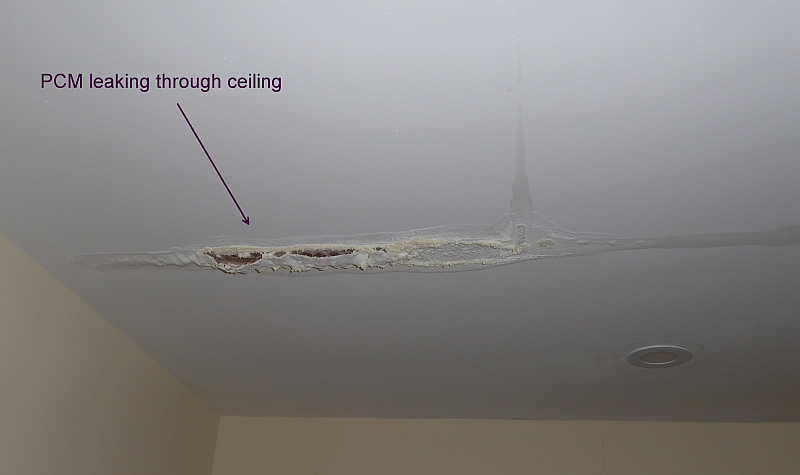

First of all, my apologies for being silent for so long. TBH, having finally settled here in our new home I needed a break from self-build. Not for any particular reason at all, just that I'd been living and breathing it for so many years that I needed some time out, a bit of breathing space if you like. Old age seems to do this, creep up on us almost unnoticed (and I'm now in my 70's). Also I was spending way too much time here, to the exclusion of other things I should have been doing. Anyway, thought I'd post here to hopefully shed some light on how things have gone with our Sunamp adventure, and give a bit of a gentle warning. Those who've been here, and on Ebuild before this place, may remember that we bought a Sunamp PV right back in the early days, before this place existed. We ran that for well over a year, with a few minor teething problems, but it was enough to convince me to swap it for a larger Sunamp UniQ eHW 9, which I did in September 2018. That also had a few teething problems, but Sunamp sorted them out quickly and without fuss. Since then I've been more than happy with the Sunamp. It's provided reliable hot water, mostly heated by excess solar generation, in fact far more hot water than we have ever needed as it turned out to be a bit over-sized. The first time we went away on holiday I turned everything off and was amazed to find that when we got home a week later there was still piping hot water available. I cannot complain at all about its performance, it has been significantly more efficient than a hot water cylinder, which was the reason for me being so enthusiastic about it back in 2016. Sadly, our Sunamp died on Saturday morning, and ejected its phase change material all over the floor, down through the ceiling in the kitchen below: A check upstairs in the services room confirmed that it's death had been spectacular, with PCM all over the floor and a long icicle of sodium acetate crystals down the back of the unit, from the burst casing inside: To it's credit, despite this it had delivered two showers that morning before we spotted the problem. Sadly this was to be its dying endeavour. I contacted Sunamp, not because of any warranty claim (there was no warranty anyway) but to ask them to put me in contact with a local installer for a replacement. I spent the weekend looking at the specs of the newer Thermino models and, given that the 9kWh (11kWh) UniQ was overkill for just two showers a day I decided its replacement would be the smaller Thermino ePlus 150, with the PV02 key to better match it for PV heating via the Eddi (when summer comes back). I found a couple of online suppliers, price, including VAT looked to be around £1,800 or so, plus delivery, which sort of seemed OK. I'm not up to getting the old unit downstairs and the new one up stairs, so I contacted a few local plumbers. All said they wouldn't touch this job. No idea why, it's a pretty straightforward swap, as the PRV, TMV etc is all there, just a matter of re-jigging two 22mm pipes. Seems the technology just scared them off, or, perhaps, it might have something to do with dealing with Sunamp? After a lot of delay, Sunamp customer services came back to me, asked for photos, then went silent. I got on to them again and they gave me contact details for a couple of installers. I contacted them, first one got back to me saying it would be around £6k to swap out our failed unit for a new one. I questioned this. He said it was about a day's work. Now, I'm all in favour of paying a fair rate for a job, but I know how long this job is going to take and I know the cost of all the materials. I am not going to pay a bloke £800 plus per hour, no matter how damned good he is! So, looks like I have to fall back to hiring a stair climber and doing it myself. PITA, as I'd have happily paid someone a few hundred quid to do this (over and above the cost of the bits) but I point blank refuse to stuff over £4k in someone's pocket for a job that is so straightforward, especially when there are installers advertising prices of around £4k to replace an existing hot water system and cylinder for a Sunamp, a job that is a heck of a lot more work. Sorry for the rant, thought it was worth posting here as a warning to others thinking of going down the Sunamp route. I can't fault the performance, but if the cost of repair and maintenance by a Sunamp approved company is so crazy then it may give some pause for thought. I've half a mind to bin the Sunamp and just get a high efficiency 150 litre cylinder installed. No idea what that might cost, but I doubt it would be over £6k. PS: Seems I have hundreds of PMs that have accrued in my time away. Sorry, but I doubt that I have a hope in hell of answering them all!19 points

-

Update: Received the following just now- “Please accept our apologies in regards to not informing you when we issued the CIL Liability notice out at that time, as the originally email with the notices was sent out to your agent directly dated 04/10/2023 (attached). Due to the situation where development has commenced on site and you didn’t get notified, on this occasion we will allow discretion whereby you can submit the relevant forms, and we will grant the relief. Please do note that the full CIL charge plus the additional surcharges will not be imposed.” Thank goodness! These last 24 hours have been traumatic to say the least. But it appears that they do have some heart following my email to them detailing all the flaws in their process conducted. Thank you all for your input and advice. What an amazing platform we have here 😀18 points

-

Prompted by a private message today We have just finished the house With just I say just the drive and patios to do As with our previous build I’ll put the cost m2 Excluding the purchase of the plots But including fees surveys Architects etc etc While I’ve a trade background and plenty of contacts There’s lots of aspects of building a house that where as new to me as they would be to most of you I’m 63 and my wife is 60 and both work full time Monday to Thursday From our previous build to this we’ve tried to do as much of the work ourselves as we possibly could The figures are to encourage Not to discourage and show that you can build a house far superior and much better insulated for less money than your average Persimmon home we are at 420 m2 and have spent Just short of 350k We expect to pay 12k for gates and allowed 20 k for materials for the drive and patios Which the 39k vat refund should cover The seller wouldn’t split the two plots Or the field So we may have another build in us 😁17 points

-

I should probably start a blog for this sort of thing, but I just wanted to let y'all know that we finally got planning permission - 4.5 years after buying the site, after one application with a committee hearing, and the latest application that took nine months to determine. Thanks to everyone on here for their help, advice, and nudges on expectation alignment!15 points

-

Major news!!! Guess what? Sunamp have just emailed me to say that they are going to replace our unit as it is covered by the 10 year warranty on the core! They emailed me as I was typing the reply above.13 points

-

Well it's the second day on week 4. The ground floor screeding is being done as I type this. To date all the walls are up (they come fully glazed, partially rendered and plasterboarded). The roof has been tiled and guttering fixed, the first fix electrics are done, the first fix plumbing is done (wastes and supplies for basins, wc's etc come ready installed in the panels), the underfloor heating is in and the MVHR ducting in place. In the service room is the cylinder, expansion vessel etc for the ASHP and the external unit is here wrapped, sitting on it's pallet. They started on the 8th April and expect to hand over at the end of May. We elected to use Dan Wood as a "half way house" - it's our original design (although with a nod to that sort of style). We didn't go extreme, much as we would like as I wanted a smooth planning experience, which we got. So, some of the standard Dan Wood bits we omitted. They can finish right up to carpets; handing over complete, save for the kitchen (too many choices apparently). We wanted a UK stair with closed risers so it could be carpeted. DW use bare wood, open riser and being aimed at the German market, the pitch is lower so the going messed up our internals too much. We also left out the doors (odd looking with the leaf rebated and closing against the face of the frame) and floor finishes save for the bathrooms. Those are now down to us. We had to provide the foundation (insulated raft for us) and drainage/service connections. However, it's been a dream not having to organise anything once they sign off the slab as ok. Men turn up at 7.00am sharp and work to between 5 and 6. Saturdays 8 till 1 ish. All materials are either brought with them or turn up on time. Electricians, plumbers, and scaffolders are woven into the work and are here at the correct point. The electrician was here until 11pm finishing off first fix because the next trade needed it done. Every single day it progresses. It probably isn't the cheapest way of doing it ( about £1730/m2 ex foundations) but the joy of not having any arguements with individual contractors makes up for it and there is no doubt the polish crew working on this house work damm hard and do a good job. You have to credit their attention to detail too. They obviously do this all the time as all the membranes are properly taped and sealed, the windows being inserted in the factory are done properly, etc etc. It's clear they have designed out issues over the years and have come up with solutions that work - hence the 20 year guarantee. We could buy the plot but needed to sell our house to fund the build. We are in a static caravan at present on site. Having reached retirement the certainty of getting the build done in a sensible timescale so we could get on with enjoying life was a big driver for this approach. Hopefully it'll be a family Christmas settled into a house this year instead of renting a cottage to escape the cold and damp of a 32ft static!11 points

-

Morning all. I don’t drop in here very often these days but just happened to browse on my way back from an extended trip to the USA. Lo and behold I see a post from @Jeremy Harris talking about Sunamp so thought I stick my head above the parapet and say hi. I’ve just looked at when I last posted here. It was June 2020! Where in hells name does time go? So here’s a quick summary of what I’ve been up to in that time (possibly not in chronological order): Fully retired (two years ago). Finished my build which is well documented here and there on this forum. Then sold it in 2021 and bought a “project” which I gutted (nothing left but 4 external walls, the roof and a worrying array of steel and acroprops). Then spent all lockdown rebuilding it. Finished the house but am still working on the landscaping. Spend vast amounts of time faffing about on my small holding (came with the house). Have I learnt anything? Yes, a fair bit: Stop buying houses on the national park, planning is a PIA (but the views are exceptional). When you retire you can’t work out how you ever had time to work! I can’t sit still. Wish I could (I’ve always known this really). Renovating an existing property is way more difficult than a new build. Building during lockdown was a complete nightmare. The window supplier/installer is more important than the window! Actually had a great experience with this renovation which is a world apart from the pain I experienced with EcoHaus SW and Internorm. Just stay WAY clear of “bleeding edge” technology. Exhibit A: SUNAMP (I might comment on the thread which started this resurrection off). Land is a time sync, the level of maintenance is mind blowing BUT it gives you an excuse to buy a digger, tractor and trailer. Plus a myriad of attachments Well that’s it for now. I can’t promise I’ll return to being a regular contributor. I simply spend much less time time in front of technology these days. I much prefer being outside. P.S. I think I’ve got one more build in me before I fully reach my target of eccentricity and too many animals.11 points

-

11 points

-

10 points

-

Small progress. Just because my LPA were teeling me off, I submitted an application and then an appeal to have my PD rights reinstated. This is for a barn conversion completed in 2017 (not by me). My LPA seems to remove PD rights on all new houses. So, one small step forward. I'll post up a sanitised version of the appeal docs and decision notice when I get a few minutes.10 points

-

We've had to keep this a big secret. About 2 years ago, we were approached by Channel 4, asking us if we wanted to feature on Grand Designs. Like many of us on here, having watched the show a lot, and seeing how they typically go, we immediately said 'no' 😂 . After a fair bit of discussion, we came round to the idea, as we thought it would be a nice professionally produced story of our self-build, and so here we are. You can catch our full story and how it all went, on Wednesday 2nd October, Channel 4, 9pm. And for a sneak peak, you can see what we've been building on our Instagram: @thefoxesmaltings10 points

-

After what seems like an age (but is not compared to others on here) we have at last are formal planning approval! We had quite journey, some of which is detailed here. We were told by our planning consultant just before Christmas that it would be approved by the 10th but of course until it actually states "Application Approved" on the portal then of course nothing is guaranteed. We were on site today cutting the overgrown boundary to the rear when I got the call to say that it had been approved. So, just a bit to do over the next year or so! Onwards and Upwards.9 points

-

Our certificate was emailed over today , feels like another milestone on the build, despite the fact this will be our second Xmas in the house officially we have(now) completed .9 points

-

it's been a long journey (although about a 1/3 of the time it took @Pocster) but we finally have our final certificate sign-off from BCO. we are over the moon to have passed that hurdle. There's still a long way to go but we are living in the house now and it is performing beyond our expectations and is a wonderful place to live. thank you to everyone on the forum for your help along the way. this place has been invaluable for us.9 points

-

To close off, planning permission was granted 2 days ago. A suitable drink was taken that evening 😁9 points

-

Winner winner chicken dinner ! Sent an appropriate email about poor service , lack of work required list after bco viewings etc etc etc Said once I get the G3 thing in then all passed and completion certificate issued . @ToughButterCup just checked the dictionary.. Legend = Pocster Pocster = ( see Legend ) .8 points

-

Chuffed to bits, finally finished my diy install of my nice shiny 7kW Arotherm. Have only used for dhw but working a treat once I realised that my esbe diverter valve was wired back to front and I was heating the ufh ! Just need to finish off wiring the OEM stuff. Old boiler out : New unit : Primary Pro and anti-freeze valves8 points

-

last weekend i finished my last bit of plumbing in the house for what will be quite a while! i've still got a few things to do (e.g. dog shower, studio bathroom, basement toilet, outside tap) but they're not critical and can wait a year or two except maybe the outside tap. everything is working (and will hopefully stay that way 🤞). showers are gorgeous and no splashes on the toilet or toilet paper in the master shower in case people were worried. toilets and washing machine are being fed by the RWH tank which gives a great feeling and a lack of guilt when using the large flush option. i just wanted to say thank you to all the contributors on this thread. i couldn't have got it all done without your help and guidance. i think i definitely owe a few on here a few beers. i hope this thread is useful to others who are doing their own plumbing if they're able to read it all. my takeaways from doing my own plumbing? i've saved myself a small fortune but i now hate plumbing with a passion. 🤣8 points

-

By way of background, I am the very aged IT geek that has done all of the SysAdmin since we first set up BuildHub about 9 years ago. I am no longer involved in Forum Management or politics; I just in keep the forum up and smoothly running, pro bono. i have also administered and run a number of community forums and wikis over the last few decades, mostly using open source forum packages such as phpBB and MediaWiki. However when the founding members set this forum up, we decided to use a commercial Forum package (there was a one-time purchase, plus an annual maintenance fee), because this customer funded business model offers us a better feature set and continuous through life improvement. We chose the forum app from the company now called Invision Community. This a PHP application that runs on a LAMP stack on a hosted Virtual Private Server (VPS). The VPS has grown in cores / RAM / storage over the years as the size of the forum and its user population have also grown. Three years ago, I moved the LAMP stack into a Docker Compose project, and the VPS runs this single dedicated Docker Project which is on open Github. If you want to know more then read the README at Github: TerryE/docker-buildhub which explains the setup. Our Hosting Provider is currently doing an infrastructure refresh so we have to migrate to a new VPS and at the same time I am retiring the use of Docker and switching to the open-source equivalent, podman. See this issue, if you want to know more: A Gemini Conversation about Migrating VPs and switching to podman. Warning: it's a bit long (17 pages) and technical, but it lays out the issues and context. This topic is just to keep interested members informed. Any technical discussion / comment is welcomed. I have opened a companion topic in Forum News and Site Issues: Rehosting the Forum Virtual Server to discuss the more general / policy aspect to allow this thread to focus on the nerdy stuff. 🙂 Can I ask you all to keep to the technical discussions here and use the companion topic for general / policy stuff. @TerryE is my user account but I also have the Godlike @Admin account to hide / delete off-topic posts if the mods don't move them to the general topic. 🤣😱7 points

-

We’re rebuilding a Victorian bay window with a focus on thermal efficiency and restoring some period detail. To achieve this, we designed and cast our own bespoke window cills using GFRC, 3D printing, and innovative materials like glass bubbles to reduce weight and improve insulation. This post shares our design process, casting experiments, lessons learned, and the final results. Design I used SketchUp to produce the design for the side and centre cills. The bay has external wall insulation so the cill was designed deep to accommodate 10mm aerogel, 50mm PIR, render and the offset from wall. The 10mm aerogel was something I wanted to try out, and doesn’t add much compared to just using 60mm PIR. For some reason the grey versions of aerogel with a 0.015 thermal conductivity are not easy to find, so settled with the 0.019 grey blankets. We are targeting below 0.15 U value. The EWI gets us to 0.16 with additional internal insulation needed to be below target. The cills themselves are a thermal bridge 210mm deep then 100mm of structural insulation for a 0.34 U value, I haven’t yet decided on the further internal insulation to get below 0.15. I am trying new things out with this and will try VIPs. I have a budget for trying out new insulation. 3D printing The first concept of the design was printed out in a 3D model, including a wall return, stools for the jambs and mullion and underside drip. And later its mold to test the casting process. Structural insulation The plan was to install the cills on the exterior half of the wall, then given the deep cills a section of structural insulation was fixed into the wall to provide some support for the cill in case they were used as a step. Here this is fixed to the top of the wall and replaces the 50mm of PIR which otherwise would have been used. Casting Once the cill designs were done, I made a mold of the cills for casting with concrete and sand. The mold was 3d printed and via some experimentation manage to find a way to get a stone effect for the face coat. The idea of casting my own cills started while looking at GRFC concrete countertops, so my mix included glass fibres. The hope is that they prevent cracking, but the cills are already substantial so they probably don’t need them, but I kept with my original mix design. I don’t think the glass fibres added much to the process, except additional complication. If its reduces cracking then that’s helpful. Glass Bubbles I later tried an experiment using glass bubbles. Half the sand was substituted for glass bubbles to improve the thermal efficiency of the cills, (only a little) but its main advantage was in reducing the weight so it was possible to move the cills around with some ease. It also helped reduce deliveries of the sand. I was using a white sand which was an annoying bulky delivery. The glass bubbles tended to rise to the top of the mix, here the top is the bottom of the cill which was problematic for creating a flat surface. I later experimented with covering this to produce a flat surface but I manage to instead amend the mold design to be fill from its back. The advantage of this was that the slightly uneven surface was in an area where it didn’t matter and also the glass bubbles would be situated more evenly towards the back of the cills thus helping with the thermal efficiency of the cills on their internal side. Test casts I had about eight different cills cast before being totally happy with the design and the casting process. I experimented with using cast stone dust, but with a bad result (probably from my poor face coat application) so I moved away from a “bath stone” look to a white to be further finished. Completed Cills Once the cills were done, I was able to see how to progress upwards for the rest of the bay window. At the start we were happy to accept the bay would be a thermal bridge requiring lots of internal insulation. The benefit with this design is that much of the insulation is now external saving on the floor space. It took some time, which I have and I am happy with the result. Since I installed the jambs and mullions and making the header/lintels copying the original design in the area. Plus the cost is much reduced. The original plan was to spend 30k on the bay window build, as a standard build, that cost without windows relying upon insulation being done separately afterwards. Instead we have managed to spend 5k on tools and materials, including £500 for a 3d printer but lots of my time.7 points

-

Good morning. Been quite some time. I doubt anybody will remember me, but I used to enjoy participating on the forum. Only reason I disappeared a couple of years ago was, wife got ill, and to be honest, I found myself getting depressed. I don't think I even realised the depression, until I came out the other side.....I have missed giving Pocster a hard time for his solweld skills though. I hope all of your projects are going well. I must say, I'm looking forward to being back. The skill and knowledge level on the site has always been fantastic. Together with the willingness to share that knowledge, and the pitfalls, and good times. The only thing that would be useful to me at the present time would be if anybody has any recommendations for a really good planning consultant in the Hertfordshire area. Anyway, I look forward to participating again in this excellent forum. Best of luck to all. Regards Jim7 points

-

I’m sorry but installing insulation takes time and I always charge for it. It is not something that should be included in the rates the same as feature bands, cutting up gables and cutting the bottom course of blocks where others have lost the ability to use a laser level correctly. I won’t take on projects with tongue and groove insulation because it’s not fit for purpose. Cutting and installing full fill insulation requires the following skills. 1) be able to use a tape measure 2) be able to use a long sharp knife and a cutting slot. 3) be able to think ahead 4) checking each junction as you go. 5) protecting work properly as brickwork progresses Gaps in insulation is my pet hate and the lads who work with me know it and have known it for years. I can guarantee that there isn’t a single gap in any of the cavity insulation on the 2 houses that I have just built for myself. Like I said it’s not rocket science but it does take time to get it bang on. Time should be paid for. Some of the bricklayers that have worked for some of this forums members were most likely used to working on a ‘rate per 1000 all in’ to include all the sundries. I stopped giving my time away for free 30 odd years ago. You pay peanuts you get monkeys. I do agree that there are plenty of poor bricklayers about but to tar them all with the same brush is pure stupidity.7 points

-

I hate these types of threads.....there is absolutely zero standardised way of quantifying this question. There are far too many variables in how folks achieve a self build and what they include in their costs to enable a like for like comparison. @nod is an absolute outlier and every time this question is raised pipes up about how little he has spent per m2 with no context to how that was achieved. Is land included in your cost there, i expect not, how much have you spent on labour throughout vs how much have you done yourself? There is not much to be saved on materials...shopping around and economies of scale will help but the margains for material cost savings are small compared to the savings which can be made if you eliminate external labour costs and are able to do the work yourself. Labour costs are the killer and individual self build costs per m2 are primarily determined by how much work they can actually do themselves. But it comes at a cost of time.7 points

-

For starters, my list includes: + force the inspectorate and LPAs to publish full stats and don't let them play games e.g. taking 3 months to get to validation. Put the bottom 5% in 'special measures' without fail. + penalise LPAs financially if they're slow - return planning fees after 13 weeks, automatic approval after 20 weeks. + penalise LPAs if the pre-app advice they give is wrong. Allow recovery of resulting follow-on costs in the county courts (architects fees etc) due to erroneous pre-app advice. + force LPAs to accept paid-for meetings with applicants. + stop LPAs using generic terms without more detailed definition - amenity, environment etc. + allow applicants to nominate applications for planning committee review. + make single dwellings exempt from part O, SuDs, biodiversity, nitrate neutrality rules. + make LPAs suggest design amendments (in at least 3 rounds) instead of just blank refusal. + disallow LPA refusal using generic terms without evidence & substantiation. For instance if the LPA thinks the design is 'too big' they should justify why (e.g. floor areas of neighbours, average floor areas in LPA region) and propose a figure for an acceptable floor area. + for appeals, throw out the LPA statements of case (i.e. appeal automatically allowed) if the LPA doesn't follow the appeals procedural guide. + automatically award full costs (including applicant's time at a prescribed rate) if an appeal is allowed - right now, there are no repercussions for an LPA that wastes applicant's resources by going to appeal.7 points

-

Well, technically, we can move in. I needed to get the downstairs bathroom finished which I’ve just done. Electrical/fire sign off was completed last week and I’ve got the certs. Stairs are finished. I’ve configured the Loxone system which is mostly working as we need. Still lots to do for final sign off but BC have said we are fine to move in now. We’ve also gained two orphaned lambs so that takes care of the grass cutting 😂 I also plumbed in the drinking water tap so it effectively is straight out the borehole through a pre-filter, into an accumulator, through another filter then UV then to the tap. Tastes lovely.7 points

-

Good luck with your project. I can safely say that having the exact opposite experience, e.g. discovering buildhub 3 years before my build actually started. Has made more of a difference than any other factor. I had no previous DIY or building experience. In no particular order here a few areas where BH was instrumental in shaping my house build journey. 1. Insulated slab foundation. 2. UFH in slab, not screed 3. Proper ASHP configuration. People like HeatGeek on YouTube are now advocating this stuff, but back on 2018-2019 BuildHub was already there. I have an insane quote from a Heating company in 2019 pricing my ASHP/UFH set-up @ £40,000+. I would be surprised if my ASHP/UFH install cost me more than £5000. 4. Going from resisting MVHR, to embracing it. The sooner you incorporate the MVHR ducting solution into the fabric of your build, the easier things will be. Every structural decision needs to accommodate how the ducts are going to route through the building. 5. Ducting requirements for ground works and in the slab. The insulated ASHP pipe is a particular pita to install. 6. Getting an electrical supply kiosk/water supply as soon as you own the land. All these services can be changed by you later in the build without involving the infrastructure companies. 7. Do your own heatloss calculation using Jeremy Harris’ spreadsheet. There is also a great MVHR calculation spreadsheet, but this might not be as robust. 8. Manifold approach for domestic plumbing. Also hot return, if applicable. 10mm pipe for certain outlets. I did all of the plumbing in my build, this was only possible because of the discussions here. The manifold photos are just eye candy to me now. I find the best way to search BH is with Google with “buildhub” at the beginning of the search string. For some reason the internal site search is not very effective. I find the best way to catalogue interesting threads is to use the “Follow” thread button, but without email alerts. You can then more easily find topics when you need to go back to them. The “Activity” drop down allows you to filter the site just showing threads you follow using “My Activity Stream”, “Content I follow”. Unless I am mistaken using the heart reputation button on individual posts, does not actually allow you to find them again, it does not function as a “like” button. Just found out this is not exactly true, see edit. *Edit. Thank you @joshwk, just playing about with my profile screen, if you click on the green reputation button, you can see all the posts you have hearted. You can do this on any users profile.7 points

-

I installed the MVHR unit this week and got someone to commission it. It’s very quiet. You can hear a gentle hum from the kitchen terminal when standing underneath it but the others are silent. The external terminal isn’t as bad as I thought it was going to look but it’s still by the front door. I regret a bit not changing the whole floor plan of the porch/lean to bit of our house putting the plant room on an end elevation. In hindsight I ought to have combined it with the utility room with a wall separating them. The benefit of where it is that’s it’s right in the middle of the house though. The other small issue is the board on board cladding creates a void behind the terminal where the inside cladding board is which could allow rainwater to sit. I’ll need to add a block to fill it in. The board on board cladding has caused similar issues like this across a few areas of the house. Worth thinking about for anyone else considering board on board. Downstairs bathroom nearly finished. The Aqualisa shower was straightforward to fit but we pulled the speed fit hose out of the connection inside the rail which was a bugger to get back in. Bit concerned it came out so easily. I’m not massively impressed with the Aqualisa Optic Q shower control given the cost of it. It all feels a bit loose and plasticky. We have two and both the same. The rest of it is well made. The mixer and diverter are in the coomb upstairs making it really easy for future access as I made the coombs slightly wider and higher by removing the coomb completely on the opposite side of the roof. We gained a bit of floor space and it allowed me to widen this coomb by 150mm. I did this to make fitting the shower controls up here much easier. It would have been very tight otherwise. Doors and skirting fitted. Doors and hardware are by LPD. Unfortunately they don’t do smaller doors to fit the wardrobe. However Deanta do a very similar door (looks identical in the pictures) which can be custom made. Not cheap unfortunately and the lead time is 20 weeks. Also removed all the dust protection from our lights in the vaulted ceiling so it’s the first time we’ve seen them up properly.7 points

-

Hiya. I'm Scottish base and have family that live on one of the inner Hebrides and have lot's of experience dealing with BC on the Islands. Also I deal with Scottish Building Standards on a regular basis and have done so for the last 40 years. Some of the BC officers I know quite well, we have a chat on the phone about our careers and reminisce on how good the old times were. In other words they are folk just like us.. there is the odd exeption but that is life. In the round though BC officers actually do have your best interests at heart. It would be great to have a BC officer or two join BH! On the Islands there is a lot of politics. Some Island builders are really shite, cut corners in a big way, some are better / good. BC know who they are so maybe you are getting a heads up and not just seeing the wood for the trees about the work that has been done by others. Now you are doing a bit of work yourselves.. well how much and when did you start doing a lot yourselves? It is in your own interests to build your house right? There is always friction on the Islands... BC know this but are not corrupt at this level. There are loads of other Islanders and folk moving there that do DIY projects so you are not the first and last. @JWHIT "surely this is trespass" My advice.. get this right out your head now. If the BC officer can access your site then you have a Health and Safety issue and they can hammer you on that. The HSE law is quite clear on this all over the UK, if your site is accessible then you are on a hiding to nothing. Have a looked at your site security? Don't pursue this route as you will likely regret it. Too late for that, BC can hammer you much earlier. There is no argument in law for shoddy HSE by saying.. hey I'm insured. Insurance is for when you have tried to do your best and things still go wrong. If they can see bad things from outside the site boundary then surely.. you may be making a cock up? If you try and play hard ball with them then they will pull your trousers down and you won't get to pull them back up until they have run you ragged. Now you may feel that the BC officer has turned up with no appointment.. but they are allowed to do this under UK HSE law (not just Scottish law) .. part of their remit is pubic safety.. they can hammer you on this too! To lay it on a bit thicker they may start to ask if your project should fall under CDM regulations., just to give you the run around. In summary: 1/ Yes there is Island politics, don't worry too much about the main Island Contractor not getting the job. 2/ Phone the officer up and ask when they are next on the island and arrange to meet them in person. This is so imprortant. You are on an Island.. you must get to know folk.. the emails you get from BC only show a snap shot.. sometimes they write stuff that seems really daft / aggressive.. but they are pushed for time and under funded. Cut them some slack and cut yourself some slack too. Keep an open mind as while you see this as a personal opinion then they may be able to give you good advice? Also if you hit it off with them then later on when you apply for a completion certificate you'll probably find that part of the process much easier and not get hit with a load of things that don't conform. 3/ Build a rapport with the officer.. recognise that they may be trying to help you rather than hinder. You may have a young and inexperienced BC officer. Be very careful here not to bully as their boss will then give you the big stick! Listen to what they are saying.. put forward your ideas and have a bit of fun.. seriously they are just folk. To finish @Kelvin may be able to give you some advice about how you deal with BC when relocating to the north of the UK ( Scotland) 4/ Some of my family live on Tiree. Clocked this at the end! Well it does.. Some of the building regs are open to opinion / discussion / detailed design. BC officers often hold professional qualifications / have great experience. They are entitled to question. As before one big stick they do hold is the public safety issue (I do it too as an SE) . Lot's of folk on BH think that this is their house and they can do what they want. BC say and I.. that house has to last for 50 years at least and you may sell it to a family in a couple of years time. Our duty is not just to you but all the folk that come after. Just copied this right at the end. The above is misleading as if it is deemed to be a risk to public saftey then the LA can effect immediate access as what they do will call on the Fire service, the Police , gas board and me as an SE. You see.. who knows what building regs have been compromised? Is it just an extractor fan of a serious structural defect that could cause a gas leak? If push comes to shove and I'm acting for the local authority.. I'll find a legal way of getting into your property if I feel there is a safety issue. You are pissing in the the wind! If you have nothing to hide then you should be relaxed about all of this.7 points

-

Folks, We are on our self-build journey, we selected timber frame then short listed 4 suppliers and in the end chose MBC. They erect our medium complexity house in 8 working days - very impressive. I think MBC's strength is their experience which shows in the detail / thought in the design office and the efficiency of their erection teams. Our site is constrained so working out the order to deliver materials, how things are stacked, the order that things are lifted by the crane is complex. The team didn't seem to make any mistakes and just kept working, rain or shine. [To confirm I'm just a paying customer and have no other association with MBC]6 points

-

Brief update on this one just so the thread and any other troubled onlookers are aware. I've now gone through and inspected the eaves detail for everywhere I can for this extension. Found some horrifying things and insulated it the best I can. Those steps being:- :- Remove all poorly seated wool covering wall plates. :- Seal all gaps between ceiling PIR and wall plate with wool / foam/ tape. :- Reinstate PIR insulation where there was none :- Form Wedge to force wall PIR to be uptight against block :- Seal all gaps between Wall PIR and block with wool / foam / tape. :- Reseat wool covering wall plate and all sealed areas. I'm very pleased to report that this has made a huge difference. I have not had chance to put my thermal cam back on, but you can feel it in the room. It's actually retaining heat through the day now, heating on in the morning for a few hours and you could still feel the residual heat in there by midnight. Perhaps i'd got used to having essentially balls-all insulation in there so im hypersensitive, but very promising so far. and that's without any form of curtain / blinds etc. All the glazing (of which there's lots) is still entirely bare. Not to say im going to stop there, I will be still removing all the roof to fully seal it and add more insulation. But atleast now my horrifying suspicion that I may need to add interior insulation in an already finished room... has been quelled. I'd REALLY hoped I wouldn't have to do that and it looks now that i wont have to, so im very glad for that atleast. Id rather spend the time and money on further improving the roof, glazing and adding exterior wall insulation to the walls if I need to. Anyhow, some more images of fixes for future ref for anyone.6 points

-

6 points

-

6 points

-

This is a classic mathematics problem. One of the most practical uses of differentiation is finding the maximum or minimum value of a real-world function. In the following example, you calculate the maximum volume of a box that has no top and that is to be manufactured from a 30-inch-by-30-inch piece of cardboard by cutting and folding it as shown in the figure. What dimensions produce a box that has the maximum volume? Mathematics often seems abstract and impractical, but here’s an honest-to-goodness practical problem. If a manufacturer can sell bigger boxes for more money, and he or she is making a million boxes, you better believe he or she will want the exact answer to this question: Express the thing you want maximized, the volume, as a function of the unknown, the height of the box (which is the same as the length of the cut). Determine the domain of your function. The height can’t be negative or greater than 15 inches (the cardboard is only 30 inches wide, so half of that is the maximum height). Thus, sensible values for h are 0 ≤ h ≤ 15. Find the critical numbers of V(h) in the open interval (0, 15) by setting its derivative equal to zero and solving. And don’t forget to check for numbers where the derivative is undefined. Because 15 isn't in the open interval (0, 15), it doesn’t qualify as a critical number. And because this derivative is defined for all input values, there are no additional critical numbers. So, 5 is the only critical number. Evaluate the function at the critical number, 5, and at the endpoints of the interval, 0 and 15, to locate the function’s max. The extremum (dig that fancy word for maximum or minimum) you’re looking for doesn’t often occur at an endpoint, but it can — so don’t fail to evaluate the function at the interval’s two endpoints. You’ve got your answer: a height of 5 inches produces the box with maximum volume (2000 cubic inches). Because the length and width equal 30 – 2h, a height of 5 inches gives a length and width of 30 – 2 · 5, or 20 inches. Thus, the dimensions of the desired box are 5 inches by 20 inches by 20 inches.6 points

-

The goal of this thread is to try and share topics for people to consider both in terms of their SIPS company and the SIPS system. I have tried to keep emotions out and try to structure the information so that it reads OK. However I'm sure some parts may appear random. Your mileage may vary and not all SIPS companies, and SIPS systems are the same. Likewise some of these situations could equally apply to non SIPS builds and just be good practice, however I would encourage the following: For many self builders, this will be their first time building a home (myself included) and therefore having the right things to look out for can be pretty useful. For context, my build was less modest than @G and J at over 300m2. 1) Understand how their contract is structured (and why). This is not the SIPS companies' first rodeo. Your SIPS company may want to sign you up for ‘Design’, ’Fabrication’ and ‘Install’. As a self builder, this can sound appealing as it means all this complexity is dealt with by one company and a single point for you the self builder to deal with. They may even offer to use their own appointed Structural Engineers as well. In this model, there are 2 key risks to watch out for. Firstly, their goal is not necessarily to design the physical house as you want, their goal is to design a structure that meets regulations, to the lowest cost/highest margin possible to them. So when discussions arise over compromises in the design, what you may find is that this package deal is compromised so you are the one making compromises. The 2nd and related risk is, they will load the contract with substantial fiscal penalties for withdrawal - such that your leverage to walk away from a design you many not be 100% happy with is left at almost zero. Same goes for using their Structural Engineers, as in this model, they are working for the SIPS company, not you. So their interest is in keeping their client happy - which is the SIPS company. So what can you do to avoid this? Break the contract down into smaller chunks that allow you to exit if your needs are not met. This will be a common theme in this feedback, but you need to be prepared that this will take time to negotiate and you need to be prepared that they may refuse and therefore prolong your search for a SIPS company. Same goes for the SE, find your own structural engineers who work for You - the paying customer. Granted, exiting at this point will still have a cost, but it is far far smaller than the potential penalties over the whole package value. 2) Design compromises, Steel and Timber vs SIPS public image In my experience, the value proposition of SIPS for large open spans and vaulted ceilings - especially on our 2nd floor did not reflect reality. What we ended up with was effectively a steel structure holding up SIPS panels. This was with even modest room widths (4.5m) and a 35degree pitch roof. (I will come back to steel later in the install topics). This room has both a Steel ridge and 2xSteel rafters, and its overall floor area is 20m2, so not particularly big. These steel components - more so the rafters, represent lovely cold bridges down through your SIPS envelope. In addition to this, what you may see in the pictures relating to joining your SIPS panels is the SIPS splines. In reality, what you may see is the splines replaced with timber. Again, some of this will be by engineering need, however in my case I have more timber than splines. Especially on my roof. This giving me in many places an effective width of 4 joists between SIPS panels (timber spline:rafter:rafter:timber spline). So again, rather than a complete SIPS envelop, you are left with more lovely cold bridges which will need more insulation (internal layer of PIR) to compensate, even with the thickest of SIPS panels - thus defeating a huge point of why you may have selected SIPS in the first place. How to avoid this? Again this goes back to contracts and breaking out at least the design phase as a single entity. That way you have a chance to force more of these topics and leverage to walk away. Ask for examples of final fabrication designs that are similar to yours (in terms of scale/size) BEFORE signing up. The final fabrication is important, as this is where the rubber hits the road and you can see how they intent to fabricate the kit. 3) Installation What you may find is your SIPS installers have no affiliation with your SIPS company and there may be several layers of subcontractors used, potentially ones that have never installed SIPS or worked for your SIPS Company before. In my experience, my SIPS company were an abject failure in managing the install team. Those failures were not limited to: No formal project planning of the install, around when installers would (or would not be) on site, what sequence of install events needed to happen in what order, how installers were paid, how long the install would take and large gaps between reviewing install accuracy and completeness. The net effect of this is that it is YOU that is left to manage the install team, and subsequent impacts and fall outs from install issues. 4) Scaffolding (and other ancillary dependencies like plant) Your SIPS Install team will need scaffolding to complete the install. Demand a scaffolding plan from the SIPS company a minimum of 6 weeks before install is due to start. That plan at minimum should cover the number of lifts, any initial gaps for access, at what stage in the build additional lifts may be needed. Going back to point 3) my experience was that the first time the install team looked at my design and any complexity was 1 week prior to arrival, where a long list of pre-requisite expectations were then given - over and above the pre-flight install checks I had already completed with the SIPS company. This is because in my experience, the SIPS company basically scoured the UK to find "anyone" who might be available to install a SIPS kit (more on this coming). The net effect of this is delays to your program - I had to get scaffolding basically at a weeks notice which then puts the pressure back on you and compromises how thorough you can be in securing those services. Furthermore, once install commences, demand ongoing updated scaffolding plans to reflect any changes they might need in advance (with a minimum 1 weeks notice). In my experience, my installers planned only from one day to the next. Meaning they could ask for scaffolding changes almost every other day. This requires you to then get your scaffolding company on a hotline - and costs a ton of money. As I'm sure applies to many of us, our designs are not square boxes, again, part of the value prop for SIPS was for creating interesting shapes, roof overhangs etc, all of which make scaffolding more complex than a square box new build from a major house builder. So there is an understanding that modifications in the scaffolding will be needed. However these cannot be managed on a day to day basis. 5) Timelines - Plant machinery Demand from the SIPS company a contractual timeline for the install. This needs to be done at the beginning of the engagement with your SIPS company. They wont like this, because it forces them to think and try and evaluate risk early on in their work and have methods to hold their subcontracting installers to account, which they are not used to doing. The numbers they generally provide are based on an average build and where everything has run smoothly. DO NOT assume this will be the case. It was not for me, and I know not for others as well. Any notion of a 4 week build for the kit is not realistic. Something large and complex may be something like 16 weeks of install time. This timing and planning directly relates to plant and machine hire (although I acknowledge there are other knock on impacts for when follow on trades can start and your overall build plan). DO NOT assume the responsibility for plant hire (cranes and telehandlers), push this back onto the SIPS company. Why? because when it's on you, you will be amazed how little bother is given to how efficiently this plant is used, whether it's busy or idle. Likewise when someone else is paying, the need to be specific in what is required is replaced by asks for the biggest (and therefore most expensive) equipment that takes any challenge off the install team. And of course, if the install takes longer, its you picking up the tab. Part of this experience is based on hearing about installers who more frequently work on building sites, where multiple houses are being erected, at different stages. Meaning they can hop between installs as they wait for something, or some dependency to be cleared. So on those builds, the equipment always looks busy as it's serving multiple builds and a) they don't give it a second thought to the use of the plant and b) they always expect it to be there waiting on them on tap. This is obviously not the case on a single self build (i.e. most of us). 6) Installer competencies Following on from my earlier comments around the volume of steel in my build. My installers had limited experience of installing steel at this complexity or volume (~70 individual steel pieces). I would have been bettered served with a dedicated steel install team. Why? My install team could not set out where steels would be placed, and therefore worked on a model, where a steel was placed, then SIPS walls added, until they needed the next steel in place. This stepwise fashion of steel, sips, sips, sips ... N+1 then steel meant the hired crane sat idle for most of the day(s) rather than placing as many steels into place as possible. Even simple concepts like pre-erecting joined steels on the ground prior to lifting was unknown to the install team, thus meaning each steel was lifted one at a time. Furthermore, this stepwise method prevented the steels from being bolted and levelled until after all panels were installed. This leads to panels covering over the steel pads and holes for bolting, which then leads to large sections of SIPS panels needing to be removed at a later date to access these bolt holes! What is most galling over this scenario (beyond the wasted crane time), is the tolerances that the SIPS company demand for your slab (+/- 10mm over 10m), yet they could not accurately place steels without this step wise build method. 7) Marking their own homework You may find there is no "formal" or "accredited" sign off for your installation. That process is an internal one where your SIPS company effectively self certifies their install is in line with the approved design (you can already probably guess where this heads). As the client - you need to find other ways (either yourself or through other professionals) to mark their homework. In my scenario (I ultimately feel lucky) I caught structural defects in the installation method BEFORE it was too late. This is especially challenging when some build parts do go quickly and large swathes of a building go up before you might get a chance to check. Those defects resulted (painfully) in a 2 month wait for the SIPS company to acknowledge (and no progress on site), and then further install delays as they removed panels and re-installed correctly. Roofing and Wall membranes can hide a multitude of sins. Don't wrap the building until you are happy. 8 ) Foam or no foam In my re-search prior to finding a SIPS company, I had never come across the idea of a dry fit SIPS kit. This is where NO foam is used during panel install, and only used sparingly at the end of the build. I came across DRY fit once my install started as that's what the SIPS company stated was their approach. This contradicts their public documents, every other kit I looked at, and also, any notion of having a (reasonably) airtight fabric. As i was doing some adjustments at the weekend to move a location for velux, here is a great example of what happens with a timber spline into a SIPS panel without foam. No whilst I know more of my kit is foamed than it may have been (as i caught it early), I know for a fact it is not consistently foamed with any quality. What can you do to avoid this? Get it in writing that the kit will be foamed on every join DURING install, and watch them like a hawk. This is probably a good place to end for the moment, needless to say, I am not a SIPS fan (for all of the above). It has brought needless delay, complexity and above all significant cost - you could realistically buy a decent home for the amount of money it has cost for this kit and its install, without any of the upsides of speed or thermal performance. I'm fully aware my experience is a sample size of 1 (with some other bits of feedback I've gathered directly) - however it is real world experience.6 points

-

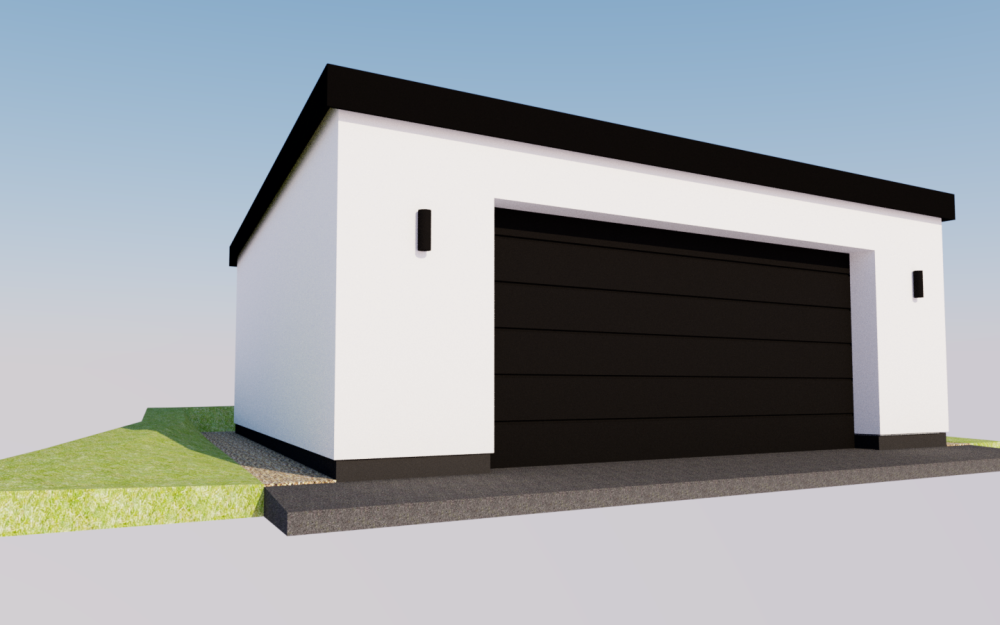

Well I took my own sweet time as ever but I've finally made it from SketchUp dream. To block built reality - and even a driveway going in after three years of occupation! The build was a long slow process, fitting it in between work, other projects, trades availability etc but I'm very pleased with the end result and so far it's performing as planned (should a garage perform?) One thing is for certain, it will never pay back the investment, a bit like the cars and motorbikes that reside within, but I'm not concerned about that. Anyway, it was not all 'standard' construction so I'll put a few posts up seperately highlighting the different stages that may be of use to others.6 points

-

Each time I buy a resin shower tray 5 on this build They come supplied with a trap I always replace these with a Mcalpine trap Hand tightened But the best out there Around £206 points

-

A couple of weekends ago, my wife and I spent some time at the MBC factory and got to ask some questions of the team there. There were quite a few different people there; sales, design, windows, even Kevin Blair, son of the founder Joe Blair, who took us on part of the factory tour. We were there for over 2 hours, including a 1-1 session where I covered any outstanding questions I still had. It was an informative day and great to see how they've developed and expanded. Seems they just keep buying more and more space whenever any adjacent units become available! Great session and I took a lot of photos. A couple are attached but the remainder can all be found at https://www.dropbox.com/scl/fo/11i21jn1n6ko1uclcbrm7/AMtb-Jt48ljlTc0lPfiQeKk?rlkey=f08zqofj4l1qllgrxphtnawtc&st=uxhdqk71&dl=0 They seem quite busy and are seeing an increase in demand from people building lots of houses, especially in the social sector where they explained it is easier for a company to secure any additional funding required for Passivhaus standards as they can offset it against potential future requirements to help with heating costs etc. From a pure materials perspective, they acknowledged the challenges of Brexit, COVID-19, etc. and how that initially affected costs and quotes quite significantly but things are a little more settled now and as they expand, they're able to secure pricing for longer periods as they're able to commit to larger orders. They're also sourcing from multiple suppliers and multiple regions as costs and availability flex due to growing seasons etc. Process Pre-start meeting - they discuss design guidelines and decisions with you and get your architectural drawings if available. MBC redo the designs in their software, including the 3D roof design. This takes about 4 days and they can then be provided back to your architect (if applicable) to update anything that did not translate from your original vision into an engineering specification. General arrangement - that design is then turned into the build instructions for the factory. The full structural engineering package is provided by Adept who MBC have been working with for over 22 years. They have 20+ engineers. Once erected - cut all your holes for service penetrations etc. and then MBC will come back to tape etc. and provide their full airtight package. These teams are all employed by MBC so are well versed in airtight requirements. PHPP - standard MBC timber-frame features are available for PHPP modelling, but they don't do any modelling themselves; you'll need someone to do that. Building Regulations - MBC don't do building regulations drawings/documentation so your architect or an architectural designer would need to do those. File ownership - MBC don't provide you with the source files from their various software packages but will do exports in various formats for you. General MBC Passive Foundation - they don't subcontract this (technically) as they own the company that does it. This is the same for the timber-frame insulation - they own that company too. You excavate the ground to (mostly) a 100kn bearing capacity and backfill with MOT Type 3. MBC then come along and puts in MOT Type 1, sand blinding, EPS etc. If you're putting UFH in the slab, you need to do this, MBC doesn't. Then comes the concrete. Site access issues - they can work around most issues. They've not been able to find some way to make it work. They send someone to the site to investigate constraints and then plan accordingly. What things influence higher cost - big open spaces, the weight of things (like green roofs) and features that require hidden fixings or complicated connection details. They have not seen any issues with mortgage companies or warranties concerning their timber-frame installations. Materials and Sources They source their materials from different places depending on the market and where things are growing. All timber is FSC sustainably harvested with documentation. They secure pricing with suppliers based on estimated cubed usage, and swallow any pricing fluctuations once a price for your timber-frame has been agreed. External walls and floors are treated. Some locations require additional treatments for things like longhorn beetles. Windows They supply and install Rationel and Velfac windows. Solarlux (generally aluminium) as a gap filler when there are requirements that can't be met by Rationel or Velfac. The Rationel windows are primarily timber/ali-clad with a larger profile, whereas the Velfac are composite, aluminium/timber and have thinner profiles. MBC are of course happy for you to choose windows from someone else so long as you use an installer that is manufacturer-approved and that they are installed to MBC airtightness specifications which they will provide. Choosing MBC to design and build the timber-frame and to install the windows can save some time in some situations; MBC will happily place the order for the windows based on their design drawings. Some window companies will want a structure to measure against unless you are willing to take the risk of measurements being incorrect. Furthermore, there is no possibility of the timber-frame supplier and the window supplier blaming each other for any issues if MBC does both! Installation of windows is by NKG as sole installers. They are very experienced with housing and deliver consistently good quality installs. Their window systems manager, Jason, was at Rationel for 15 years, was an installer himself for 3.5 years, and before that was a carpenter. How can you save money with windows? Bifolds are more expensive than sliders. The taller and wider the glass, the more expensive it gets, large spans especially. Openers are more expensive, but only marginally so in the grand scheme of things.6 points

-

Hello all. I know that a lot of folk talk about using D4 glue but this can lead to trouble. The designation D4 relates to the durability of the glue..durability is related to for simplicity the weather exposure.. you can buy D4 from say B & Q, Tool Station, Screwfix and loads of other places. Now I'm fine if you want to use "D4" that is bandied about on BH for sticking some non structural floor boards together. I'm not OK about you using this sole designation D4 (durability) in a stuctural application. A Tesco / Asda etc plastic bag is durable (probably deserves a D4 rating) for lying for years at the side of the road but it's not structurally strong! Glulam beams for example are bonded together with a structural glue that conforms to for example BS EN 301 which deals with glues that have structural stength AND the durability rating which is D1, 2, 3 & 4. Why would you not want to use a glue with both a structural and durability rating that the Glulam folk use? A structural glue requires both stength and durability. Structural glues tend to be resin based.. like old fashioned Araldite that your Mum and Dad used for fixing their glasses... Cascamite structural glue does the job and has both a structural and durability rating. Please folks can we stop recomending D4 when we are discussing bonding structural components.6 points

-

Well this is entirely our original design but adapted for the DW system so they can do it (if you alter any of their standard designs by say moving a window it becomes "bespoke"). We omitted additional cladding due to cost and didn't do the glazed gable and fancy aluminium glazing as their system couldn't handle it. The interior is however exactly as we wanted. Sure there were compromises to make but we should be in, carpets laid and sitting on the sofa watching TV within 12 months of clearing the site and bringing on the static. We are both in our later 60's so didn't want a prolonged build on site, been there, done that. Garden to sort but can enjoy a warm modern house this winter after the last couple of renovations of old, cold "characterful" houses.6 points

-

I appreciate that I am most likely speaking to the converted regarding this topic, but we are currently renting a property on a large Persimmon built housing estate, and I honestly find it so depressing and cannot understand why anyone would choose to purchase one of these houses. Not only is the build quality shocking, but each house is orientated 180 degree relative to the house in the parallel road. Eg, you would never sit in your back garden, as you are overlooked by about 6 houses. You have to always be mindful when looking out your windows, for fear of staring directly at someone who is looking directly at your house. If nothing else, it will make us get on with our self-build, and make us appreciate that we are fortunate enough to be in a position to do a self-build.6 points

-

I see a few mentions of the expense of MVHR. I self installed a simple system complete for less then £1500 in a 260m2 house. It has no sensors just manual boost which we use occasionally, otherwise it stays on trickle rate 24/7, even when some doors and windows are open. Really happy with the air quality (which I monitor with sensors), best value for money in the whole project and a no brainer in a new house IMO.6 points

-

Just to add to this with a bit of experience of what I would do differently "next time". I had installed 50mm twin wall duct for the electric supply. After completing the raft that duct was extended by the groundworkers to the electric kiosk with the meter some 20 odd metres away. Only later did I consider the cable needs - 3 phase 25mm. Upon picking it up from the suppliers I could immediately sense a problem coming. A) it was heavy and B) it didn't bend well. This week I discovered drawing it through a 50mm duct was not practical - should have used 80mm at least. Also the bends in the duct made pulling the cable through a nightmare. Luckily, after a struggle we got it outside the raft (all of 3 metres) but had to dig down to it and cut it open to get past the first (of several) too tight bends. Finally have strained back trying to pull it the last 5 metres - can't even bend over at present! Resourceful wife asked two random men in a family of four passing by to help and they very kindly stepped in and pulled it the last bit while I sat on the floor in a lot of pain. So, 1) work out cable needs in advance. 2) use a bigger duct than you think you need 3) consider running the cable through the duct laid out in a straight line, then placing both duct and cable in place in one go so you know it will bend where you need it to! 4) just get someone else younger and fitter to do it!6 points

-

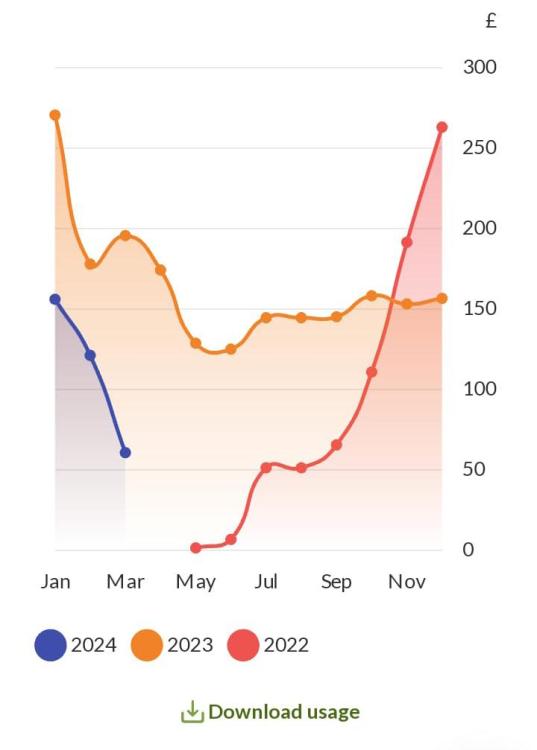

All the reading of posts on here at the design stage and the hard work implementing the experience of others on your own self build can be summed up / justified with just 1 image. Even when building on a very tight budget. This is my energy usage @ The Windy Roost since we got here. Upto January 24 we were in the static, we were never really warm used Air to Air heatpump for heating, hot water and cooking was LPG. We also had around 4 summer months of our cabins being used, again electricity for heating and cooking, DHW is LPG. The blue line makes me feel warm and fuzzy inside. That's our electricity for the self build, a whole house fully electric and blissfully warm with ample DHW. (With some limited cabin usage). To all self builders going through this, it's worth the effort👍.6 points

-

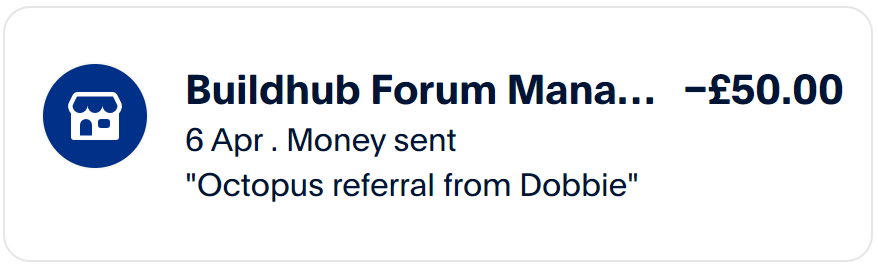

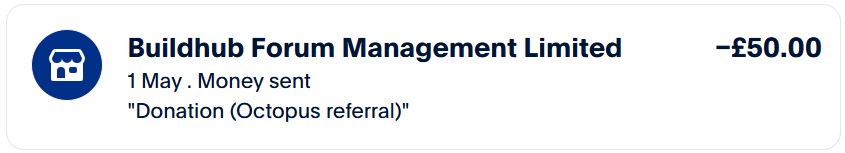

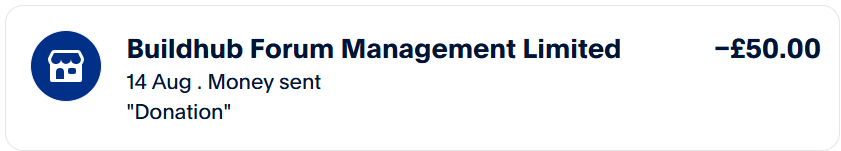

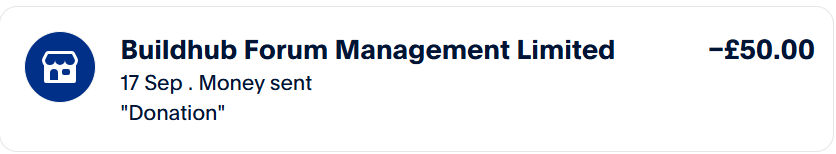

Help BuildHub financially while getting a £50 credit on your energy account! For anyone considering moving to Octopus Energy, please message me for a referral code. Using that code will result in £100 being split between you and Buildhub. When the credit arrives in my Octopus account, I'll transfer £50 to the BuildHub Paypal account and post a confirmation screenshot in this thread (or to you privately, if you prefer) as proof the transfer happened. As you know, BuildHub is a non-commercial forum run entirely by unpaid volunteers. We pay for hosting etc solely through member donations. If this referral scheme is successful, the need for periodic donation drives will significantly be reduced, or perhaps even done away with completely. Thanks for helping to fund the forum! List of referrals: @trialuser @Dobbie @Jenki @Originaltwist @Mattg4321 - Code submitted 3 May 2024, transferred 13 June 2024: @Chanmenie - Code submitted 30 April 2024, transferred 14 August 2024: @SB2023 - Code submitted 5 September 2024, transferred 17 September 2024: @MikeSharp01 - Code submitted 17 September 2024, transferred 18 October 2024: @-rick- - Code submitted 2 October 2024, transferred 20 November 2024: Anonymous - Code sumitted 9 January 2025, transferred 28 January 2025: @jayc89 - Code submitted 17 February 2025, transferred 6 March 2025:6 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)