Leaderboard

Popular Content

Showing content with the highest reputation on 05/06/23 in all areas

-

I don't really believe in the cleaner. Just leave the expanding foam can attached to the gun at all times, even when it is empty.5 points

-

3 points

-

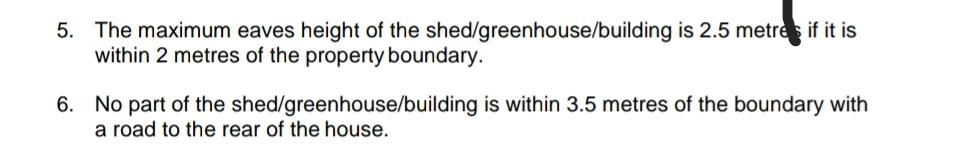

I'm working on not actively pissing the neighbours off with a monstrous build, but after that I'm just going to fill the space up and worry about a retrospective PP app if I have to. More fuel for digging out an extra 200mm or so of spoil and dropping the building / ridge height as much as possible. Life's best when everyone is playing nicely together at the end of the day . I'm happy with 2.1m minimum internal head height and a reasonable pitch apex roof ( solar E/W split ) and hopefully nobody will give a toss.2 points

-

Blown beads. Leave the cavity run as low as you can. Right to the foundation if you can get your SE to agree. Don't cross the cavity with the DPM. Have a separate DPC on the outer leaf. This will give some allowance for mortar droppings not to bridge the cavity above DPM as they'll just fall to the abyss harmlessly. Then fill the cavity with blown beads. If you have a line of aerated blocks in line with the floor insulation you'll get performance matching an insulated raft foundation.2 points

-

2 points

-

Well if they do notice (they never measured my build with a height limit) you could always act dumm and apply for retro permission. 😎2 points

-

It's a breathable membrane so vapor will be breathed in/out along with the air from the outside (uncontrolled) and the inside (controlled but practically impossible to control 100%). The insulation wool is also full of air pockets so the vapor will hang around in there. If it hangs around when the outside temperature drops, it will condense on the timber. The air gap is there to make sure the air doesn't hang around.1 point

-

"Fun fact, if the ground on which your outbuilding is located is sloped or undulating then you get the benefit of measuring from the highest point. This can mean creating a part-excavated building (as others have mentioned) if you need more head height than would be achieved with a standard 2.5m building on flat ground," Sadly my LA though exactly the opposite. My outbuilding was 4m to the ridge, and 3m at the eaves. It was on a slope, though, so there was a 1m retaining sleeper wall and the eaves height at door level was 2m (and you descends a set of steps to the floor). I tried hard to convince them that they did not, therefore, have to worry their heads about Planning Permission. They disagreed. The measurement, they said, must be from the bottom of the structure, not from the land around it.(It got Planning permission, of course).1 point

-

You would think so - I did - but imagine my surprise when my gun continued to work perfectly fine having sat with a half-used foam canister on it for over a year! A little bit of coughing and spluttering for a couple of seconds but after that it was like I'd only put it away yesterday.1 point

-

I'm feeling oddly supportive of the BCO here. He needs to know that nobody will fall out of the window. So use a barrier, or make it easy to be sure about the glass.....they can't know or remember everything and it isn't their job to research everything about every project...the fee doesn't cover that. Neither is it their job to search every panel for sometimes obscure marking and to have the BS or Eurocode with them. 'Dear BCO the windows satisfy clause x because they are made of glass type y, which is deemed to satisfy under z. The windows are etched with the evidence, see these photos, showing that they are to Eurocode a, and here also is the manufacturer's statement to confirm. If that is not possible then there is a problem. and bco is right to not accept it. If you choose, instead, to fit a barrier then it is easy to obtain an attractive grille, which could be an external panel such as for a deck, ie something that is attractive enough and not being contemptuous, and obviously temporary..1 point

-

Tell me about it. I have one. Luckily for me they've clearly used up more than their 50% in PD, so I doubt very much they'd be causing me any grief.1 point

-

Ffs ! They even do sex toys !! https://www.amazon.co.uk/Makita-XRV02T-Lithium-Ion-Cordless-Concrete/dp/B06XKT6LGG https://www.powertoolworld.co.uk/makita-dvr350z-18v-lxt-cordless-vibrating-poker-body-only “ body only “ dirty (expletive deleted)ers !1 point

-

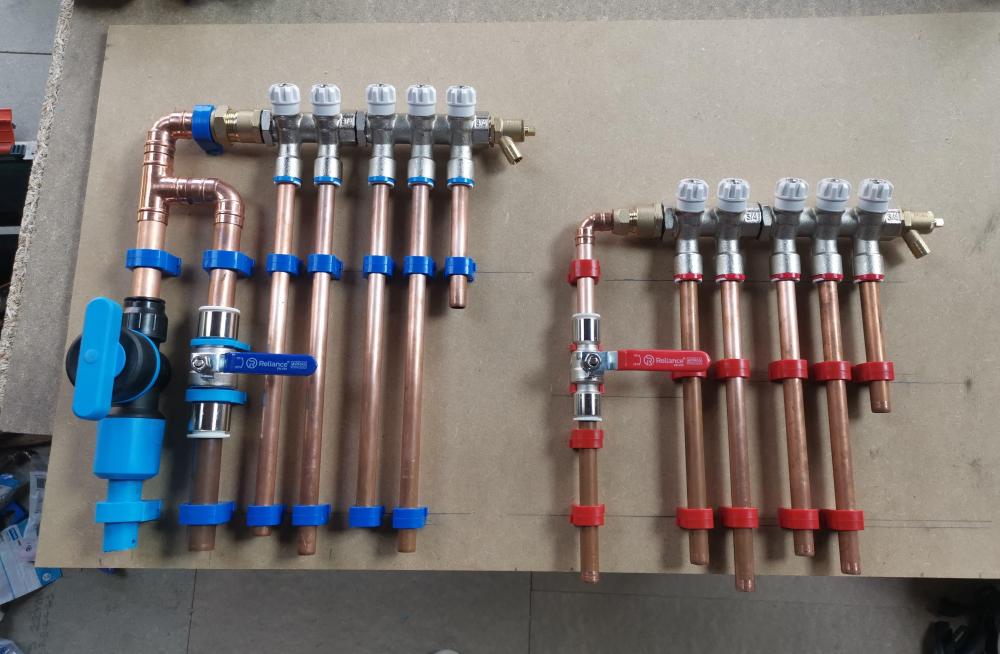

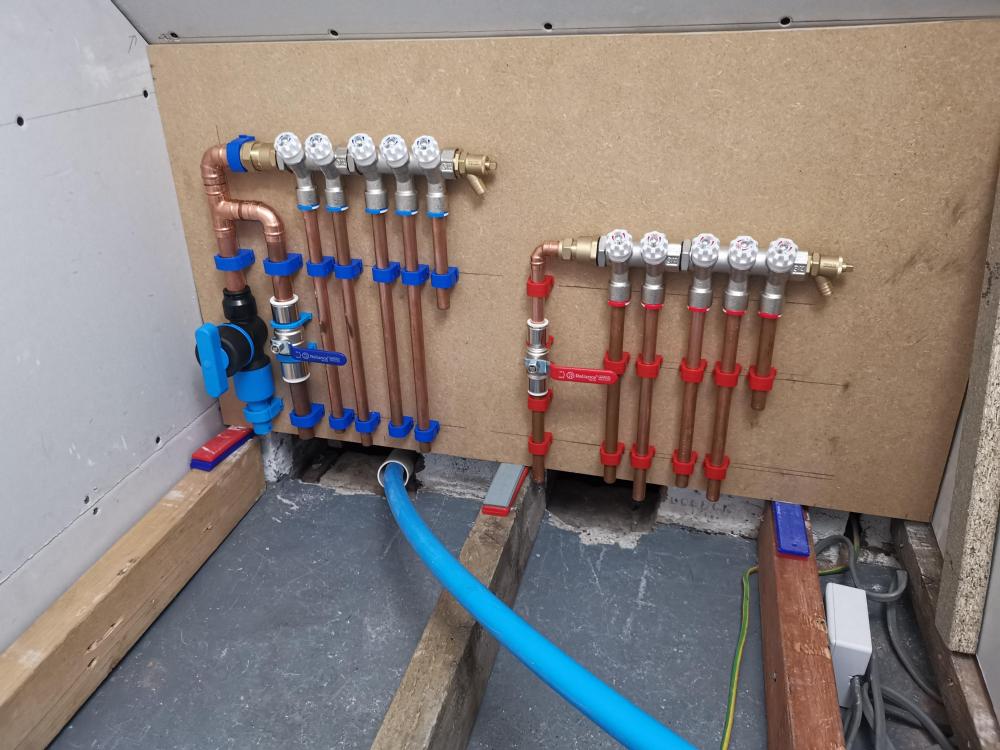

Almost seems a crime to put this in a cupboard... My plan is to change the copper tails to layflat, copper was just to keep my clips in alignment, so that it's just a continuous pipe with no joins to each appliance. Dedicated 22mm feed to the boiler. 1 spare on each, but room to add another 2 port to the ends if needed in the future. Any suggestions of changes before I solder this up? (Feeds close to the main due to space limitations under the floor so I had to bunch them up to fit between joists and through the gaps in brick.) As it's in the bunker with the ufh manifold I assume I'm going to have to lag up these colds to stop condensation @Nickfromwales?1 point

-

A keen, enthusiastic, team who has put so much effort into a quote gets some brownie points there! If you can afford it, like them, and like their advice... I'd go with it!1 point

-

1 point

-

To be fair, you do get what you pay for. Spectrum are very knowledgable at what they do, very focused and well versed. Known them for years, I admire what they have accomplished.1 point

-

We went for 240mm cavity blown beads, gives a 440mm thick wall. Partially did this as the solid wall in the footings would be exactly 1 block length thick.1 point

-

Check if they are pine or Oak. I suspect Pine because they don't appear to have itemised labour for building the beds eg level ground, trench for concrete strips, the concrete, cut and fix etc? Might be cheaper elsewhere but this is what Google found quickly.. Treated pine.. https://countrysupplies.uk.com/new-pine-sleepers-p-10977 100 x 200 x 2.4m £27 Oak.. 100 x 200 x 2.4 £40 https://www.oakviewfencing.co.uk/product/new-oak-sleeper?gad=1&gclid=Cj0KCQjw9deiBhC1ARIsAHLjR2CcYsUMQTiZbmC6N6jHl2pReOfIyRQaVDAqQqld43uoBL71l0oChesaAikLEALw_wcB but you may have to add delivery. As they are seats they probably should be "new" rather than real ex railway sleepers as the latter are treated with mild carcenogens.1 point

-

It could be done for the living areas where there's plenty of circulation with doors open etc. However for the bedroom's without ensuites they'll be a ventilation dead end when the doors are closed and would suffer high CO2 levels at night. Well planned the ducting is quick easy and cheap to install.1 point

-

If bothered you can counter batten your service cavity internally at 400cc. You tube has shown 1200cc rafter spacing so I wouldn't worry about it falling down.1 point

-

1 point

-

If your floor system is 600mm c-c then wall framing can match and you can align everything - even/equal and proper distribution of loading - essentially you are able to point load the entire structure top to bottom - the better building practice plus anything your chasing through the walls such has MVHR and plumbing have clear run top to bottom - no zigzags to contend with1 point

-

Yes, why use 400mm when 600mm will do. Usually specified by structural design. Whole timber frame in 600c/c here but intermediate floor was 400c/c due to span and a little bit o space saving.1 point

-

Ask him to call or email me clarifying what he wants.1 point

-

@Mr Punter is right. Foam gun cleaner is a con. Leave the foam can on until it's done. Clean the nozzle with a Stanley knife before you use it. If you take a can off, clean it with cleaner, but don't get it all, the foam will harden and you'll have to bin you gun. A can left on a gun will supposedly last two years.1 point

-

1 point

-

Sigma are probably one the best at the price Easy sell when you have finished with it1 point

-

What’s going on the walls..? And nothing needed between the board edges as the flex adhesive will sort that as you butt them together. Don’t forget to start with your highest point first and also remember where your drains are going. Are you planning any sort of electric tile heating ..?1 point

-

For a one off job this worked for me, bit tricky getting the knack to line up larger tiles & seeing the cut line with water everywhere - but you're not going to beat £60 even hiring. https://www.screwfix.com/p/titan-tc115i-500w-electric-tile-cutter-240v/196vv1 point

-

Wrapping the outside of that steel is key. Aerogel or this product possibly: https://www.ecologicalbuildingsystems.com/product/phonotherm-200 Covered here: Yours is not an i-beam though so may be overkill? But may give you ideas...1 point

-

Be careful @Marko. A letter means nothing, if you want proper confirmation that your outbuilding does not require planning permission then you should apply for a certificate of lawfulness, anything less is simply an informal opinion and subject to change. As others have said, if the building is within two metres of any boundary and if the building is (or in your case will become) more than 2.5m tall in relation to external ground level then planning permission is absolutely required. Whether you would be applying for the extra height or for the whole building doesn't really matter, it's the same thing either way. Fun fact, if the ground on which your outbuilding is located is sloped or undulating then you get the benefit of measuring from the highest point. This can mean creating a part-excavated building (as others have mentioned) if you need more head height than would be achieved with a standard 2.5m building on flat ground, but can also mean that should there happen to have been a tall spot of ground within the footprint of your outbuilding before you built it, your building can be up to 2.5m from the top of that tall spot. Which is now hidden below your building, or removed as part of the provision of the building. Should the local planning authority, who must must have evidence of a breach of planning control to take enforcement action but who cannot ask you to remove the building to expose the original high spot (should it still exist) ultimately decide that, contrary to their informal advice, your building does require planning permission then I wouldn't mind betting that your land was uneven, and higher in the middle of the footprint than around the edges. Now that I come to think about it, I reckon the distance from the top of the highest point of the land the building now sits on to the top of the building, even with the extra roof height, was actually no greater than 2.5m. Wasn't it?1 point

-

1 point

-

We often use vent board on uneven floors We bed them down with rapid set flexi adhesive Then put some screws in once set Only a dozen per board Gives a rock solid flat floor Paint both sides of the cement board with SBR 3-1 mix1 point

-

That's a quick rabbit hole to close - no PV generation in winter is pants. About 10 to 20% of summer performance. Spend on insulation1 point

-

I think it was @ProDave or was it @jack who warned me: once you have agreed the design don't change it. Its hugely wasteful of money time and effort. "Will you design me a really nice laundry room: one that's super convenient and easy to use?" "Of course I will. We'll adapt the old piggery" An old piggery next to the plot was knocked down and rebuilt at the same time as the build. 8m by 3m by about 3 high. Smashing little utility store and laundry room. But tight. Very tight. Only just wide enough for both machines, and a real squeak to get the machines at the right height so the washing baskets can slide neatly under the machine. Emphasis - 'only just fits ' - in all sorts of ways Well, 8 years later, she's got it : unveiled with suitable fanfare yesterday washing machine and tumble drier at waist height under - machine storage for the washing basket water on/off easily reached power sockets jus' right utility sink within reach of both machines hot and cold water auto occupancy light (12 minute dwell time set (her choice not mine) hanging bar for drying damp clothes assorted shelving There I was like Mutley : Medals, medals, gimme medals. If not Brownie Points will do. Medals woman, medals. "Look sweetheart, see how the laundry baskets fit perfectly under the washing machine" Big smile. "Medals, medals woman." I didn't see it coming - it was a real blind-side strike. "Oh yes, that space under the machines is just right for our two flight bags" Reaches round takes the flight bags of the shelves and shoves them under the raised machines. Only one thing for it: don't show her how hurt you are. "Wonderful idea of yours darling - simply inspired" Its just another way of showing her how much you love her.1 point

-

We used the following wording: This letter is notification of exemption of Approved Document R. The proposed dwelling is in an isolated area and is isolated from a relevant connection. Please see page 4 point 1.7 of Approved Document R Volume 1 2022 edition for further information, this is also quoted below. “Where a developer seeks to rely on the building being in an ‘isolated area’ as a reason to exempt new dwellings from requirement RA1, the developer must provide evidence in support of the exemption. This should include an explanation of how new dwellings are in an area that is isolated from a relevant connection, that the cost of providing a USO-standard public electronic communications network connection exceeds the cost cap and why the prospect of a connection to a relevant network in the isolated area is considered too remote to justify equipping the building with the relevant gigabit-ready physical infrastructure. The application of this exemption will vary in different circumstances.” We have attached screen shots from various major providers each stating that full fibre is not available in the area currently. And attached screenshots from City Fibre / BT / Virgin showing cant supply Fibre1 point

-

ICF hidden benefits? Here's a thing.. sometimes rather than comparing each individual element try if you can to look at the design in the round. It's hard to do but just have a look at the house you want to build and trust your intuition.. never be afraid to ask questions at the early esign stage as you are doing. Take a two story house with big open plan spaces on the ground floor and lots of glass... especially looking out to the back garden. When the wind blows it wants to push the house sideways.. we call this lateral stability. If you build a brick / block house then you end up often on the rear elevation with lots of glass with not much length of masonry wall between the glazing panels. You have a series of piers that want to not "topple over" sideways in the plane of the wall.. part of the problem lies in that masonry can't take tension forces that well. When you push a masonry pier sideways you get compression at one side.. and often undesirable tension at the other which can "burst the ball" SE design wise unless you have a lot of load above. If you start to push the amount of glass and fix some of that to the masonry piers you invite the problem where the masonry has to carry the wind pressure /suction loads from the glass.. it can go horribly wrong here as an SE and you then need say to say.. we wind posts etc... you go from hero to zero! In summary masonry is good at carrying vertical loads but not so good when you need to rely on a small length of wall to resist the sideways wind force or suction / pressure loads from glazing. It can / does work well when you have a good length of masonry wall though. Traditionally when faced with this problem we introduce a steel goal post which works to resist the sideways forces, take some of the vertical load and the pressure suction from the glass. We do this lots when folk knock the back out of an existing house. But there is a cost attached.. you need to fix the steel goal post to the rest of the structure and you need often to do some work to the underbuilding.. it gets messy and expensive. Now ICF has hidden advantages that can potentially save loads of cash. Imagine you have a wall with two large glass panels.. 5.0 - 6.0m of glass and 700 - 900 mm of wall each end, 700 -900 mm between the galss panels and say 500 - 700 mm over the top of the glazing.. this 500 - 700 mm could extend up into the second floor (you need to sequence the pour if you do this). The concrete core is just say 150mm thick. You do your ICF wall but around the openings you add a bit of extra reinforcement. Here what you do is to create a concrete portal frame (goal post) all hidden in the wall and in the concrete you are going to pour anyway.. the goal post all for a few extra rebars.. Another gem is that you can sometimes get the extra rebar that form the goal posts hidden in the concrete to resist the pressure / suction loads from the glass. Hope this helps. If you fancy post some drawings and I'm sure we will all chip in with further thoughts.1 point

-

A fair call. I find I only have two tools to compensate for my inexperience, asking and researching/analysing. Asking is much preferred but I feel a bit guilty asking so many questions sometimes.1 point

-

This is not btw aimed at any Welsh plumber in particular: https://www.powertoolmate.co.uk/power-tools/cordless-other/makita/makita-mw001gz-40v-max-xgt-cordless-microwave-naked.htm?0 points

-

Does anyone admit to actually eating a Fray Bentos pie? Once as an experiment can be accepted but to eat a second?0 points

-

Imagine @Nickfromwales turning up for his tiling job ; microwave strapped to the back 🤣0 points

-

0 points

-

0 points

-

😲 I don't know what type of girls you date mate, but that would give even a hippo a limp!!!0 points

-

They made a (expletive deleted)ing microwave! They competing with Dewalt or (expletive deleted)ing kenwood ! . Quite different markets I would think !0 points

-

Kooltherm £££££ Another steak dinner for the Architect and a week in the Rivera for the Kingspan salesman.0 points

-

Typical Makita shite . Can’t make proper tools so do a (expletive deleted)ing microwave . Note ! There’s no Dewalt microwave 💪0 points

-

Hope Festool does their own version. Bet there'll be a spit-roast in there, chip frier, pizza oven, a slow cooker, a waste disposal unit, anna drinks chiller OK, it'll be £7000 quid, but think how much @SteamyTea could earn going round self-build sites. It'd keep him too busy to post on BH ....😝0 points

-

You have plenty of time to build a new one, this thread could go on for years.0 points

-

I’ve been aware of this system for a while, I can only see it being good to fill up small holes rather than 50mm gaps left by your standard builder.0 points

This leaderboard is set to London/GMT+01:00