Leaderboard

Popular Content

Showing content with the highest reputation on 01/16/25 in all areas

-

Out of the blue I had a phone call just after lunch from the installer, who was on his way to us, about 2 hours away. Two vans arrived just before 15:00, one with the lifting crew and a stock of Sunamps, the other with the plumber. Within ten minutes the new Sunamp was up the stairs and ready to install, ten minutes later the old one was out, loaded in the delivery guys van and they were off. The new unit has been in for about half an hour or so and is now charging, the installer's happy all's well and has just left. Total time from the first van arriving to last van leaving was 1 hour 40 minutes, so not a difficult job. Does make me wonder how the chap from Bristol had the brass neck to want several thousands pounds labour for a job that took less than two hours . . . Anyway, hats off to Sunamp, I really can't fault the speed with which they've fixed this. Impressed by both the handling crew who did the delivery and lifting and by the installer. Poor lad had driven all the way down from Nuneaton to do this job.4 points

-

@Nickfromwales, Out of curiosity I had a good look at the sensor string in our failed unit, to see if it had moved. Easy to determine that it hadn't, as there's no form of gland at the top of the dip tube on our old unit and the cable was folded over where it had been under the insulation, so would have been physically restrained from moving upwards. I pulled the sensor string out to check, and it looked undamaged, same as when it went in from what I can remember. I also had a look to see if there was somewhere obvious that the PCM had leaked from but couldn't see anything. The filling plug (which I had thought might be a blow-off point) looked fine, in fact the area at that end of the cell looked pretty dry, as did the pipe entry points into the top of the cell. If I had to guess, based on the fact that the PCM had pushed up around the edges and leaked out around the pipe entry points (but not obviously out of the cover over the heating element terminals) my suspicion would be that the casing might have cracked, perhaps somewhere close to the top corner, at the pipe entry end somewhere. The PCM looked to have pushed up between the cell case side and the VIP panels in that area. Doesn't really make anything any clearer, I'm afraid. All that seems fairly certain is that this failure wasn't caused by anything on the water side, there was zero evidence of any water leakage at all, so I suspect the concerns I expressed earlier about some sort of over-pressure event almost certainly had nothing at all to do with it. Very annoying not being able to understand the exact cause of the failure, both because I'm too damned curious for my own good, and always want to know WHY stuff happens, but also because it'd be reassuring to better understand these things, perhaps even to find ways to reduce the risk of it happening again. Guess I'll just have to accept that it is what it is.2 points

-

None at all. He checked the pressure regulating valve, checked the 100 litre accumulator sat almost next to the the thing and checked the incoming pressure from the well pump and, quite sensibly, concluded that there was zero risk of the supply going over the upper pressure limit. He did also say that he'd never seen a failure caused by supply over-pressure, he reckoned leaks were most often down to poor workmanship during installation. He reckoned most failures were electrical or poor installation workmanship, with a strong view that the latter was the cause of a fair few. PCM leaks weren't high on the list of things that happen, especially with the newer models, according to his view. The pipe work has been simplified on the new unit, too. It doesn't have two sets of heat exchanger pipes, just one set, which makes installation a bit simpler for electric-only installations, like ours. Most impressive takeaway from today was just how awesome the Zonzini stair climber was. Instead of me sweating away for hours with a sack truck, ropes and a tirfor winch to get the thing upstairs, the motorised Zonzoni just drove straight in the door and up the stairs in a couple of minutes! Having seen it working I'd no hesitate to just hire one if I ever needed to move anything hefty. I reckon I could have very easily got a new unit in and the old unit out using one of these, and really it's the heavy lifting that is the hardest part of the job, the rest is pretty straightforward.2 points

-

That's one hell of a result, nice work. You’ve just put another dent in their impressive trading losses…… Without wishing to derail your post I happened to glance at Companies House during my current jet lag malaise. Those guys are burning cash at an impressive rate. In the two years to March 2013 a cool c£7.8m. In the same period they list new loans of £15.8m. But it also looks like they’ve landed another £4m in loan notes from the Scottish National Investment Bank in the last couple of months. Bleeding edge is an expensive game and they’re clearly not playing at it! I don’t really understand the financials of the market but with a long tail of investors and some hefty debt there clearly must be the view that there is a pot of gold at the end of the rainbow!2 points

-

I remember the last time this lot were in, and the Future Homes standard was put into legislation, raising air tightness and insulation standards for new houses, with a 7 year lead-in time for the house building industry to adapt. Due to commence in 2015, Cameron’s govt scrapped it just before it was due to start. Presumably due to some effective lobbying from men in sharp suits on behalf of the house building industry… imagine - 10 years of houses built to a standard of efficiency that would be instantly suitable for heat pump based heating. What a political disgrace that we are a decade down the line, and no further forward.2 points

-

We replace ~1.4M gas boilers every year, presumably mostly because they are beyond their useful life. Thats 1.4M (missed) opportunities to fit an ASHP at a time when the homeowners are anyway chucking out their existing heating. The challenge is presumably that many of these are distress purchases. Somehow we need to find a way to fit ASHPs in these cases as well as the cases where there is more time.2 points

-

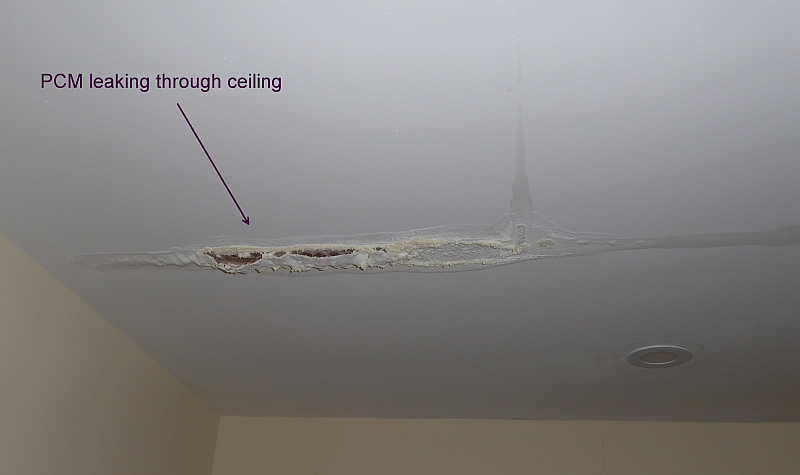

First of all, my apologies for being silent for so long. TBH, having finally settled here in our new home I needed a break from self-build. Not for any particular reason at all, just that I'd been living and breathing it for so many years that I needed some time out, a bit of breathing space if you like. Old age seems to do this, creep up on us almost unnoticed (and I'm now in my 70's). Also I was spending way too much time here, to the exclusion of other things I should have been doing. Anyway, thought I'd post here to hopefully shed some light on how things have gone with our Sunamp adventure, and give a bit of a gentle warning. Those who've been here, and on Ebuild before this place, may remember that we bought a Sunamp PV right back in the early days, before this place existed. We ran that for well over a year, with a few minor teething problems, but it was enough to convince me to swap it for a larger Sunamp UniQ eHW 9, which I did in September 2018. That also had a few teething problems, but Sunamp sorted them out quickly and without fuss. Since then I've been more than happy with the Sunamp. It's provided reliable hot water, mostly heated by excess solar generation, in fact far more hot water than we have ever needed as it turned out to be a bit over-sized. The first time we went away on holiday I turned everything off and was amazed to find that when we got home a week later there was still piping hot water available. I cannot complain at all about its performance, it has been significantly more efficient than a hot water cylinder, which was the reason for me being so enthusiastic about it back in 2016. Sadly, our Sunamp died on Saturday morning, and ejected its phase change material all over the floor, down through the ceiling in the kitchen below: A check upstairs in the services room confirmed that it's death had been spectacular, with PCM all over the floor and a long icicle of sodium acetate crystals down the back of the unit, from the burst casing inside: To it's credit, despite this it had delivered two showers that morning before we spotted the problem. Sadly this was to be its dying endeavour. I contacted Sunamp, not because of any warranty claim (there was no warranty anyway) but to ask them to put me in contact with a local installer for a replacement. I spent the weekend looking at the specs of the newer Thermino models and, given that the 9kWh (11kWh) UniQ was overkill for just two showers a day I decided its replacement would be the smaller Thermino ePlus 150, with the PV02 key to better match it for PV heating via the Eddi (when summer comes back). I found a couple of online suppliers, price, including VAT looked to be around £1,800 or so, plus delivery, which sort of seemed OK. I'm not up to getting the old unit downstairs and the new one up stairs, so I contacted a few local plumbers. All said they wouldn't touch this job. No idea why, it's a pretty straightforward swap, as the PRV, TMV etc is all there, just a matter of re-jigging two 22mm pipes. Seems the technology just scared them off, or, perhaps, it might have something to do with dealing with Sunamp? After a lot of delay, Sunamp customer services came back to me, asked for photos, then went silent. I got on to them again and they gave me contact details for a couple of installers. I contacted them, first one got back to me saying it would be around £6k to swap out our failed unit for a new one. I questioned this. He said it was about a day's work. Now, I'm all in favour of paying a fair rate for a job, but I know how long this job is going to take and I know the cost of all the materials. I am not going to pay a bloke £800 plus per hour, no matter how damned good he is! So, looks like I have to fall back to hiring a stair climber and doing it myself. PITA, as I'd have happily paid someone a few hundred quid to do this (over and above the cost of the bits) but I point blank refuse to stuff over £4k in someone's pocket for a job that is so straightforward, especially when there are installers advertising prices of around £4k to replace an existing hot water system and cylinder for a Sunamp, a job that is a heck of a lot more work. Sorry for the rant, thought it was worth posting here as a warning to others thinking of going down the Sunamp route. I can't fault the performance, but if the cost of repair and maintenance by a Sunamp approved company is so crazy then it may give some pause for thought. I've half a mind to bin the Sunamp and just get a high efficiency 150 litre cylinder installed. No idea what that might cost, but I doubt it would be over £6k. PS: Seems I have hundreds of PMs that have accrued in my time away. Sorry, but I doubt that I have a hope in hell of answering them all!1 point

-

Considering upgrading the internal insulation on some external walls. House was built in 1982 and the plans say the external walls are: 100mm fyfestone, 2 coats of synthapruffe, cavity, 100mm concrete block, 50x38 studs, 60mm quilt insulation, 50mm gap, vapour barrier (non breathable) 9.5mm plasterboard. I can afford to lose a little floorspace (50-60mm), and I know the better solution would be to strip the existing plasterboard, install 4x2s, 100mm insulation and vapour barrier but I'm under instruction to keep the disruption to a minimum. To that end, I'm considering insulated plasterboard as an option. Specifically, dot an dab 55mm plasterboard over the existing plasterboard...or 25mm batten and 27mm insulated plasterboard over the existing wall. (I'm presuming no vapour barrier required). What are the pros and cons of either of these options?1 point

-

1 point

-

I've seen a bunch of press and commentary in recent days that's broadly for (at least agnostic about) heat pumps but against MCS and the current state of subsidies 1/ MCS weakening the process for pre-contract heat loss calcs (read the comments!) disliked by all sides it seems 2/ HPA report 39% of workforce (MCS) trained in HP install don't go on to work on heat pumps, due to lack of demand that they put down to confusion and high electricity prices 3/ Today's report that government set to drop the 2035 ban on gas boilers. (plus my own experience this week that the MCS "tax" on installs is bloating prices of all components, making post-install maintenance/replacement of parts 10x what it should be) common themes are - the mandatory/monopoly on training is a barrier to take up and not yielding better consumer experience - the various government incentives are just meddling and confusing the market - the existing domestic gas subsidy, and electricity "green transition tax" work against the HP goals and intention Far too early to write an obituary for MCS, but grumbling is getting louder so lets imagine what may be next. It's political suicide to talk about dropping the gas subsidy within my lifetime, but it's clear the financial incentives for electric / heat pumps need to move away from install time and to long-term usage being guaranteed to be lower than gas. So as a first step, how about making gas disconnection free, and allow domestic properties to opt into electricity price subsidy for any house that removes gas? i.e. whatever costs savings they would be having via their gas bill could be received in electricity prices instead. This will skew the market in another way, and no doubt have its own unintended consequences, but broadly does mean as people increasingly electrify cars/cooking/etc it becomes a "no brainer" to disconnect gas to get a lower price for everything. Then step two is introduce a higher price for gas reconnection, and lower subsidy if switching back. Make a rachet mechanism. And eventually when a critical mass have switched, the gas subsidy be removed and replaced by a welfare mechanism for those that need it most (equally targeted to insulation and HP migration investments as keeping hydrocarbons artificially cheap to burn) But IANAP1 point

-

The one they used didn't have tracks, but motorised wheels and moving step things that grabbed each stair and lifted the wheels up the next step. It also had a motorised lift platform, which made getting the heavy box out of the back of a van easy, it's a bit like a mini-forklift. It definitely wouldn't go up a ladder though, I'm afraid!1 point

-

Gosh, Jeremy I have been away and didn’t see this. So glad to hear that. your about but not about your problem. I have quoted you so many times.1 point

-

Yeah, I was always concerned about Honeywell's TPI control algorithm which, whilst excellent at minimising (effectively eliminating) overshoot/undershoot does so at the expense of upto 6 demand cycles per hour (actually, writing that down I think it can be lowered to 3). I've been expecting having to deal with the consequences of additional wear this will have on the system for 14 years now but so far, touch wood, no failures to report.1 point

-

Would you consider installing the next one in some sort of bund? I've a drain in my plant room I case something goes pop someday.1 point

-

To be fair, I didn't ask them to fix the damage. The flooring damage is a ten minute job, as I have a part-box of left-over carpet tiles I can use. The plasterer was around earlier and having had a good look can't see any damage or reason to pull the ceiling down and replace it, so I'm just going to make good the surface and try repainting it, perhaps with a coat of some sort of stopper/sealer first. It's not a large area, so not worth getting a decorator in. I can't see any build up of crystalline PCM in the ceiling void, it looks almost as if the felt of the carpet tiles has worked as a sort of crude filter to leave most of the crystals behind.1 point

-

All prepared! I managed to quickly Sikaflex a bit of plastic angle along the rear, to seal the bit I wouldn't be able to get at, and got the installer to fit the new unit slightly further out. All I need to do now is add the other three sides, the plan is to just bond and screw some boards around the edges of the bit of varnished marine ply that the unit is sat on. I'm pretty sure this will catch any PCM leak, should I be unlucky enough to experience another one. I'm also going to seal up that hole in the floor, when I replace the damaged carpet tiles around the unit (I still have a load of spares left over from fitting them, it's good to hoard stuff sometimes!). Sunamp have definitely made some significant changes to the way their control system works. The original unit I had just went through an initial commissioning stage on first power on where it clacked the contactor on and off repeatedly for around 20 minutes. This new one smoothly modulated the power at a rate of increase of around 150W per minute during that initial stage. No doubt this is a fair bit more benign in terms of the way the PCM initially melts around the element. I can't really fault Sunamp, unless I was being really picky. They agreed to change the unit on Tuesday and by just after 16:00 on Thursday the job was completed. That's pretty good service in my view.1 point

-

1.5 weeks now and they still have not corrected the CIL figure that they made in their favour by 9%. How did they do that? Oh, by measuring external area, that's how. Any only other people or organisations who would say 'you have to sign this promissory liability note and then, maybe if you play your cards exactly right, we won't charge you?' 'And f... any little thing up, and you can be sure we'll nail you?' The mafia maybe? Drug dealers? Loan sharks?1 point

-

It is a bit odd that not all local authorities have CIL. Some have S106 still, and others nothing. I have the same grievance with single yellow line parking restrictions, they need to be the same nationally, double yellows are, and it is not as if the speed limit signs that say 60 MPH are 60 in some LAs, 70 in others and 40 in the next country. All a (expletive deleted)ing nonsense having 'local rules' on taxation.1 point

-

@Jeremy Harris that’s excellent news, let’s hope the current model has some subtle modifications to prevent a repeat failure! We’ve got a few years left on our warranty and I’ll be paying closer attention to our Sunamp in the future. It’s kind of easy to forget it’s there as it quietly goes about doing its thing (or quietly spilling its guts). Out of interest are they going to fix the damage caused to the house or have they swerved that one?1 point

-

If the floors solid you could likely fix down 4 sides with CT1 or something.1 point

-

1 point

-

1 point

-

From a government perspective, they're not totally nonsense. They're there to trip you up, cost you money, and piss you off. Our build is being held up at the moment because one of the pre-commencement conditions of our planning approval is a detailed landscape plan. So, we can't put a spade in the ground until we have given them a detailed plan (down to percentages of hedge species and wildflower mix) - despite the fact that we can't landscape until we've a) built the new house and b) knocked down the old one. It's like an episode of Yes, Minister with our planning department.1 point

-

It would take careful timing to have more than one flush at the same time, and it wouldnt usually matter anyway. But it must all be roddable, just in case. Also becsuse people sometimes flush things they shouldn't. Following building regulations is best and you'd need yo be expert to do ut an alternative way.1 point

-

I suspect it’s simplicity of rules/process being prioritised over sanity of concept. The building world reacts well to ‘do this or else, then do that or else’, so maybe they’ve just gone for something easy to understand and workable. I was stressed about the stupidity of our building control company’s admin, but not about the CIL peeps or their process. And the nice CIL peeps did guide me through beautifully.1 point

-

Toulouse on the same pipe. Pas de probleme. But put the I/C where the foul drain exits the house ( not one the same line as you show above) Rodding... Think of a packed lunch from your place on its way to meet everyone else's. Where would you put a rodding point to clear the inevtable traffic jam? Photograph the foul drain before the trench gets back-filled Buy enough rods to clean la pipe.. Store them in a locked container. Keep the key to the container where the rods are stored round your neck. Do not lend them to your children. Yep, that's right, I'm still bitter about it.1 point

-

I’m not sure exactly what you have drawn there, but none of it complies with any regs, all those blue lines need to end up in some form of inspection chamber or gulley that is accessible for unblocking purposes.1 point

-

There is a school of thought that ASHP should be sized at least 10% bigger than design required, just to help cope with defrosting. Living with a heat pump 100% oversized (I do) isn't an issue. You just operate as appropriate. Doing weather or batch charging, I have done both with zero issues. Most situations an ASHP is designed for -3 degs. So no where near the oversizing required for the top of Scotland, where you could be designing for -10. A larger heat pump also seems to bigger range of modulation than a small one from what I've seen. Not sure that is true. If you are air tight and can provide proof of it and proof of other improvements, not sure there is an issue. Most of the issues are down to assessors or so called designer with no clue. Or owner thinking they know better because they like a house at 16 degs. It's tax payer money (£7500) so needs to fit for purpose if you sell in two years time. Then there is homeowners wanting to operate as they did with the gas boiler, short on time control over multiple zones. Most the buying public really aren't ready for a heat pump, they have been fed on rubbish information for years, saying zones good, high flow temps and short operation windows are fine. So running at low flow temperature for long periods just sounds wrong (and so will be very expensive). Heat pumps as currently sold, are a rich man's play thing, even after grants, the prices quoted to install are in the general daft and well beyond the general person.h. Building well, in the first place, fixing issues with poor housing stock (insulation and airtightness or bulldozer) are the first fix. Second is education of installers and general population (most would have zero interest in both categories). As @Roger440 pushing people into energy poverty isn't an answer. Rant over1 point

-

The boiler is set up to run on WC for CH with DHWP Only parameters that I have found and adjusted to suit the house and optimise the boiler are only applicable to CH (DHWP are max output (19kWh) and max flow temp (82 Deg C). Max Water Temp Limit 70 Deg C Max Output 40% (so 8 kWh because anything more is not needed - I may drop this further to around 6 kWh) No Anti-cycle parameters that I have found Pump Over run is non adjustable (set to a 3min max from factory) I'd attach the Installation and operation manual but it's too large but a google for Viessmann 100-W B1GA should get you to a copy The Valliant (Glow worm) Anti-cycle parameters took me for ever to get my head around but once I did it was very useful and getting a 24 kWh boiler with a 10 kWh min to work much better with less cycling! (mainly because I was also using pump overrun to manage the time between burns as well)1 point

-

Unfortunately not. HMRC makes no distinction between integrated or not. https://www.gov.uk/guidance/goods-and-services-you-can-claim-for-under-the-vat-diy-scheme1 point

-

Our BM's have them in small bags and stupidly expensive Why cover our flat roof with chippings @SteamyTea ? We were told that they would keep the roof surface cooler. But every roof needs maintenance - so you need to walk on it and thus risk puncturing the membrane. When we asked the builder about maintenance - he said that the roof wouldn't need maintenace. Yeah , right. And then we asked him how we could re-point the gable wall above the flat roof without pushing the 'grit' through the membrane he went quiet. We used specialised reflective paint on the surface instead.1 point

-

This was stressful at the time as brick can make or break aesthetics If I did it again I would make more of an effort to mock a small area up before pulling the trigger on bricks Got away with it and bricks settled in nicely, personally I’d rather of had more of a tumbled farmhouse style brick/ less red but had to be something the wife liked as well Maybe would have paid extra for lighter mortar also1 point

-

My routing was quite onerous, once in the house already had 22mm plastic pipe (12m each way), no easy way to replace. So just use a close coupled tee (28mm to existing 22mm) and additional pump. Pump is powered with diverter valve. Works well. Pump £100-150. Two 28 to 22mm tees. 6kW will heat cylinder in about 45mins.1 point

-

I, too, haven't been here for a long time, I needed a break after the build and just had to get away from self-build related talk for a time, as it was gradually doing my head in (as well as absorbing a great deal of time). I admire your enthusiasm, though! There is no way I'm ever going to even think about another project, even though I still keep thinking of things I'd do differently if doing it again.1 point

-

I question the whole 'only well insulated homes can use heat pumps' argument. My house is very, very far from well insulated, nor is it in any sense airtight. And it's working very well with a heat pump. I can see why flow temperature and delta T has an impact, with a wet system, but that will hurt a gas or oil system too. And it's irrelevant to an A2A system.1 point

-

Help us to help yourself. Clearing the area. What is there now? How accessible is it.? Clear site and prepare. 2 days? Dig trenches. 1 day? Pour concrete 1 day Block or brick walls 2 days. Stone base 1 day Concrete slab 1 day Clear up and leave. 1 day 1 day float Does that sound right? 10 days x 2 men at £250 = £5k. Materials about £4k Add 20% for overheads About £11k Add 20% vat. 13k More if tricky access, biggish firm , anything you havent mentioned, drains, insulation if required, London or SE.1 point

-

Somebody - maybe us, needs to put together a briefing paper / manifesto / letter to HMG via the MPs and the PM to let them know what's going on, why it's all wrong and offer some solutions. We could probably send a letter to the majority of MPs, we all live in a constituency somewhere don't we. The challenge will be getting us all to agree what needs to be said.1 point

-

MCS is the root of the problem, I am sure many agree. Their heat loss calculations often come up with silly answers and result in an over large heat pump, particularly for new builds, and their pricing structure seems to end up with a very large figure, even after deducting the £7500 grant, leading many to conclude the only person benefiting from the grant is the installers who pocket a very large sum for the install. A TOTAL re think is needed. Zero VAT on heat pumps even to retail customers would be a good start. Get rid of the MCS monopoly. Allow anyone to install them, and then submit their invoice for parts, labour and material to receive some of the cost back as a grant. Make fitting of ASHP's permitted development under planning. Of course it won't happen, too many vested interests. Ask Norway how they do it? I bet they don't have anything like MCS? First thing is ensure from NOW (not some date in the future) all new builds have a heat pump for heating. Just write it into building regs. No heat pump, no completion certificate. No bureaucracy, simple. Or just make a properly calculated SAP EPC A mandatory for new builds. Same for at least some PV on the roof. Swapping out boilers for heat pumps is not proving value for money under the current schemes, concentrate on new builds first then find a better way to encourage heat pumps in existing houses.1 point

-

The wall which has 50mm PIR in the 70mm cavity is an issue, cavities need to be fully filled before applying EWI, otherwise its a bit pointless, you just end up with a thermal bypass and the chimney effect within the cavity, so get this filled up before you do this area. With regards the pebbledash, as long as its sound, not loose etc, this will be fine, you will be bonding your insulation boards with both adhesive and mechnical methods, you may just use a little more adhesive than a flat wall would otherwise use, so make sure you account for this when ordering. If its loose in places but not all over, remove the loose and build it up with levelling render before continuing, and if its all loose, then its all off before starting EWI. With regards material choice, Mineral wool is less thermally efficient, but you would also gain acoustic benefits from using it, whereas EPS is the opposite, better with thermal, but less so with acoustic.1 point

-

that mount is very clever. But I still think it looks pretty bad to pace a tv there. Even when it's off, it detracts from the natural beauty of a fireplace. A fireplace should not have a large black rectangle above it. A mirror yes, a nice painting also, but not a tv. When the TV is not in use, it occupies a far too prominent location in the room. Unless the room is ONLY going to be used for tv watching, the tv should be balanced with other elements of the room. But if it really is going to be a cinema room, then you don't need a fireplace there.1 point

-

1 point

-

In 2006 I was involved in a couple of very interesting cross-industry events on the Blair Government's proposals for Zero Carbon Housing; the Pre-Budget Report that year announced their ‘ambition’ that all new homes should be zero carbon within a decade. The announcement was a big surprise, but it gathered quite a lot of momentum and seemed possible that it might actually get adopted as policy. Difficult to believe that was almost 20 years ago and that so little progress had been made.0 points

-

0 points

-

For some reason I read this as '6 cats out to electric gate'. Was about to call the RSPCA!0 points

-

Oh don’t worry, you’ve not missed out, there’s still time to skin and gut a few for a casserole.0 points

-

Welcome back. I will come over hand help (make the tea) while the strong boys do the lifting. There are still discussions about 'thermal mass'.0 points